Version: 1.00(oct. 02. 2013) navien america, inc. 20 goodyear lrvine, ca 92618 tel +949-420-0420 fax +949-420-0430 www.Navienamerica.Com getting service if your boiler requires service, you have several options for getting service: ● contact technical support at 1-800-519-8794 or on the website: www...

* lead free h model ncb-180 / 210 / 240 user’s information manual keep this manual near this boiler for future reference whenever maintenance or service is required. * the wetted surface of this product contacted by consumable water contains less than one quarter of one percent(0.25%) of lead by wei...

2 contents contents 1. Safety information 3 2. About the boiler 6 2.1 description of the boiler 6 2.2 parts of the boiler 6 2.3 the front panel 7 3. Operating the boiler 9 3.1 turning the boiler on or off 9 3.2 adjusting the temperature 9 3.3 viewing basic information 10 3.4 resetting the boiler 11 ...

Safety information 3 warning if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. A. This appliance does not have a pilot. It is equipped with an ignition device which automatically lights the burner. Do not try to ...

4 safety information danger this boiler’s water temperature is set to 120°f (49°c) at the factory for your safety and comfort. Increasing the temperature increases the risk of accidental scalding. Water temperatures at or above 125°f (52°c) can cause instant scalding, severe burns, or death. Before ...

Safety information 5 caution ● do not attempt to repair or replace any part of the boiler, unless it is specifically recommended in this manual. For all other service, contact an authorized technician or licensed professional. Improper adjustments, alterations, service, or maintenance may lead to pr...

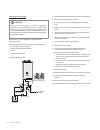

6 about the boiler 2.2 parts of the boiler front view exhaust gas vent combustion air intake bottom view # description a pump drain plug b space heating strainer c space heating supply connection d space heating return connection e dhw hot water outlet connection f gas connection g cold water inlet ...

About the boiler 7 2.3 the front panel the front panel allows you to adjust the temperature and view the operating status or error codes. Remove the protective sheet from the front panel before using it. B a f g h c d e i j psi o/r condensing combi boiler ncb r s mode 2.3.1 icons and digital display...

8 about the boiler k l m n o p psi o/r condensing combi boiler ncb mode r s 2.3.2 buttons using the buttons on the front panel, you can turn on or off the boiler, monitor the current operation status, and set the values required for the boiler’s operation, such as space heating and dhw supply temper...

Operating the boiler 9 2. Press the + (up) or – (down) buttons until the desired temperature appears on the display. Mode you can adjust the temperature while the display is flashing. Once the display stops flashing, the temperature setting is stored. Note ● take note of the original heating tempera...

10 operating the boiler 3.3 viewing basic information to view information about the boiler, press the mode button three times. “info” will appear on the display. Mode press the + or – buttons to switch between the information types. Display description psi o/r s r space heating supply water temperat...

Operating the boiler 11 3.4 resetting the boiler if an error message appears, you can try resetting the boiler to resolve the problem. To reset the boiler, press the reset button. Mode if resetting the boiler does not solve the problem, refer to the troubleshooting section of this manual or contact ...

12 maintaining the boiler 4.1 cleaning the boiler caution make sure the boiler is turned off and the power supply is disconnected before cleaning the boiler. The boiler may remain hot for several minutes after it is turned off. To prevent burns, wait until the boiler has cooled down before cleaning....

Maintaining the boiler 13 4.3 cleaning the inlet water filter (dhw side) to clean the filter: 1. Drain the dhw side of the boiler. Refer to “4.2 draining the boiler” on page 12. 2. While the filter is removed, rinse it with clean running water (cold) and, if necessary, scrub it clean with a brush. 3...

14 maintaining the boiler 4.4 cleaning the strainer (space heating side) if the heating performance is decreased, you can increase the heating performance by filtering impurities from the system. To clean the strainer: 1. Drain the space heating side of the boiler. Refer to “4.2 draining the boiler”...

Maintaining the boiler 15 7. Allow the filter to dry completely. 8. Reinsert the filter into the plastic assembly. 9. Place the filter assembly back into the boiler and secure it with the screw. 10. Replace the front cover. 11. Reconnect the power supply to the boiler. 12. Press the power button on ...

16 maintaining the boiler if hot water will not flow and you suspect that the boiler is frozen, follow these steps: 1. Press the power button on the front panel to turn off the boiler. 2. Close the gas valve. Gas valve opened closed 3. Open the hot water faucet that is closest to the boiler. 4. Use ...

Maintaining the boiler 17 4.7 maintenance schedules owner maintenance daily ● check boiler area ● check pressure / temperature gauge monthly ● check vent piping ● check air piping (if installed) ● check air and vent termination screens ● check relief valve ● check condensate drain ● check air vents ...

18 maintaining the boiler cleaning the condensate trap 1. Inspect the condensate drain line, condensate fittings, and condensate trap. 2. Remove any sediment in the trap. 3. Fill with fresh water until the water begins to pour out of the drain. Checking all piping for leaks eliminate all system or b...

Maintaining the boiler 19 warning following installation, the valve lever must be operated at least once a year to ensure that waterways are clear. Certain naturally occurring mineral deposits may adhere to the valve, rendering it inoperative. When manually operating the lever, water will discharge ...

20 maintaining the boiler flushing the heat exchanger caution flushing the heat exchanger is a somewhat complicated procedure. Read the following instructions carefully before attempting this procedure. If you are uncertain about any of the steps in the procedure, contact an authorized technician or...

Troubleshooting 21 mode if resetting the boiler and attempting the remedies suggested below do not resolve the problem, contact an authorized technician, a licensed professional, or technical support at 1-800-519-8794 for service instructions. Problem possible cause(s) what to do no water comes out ...

22 troubleshooting 5.2 understanding error codes when an error code appears on the front panel, refer to the following chart for a definition and possible remedy for the situation. Error code reason self-diagnostic / action e003 ignition failure ensure that the main gas supply valve is open. E004 fa...

Warranty 23 warranty period navien products come with a limited warranty covering labor, parts and the heat exchanger. The following warranty periods begin to run from the date of original installation. The date of original installation must be provided to navien, and upon request, proof of the orig...

24 warranty ● performance problems caused by improper sizing of the boiler, the gas supply line, the venting connection, combustion air openings, electric service voltage, wiring, fusing or any other components, parts or specifications. ● improper conversion from natural gas to lp gas or lp gas to n...

Memo.