- DL manuals

- Navien

- Water Heater

- CH-180

- Installation Manual

Navien CH-180 Installation Manual

Summary of CH-180

Page 1

Keep this manual near the navien combination boiler for future reference whenever maintenance or service is required. Ch-180 asme ch-210 asme ch-240 asme.

Page 2

Installation manual - contents accessories specifications components & dimensions warinings rating plate location selection plumbing pressure relief valve condensate disposal gas piping gas pressure testing venting pressure reducing v/v outdoor temp. Sensor electrical connection remote controller in...

Page 3: Accessories:

Description qty navien condensing combination boiler 1 remote controller 1 operation and installation manual 1 wall mounting bracket 1 condensate drain hose 1 tapping screws & anchors 4 vent terminators 2 wall flanges 4 pressure reducing valve kit 3 accessories: check that you have received all of t...

Page 4: Optional Accessories:

Description navien plumb easy valve set (pressure relief valve) – heating navien plumb easy valve set (pressure relief valve) – domestic water navien condensate neutralizer navien ready-link communication cable outdoor temperature sensor with cable optional accessories: contact your navien combinati...

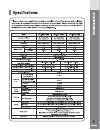

Page 5

Flow rate (dhw) 77 ı (43 ç ) temp rise 3.4 gpm 4.0 gpm 4.5 gpm.

Page 6: Key Components: Ch

No description navien part no. No description navien part no. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 intake air duct fan motor wps dhw heat exchanger s/h strainer motorized 3-way valve circulation pump s/h supply adaptor s/h return adaptor pcb board dhw cold water inlet...

Page 7: Dimensions: Ch Models

Dimensions: ch models description diameter exhaust pipe intake air duct space heating supply connection auto feeder connection gas inlet connection space heating return connection dhw supply connection dhw cold water inlet connection 3" 3" 1" 1" 3/4" 3/4" 1/2" 3/4" a b c d e f g h ch 7 % $ & ' ( ).

Page 8: Installation Warnings:

Installation warnings: 8 read all safety warnings in the “user’s operation manual”. The additional safety issues outlined below must also be followed completely when installing this navien combination boiler. 1. 2. 3. 4. 5. 6. 7. All applicable local, state, national and provincial codes, ordinanes,...

Page 9: Installation Warnings:

Installation warnings: 9 protect against snow accumulation around the vent terminations. Ensure the exhaust pipe and the intake air pipe remain clear from obstructions at all times. Do not overtighten fittings as pipe and/or fitting damage may occur causing leakage. Do not install the combination bo...

Page 10: Getting Started:

Getting started: check the rating plate be sure the gas type and electricity voltage match the rating plate. Use only the gas type indicated on the rating plate of the navien combination boiler. Using a different gas type will cause abnormal combustion and boiler malfunction. Be sure to use 120vac 6...

Page 11: Check Rating Plate

Check rating plate sample rating plate do not install the unit in a location where there is excessive high humidity such as a bathroom, damp crawl space and other areas such as this. This may cause the unit to malfunction. To avoid possible electrical shock, do not touch the internal components of t...

Page 12

Locating the combination boiler: warning considering the location “ in accordance to ansi z223.1/ nfpa 54 and/or can/csa b149.1 gas installation code” location selection may not necessarily affect the operation of the navien combination boiler but it will affect the customer’s experience and level o...

Page 14: Plumbing:

The piping materials used should meet local codes and industry standards. Piping must be cleaned and flushed-out before installation. Do not apply torch heat within 12" of the bottom connections of the unit. Perform all solder connections at a safe distance from the (brass) male connectors below the...

Page 15: Plumbing:

With clean, potable water free of corrosive chemicals, sand, dirt, or other contaminates. With inlet water temperatures above 32°f(0°c), but not exceeding 140°f(60°c). Free of lime and scale deposits. Navien combination boiler is equipped with a factory installed pressure sensor type low water cut o...

Page 16: Plumbing

Diaphragm expansion tank closed-type expansion tank plumbing 16 expansion tank the expansion tank must be located as shown in a~f basic application drawings.(page 20 ~ 25) (refer to the expansion tank manufacturer’s instructions for additional installation details.) always locate and install the sys...

Page 17: Plumbing: Guide Line

17 plumbing: guide line case i. With backflow preventer installation if using mixing valves on the domestic hot water outlet, choose one which prevents cold water pressure from overcoming hot water line pressure. The flow rate of hot water may vary when more than two faucets (appliances, fixtures, e...

Page 18: Plumbing Guideline

Plumbing guideline 18 plumbing case ii. Non-backflow preventer installation if using mixing valves on the domestic hot water outlet, choose one which prevents cold water pressure from overcoming hot water line pressure. Hot water temperature may vary when more than two faucets (appliances, fixtures,...

Page 19

Caution do not open the auto feeder connection cap, unless the pipe is connected to the auto feeder valve. As shown above, navien’s have to establish the water supplement plumbing is not recommended. Case iii. Non-auto supplement backflow preventer installation water supplement dhw cold water inlet ...

Page 20: Plumbing :

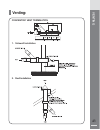

20 plumbing : a . In-floor heating (zoning control) system (with wiring diagram) wiring daigram water supplement dhw cold water inlet dhw supply.

Page 21: Plumbing :

Plumbing : 21 b. In-floor heating system (recovery control) water supplement dhw cold water inlet dhw supply 3-way mixing valve in-floor heating expansion tank manual valve backflow preventer circulation pump air seperator regulator hydro tee legend.

Page 22: Plumbing :

Water supplement dhw cold water inlet dhw supply 22 plumbing : c. Snow melting system..

Page 23: Plumbing :

Plumbing : 23 d. High - low temperature system. Water supplement dhw cold water inlet dhw supply.

Page 24: Plumbing :

Water supplement dhw cold water inlet dhw supply 24 plumbing : e. Hydro - seperator system.

Page 25: Plumbing :

Plumbing : 25 f. Base board system. Water supplement dhw cold water inlet dhw supply.

Page 26

1/2.

Page 28

A condensate drain line must be connected the port at the bottom of the unit(see below). The end of pipe should drain to a laundry tub or to a floor drain. A condensate drain tube is included with the navien combination water/space heater. This tube must be connected to the port at the bottom of the...

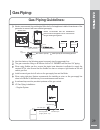

Page 29: Gas Piping:

Gas piping: 29 gas piping guidelines: navien recommends the combination boiler be the first appliance installed downstream of the gas meter to ensure it will have sufficient gas supply. Use the charts on the following pages to properly size the gas supply line. The gas connection fitting on all navi...

Page 33

Measuring inlet gas pressure: pressure test port on gas line connect a manometer to the pressure port and reset it to zero. 4. Re-open the manual gas valve. Check to see that there are no gas leaks. 5. Open multiple fixtures that have high flow rates ( i.E. Bathtub, showers, kitchen sink) to ramp th...

Page 34

Please use approved to ulc-s636 pvc and cpvc glue, because navien vent collar material is pvc and cpvc..

Page 37

Warning: this combination water/space heater is factory set for return loop water temperature to be less than 140°f (60°c) and for use with sch 40 pvc vent. If you requested higher than 140°f (60°c) return water back to combination boiler, you must set the dip switch as illustrated (dip switch no.2 ...

Page 40

Test procedure to common vent system visually inspect the venting system for proper size and horizontal pitch and deter mine there is no blockage or restriction, leakage, corrosion and other deficiencies which could cause an unsafe condition. Seal any unused openings in the common venting system. 1....

Page 41: Venting:

Venting: the following diagrams represent some typical venting configurations and are included to assist you in designing your vent system. Possible configurations are not limited to these diagrams. Vent configuration options: option #1: 3" 2-pipe side wall vent option #2: non-concentric venting thr...

Page 42: Venting:

Venting: exhaust intake option #3: 3" 2-pipe vertical vent termination 12" minimum from any obstruction (adove, below, left or right) 12" min where shown tee as vent terminator is just an idea. Please find and use proper termintor following each jurisdiction. Venting 42.

Page 43: Venting:

Venting: concentric vent termination 1. Sidewall installation 2. Roof installation venting 43.

Page 44

Read all safety warnings in the “user’s operation manual”. The additional safety issues outlined below must also be followed completely when installing this navien combination boiler: follow all local codes and/or the most recent edition of the national fuel gas code (ansi z223.1/nfpa 54) in the usa...

Page 45: Pressure Reducing Valve

Pressure reducing valve please do not deliberately remove the pressure reducing valve installed in the body of dhw cold water inlet adapter. Please refer to the graph and change the water pressure reducing valve for proper operation. See graph above for the water flow(gpm) and water pressure(psi) to...

Page 46: Pressure Reducing Valve

Pressure reducing valve 3. Installation example 4. Replace the pressure reducing valve procedure all ch models are shipped from the factory with a package of 3 flow regulators for use with various flow rates. Each included reducing valve (flow regulator) allows for a specific amount of water flow th...

Page 47

Outdoor temperature sensor (optional): outdoor temperature sensor installation outdoor temperature sensor installation guidelines pull the terminal block out attach the body to the wall with screws/anchors provided run wire into the body through grommet opening connect wires to the terminal block re...

Page 48

Outdoor temperature sensor (optional): external temperature return k-factor [ dip switch #4 of 8 on] external temperature k-factor (supply temperature setting) k-factor (return temperature setting) boller setpoint boller setpoint 176 158 140 122 104 86 68 68 59 50 41 32 23 14 5 -4 -13 140 131 122 11...

Page 49: Dhw Heat Exchanger:

This information applies only to the dhw piping lines. Navien recommended, when frozen pipes please contact the installer or navien’s technical department toll-free at 1-800-519-8794 dhw heat exchanger: general information caution the dhw heat exchanger was tested and certified in accordance with ia...

Page 50: Electrical Connections:

Electrical connections: label all wires prior to disconnection when servicing coltrols. Wiring errors can cause improper and dangerous operation. Verify proper opation after servicing. Electric wiring: grounding and surges caution follow the electrical code requirements of the local authority having...

Page 51

Remote controller installation: remote controller nr-10pu the following are considerations for determining the location of the remote controller: disconnect the power to the combination boiler before installing the remote controller. The wire on the reserve of a remote contoller is connected to the ...

Page 52: Pcb Board Settings:

Pcb board settings: combination boiler temperature settings: hot water temperatures over 125°f can cause severe burns instantly or death from scalding. With the navien combination boiler, the temperature has been preset at the factory ! $* +!*+ +! * =!>! >=> $! =!>! + ?> > *==>=!>!+ +!$ +!+!!* conne...

Page 53

Cascade connection and set-up procedures: only 1 combination boiler can be installed in a cascade system and it must be the master. The slave units can only be navien nr-(a) or np-(a) water heater. The maximum number of units per cascade is 16, supplying as much hot water as needed. (in case of casc...

Page 54

2. Step 2: cable connection and dip switch change a multiple unit, which is composed of 1 combination boiler and up to 15 water heater(np series), can be connected by using naviens’ multi-link communica- tion cables inside. The combination boiler shall be set as a master unit, which can be done by s...

Page 55

Slave n slave n-1 slave n-2 slave n-1 master - the diagram above displays the master unit and slave unit connected with the ready link communication cable. - the recommended location for the master unit is in the center. - the dip sw7, which is used only for organizing cascade system. Be switches on...

Page 56

Fnd1 of the slave 1 unit will read “s001”. Slave 2 unit also can be set-up as above. After the slave set-up, each fnd1 will read as below: #1 switch (dip sw1) and #6-8 switches (dip sw2) should be set to on position. After all unit power on, push and hold the tack sw3 and tack sw4 of the master unit...

Page 57

5.2 slave unit set-up this procedure is same as the 3.2 slave set-up of step 3: communication set-up. After the slave set-up, each fnd1 will display on the pcb as below: 5.3 set-up finish after the slave set-up, dip sw1 and dip sw2 should be set to the original position and push and hold the tack sw...

Page 58

Combination boiler dip switch settings: there are two sets of dip switches; one set has 6 switches and the other has 8 switches. Set of dip switch #1. (6 switches): 1 & 2: burner operation mode select (do not used) no description function on off 1 operation select 1 (1) operation mode select 2 opera...

Page 59

Set of 8 switches: operation mode selection #5 & 6: model selection (do not used) model dip s/w 5 6 ch-180 off off ch-210 on off ch-240 off on dip s/w no. Description function on off 1 ready-link multi-system select ready-link multi-system master single unit operation 2 hot water pre-heating functio...

Page 60: Dip Switch 7:

#4 & 5& 6 (space heating used only): supply / return temperature selection temperature dip switch 4 5 6 120 ı (49 ç ) off (supply) off off 140 ı (60 ç ) on off 160 ı (71 ç ) off on 180 ı (82 ç ) on on 95 ı (35 ç ) on (return) off off 110 ı (43 ç ) on off 125 ı (51 ç ) off on 140 ı (60 ç ) on on x y ...

Page 61: Installation Checklist:

Installation checklist: are the proper clearances from windows, doors and other intake vents maintained? Is the distance between the combination boiler and point of vent termination minimized? Is distance between combination boiler and major fixtures within the house minimized? Are the proper servic...

Page 62

Is there an approved pressure relief valve installed on the hot water outlet and space heating outlet? Does the rating plate on the pressure relief valve indicate a btu level equal to the maximum btu rating of the combination boiler? Is the pressure relief valve 1/2” on the hot water outlet? Is the ...

Page 63

Venting electrical wiring has the combination boiler been vented with 3" pvc, cpvc, polypropylene or bh special gas vent (s636 pvc) for category iv appliances or in accordance with this manual and/or your local code? Ensure that abs cellular core or pvc cellular core pipe has not been used as ventin...

Page 64

Dip switch settings: for the set of 6 dip switches: are switch #1 and #2 in the down (off) position? Is switch #3 properly set for the gas supply type? Is switch #4 properly set for the cacade vent type? (individual vent or common vent) are switch #5 and #6 set for the proper model number? Final has...

Page 65: Maintenance

Maintenance important this unit requires very little maintenance, however a qualified technicial should inspect it at the beginning of every heating season and/or when have a problem unit. Annual maintenance and inspection make sure: thecondensatefreelyflowsfromtheunit,andiscleanedofsediment. airv...

Page 66: Completing The Install:

Factory default setting of dip switch: completing the install: ch-180 ng ch-210 ch-240 ch-180 propane ch-210 ch-240 if you answered “yes” to all of the questions in the above checklist, your install is now complete. If you answered “no” to any of the points in the checklist, please review the instal...

Page 67: Wiring Diagram:

Wiring diagram: b: blue o: orange p: pink r: red w: white y: y ellow bk : black br : brown gr/y : green/y ellow color code pv bk bk rr rr rb rb bk bk bk bk b b bk bk r r w w bk ac 26v ww y y ac 9v ac 19v “a” r w bk bk bk bk br br r thermal fuse high limit s/w wps gps aps cn13 cn12 min max modulating...

Page 68: Ladder Diagram:

Ladder diagram: hot 120vac power switch transformer primary secondary 150vac 15vdc 19vac 24vdc 26vac 5vdc 9vac floe sensor aps wps gps fan hall sensor h/w thermostat c/w thermostat s/h return thermostat s/h supply thermostat high limit s/w exhaust limit s/w mcu 1 mcu 2 thermistat thermostat 5a 5a ne...

Page 69: Wiring:

Wiring: the unit must be in off position before connecting the electrical wires. Make sure the circuit breaker on the distribution panel is off or on/off switch in the navien combination boiler is off. From the bottom of navien combination boiler, connect the 120 vac. When room thermostat needs exte...

Page 70

In-floor radiant heating system and baseboard heating system fan-assisted hydro heating system room thermostat (with battery) combination boiler ac24v y r room thermostat w r g y rd wh t t --a/h-- heating --t/s-- heating --------- field wiring combination boiler ac24v y r rd wh t t --a/h-- heating -...

Page 71: 1.1 Case Disassemble

Components diagram & parts list: 1.1 case disassemble components diagram & parts list 71.

Page 72: 1-2. Case Part List

1-2. Case part list 1 2 2-1 3 4 5 6 6-1 7 7-1 7-2 8 9 10 11 12 13 14 100 101 102 104 case cover emblem case upper bracket case lower bracket deco intake air duct ass’y intake air duck packing exhaust pipe ass’y exhaust pipe o-ring exhaust pipe packing intake air filter intake air filter support tran...

Page 73: 2-1. Burner Disassemble

Components diagram & parts list: 2-1. Burner disassemble 17 80 20 79 24 2 6 - 1 1 8 - 4 1 8 - 3 3 4 - 1 1 8 - 1 1 8 - 2 26 39 40 43 83 44 34 86 33 27 43 83 79 80 30 82 86 28 27 20 31 29 18 22 100 106 113 100 105 100 100 117 104 100 123 100 103 111 104 107 107 components diagram & parts list 73.

Page 74: 2-2. Burner Part List

17 18 18-1 18-2 18-3 18-4 20 22 24 26 26-1 27 28 29 30 31 33 34 34-1 39 40 43 44 79 fan motor flame rod ass’y flame rod flame rod packing a flame rod packing b flame rod bracket air pressure sensor burner burner bracket (l) manifold solenoid valve aps venturi aps venturi packing thermal fuse ignitio...

Page 75: 2-2. Burner Part List

80 82 83 86 100 103 104 105 107 111 113 116 117 123 tube tube (550l) tube o-ring screw d4 × 8l screw d4 × 6l bolt d4 × 10l (sts) screw d4 × 14l screw d4 × 14l bolt m4 × 12l (sts) screw d4 × 25l fan motor damper o-ring screw d4 × 4l bh2202024a bh2203001a bh2202041a bh2421008a bh1705007a bh1612004a bh...

Page 76: 3-1. Water Way Disassemble

3-1. Water way disassemble components diagram & parts list: components diagram & parts list 76.

Page 77: 3-2. Water Way Part List

15 16 21 23 24 25 32 41 42 45 46 47 49 50 51 52 54 55 56 57 58 59 60 61 63 64 65 66 67 69 71 72 high limit switch high limit switch bracket wps packing h/e bracket r h/e bracket l inlet water filter heat exchanger ass’y exhaust duct exhaust duct packing exhaust limit switch primary h/e inlet adapter...

Page 78

73 74 75 76 77 78 81 87 88 89 90 92 93 94 95 97 98 99 100 101 104 106 110 114 119 120 121 - water pressure sensor secondary h/e inlet adapter circulation pump drain coke pump bracket pump packing fastener c *@ *@ back-up ring +*@*@ pump fastener clip a clip c +!$ *@ fasten...

Page 79: Memo

Memo memo 79.

Page 80: Memo

Memo memo 80

Page 81: Memo

Memo memo 81.

Page 82: Memo

Memo memo 82.

Page 83: Memo

Memo memo 83.

Page 84

Rethink, reduce, reuse 20013057g navien gas combination boiler version : 4.01(dec. 27. 12).