- DL manuals

- Navien

- Boiler

- NCB-24LSWE

- Service Manual

Navien NCB-24LSWE Service Manual

Condensing Combi Boiler

Service

Manual

Service Support

Options for service support include:

●

Technical Assistance Service (TAS). A list of official TAS providers is available at

http://www.navienuk.com

. Contact a TAS for all warranty claims.

●

The technician or company that installed your boiler.

●

A registered service provider.

When you contact a TAS, please have the following information available.

●

Model number

●

Serial number

●

Date of purchase

●

Installation location and type

●

Error code information from the front display panel if available

Version: 1.0 (Oct. 19. 2015)

KD Navien Co.,Ltd

Summary of NCB-24LSWE

Page 1

Condensing combi boiler service manual service support options for service support include: ● technical assistance service (tas). A list of official tas providers is available at http://www.Navienuk.Com . Contact a tas for all warranty claims. ● the technician or company that installed your boiler. ...

Page 2: Warning

Condensing combi boiler service manual model ncb-24lswe ncb-28lswe ncb-34lswe ncb-40lswe keep this manual near the boiler for future reference. Warning the safety information contained in this manual is important. Not following the safety precautions may cause a fire or explosion and result in prope...

Page 3: Revisions

Ncb service manual 1 version 1.0 revisions version description of changes date 1.00 first issue mar. 12, 2015.

Page 4: Contents

2 ncb service manual version 1.0 contents 1. Safety information 5 1.1 safety definitions 5 1.2 safety symbols 5 1.3 instructional symbols 5 1.4 safety precautions 5 2. Product information 12 2.1 product information 12 2.2 components 13 3. Technical data 17 3.1 general specifications 17 3.2 dimension...

Page 5: Navien Warranty

Ncb service manual 3 version 1.0 navien warranty warranty period navien products come with a limited warranty covering. The warranty covers labour, parts, and the heat exchanger. The warranty period starts from the date of original installation. The date of original installation must be advised to n...

Page 6

4 ncb service manual version 1.0 abbreviations and definitions abbreviation definition ncb-ce general name for ncb-24lswe, ncb-28lswe, ncb-34lswe, and ncb-40lswe products ng natural gas lp propane gas ap air pressure aps air pressure sensor dhw domestic hot water fm fan motor garc gas air ratio cont...

Page 7: 1. Safety Information

Ncb service manual 5 version 1.0 1. Safety information 1.1 safety definitions the following safety symbols are used in this manual. Read and follow all safety instructions in this manual to avoid unsafe operating conditions, fire, explosion, property damage, personal injury, or death. 1.2 safety sym...

Page 8: Danger

6 ncb service manual version 1.0 danger flammable vapour vapours from flammable liquids can explode and cause fire resulting in death or severe burns. Do not use or store flammable products such as gasoline, solvents, or adhesives in the same room or area near the boiler. store flammable products ...

Page 9: Danger

Ncb service manual 7 version 1.0 danger hot water temperature setting water temperatures at or above 52°c can cause instant severe burns or scalding that can result in serious injury or death. households with small children, or disabled or elderly people, may require a temperature setting of 49°...

Page 10: Danger

8 ncb service manual version 1.0 danger important safety preautions read the safety information before operating or servicing navien boilers. confirm the location of the gas shut-off valve. During servicing, close the manual shut-off valve if the boiler overheats or is subjected to fire, flood, ...

Page 11: Warning

Ncb service manual 9 version 1.0 warning isolate the gas supply if the boiler is damaged. Identify the location of the gas shut off valve and ask a qualified technician to demonstrate how to close the valve. If the boiler is damaged due to overheating, fire, flood, or any other reason, close the s...

Page 12: Caution

10 ncb service manual version 1.0 caution do not attempt to repair or replace any part of the boiler unless it is specifically recommended in this manual. For repairs not covered in this manual, contact a qualified technician or a licensed professional. Incorrect adjustments, modifications, servic...

Page 13

Ncb service manual 11 version 1.0 general installation guidelines navien guarantees that no harmful substances or materials have been used in the manufacture of this product. All current and local laws and regulations must be observed when the boiler. The boiler must be installed in an adequately ve...

Page 14: 2. Product Information

12 ncb service manual version 1.0 2. Product information 2.1 product information the ncb series gas boiler is a fully modulating gas appliance which has a built-in circulation pump and air vent. It provides central heating and domestic hot water. Depending on the heat capacity, three models are avai...

Page 15

Ncb service manual 13 version 1.0 2.2 components the following diagram shows the key components of the boiler. Component assembly diagrams and particular parts lists are included in the appendices. Ncb-24/28/34lswe.

Page 16

14 ncb service manual version 1.0 ncb-24/28/34lswe.

Page 17

Ncb service manual 15 version 1.0 ncb-40lswe.

Page 18

16 ncb service manual version 1.0 ncb-40lswe.

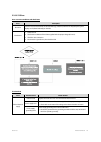

Page 19: 3. Technical Data

Ncb service manual 17 version 1.0 3. Technical data 3.1 general specifications the table below lists the boiler’s general specifications. Specification unit ncb- 24lswe ncb- 28lswe ncb- 34lswe ncb- 40lswe heating capacity (max/min) kw 20.0/4.2 24.0/4.2 29.0/5.1 34.0/4.0 dhw heat capacity (max/min) k...

Page 20

18 ncb service manual version 1.0 specification unit ncb- 24lswe ncb- 28lswe ncb- 34lswe ncb- 40lswe specific flow for kitchens (Δt=45°c) l/min 7.6 8.9 10.8 12.7 electrical supply - 230 v / 50 hz nominal current a 0.6 0.62 electrical maximum rating w 130 electrical protection - ip x5d boiler mountin...

Page 21

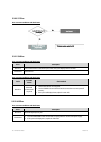

Ncb service manual 19 version 1.0 3.2 dimensions the following diagrams show the dimensions of the boiler. The table below lists the pipe diameters for various connection points. Supply connection pipe diameters re description diameter a flue exhaust/air intake 60 mm/100 mm, 80 mm/125 mm b space hea...

Page 22: 4. System Details

20 ncb service manual version 1.0 4. System details 4.1 setting the dip switches caution do not remove the front cover unless the power supply is turned off or disconnected. Failure to do so may result in electric shock. The boiler has two sets of dip switches on the main circuit board (pcb) and two...

Page 23: Warning

Ncb service manual 21 version 1.0 4.1.2 front panel dip switches setting the front panel dip switches the dip switch on the front panel configures the fuel selection, source of the heat demand, and the temperature control standard. Switc function setting 1 & 2 fuel selection g20 (lng) 1-off, 2-off g...

Page 24: Caution

22 ncb service manual version 1.0 4. Remove the boiler’s front cover by loosening the 4 phillips head screws securing it to the case. Caution ensure that no cables obstruct the pcb assembly before inserting it in position. If the assembly is stuck, do not force it. Doing so may damage the cables and...

Page 25: Warning

Ncb service manual 23 version 1.0 4.3 gas conversion this default gas supply configuration for this boiler is natural gas. If it is converted to propane gas, the conversion kit supplied with the boiler must be used. Warning this conversion kit must be installed by a qualified service agent*. All con...

Page 26

24 ncb service manual version 1.0 6. Loosen the four screws indicated in the illustration below. 7. Remove the pcb assembly. 8. With the internal components exposed, locate the gas inlet pipe and the gas valve in the middle of the unit as shown in figure 2-1 and figure 2-2. Figure 2-1. Ncb-24/28/34l...

Page 27: Warning

Ncb service manual 25 version 1.0 9. Loosen the hex nut at location a - the connection above the gas valve where it connects to the pipe (refer to figure 3-1 and figure 3-2). When the hex nut is loosened, carefully separate the pipe from the gas valve. 10. Detach the gas inlet pipe from the gas valv...

Page 28: Danger

26 ncb service manual version 1.0 figure 5-1. Exploded view of gas pipe assembly (ncb-24/28/34lswe) figure 5-2. Exploded view of gas pipe assembly (ncb-40lswe) danger see figure 5-1. Inspect the o-ring each time the connection between the venturi and gas valve inlet adapter is disassembled. The o-ri...

Page 29: Warning

Ncb service manual 27 version 1.0 replace the orifice with the new lp gas orifice. Ensure that the orifice is seated properly inside the port before proceeding to the next step. 11. Reinstate the gas inlet pipe to its original position and replace all of the screws and ensure all connections are sec...

Page 30: Danger

28 ncb service manual version 1.0 model gas type max min % co % co ncb-24lswe g20 9.27% 8.78% g31 10.40% 10.00% ncb-28lswe g20 9.20% 8.65% g31 10.42% 10.00% ncb-34lswe g20 9.10% 8.50% g31 10.30% 9.90% ncb-40lswe g20 9.20% 8.70% g31 10.50% 10.40% table 2. Co 2 value (co 2 values at high flame setting...

Page 31: Danger

Ncb service manual 29 version 1.0 model gas type g20 g31 [20 mbar] [37 mbar] output consumption gas flow gas flow load kcal/h kw kw m 3 /h m 3 /h ncb-24lswe max. 16,770 19.5 20.0 2.142 0.804 min. 3,552 4.1 4.2 0.450 0.169 ncb-28lswe max. 20,124 23.4 24.0 2.570 0.964 min. 3,522 4.1 4.2 0.450 0.169 nc...

Page 32

30 ncb service manual version 1.0 4.4 the front panel the front panel enables users to adjust the water temperature and view the operating status and error codes. Remove the protective sheet from the front panel before using it. 4.4.1 lcd display display function remarks space heating mode space hea...

Page 33

Ncb service manual 31 version 1.0 segment status display function remarks wait system is waiting for a response from the main controller when the boiler performs an error test or an error history report. Rst error reset clr deleting the error history and parameters. Init factory reset tec maintenanc...

Page 34

32 ncb service manual version 1.0 long key combination function remarks [power] long key (300 msec) power on / off [eco] + [space heating] long key (2 sec) displays error history accessible from operation mode> or mode> only. [eco] long key (2 sec) displays user parameters accessible from operation ...

Page 35

Ncb service manual 33 version 1.0 4.4.3 turning the boiler on or off to turn the boiler on or off, press the [power] button. If the boiler is in an error condition, the error code will continue to be displayed on the front panel even when the boiler is off. Item description display power on press to...

Page 36

34 ncb service manual version 1.0 item description display 1. Normal status boiler on in operation mode> the current water temperature and the space heating icon are displayed. In this example, the current water temperature (60°c) is displayed. 2. Level1 error a level 1 error has occurred the curren...

Page 37

Ncb service manual 35 version 1.0 4.4.5 displaying and resetting errors 1. When an error higher than level 2 occurs, the boiler may stop operating or have only basic functions. The boiler will enter directly from or . 2. When an error occurs in other modes, only the error icon flashes. The boiler en...

Page 38: Note

36 ncb service manual version 1.0 the temperature can be adjusted while the display is flashing. If no buttons are pressed for 5 seconds or if the eco button is pressed, the current temperature setting will be stored automatically. Note record the original heating temperature setting in case you w...

Page 39

Ncb service manual 37 version 1.0 4.4.8 viewing basic information ① to enter , press [eco] for > 2 seconds from . ② press [+] or [-] to navigate through the user parameters. ③ the current parameter setting has a letter prefix followed by 3 digits. ④ press [reset] once to return to . ⑤ if no changes ...

Page 40

38 ncb service manual version 1.0 item description display (e) flow rate the current flow rate (lpm) is displayed. A flow rate sensor is used to detect flow in the system. Eg.) 10.2lpm (f) outdoor air temperature the current outdoor temperature is displayed. An optional thermostat is used to detect ...

Page 41: Note

Ncb service manual 39 version 1.0 4.4.9 displaying error history 1. In or mode>, press [eco] and [space heating] for > 2 seconds to access the error history mode. The most recent error will be displayed first. 2. Press [+] or [-] to search for the error. A total of 10 errors are stored in memory and...

Page 42

40 ncb service manual version 1.0 4.4.10 displaying service information 1. In or , press [eco]+[dhw] at the same time for 5 sec to access service information. 2. Press [+] or [-] to navigate through the user parameters. 3. The current data stored for each service item has a letter prefix followed by...

Page 43

Ncb service manual 41 version 1.0 item description display (e) flow rate the current flow rate (lpm) is displayed. A flow rate sensor is used to detect flow in the system. Eg.) 10.2lpm (f) outdoor air temperature the current outdoor temperature is displayed. Eg.) at 15℃ (g) outdoor reset curve outdo...

Page 44

42 ncb service manual version 1.0 item description display (n) target aps the target aps voltage (v) is displayed. Displays the aps voltage value to one decimal place. Eg.) 3.2 v (o) current aps the current aps voltage (v) is displayed. Displays the aps voltage value to one decimal place. Eg.) 3.2 v...

Page 45

Ncb service manual 43 version 1.0 4.4.11 service status information 1. From or , press and hold [summer/winter] and [dhw] simultaneously for > 5 seconds to enter . 2. Press [+] or [-] to navigate through the service status information items. 3. The current service status information item is identifi...

Page 46

44 ncb service manual version 1.0 (h) successful second ignition the number of successful second ignitions is displayed. Eg.) five successful second ignitions have occurred. (i) successful third ignition the number of successful third ignitions is displayed. Eg.) three successful third ignitions hav...

Page 47: Caution

Ncb service manual 45 version 1.0 4.4.12 parameter setting mode parameter settings can be modified for boiler operations in different operating conditions, such as the space heating and dhw temperature ranges. Follow the instructions below to access special parameter mode and change the available se...

Page 48

46 ncb service manual version 1.0 entering parameter setting mode 1. Press [+] or [-] to navigate through the parameter setting items. 2. Parameter setting items are identified with a letter prefix followed by three digits of related data. 3. The display goes into if no activity is detected for 5 mi...

Page 49

Ncb service manual 47 version 1.0 item description display (a) outdoor reset this mode is used to configure the outdoor reset control. By default, the mode is disabled. Outdoor reset in use outdoor reset not in use (b) heating system outdoor reset control this mode is used to configure the type of h...

Page 50

48 ncb service manual version 1.0 item description display (d) highest outdoor temperature this mode is used to configure the highest outdoor temperature setting. The boiler will operate at the highest setting in the supply or return temperature setting range for that temperature. Outdoor high tempe...

Page 51

Ncb service manual 49 version 1.0 item description display (i) anti-fast cycling time the anti-fast cycling time is the duration that the boiler stops space heating when the supply or return temperatures reach the set temperatures. The boiler will not resume heating until the duration elapses even i...

Page 52

50 ncb service manual version 1.0 item description display (n) ch burner off temp during heating, the boiler turns off the burner when the supply temperature meets or exceeds the burner off temperature. Range default 0 to 30 ℃ 2 ℃ eg.) at 2℃ (o) ch burner on temp during heating, the boiler turns on ...

Page 53

Ncb service manual 51 version 1.0 item description display (t) low burner time this menu sets the burner to operate at a low flame setting during initial heating. Range default 0 to 20 min 1 min if low burner time is set at 15 minutes. (u) burner acceleration time this menu sets the burner’s acceler...

Page 54: Note

52 ncb service manual version 1.0 item description display (w) maintenance time this menu sets the maintenance time. Range default 0 to 999 days 0 maintenance time (+) reset all parameters this menu resets all boiler parameters to the default settings. To reset: 1. Press [+] or [–] to change the dis...

Page 55

Ncb service manual 53 version 1.0 entering test information mode 1. In or , press [eco]+[summer/winter]+[s.H] for > 5 sec to access information mode> 2. Press [+] or [-] to navigate through the test information mode items. 3. Press [eco] once to access the currently displayed mode. Item description ...

Page 56

54 ncb service manual version 1.0 component test performed display fan motor gradually increases the fan motor speed from 0 rpm to full speed and then decreases the speed to 0 rpm. The current aps value and the current speed (rpm) are displayed alternately at two second intervals. Pump turns on the ...

Page 57

Ncb service manual 55 version 1.0 setting operational conditions 1. In , press [+] or [-] until “2. Opr” is displayed on the front panel. Then, press [eco] once. 2. Cannot be accessed if the boiler is in an error condition. 3. When opens, either summer mode or winter mode is automatically selected d...

Page 58

56 ncb service manual version 1.0 4.4.13 resetting the boiler (factory reset) to resolve some error conditions, reset the boiler by pressing [reset]. If the problem is unresolved after resetting the boiler, refer to the troubleshooting section of this manual or contact a tas. 1. In , press and hold ...

Page 59

Ncb service manual 57 version 1.0 4.5 version display press [reset]+[+] for more than 5 sec in . Then, the main controller firmware version and the panel firmware version will each be displayed for 3 seconds before the system returns to . Item description display (a) main controller f/w version disp...

Page 60

58 ncb service manual version 1.0 4.8 electrical diagnostic contacts and wiring diagram.

Page 61

Ncb service manual 59 version 1.0 section test points colour coding readings remarks terminals wires high v o lta g e input voltage con1 (1,3) blue brown 2p ac 230 v 3.15 a fuse is connected to the brown cable. Con17 green yellow 1p earth ignition transformer conw1 (2,4) brown - blue 2p ac 230 v inp...

Page 62

60 ncb service manual version 1.0 4.9 key component descriptions 4.9.1 pcb item description function controls each component and monitors the overall performance of the unit. Fault pcb malfunction. Symptoms a system component may not operate and generate an error code. In most pcb failures, the boil...

Page 63

Ncb service manual 61 version 1.0 4.9.2 high temperature limit switch item description function 1. Overheat prevention switch. 2. If the switch detects extremely high temperature, the boiler will automatically trip and shut down. 3. Excessive high water temperatures (> 105°c) in the heat exchanger w...

Page 64

62 ncb service manual version 1.0 4.9.3 thermistor item description function measure hot and cold water temperature at the boiler’s space heating outlet and inlet connections. Fault inaccurate water temperatures from inside the boiler. Symptoms 1. If a thermistor fails, an error code is displayed be...

Page 65

Ncb service manual 63 version 1.0 4.9.4 fan motor item description function supplies combustion air for the burner and purges exhaust flue gas. To maintain gas input over long flue runs, the fan use aps to provide ideal combustion levels. Fault 1. Fan speed failure: when fan speed is approximately 0...

Page 66

64 ncb service manual version 1.0 4.9.5 flame rod assembly item description function repeatedly discharges a high voltage spark at the main burner until the gas ignites. Fault 1. Unable to ignite the gas. 2. Results in multiple unsuccessful ignition attempts. Symptoms 1. The boiler does not ignite a...

Page 67

Ncb service manual 65 version 1.0 4.9.6 ignition transformer item description function provides voltage for the igniter for gas ignition purposes. Fault 1. The igniter is unable to ignite the gas. 2. Results in multiple unsuccessful ignition attempts to. Symptoms 1. The boiler does not ignite and er...

Page 68

66 ncb service manual version 1.0 4.9.7 aps item description function measures the air pressure entering the burner system. Fault 1. Noises occur during combustion. 2. Imperfect and/or abnormal gas flame. 3. Incorrect voltage at the aps. Symptoms 1. The boiler does not operate. 2. Excessive carbon m...

Page 69

Ncb service manual 67 version 1.0 4.9.8 main gas valve item description function 1. Controls the amount of gas supplied to the burner based on fan speed. 2. When the unit experiences abnormal combustion, it automatically shuts off the gas supply to prevent unsafe situations. Fault unable to open/clo...

Page 70

68 ncb service manual version 1.0 4.9.9 burner (to be revised) item description function 1. Pre-mixes air and gas to reduce emissions and increase efficiency. 2. The burner produces the optimum air/gas mixture required to produce the correct level of heat during combustion. Fault 1. Unable to initia...

Page 71

Ncb service manual 69 version 1.0 4.9.10 flow sensor (to be revised) item description function to detect water flow in lpm (litres per minute) to provide a steady hot water temperature. Fault 1. Unable to detect or measure water flow rate. 2. Damage to and/or leakage from the water flow sensor. Symp...

Page 72

70 ncb service manual version 1.0 4.9.11 primary heat exchanger item description function 1. Main component used in the boiler for heat transfer. 2. Multiple pipes on surface of the heat exchanger and inside the combustion chamber are used to minimise heat loss. Fault 1. Water and/or exhaust gas lea...

Page 73

Ncb service manual 71 version 1.0 4.9.12 secondary heat exchanger item description function 1. Secondary component used in the boiler for heat transfer. 2. There are multiple paths of water pipes on the heat exchanger as well as inside the combustion chamber which minimises heat loss. Fault 1. Water...

Page 74

72 ncb service manual version 1.0 4.9.13 dhw heat exchanger item description function heat transfer between space heating and dhw water. Water heated in the primary and secondary heat exchangers is circulated to the plate heat exchanger. Also, the plate heat exchanger filters the water in the space ...

Page 75

Ncb service manual 73 version 1.0 4.9.14 circulation pump item description function 1. Provides internal or external water circulation. 2. Internal circulation minimises the effects of temperature fluctuations. External circulation quickly delivers hot water to taps and results in water conservation...

Page 76

74 ncb service manual version 1.0 4.9.15 3 way valve item description function uses a dhw flow sensor and pcb to cycle water between the space heating system and the dhw heat exchanger. Fault 1. No hot water in space heating mode. 2. No domestic hot water in dhw mode. Symptoms dhw supply stops and f...

Page 77

Ncb service manual 75 version 1.0 4.9.16 water pressure sensor item description function analysis of heating system water pressure ratios. Fault unable to detect or measure changes of water pressure. Symptoms the water top-up system does not operate automatically. Error codes e351, e352, e353 diagno...

Page 78

76 ncb service manual version 1.0 4.9.17 dual venturi item description function controls the tdr by adjusting the gas/air mixture rate. A synchronous motor is used to provide two control phases for mixing gases. Fault 1. Blades will not close. 2. Blades will not open. Symptoms 1. Boiler operation st...

Page 79

Ncb service manual 77 version 1.0 4.9.18 expansion tank item description function 1. Removes air from the system during heating. 2. Relieves system pressure caused by expansion as the water temperature increases. 3. Uses a built-in low level water sensor to maintain the water in the boiler at a cons...

Page 80: 5. Troubleshooting

78 ncb service manual version 1.0 5. Troubleshooting 5.1 error code classification classification error code error level function diagnosis/actions combustion system e001 3 2 heat exchanger overheating manual reset e003 3 ignition error manual reset e004 2 false flame detection auto reset e012 3 fla...

Page 81

Ncb service manual 79 version 1.0 5.2 error code list and actions error code sub code function diagnosis/actions e001 0 heat exchanger overheat 1. Clean the strainer. 2. Check voltage via pcb at the pump 3. (ac 230 v) 4. Check that the flow rate is correct 5. Check if water is circulating in the hea...

Page 82

80 ncb service manual version 1.0 error code sub code function diagnosis/actions e109 0 fan motor activity error 1. Check and clean the air intake filter. 2. Check and clean the fan motor. 3. Test the voltage from the pcb to ensure that it is correct. Replace fan if pcb voltage is normal. E110 1 exh...

Page 83: Important

Ncb service manual 81 version 1.0 error code sub code function diagnosis/actions e517 0 dip switch setting error check the dip switches on the front panel and the pcb. E594 0 eeprom operation error check the pcb. E615 0 heat exchanger 1, high limit switch input data error check the pcb. 1 exhaust se...

Page 84

82 ncb service manual version 1.0 5.2.1 error 001 error conditions and checklist error description e001 heat exchanger overheat 1. If the space heating water temperature is higher than 105℃, e001 will be displayed on the front panel to warn users of high temperature conditions. 2. If the space heati...

Page 85

Ncb service manual 83 version 1.0 testing methods error type cause testing method circulation errors circulation pump fault the circulation pump and fan run continuously in the error condition, 1. Check the power supply to the circulation pump (ac 230 v). 2. Replace the pcb if power is not available...

Page 86

84 ncb service manual version 1.0 5.2.2 error 003 error conditions and checklist error description e003 ignition fault when ignition faults occur, the boiler will attempt ignition 5 times. If a flame does not start, the system displays ‘003e’ on the front panel. This error code can be cleared manual...

Page 87

Ncb service manual 85 version 1.0 scenario2.

Page 88

86 ncb service manual version 1.0 testing method error cause testing method ignition failure gas supply fault 1. Check that the main gas valve is open. 2. Check the gas supply pressure. Ng: 17 - 25 mbar, lp: 25 – 35 mbar lp pressure drops can occur during winter. 3. Check the diameter of the flexibl...

Page 89

Ncb service manual 87 version 1.0 failure mode cause check method ignition failure ignition gap: 3.5-4.5 mm (1/8”) no spark from the electrode when no discharge is seen at the electrode during ignition: remove the electrode and check for cracks in the insulator. Adjust the gap if discharge is visibl...

Page 90

88 ncb service manual version 1.0 error cause testing method ignition failure main gas valve 1. Test the primary and secondary voltages at the main gas valve. Use a multimeter, between the yellow - white wires and verify the voltage is dc 24 v 2. If there is no voltage, replace the pcb. 3. If the vo...

Page 91

Ncb service manual 89 version 1.0 error cause testing method repeated ignition failure flame error 1. Inspect the flame area for deformation or foreign deposit. Repair or replace the part. 2. Check that the flame rod wiring connections are secure and free from damage. 3. Check the boiler case ground...

Page 92

90 ncb service manual version 1.0 5.2.3 error 004 error conditions and checklist error description e004 false-flame detection 1. Pre ignition false-flame 2. If a flame signal is detected continuously for 3 sec before combustion (stand-by, pre-purge, pre- ignition), a false-flame error 004e (automati...

Page 93

Ncb service manual 91 version 1.0 5.2.4 error 012 error conditions and checklist error description e012 loss of flame if the system detects a loss of flame during combustion, the system stops the gas supply and attempts to restart. Then, the system adds the instance to the flame loss count. If flame...

Page 94

92 ncb service manual version 1.0 testing method fault possible causes testing method flame loss and noise occurs after ignition low gas supply pressure 1. Check the gas supply pressure. Ng: 17 - 25 mbar, lp: 25 – 35 mbar lp pressure drop occurs frequently during winter. 2. When static pressure is n...

Page 95

Ncb service manual 93 version 1.0 fault possible causes testing method flame loss and noise occurs after ignition flame loss during stage 2 blockage in the gas orifice plate. Flame loss will occur if the gas orifices in the dual venturi are clogged. Remove the gas inlet pipe and check for debris ins...

Page 96

94 ncb service manual version 1.0 5.2.5 error 016 error conditions and checklist error description e016 bi-metal overheated if the overheat controller on the heat exchanger is initiated during boiler combustion or standby, the system displays ‘016e’ (manually cleared) on the front panel. The boiler ...

Page 97

Ncb service manual 95 version 1.0 testing method fault possible cause testing method defective safety device defective overheat controller check if the overheat controller’s contacts are faulty. Use a multimeter to test the resistance. Normal resistance is 0.3Ω and a fault condition would be infinit...

Page 98

96 ncb service manual version 1.0 5.2.6 error 030 error occurrence conditions and check items error description e030 exhaust gas temperature error if the overheat controller on the top of the exhaust duct is initiated, the system displays the heat exchanger bimetal overheat message 030e (cleared man...

Page 99

Ncb service manual 97 version 1.0 testing method fault possible causes testing method heat exchanger overheat damaged or obstructed heat exchanger 1. High exhaust gas temperatures can cause damage to or obstruct the heat exchanger. 2. Flush the heat exchanger to remove scale deposits. 3. Replace the...

Page 100

98 ncb service manual version 1.0 5.2.7 error 046 error conditions and checklist 5.2.8 error 047 error conditions and checklist.

Page 101

Ncb service manual 99 version 1.0 5.2.9 error 060 error conditions and checklist error description e060 dual venturi error dual venturi wiring is disconnected or the dual venturi malfunctions. The boiler switches to lock-out mode, performs a continuous post-purge continuously, and starts the circula...

Page 102

100 ncb service manual version 1.0 testing method fault possible causes testing method dual venturi action error defective dual venturi cable or harness 1. Disconnect all cables from the dual venturi. 2. Use a multi-meter to test the dual venturi’s electrical wiring. Dual venturi not operating 1. Tu...

Page 103

Ncb service manual 101 version 1.0 5.2.10 error 109 error occurrence conditions and check items error description e109 fan motor speed error the system checks the fan speed signal when the fan starts. The error message 109e (cleared manually) is displayed in the following cases: 1. If fan speed is l...

Page 104

102 ncb service manual version 1.0 testing method fault possible causes testing method fan action error no fan operation 1. Check the voltage at the fan. Black + yellow, dc 340 v 2. Replace the pcb if the voltage is not present. When replacing a pcb, turn off the boiler and wait for at least 10 sec ...

Page 105

Ncb service manual 103 version 1.0 5.2.11 error 110 error conditions and checklist error description e110 air pressure error the system detects the air pressure and the fan speed and displays 110e on the front panel in the following cases: 1. When the initial fan auto-adjustment is not performed. 2....

Page 106

104 ncb service manual version 1.0 testing method fault possible causes testing method 110e exhaust blockage intake air supply / exhaust flow error 1. If 110e occurs intermittently during ignition or combustion, compare the standard speed with the current speed at min/max combustion. If the current ...

Page 107

Ncb service manual 105 version 1.0 check method fault possible causes testing method faulty sensor temperature sensor connection fault check if the temperature sensor is open and if the connector is connected properly. Temperature sensor fault test the resistance of the temperature sensor. The senso...

Page 108

106 ncb service manual version 1.0 5.2.13 error 218 error conditions and checklist error description e218 open heat exchanger input temperature sensor if an open (-10°c or lower) heat exchanger input temperature sensor is detected, the system displays ‘218e’ on the front panel. If this occurs, the b...

Page 109

Ncb service manual 107 version 1.0 testing method fault possible causes testing method defective sensor temperature sensor connection fault check if the temperature sensor is open and if the connector is connected properly. Temperature sensor fault check the resistance of the temperature sensor. The...

Page 110

108 ncb service manual version 1.0 5.2.14 error 302 error conditions and checklist error description e302 low water pressure low pressure faults are monitored by a water pressure sensor and when a fault is detected the system displays ‘e302’ low water level error is generated if water pressure is 0....

Page 111

Ncb service manual 109 version 1.0 5.2.15 error 352 error conditions and checklist error description e352 high water pressure if an error signal is received from the water pressure sensor, the system displays the ‘e352’ on the front panel. High water pressure errors occur if the water pressure is 3....

Page 112

110 ncb service manual version 1.0 5.2.16 error 353 error conditions and checklist error description e353 water pressure sensor fault if a voltage error ( 5 v) at the water pressure sensor is detected continuously for 3 sec, the system displays ‘e353’. When this error occurs, the boiler shuts down. ...

Page 113

Ncb service manual 111 version 1.0 5.2.17 error 407 error conditions and checklist error description e407 hot water outlet thermistor open or short if an error (open: -10°c or lower) in the dhw outlet elbow input temperature sensor is detected, the system displays the 407e error on the front panel. ...

Page 114: Note

112 ncb service manual version 1.0 check method fault possible causes check method defective sensor defective temperature sensor connector check if the temperature sensor is open and if the connector is connected properly. Temperature sensor check the resistance of the temperature sensor. (defective...

Page 115

Ncb service manual 113 version 1.0 5.2.18 421error error conditions and check items error description e421 cold water inlet thermistor open or short if an error (open: -10°c or lower) in the dhw outlet elbow input temperature sensor is detected, the system displays the 421e error on the front panel....

Page 116

114 ncb service manual version 1.0 check method fault possible causes check method defective sensor defective temperature sensor connector check if the temperature sensor is open and if the connector is connected properly. Temperature sensor check the resistance of the temperature sensor. (defective...

Page 117

Ncb service manual 115 version 1.0 5.2.19 515error error occurrence conditions and check items error description e515 error if an error occurs in the internal circuit of the pcb (e.G., resistance, transistor or relay fault), the system displays 515e (cleared manually) on the pcb. Check items 1. Defe...

Page 118

116 ncb service manual version 1.0 5.2.20 517error error occurrence conditions and check items 5.2.21 594error error occurrence conditions and check items error description e594 error if the communication is abnormal in parts of pcb, the system displays e594 on the pcb. Check items check the pcb. Er...

Page 119

Ncb service manual 117 version 1.0 5.2.23 740error error conditions and check items error description e740 abnormal outdoor sensor if an error (under 2.2kΩ or over 122.2kΩ) in the outdoor sensor is detected continuously for 3 seconds, the system displays the error message e740 on the front panel. If...

Page 120

118 ncb service manual version 1.0 5.2.24 782error error occurrence conditions and check items.

Page 121

Ncb service manual 119 version 1.0 5.3 troubleshooting guide by symptom 5.3.1 noise error type cause check method vibration noise defective installation incorrect mounting to the wall or in an improper location. Check for improper installation and reinstall the unit if necessary. Fan vibration noise...

Page 122

120 ncb service manual version 1.0 5.3.2 water temperature issue error type cause check method boiler is not operating properly. Front panel power off hot water does not run if the front panel is switched off. Defective flow sensor the boiler does not work due to the defective flow sensor. The flow ...

Page 123

Ncb service manual 121 version 1.0 5.3.3 circuit breaker operation error type cause check method circuit breaker trips power supply the circuit breaker trips immediately as soon as the power cord is plugged in the receptacle. Check the sheath of power cord, or if there is short-circuit. Check the co...

Page 124: 6. Replacement Of Parts

122 ncb service manual version 1.0 6. Replacement of parts 6.1 replacement procedure caution 1. When performing maintenance and/or servicing the boiler, always turn off the electric power, gas and water shut-off valve. Wait for the boiler to become cool. Be careful to avoid injury to your fingers on...

Page 125: Note

Ncb service manual 123 version 1.0 6.2 components replacement instructions 6.2.1 pcb 1. Turn off the gas supply to the unit. 2. Disconnect the unit from the power supply. 3. Turn off the water supply to the unit. 4. Remove the 2 screws from bottom pcb bracket and upper pcb bracket. Figure 1 5. Disco...

Page 126: Note

124 ncb service manual version 1.0 figure 4 6. Disconnect the wiring connector from the fan assembly, and then remove the 2 screws from the gas valve connection as shown in figure 5 below. Figure 5 7. Pull out the fan assembly and remove the 2 screws that secure the air intake port to the fan assemb...

Page 127: Note

Ncb service manual 125 version 1.0 6. Remove the flame rod wiring connector. Figure 8 7. Remove the flame rod from the burner assembly and replace with the new part. 8. Reconnect the 2 ignition transformer insulated cables to the new flame rod. 9. Place the new flame rod back onto the burner assembl...

Page 128: Note

126 ncb service manual version 1.0 6.2.6 aps 1. Turn off the gas supply to the unit. 2. Disconnect the unit from the power supply. 3. Turn off the water supply to the unit. 4. Refer to figure11 and remove the air pressure sensor wiring connector. Figure 11 5. Remove the hose from the air pressure se...

Page 129: Warning

Ncb service manual 127 version 1.0 5. Remove the 2 screws located at the bottom of the unit that are attached to the gas valve. Figure 14 6. Replace the old gas valve with the new part 7. Reconnect the gas valve assembly to the unit by using the 2 screws at the boiler. 8. Reattach the gas valve wiri...

Page 130

128 ncb service manual version 1.0 6.2.9 circulation pump 1. Turn off the gas supply to the unit. 2. Disconnect the unit from the power supply. 3. Turn off the water supply to the unit. 4. Open the drain plug on the pump and remove the 4 screws from circulation pump. 5. Replace with the new circulat...

Page 131: Note

Ncb service manual 129 version 1.0 6.2.11 3-way valve 1. Turn off the gas supply to the unit. 2. Turn off the 230v power supply to the unit. 3. Turn off the water supply to the unit. Drain all water from the appliance. 4. Remove the circulation pump (see page 128). 5. Remove the clip on the 3-way va...

Page 132

130 ncb service manual version 1.0 6.2.13 dhw heat exchanger 1. Turn off the gas supply to the unit. 2. Turn off the 230v power supply to the unit. 3. Turn off the water supply to the unit. Drain all water from the appliance. 4. Remove the gas supply unit. 5. Remove the two screws at the dhw exchang...

Page 133

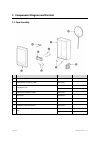

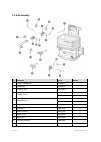

Ncb service manual 131 version 1.0 7. Components diagram and part list 7.1 case assembly # description part # remark 1 front cover ass'y 30014038a 2 panel kdc-820-1p ncb-ce, panel 30013543a 3 panel bracket, top 20030440a 34, 40k ng 20030321a 24, 28k ng 4 pcb kdc-820-xm ncb-ce, main 30013542a 5 base ...

Page 134

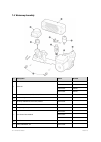

132 ncb service manual version 1.0 7.2 burner assembly # description part # remark 1 fan damper 30008825a 2 fan packing 20022744a 3 fan b/k, front 20022095a 4 fan b/k, back 20022096a 5 mixing chamber 20033575a 24, 28k ng 20031254a 34, 40k ng 6 mixing chamber packing 20027108a 24, 28k ng 20022743a 34...

Page 135

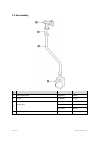

Ncb service manual 133 version 1.0 7.3 h-ex assembly # description part # remark 1 exhaust thermistor 30009478a 2 thermistor 30008366a 3 adapter sc out 20030566a 4 h/e middle pipe 30013744a 24, 28k ng 30011916a 34, 40k ng 5 flame rod ass'y 30014183a 24, 28k ng 30012226a 34, 40k ng 6 adapter cond out...

Page 136

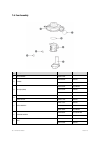

134 ncb service manual version 1.0 7.4 waterway assembly # description part # remark 1 dhw h/e 30014535a 24k ng 30014536a 28k ng 30014537a 34k ng 30014538a 40k ng 2 water pressure sensor(wps) huba, tipo 505 30014542a 3 air vent ass'y 30014543a 4 cir pump grundfos, up015-60, cesao3 30014554a 5 thermi...

Page 137

Ncb service manual 135 version 1.0 7.5 gas assembly # description part # remark 1 ventury inlet adp 30009921a 40k ng 2 o-ring 20006934a 40k ng 3 gas pipe ass'y 30013571a 24, 28k ng 30013592a 34k ng 30013604a 40k ng 4 gas valve, et76s time 30013623a.

Page 138

136 ncb service manual version 1.0 7.6 fan assembly # description part # remark 1 fan packing 20022744a 2 o-ring 20018079a 40k ng 20007001a 24, 28, 34k ng 3 inlet pipe(fan) 30013553a 24, 28k ng 30013554a 34k ng 30015141a 40k ng 4 single venturi 30014044a 24, 28, 34k ng dual venturi 20022118a 40k ng ...

Page 139: Caution

Ncb service manual 137 version 1.0 8. Inspection and maintenance schedule 8.1 annual servicing in order to maintain its safe and efficient operation, it is recommended that the boiler is serviced annually. Caution servicing must be performed by a qualified service agency or gas supplier inspection v...

Page 140: Memo

138 ncb service manual version 1.0 memo.

Page 141: Memo

Ncb service manual 139 version 1.0 memo.

Page 142: Memo

140 ncb service manual version 1.0 memo.

Page 143: Memo

Ncb service manual 141 version 1.0 memo.

Page 144: Memo

142 ncb service manual version 1.0 memo.