- DL manuals

- Nautilus

- Scrubber

- MX3-1200E

- Operating Manual

Nautilus MX3-1200E Operating Manual

Summary of MX3-1200E

Page 1

1 #lmann12 revised: 01-29-2015 nautilus mx3-1200e operating manual.

Page 2

2 nautilus mx3-1200e operating manual table of contents topic page # • introduction 3 • technical specifications 4 • optional equipment 5 section 1: operational safety • electrical safety 6 • mechanical safety 7 section 2: operation procedures • vacuum connections 8 • electrical supply 9 • water sup...

Page 3

3 introduction congratulations on your purchase of the hydro-force nautilus mx3-1200e. The mx3-1200e is designed to give truckmount-level performance in a portable machine that combines versatility with ease of transport. Years of experience, engineering, and planning have gone into the design and m...

Page 4

4 technical specifications mx3-1200e high pressure extractor height: 42-1/4” (107.32cm) length: 34-3/8” (87.31cm) width: 23-3/8” (59.37cm) weight: 160 lbs. (72.57 kg.) solution tank capacity: 12 gallon (45.4 liters) recovery tank capacity: 12 gallon (45.4 liters) solution pump: pump-tec #356 pump wi...

Page 5

5 additional / optional equipment carpet wand: aw29 wand glide – delrin for aw29 wand aw529d wand glide – teflon for aw29 wand aw529t 18” bottom velcro strap for wand holder nm5841 foam downer: ah17 hose hook: ah95 sx-15 hard surface tool: aw105 gekko handle assembly: ar51a gekko 4” grout tool head:...

Page 6

6 safety this machine is an electrical appliance. Care must be taken to reduce the risk of electrical shock. Read and understand all instructions before operating the mx3-1200e. • to reduce the risk of property damage or injury, repairs to electrical systems should only be performed by experienced t...

Page 7

7 this machine must be protected from conditions which may damage the pump, tank, hoses and other components. • freezing of water in this machine will cause serious damage. The mx3-1200e, solution hoses, and tools must be protected from freezing temperature. Store, transport, and use this equipment ...

Page 8

8 vacuum connections the mx3-1200e has a unique vacuum system which allows you to connect your vacuums in either parallel or in series. Vacuum connections can be changed quickly, with only a screw driver. ∗ this must be performed by a qualified technician while there is debate on which vacuum alignm...

Page 9

9 operation procedures knowledge of the proper operation of the mx3-1200e is required to ensure user safety and efficient performance of the extractor. Set up and operation 1. Electrical cords: two 15m extension cords are supplied with the nautilus mx3-1200e. Cord #1 powers both vacuum motors and th...

Page 10

10 2a. Water supply & chemical mixing– manual fill: • pour up to 12 gallons (45.4 liters) of hot water into the solution tank at the front of the machine. The water temperature cannot exceed 140°°°°f or 60°c. • measure and add the appropriate amount of the desired liquid chemical to the water in the...

Page 11

11 how to change the metering tip: • remove the chemical feed hose from the barb on the side of the proportioning valve. • unscrew and remove the old tip. • screw in the proper tip for your chemical tip and place the hose back on the barb metering tip kit (hydro-force item# pde001) contains 14 diffe...

Page 12

12 water supply: • once the correct metering tip is in place: o connect the auto-fill water supply hose to the water inlet (the male quick-connect on the front of the machine.) o connect the other end of the hose to a water faucet, and then turn on the water. • hot water can be used as long as the t...

Page 13

13 3. Connection of solution hose: connect the high pressure solution hose to the solution outlet (female quick connect on the front of the machine). Connect the other end of the hose to the male quick connect on the cleaning tool. When you are ready to start cleaning, turn the solution pump switch ...

Page 14

14 5. Connection of vacuum hoses: the vacuum connection on the machine can be either a 2” hose barb or 2” male flash cuff. Both are included with your mx3-1200e. The desired connector can be threaded into the vacuum port on the front of the machine. A 2” female flash cuff 1-1/2” hose adapter is also...

Page 15

15 foam downer – optional accessory: a key problem with portable extractors is that they have small tanks where foam dissipates slowly. If you have had issues with foam or are anticipating foaming problems, you will want to setup your foam downer. Foam can be drawn into the vacuums before the vacuum...

Page 16

16 6. Connection of pump-out hose: the pump-out hose is a 50’ section of 3/4” garden hose. (use of smaller diameter hose may reduce flow.) • remove the cap from the pump-out outlet fitting on the back of the machine. • connect the pump-out hose to the outlet fitting. • place the other end of the hos...

Page 17

17 7. Pressure adjustment: to make it easier to check and adjust the pressure, the pressure gauge and the pressure regulator/unloader are mounted on the control panel on the front of the machine. When the high-pressure solution pump is on and primed, pressure will show on the gauge only while the to...

Page 18

18 shutdown procedures: • if using the auto-fill system, turn the water supply off before finishing each job. This will allow use of the water and chemical already in the tank, and will reduce the amount of excess water to be disposed of later. • when finished cleaning, turn off all switches. • if t...

Page 19

19 accessory storage options: the mx3-1200e is designed to make it easier for the operator to transport the machine and the most common cleaning accessories. Bucket & sprayer storage the top of the mx3-1200e is sized and recessed to hold a five gallon bucket or two one-gallon chemical bottles as wel...

Page 20

20 troubleshooting – nautilus mx3-1200e problem cause solution machine not building circuit breaker tripped. Reset breakers or move cords to other outlets turning on - faulty power cord replace cord no power faulty switches or internal wiring check wiring & test switches - repair as needed * solutio...

Page 21

21 problem cause solution pump-out building circuit breaker tripped. Reset breakers or move cords to other outlets not working faulty power cord replace cord faulty switches or internal wiring check wiring & test switches - repair as needed * (nm5714) pump-out pump faulty replace pump-out pump (ap37...

Page 22

22 problem cause solution solution tank water source turned off turn on faucet or find other water source not filling float not on valve arm reconnect float to valve arm - adjust to proper height/level float valve faulty repair or replace float valve water hose restricted un-kink, clean out or repla...

Page 23

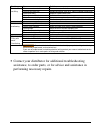

23 solution tank pump – ap48 g au ge filter pressure regulator / unloader – pt017 outlet quick connect chemical jug denotes water flow in high pressure hose denotes chemical flow denotes by-pass water flow from pressure regulator denotes incoming water flow mx3-1200e solution flow path float valve i...

Page 24

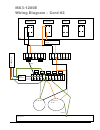

24 m1200 wiring diagram mx3-1200e wiring diagram – cord #1 vac 1 pump out sol pump machine base cooling fan vac1 vac2 vac 2 cord #1 12ga circuit breaker 10amp emi filter.

Page 25

25 vac 1 pump out sol pump machine base vac 2 pump out solution pump 12ga green circuit breaker 10amp mx3-1200e wiring diagram – cord #2 emi filter c o r d # 2.

Page 26

26 nautilus mx3-1200e switch panel: vacuum #2 – power from cord #1. When the switch is turned to the on position power is supplied to the vacuum motor. (3-stage vacuum) solution pump switch – power from cord #2. When the switch is turned to the on position power is supplied to the solution pump moto...

Page 27

27 maintenance proper maintenance is required to keep the mx3-1200e operating properly, prevent downtime and to extend the life of your equipment. This machine is an electrical appliance. Care must be taken to reduce the risk of electrical shock. Disconnect electrical power before performing any ser...

Page 28

28 clean chemical feed filter & foot valve: the filter & foot valve is on the end of the chemical feed hose that is placed in the chemical jug as part of the chemical feed system. Regularly examine the filter and clean as needed. To test the foot valve: • remove the filter & foot valve from the end ...

Page 29

29 clean the hydro-filter ii: build-up of debris in the filter screen of the hydro-filter ii will reduce the vacuum air flow and may cause a significant decrease in water recovery. A torn filter screen will allow debris past the filter and into the recovery tank. This debris can clog the waste pump ...

Page 30

30 clean waste pump-out pump: build-up of fine silt inside the waste pump can clog the pump even if the pump is not used, so this maintenance procedure should be performed regardless of whether the waste pump has been used. • after cleaning out the recovery tank, remove the cap and connect the pump-...

Page 31

31 flush solution tank and pump: (continued from previous page) • disconnect the solution hose and tool use the 4’ short section of vacuum hose to vacuum the remaining acid solution out of the solution tank. • pour two or three gallons of clean water into the solution tank. • connect a solution hose...

Page 32

32 flush chemical system: chemical build-up in the chemical system can prevent the system from drawing chemical. • rinse the chemical system with fresh water (for heavy chemical build-up, a mild acid can be added to the rinse water.) • remove the chemical feed hose from the solution tank and place t...

Page 33

33 lubricate pressure regulator o-rings: to maintain consistent adequate pressure delivery to the cleaning tool, the o-rings on the stem of the mx3- 1200e pressure regulator must be lubricated regularly. 1. Remove the black knob from the regulator. 2. Unscrew the brass knob assembly from the piston ...

Page 34

34 clean recovery tank drain debris and sand accumulation in the drain valve can damage the valve or prevent it from closing completely. This will result in dirty water leaking from the valve. Use of the hydro-filter and regular cleaning of the recovery tank will help prevent this, but occasionally ...

Page 35

35 storage prep and freeze protection procedures: your nautilus mx3-1200e must be protected from freezing. Freezing can cause serious damage to the pump, pump-out, auto-fill float valve, and any other component containing water. If the mx3-1200e is transported or stored in freezing temperatures, the...

Page 36

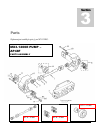

36 parts replacement parts available for repair of your mx3-1200e. Section 3 kit a – pt042 kit b – pt044 kit c – pt045 mx3-1200e pump – ap48f parts assembly.

Page 37

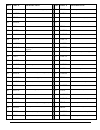

37 item description qty part number 1 plunger 1 0311-0006-0002 2 plunger guide 2 0311-0009 3 o-ring for plunger guide 2 c0100-1124 4 u-cup 2 c0220-1075 5 u-cup backing ring 2 0311-0011 6 pump head 2 0356-0002-0001 7 pump manifold 1 0356-0004-0001 8 valve assembly 4 0205-0012 8a valve seat (part of #...

Page 38

38 auto-fill assembly – m013 nm5740 float valve assembly see parts breakdown on next page br286 br286 br138 nm5751 nm5751 br282a ah102b br282a.

Page 39

39 nm5740 auto-fill float valve assembly.

Page 40

40 item description item description item description hp unloader pt017 8 piston o-ring - large 16 seat o-ring 1 black plastic knob pt017knob 9 piston retainer 17 seat 2 brass knob 10 piston retainer o-ring 18 brass body 3 locking nut 11 piston o-ring - small 19 poppet o-ring 4 spring 12 piston wash...

Page 41

41 pump-out pump ap37f parts assembly.

Page 42

42 1 2 3 5 4 4 6 7 8 9 10 39 8 3 8 9 11 12 23 100 104 2 9 8 9.

Page 43

43 8 9 15 16 17 18 8 9 21 22 23 24 32 32 37 38 39 40 40 40 41 & 41a 55 & 56 9 control panel rear view - base & base skirt hinge screws 19 & 19a 25 104 100 55 & 56 20 23a.

Page 44

44 27 & 27a 28 29 29 31 31 9 9 32 32 34 35 38 37 1 39 13 14 & 14a 30 30 26 rear view – base, base skirt & recovery tank vacuum plug assembly 109 106 107 108 36 & 79 114.

Page 45

45 32 32 43 44 45 37 46 46 47 48 50 9 50 9 51 53 3, 58 & 59 top view of base 3, 58 & 59 52 39 55 & 56 55 & 56 106 47a 47 60 60 115 115 33.

Page 46

46 48 49 49 47 47 47a 47 47a 47 47a 47a 51 51 37 9, 54 & 64 9, 54 & 64 9, 54 & 64 52 vacuum mounts & connections.

Page 47

47 44 66 69 68 70 71 pump & priming valve bottom view of base 45 117 71 110 67 68 65 60 60 3 & 59 37 39 61 & 62 57 56 9 & 54 9 & 54 63 & 55 3 & 59 61 & 62 119.

Page 48

48 9 & 41 2 bottom view solution tank & base skirt 72 1 73 9 9 8 8 39 74 75 76 77 77 78 34 36 & 36a 30 30 2 114 118 31 80 & 55.

Page 49

49 2 39 1 72 73 73 67 9, 30 & 31 82 83 2 83 82 84 inside solution tank bottom view solution tank.

Page 50

50 101 102 vacuum shutoff assembly 91 86 92 86 88 89 90 81 inside recovery tank with pump-out filter in place inside recovery tank vacuum shutoff and pump-out filter removed 85 116 87 85.

Page 51

51 pump-out connections 96 88 112 105 93 99 96 91 95 97 & 9 111 113 117 103.

Page 52

52 flow 81 92 91 99 96 9 97 105 13 14a 14 95 pump-out parts 1 39 103 9 97.

Page 53

53 key part # description key part # description 1 nm5704 recovery tank 21 ah101b quick connect female ¼” 2 nm5702 solution tank 22 br174 adapter ¼” m-f 3 pfa11 washer 5/16” flat ss 23 nm5751 washer ½” flat ss 4 nm5724 wheel 2-1/2” gray 23a nm5751a washer ½” flat ss with neoprene backing 5 nm5143 ac...

Page 54

54 key part # description key part # description 42a phy094-034 nut 10-24 nylock ss(qty 4) 67 br030 barb ½” x 3/8” mpt 43 nm5748 axle rear wheels – 22.5” 68 nm5086 hose ½” id clear coil 44 ap48f 1200psi pump with motor 69 elbow 90 barb ½” x 3/8” mpt 45 nm5096 priming valve 70 elbow 90 barb 3/8” x 1/...

Page 55

55 key part # description key part # description 93 nm5093 hose ¾” id clear coil 119 nm5705c decal csa warning 94 ph07 hose clamp for 1/2” hose ns nm5025 rivet – vac hose end 95 ap37f pump-out pump ns nm5713 adapter 2”fpt x hslip abs 96 pf20381-010 elbow 90 ¾” barb quad fttg ns nm5709 spacer unloade...

Page 56

56 description hose type length notes vac hose rec tank to manifold 2” vac – nm5726 sold per ft 29” tank end: 1 - nm5713 2 – nm5025 vac end: hose clamp pa051 vac hose vac 1 to manifold 2” vac – nm5726 sold per ft 9.5” vac end: hose clamp pa051 manifold end: hose clamp nm4472 vac hose vac 2 to base 2...

Page 57

57 your nautilus mx3-1200e is designed to give you years of reliable service. If a problem should arise use the troubleshooting section in the operation manual to diagnose and correct the problem if possible. If you are unable to determine the cause or solution to the problem contact your distributo...