- DL manuals

- Navien

- Boiler

- NHB-055

- Installation & Operation Manual

Navien NHB-055 Installation & Operation Manual

WARNING

If the information in these instructions is not followed exactly, a fire or explosion may result, causing

property damage, personal injury, or death.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas

supplier.

The installation must conform with local codes or, in the absence of local codes, the National Fuel

Gas Code, ANSI Z223.1/NFPA 54 and/or CSA B149.1, Natural Gas and Propane Installation Code.

Keep this manual near this boiler for future

reference whenever maintenance or service

is required.

Installation & Operation Manual

NHB Condensing Boilers

Model

NHB-055

NHB-080

NHB-110

NHB-150

Summary of NHB-055

Page 1

Warning if the information in these instructions is not followed exactly, a fire or explosion may result, causing property damage, personal injury, or death. Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance. What to do if you smell gas...

Page 2

2 2 requirements for the state of massachusetts notice before installation this appliance must be installed by a licensed plumber or gas fitter in accordance with the massachusetts plumbing and fuel gas code 248 cmr sections 4.00 and 5.00. Important: in the state of massachusetts (248 cmr 4.00 & 5.0...

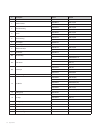

Page 3: Contents

3 contents contents 1. About the boiler 6 1.1 included items 6 1.2 accessories 6 1.3 specifications 7 1.4 components 9 1.5 dimensions 11 1.6 rating plate 12 2. Installing the boiler 13 2.1 choosing an installation location 13 2.2 mounting the boiler to the wall 15 3. Installing the system piping 16 ...

Page 4: Safety Information

4 safety information the following safety symbols are used in this manual. Read and follow all safety instructions in this manual precisely to avoid unsafe operating conditions, fire, explosion, property damage, personal injury, or death. Danger indicates an imminently hazardous situation which, if ...

Page 5

5 safety information caution do not turn on the boiler unless the water and gas supplies are fully opened. Doing so may damage the boiler. Do not use this boiler for anything other than its intended purpose, as described in this manual. Do not remove the front cover unless the power to the boiler is...

Page 6: 1. About The Boiler

6 about the boiler 1.1 included items when you open the box, you will find the following items with the boiler. Check the box for each of the following items before installing the boiler. Installation & operation manual, user’s information manual quick installation manual 2 in vent termination caps ...

Page 7

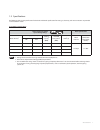

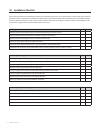

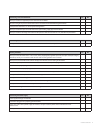

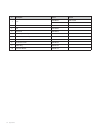

7 about the boiler 1.3 specifications the following tables list the specifications for the boiler. Additional specifications for water, gas, electricity, and vent connections are provided in the installation section. Space heating specifications navien condensing boiler space heating ratings other s...

Page 8

8 about the boiler general specifications item nhb-055 nhb-080 nhb-110 nhb-150 dimensions 17in (w) x 12in (d) x 24in (h) 17in (w) x 13in (d) x 24in (h) weight 73 lb (33 kg) 80 lb (36 kg) installation type indoor wall-hung venting type forced draft direct vent ignition electronic ignition natural gas...

Page 9

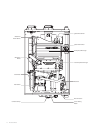

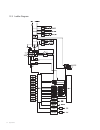

9 about the boiler 1.4 components the following diagram shows the key components of the boiler. Component assembly diagrams and particular parts lists are included in the appendixes. Intake air air filter front panel exhaust flue duct space heating supply aps pcb power switch air vent connection lwc...

Page 10

10 about the boiler dual venturi ignition transformer igniter & flame rod primary heat exchanger mixing gas guide secondary heat exchanger condensate trap gas connection space heating return gas valve fan & motor metal fiber premix burner.

Page 11

11 about the boiler 1.5 dimensions the following diagrams show the dimensions of the boiler and the table lists the supply connections. 23.6" (600 mm) supply connections description diameter a air intake 2 in b exhaust gas vent 2 in c air vent connection 3 / 4 in d rubber grommet 1 in e space heatin...

Page 12

12 about the boiler 1.6 rating plate the navien nhb boilers come from the factory configured for use with natural gas (ng). Before starting the installation, check the rating plate located on the side of the boiler to ensure that the boiler matches the gas type, gas pressure, water pressure, and ele...

Page 13

13 installing the boiler 2.1 choosing an installation location when choosing an installation location, you must ensure that the location provides adequate clearance for the boiler, adequate venting and drainage options, and sufficient access to gas, water, and electrical supplies. Carefully consider...

Page 14

14 installing the boiler caution it is necessary to leave clearance for service access. Clean, debris and chemical-free combustion air do not install the boiler in areas where dust and debris may accumulate or where hair sprays, spray detergents, chlorine, or similar chemicals are used. Do not insta...

Page 15

15 installing the boiler 2.2 mounting the boiler to the wall navien nhb boilers come with an upper mounting bracket that is pre-drilled at 16 in (400 mm) on center for easy installation on standard wall studs. If the strength of the wall is insufficient or if the framing is non-standard or uneven, r...

Page 16

16 installing the system piping prior to connecting plumbing to the boiler, flush the entire system to ensure it is free of sediment, flux, solder, scale, debris or other impurities that may be harmful to the system and boiler. During the assembly of the heating system, it is important to keep the i...

Page 17

17 installing the system piping oxygen elimination this boiler may only be installed in a pressurized closed-loop heating system, free of air (oxygen) and other impurities. To avoid the presence of oxygen, ensure all of the air is removed from the system during commissioning via strategically placed...

Page 18

18 installing the system piping low water cut off (lwco) device internal lwco the navien nhb boiler is equipped with a factory-installed, pressure-sensing type low water cutoff (lwco) device. The minimum operation pressure for this device is 6 psi by default. Note when the built-in water pressure se...

Page 19

19 installing the system piping pressure relief valve to complete the space heating system installation, you must install a 3 / 4 in, 30 psi (max.) pressure relief valve on the space heating hot water outlet. An asme approved hv pressure relief valve for space heating system is supplied with the boi...

Page 20

20 installing the system piping 3.1.3 space heating system piping when connecting the space heating system, follow these guidelines: carefully tighten all connections to avoid damage to fittings. After installing the boiler, check the space heating system's operation and inspect for leaks. The optio...

Page 21

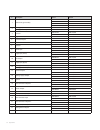

21 installing the system piping pq curves nhb-055/080 nhb-110 nhb-150 *=hv? *=hv? *=hv? Q[gpm] q[gpm] q[gpm] temperature rise conditions model 20°f Δt 30°f Δt 40°f Δt flow rate (gpm) head (ft) flow rate (gpm) head (ft) flow rate (gpm) head (ft) nhb-055 5.1 7.4 3.4 3.5 2.6 2.1 nhb-080 7.4 15.2 4.9 6....

Page 22

22 installing the system piping 3.2 connecting the condensate drain the navien nhb boiler creates condensation when it operates. This condensation has an acidic ph of 3-5. Follow all local codes and regulations when disposing of condensate from the boiler. We recommend draining the condensate into a...

Page 23

23 installing the system piping 3.2.1 condensate neutralizer kit warning to avoid damaging the appliance, the neutralizer inlet and discharge must be lower than the condensate drain. Do not allow exhaust flue gases to vent through the neutralizer. Leakage can cause injury or death from carbon monoxi...

Page 24

24 installing the system piping maintenance periodically monitor the level of media in the neutralizer and test the ph level at the outlet. We recommend an annual ph test using recognized test strips or an electronic ph meter to obtain precise measurements. Replace the neutralizing media when the ph...

Page 25

25 installing the system piping contaminant maximum allowable level total hardness 200 mg/l (12 grains/gallon) aluminum 0.05 to 0.2 mg/l chloride 250 mg/l copper 1.0 mg/l iron 0.3 mg/l manganese 0.05 mg/l ph 6.5-8.5 sulfate 205 mg/l 2. Close the manual and automatic air vents and the boiler drain va...

Page 26

26 installing the system piping thermostat configuration for the air handler interface set the pcb dip sw2 #7 to down position (off) to use a thermostat with the air handler. 1 2 3 4 5 6 on 1 2 3 4 5 6 7 8 on refer to the "3.1.1 guidelines for a space heating installation" on page 34 for wiring conn...

Page 27

27 installing the system piping 3.5.2 system application - zone system with zone valves make-up water backflow preventer pressure reducing valve additional zone zone #2 zone #1 system pump air separator expansion tank not to exceed 4 pipe dia or max. 12" zone valve (typical) boiler pump note system ...

Page 28

28 installing the system piping 3.5.3 system application - zone system with pumps make-up water backflow preventer pressure reducing valve additional zone zone #2 zone #1 air separator not to exceed 4 pipe dia or max. 12" boiler pump expansion tank note system application drawings are intended to ex...

Page 29

29 installing the system piping 3.5.4 system application - air handler system air flow air handler system pump (boiler pump) make-up water air separator expansion tank backflow preventer pressure reducing valve note system application drawings are intended to explain the system piping concept only. ...

Page 30

30 installing the system piping 3.5.5 system application - dhw system with indirect tank make-up water backflow preventer pressure reducing valve dhw outlet dhw inlet indirect tank anti-scald mixing valve system pump boiler pump dhw pump air separator expansion tank note system application drawings ...

Page 31

31 installing the system piping 3.6 examples of electrical connections warning improperly connecting the electrical supplies can result in electrical shock and electrocution. Follow all applicable electrical codes of the local authority having jurisdiction. Connecting the electrical components shoul...

Page 32

32 installing the system piping 3.6.3 wiring diagram - the navien smartzone + when navien boilers are used with a navien smartzone+ zone pump controller, an rs-485 data communication link is established through the ready-link connection. This allows the controller and the boiler to share operational...

Page 33

33 installing the system piping 3.6.4 wiring diagram - generic zone system with zone valves cn12 cn10 cn27 cn23 cn24 cn29 cn30 cn25 zone1 t/s zone2 t/s zone3 t/s zone4 t/s zone5 t/s zone6 t/s zone1 valve zone2 valve zone3 valve zone4 valve zone5 valve zone6 valve t/t lwco ac24v output t/t ch t/t dhw...

Page 34

34 installing the system piping 3.6.6 wiring diagram - air handler cn12 cn10 cn27 cn23 cn24 cn29 cn30 cn25 thermostat lwco ac24v output t/t ch t/t dhw temp. System return (optional) temp. System supply (optional) if you are using the navien manifold system, connect the pump wires to the system pump....

Page 35

35 installing the system piping 3.6.8 wiring diagram - optional supply/return temperature sensors cn12 cn10 cn27 cn23 cn24 cn29 cn30 cn25 lwco ac24v output t/t ch t/t dhw temp. System return (optional) temp. System supply (optional) temperature sensor thermal insulation cable tie note refer to "6.1 ...

Page 36

36 connecting the gas supply warning before connecting the gas supply, determine the gas type and pressure for the boiler by referring to the rating plate. Use only the same gas type indicated on the rating plate. Using a different gas type will result in abnormal combustion and malfunction of the b...

Page 37

37 connecting the gas supply note tighten the boiler connection valves with care to avoid damage. The gas connection fitting on all boilers is 3 / 4 in. 1 / 2 in rigid pipe can be used; refer to the sizing tables on the proceeding pages for limitations. Avoid using 1 / 2 in corrugated connectors or ...

Page 38

38 connecting the gas supply 4.1 gas pipe sizing tables the following tables are referenced from 2012 national fuel gas code for reference only. Please consult the gas pipe manufacturer for actual pipe capacities. Maximum natural gas delivery capacity in cubic feet (ft 3 ) per hour (0.60 specific gr...

Page 39

39 connecting the gas supply maximum liquefied propane delivery capacity in thousands of btu/h (0.5 in wc pressure drop) pipe size length (including fittings) 10 ft (3 m) 20 ft (6 m) 30 ft (9 m) 40 ft (12 m) 50 ft (15 m) 60 ft (18 m) 80 ft (24 m) 100 ft (30 m) 125 ft (38 m) 150 ft (45 m) 175 ft (53 ...

Page 40

40 connecting the gas supply 9. Remove the front cover by loosening the 4 phillips head screws securing it to the case. 10. Loosen the screws indicated in the figure below and connect a manometer to the pressure port. Reset the manometer to zero before use. Digital pressure manometer 11. Re-open the...

Page 41: 5. Venting The Boiler

41 venting the boiler warning improper venting of the boiler can result in excessive levels of carbon monoxide, which can lead to severe personal injury or death. This boiler must be vented in accordance with the “venting of equipment” section of the latest edition of the ansi z223.1/nfpa 54 natural...

Page 42

42 venting the boiler ref description canadian direct vent installations 1 us direct vent installations 2 a clearance above grade, veranda, porch, deck, or balcony 12 in (30 cm) 12 in (30 cm) b clearance to window or door that may be opened 36 in (91 cm) 12 in (30 cm) c clearance to permanently clos...

Page 43

43 venting the boiler to use non-direct venting for the boiler: 1. Insert the termination end cap into the intake air duct. Do not glue the end cap, to allow for easy removal and cleaning of the cap. Vent termination cap 2" coupling 2" vent pipe 2" 2. Provide two openings to allow for circulation of...

Page 44

44 venting the boiler ref description canadian non-direct vent installations 1 us non-direct vent installations 2 a clearance above grade, veranda, porch, deck, or balcony 12 in (30 cm) 12 in (30 cm) b clearance to window or door that may be opened 36 in (91 cm) 48 in (120 cm) below or to side of op...

Page 45

45 venting the boiler 5.2 selecting vent pipe materials venting requirements differ in the us and canada. Consult the following chart or the most recent edition of ansi z223.1/nfpa 54 or can/cga b149.1, as well as all applicable local codes and regulations when selecting vent pipe materials. Do not ...

Page 46

46 venting the boiler indoor boiler installation venting examples the following are some possible indoor venting options: 2 in or 3 in two-pipe sidewall venting 12" (300 mm) min. 12" (300 mm) min. Exhaust gas exhaust gas interior view exterior view intake air intake air 5.4 terminating the vent befo...

Page 47

47 venting the boiler 2 in or 3 in two-pipe vertical venting – intake and exhaust pipes do not have to terminate in the same area. 12" (300 mm) min. 12" (300 mm) min. 36" (900 mm) min. 12" (300 mm) min from any obstruction (above, below, left, or right) exhaust gas intake air concentric roof venting...

Page 48

48 setting the dip switches caution do not remove the front cover unless the power to the boiler is turned off or disconnected. Failure to do so may result in electric shock. The boiler has 2 sets of dip switches on the main circuit board (pcb) and 2 sets of dip switches on the front panel. Dip swit...

Page 49

49 setting the dip switches dip switch 2 (2 switch unit) the dip sw 2 on the front panel configures settings for the type of gas. Before changing the settings, lift the rubber cover to access the front panel dip switches. 2 on ng lp 2 on 1 on common vent individual vent 1 on 1 2 3 4 5 6 7 8 9 10 1 2...

Page 50

50 connecting the power supply warning improperly connecting the power supply can result in electrical shock and electrocution. Follow all applicable electrical codes of the local authority having jurisdiction. In the absence of such requirements, follow the latest edition of the national electrical...

Page 51

51 installing a cascade system when installing a cascadesystem, carefully consider the design of the system and the features of the installation location. Follow all local codes and regulations, as well as all guidelines for installing the boiler. The following sections describe additional considera...

Page 52

52 installing a cascade system system application #1- cascade system with closely spaced tees 12” (30 cm) maximum air separator slave2 slave1 master temperature sensors (required) cold water supply return back flow preventor expansion tank note connect the “ch demand (ch t/t or zone controller)” to ...

Page 53

53 installing a cascade system system application #3- cascade system with dhw indirect tank (for high dhw demand) 12” (30 cm) maximum slave2 slave1 master temperature sensors (required) cold water supply return back flow preventor expansion tank cold water dhw indirect tank aquastat air separator no...

Page 54

54 installing a cascade system system application #5- cascade system with dhw indirect tank (for low dhw demand) 12” 30 cm maximum slave2 slave1 master temperature sensors (required) cold water cold water dhw supply return back flow preventor expansion tank indirect tank aquastat air separator note ...

Page 55

55 installing a cascade system 8.1.1 piping sizes and considerations when plumbing a cascade system, consider the following pipe diameters and flow rates. Note that flow rates above 4 ft/s may cause pipe erosion or velocity noise. These specifications may vary depending on installation conditions. N...

Page 56

56 installing a cascade system 2. On the slave boiler, press and hold the diagnostic and down(- ) buttons for more than 2 seconds. “sl.01” will appear on the display to confirm that this boiler is set as a slave. Psi o/r s r psi o/r s r 3. Repeat step 2 to configure the rest of the slave boilers in ...

Page 57

57 installing a common vent system 9.1 about the common vent system the navien common vent system* provides an easy way to install the vent system for up to 8 navien nhb boiler units. By sharing the main intake and exhaust vent pipes, effective system venting is available with less venting materials...

Page 58

58 installing a common vent system adequate installation clearances caution do not install the boiler on carpeting. Install the boiler in an area that allows for service and maintenance access to utility connections, piping, filters, and traps. Based on the installation location, ensure that the fol...

Page 59

59 installing a common vent system general and local standards information when installing and operating the common vent system, the following standards and regulations must be complied with and adhered to: local codes or, in the absence of local codes, the national fuel gas code, ansi z223.1/nfpa 5...

Page 60

60 installing a common vent system vent pipe pitch and supports for horizontal runs, slope the horizontal section upward toward the vent termination at a rate of 1/4” per foot (2% slope). Connecting pipes with cement caution the vapors from primers and solvent cements can make you dizzy and are dang...

Page 61

61 installing a common vent system 9.1.2 determining the length of a common vent system follow the instructions listed below to determine the length of a common vent. 1. Add the btu/h input ratings for each unit in the cascading system to determine the total btu/h rating. 2. Determine the total leng...

Page 62

62 installing a common vent system 9.2 navien backflow damper (back-draft damper) the navien backflow damper prevents backflow (back-draft) at the exhaust vent while the boiler unit operates. By closing the exhaust vent as soon as the combustion cycle ends, the navien backflow damper retains heat in...

Page 63

63 installing a common vent system 9.3 starting the common vent system 9.3.1 backflow damper assembly follow the instructions below to assemble the backflow damper on the nhb boiler unit: 1. Remove the screws from the exhaust vent adapter. 2. Detach the exhaust vent adapter. 3. Connect the backflow ...

Page 64

64 installing a common vent system 9.3.2 connecting the pipe to the damper 1. Insert 2” vent pipe to the backflow damper to start the vent run. 2. Completely slide the vent pipe ends into the transition fitting. Tighten the clamp with a screwdriver to properly seal the joint. 9.3.3 assembling the t ...

Page 65

65 installing a common vent system 9.4 connecting and terminating the vent pipe refer to the following example to install the common vent system. The installation area should be measured to ensure that sufficient space is available to install the boiler units and the common vent system. Ensure that ...

Page 66

66 installing a common vent system 9.5 setting up the common vent system danger incorrect dip switch settings may lead to severe personal injury, death, or property damage. Refer to the following figures when setting dip switches. 1 2 3 4 5 6 7 8 9 10 on on switch (2–switch dip) function setting 1 c...

Page 67

67 installing a common vent system 9.6.3 direct vent application – horizontal installation intake maximum length 20’ (6 m) minimum length 36” (91 m) exhaust note the illustration is intended for reference purposes only. Direct the exhaust away from any building openings. During cold weather situatio...

Page 68

68 installing a common vent system 9.7 exhaust vent termination clearances (for direct vent) ref description canadian direct vent installations1 u.S. Direct vent installations2 a clearance above grade, veranda, porch, deck, or balcony 12 in (30 cm) 12 in (30 cm) b clearance to window or door that ma...

Page 69

69 installing a common vent system 9.8 maintenance periodically check the damper condition inside the backflow damper through the maintenance port to ensure optimal performance of the system. Follow the instructions to check the damper condition and replace the backflow damper if necessary. 1. Remov...

Page 70

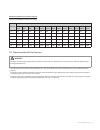

70 installation checklist after installing the boiler, review the following checklist. You should be able to answer “yes” to all of the items in the checklist. If not, review the appropriate sections to complete the installation. To troubleshoot any operational problems refer to “troubleshooting” in...

Page 71

71 installation checklist connecting a pressure relief valve yes no have you installed an approved pressure relief valve on the boiler? Does the rating of the pressure relief valve match or exceed the maximum btu rating of the boiler? Is the pressure relief valve 3 / 4 in on the space heating outlet...

Page 72

72 installation checklist pcb dip switch setting (dip sw 2, set of 8) yes no is switch #1 set correctly for return water control (on) or supply water control (off)? If continuous boiler operation is required, is switch #7 in the up (on) position? If high temperature venting has been installed (cpvc ...

Page 73

73 operating the boiler 2. Press the + (up) or – (down) buttons until the desired temperature appears on the display. Mode you can adjust the temperature while the display is flashing. Once the display stops flashing, the temperature setting is stored. Note the outdoor reset control will take preced...

Page 74

74 operating the boiler 11.3 viewing basic information to view information about the boiler, press the mode button three times. “info” will appear on the display. Mode press the + (up) or – (down) buttons to switch between the information types. Display description psi o/r s r space heating supply w...

Page 75

75 operating the boiler display description psi o/r s r space heating return water temperature (°f) psi o/r s r not available psi o/r s r not available psi o/r s r not available psi o/r s r outdoor air temperature (°f) (from outdoor temperature sensor) psi o/r s r outdoor reset curve (load type) -: ...

Page 76

76 operating the boiler display description psi o/r s r blower fan motor target rpm (x 10) psi o/r s r blower fan motor current rpm (x 10) psi o/r s r aps target voltage psi o/r s r aps current voltage psi o/r s r exhaust gas temperature (°f) psi o/r s r model type (55, 80, 110, 150) psi o/r s r gas...

Page 77

77 operating the boiler display description psi o/r s r dhw pump status psi o/r s r overheating sensing (htl) status psi o/r s r dual venturi status psi o/r s r low water cut-off (lwco) status psi o/r s r air handler interface output psi o/r s r dhw priority status to exit service information mode, ...

Page 78

78 operating the boiler note if you enter an incorrect password 10 times or make no inputs 5 minutes, the boiler will return to normal mode. To return to the previous mode, press the reset button. The factory default password is “1234”. If you make no inputs for 10 seconds in the parameter edit mode...

Page 79

79 operating the boiler setting the lowest outdoor temperature display description psi o/r s r lowest outdoor temperature (°f) psi o/r s r lowest outdoor temperature not in use this mode is used to configure the lowest outdoor temperature. The boiler will operate at the high end of the supply or ret...

Page 80

80 operating the boiler setting the pump freeze protection temperature display description psi o/r s r pump freeze protection temperature (°f) this menu is used to configure the circulation pump freeze protection temperature. When the space heating supply temperature stays below the set value for lo...

Page 81

81 operating the boiler setting the burner-on temperature differential display description psi o/r s r burner-on temperature (°f) during space heating, the boiler turns on the burner when the space heating supply temperature is below the burner-on temperature. Burner-on temperature range range remar...

Page 82

82 operating the boiler setting the return absolute min temperature display description psi o/r s r return absolute min set point (°f) this menu can be used to change the minimum return temperature range in return control mode. When custom mode is configured in outdoor reset control mode, changes to...

Page 83

83 operating the boiler setting the dhw mode-system pump display description psi o/r s r do not use system pump (no) psi o/r s r use system pump (yes) use this menu to set system pump operation for dhw mode. Default: off setting the ch mode-dhw pump display description psi o/r s r do not use dhw pum...

Page 84

84 operating the boiler setting the warm weather shut-down display description psi o/r s r warm weather shut-down temperature default: off range: off, 50°f (10°c) – 104°f (40°c) display description psi o/r s r warm weather shutdown on differential default: 5°f (3°c) range: 0°f (0°c) – 36°f (20°c) se...

Page 85

85 operating the boiler use this menu to operate the boiler with the navi-link controller connected via a ready-link cable. Default: off resetting all parameters display description psi o/r s r do not reset parameters (no) psi o/r s r reset all parameters (yes) this menu may be used to reset all the...

Page 86: 12. Appendixes

86 appendixes 12.1 gas conversion this boiler is configured for natural gas at the factory. If conversion to propane gas is required, use the conversion kit supplied with the boiler. Warning this conversion kit must be installed by a qualified service agency* in accordance with navien’s instructions...

Page 87

87 appendixes 7. Remove the pcb assembly. 8. With the internal components exposed, locate the gas inlet pipe and the gas valve in the middle of the unit, as shown in figure 2. Gas valve gas inlet pipe figure 2. Nhb series internal components 9. Use a phillips screwdriver to remove the two screws at ...

Page 88

88 appendixes warning do not adjust or attempt to measure gas valve outlet pressure. The gas valve is factory-set for the correct outlet pressure. This setting is suitable for natural gas and propane, requiring no field adjustment. Attempting to alter or measure the gas valve outlet pressure could r...

Page 89

89 appendixes 17. Turn on the gas and water supply to the boiler. 18. Measure and adjust the gas/air ratio. Option 1. Using combustion analyzer (recommended) a. Loosen the screw, rotate the plate and remove the gasket to access the emissions monitoring port as shown in figure 7. B. Insert the analyz...

Page 90

90 appendixes option 2. Using digital manometer a. Open the offset pressure port by loosening the screw two turns as shown in figure 9. Digital pressure manometer figure 9. Connect digital pressure monometer b. Connect a manometer to the offset pressure port. For dual port manometers, use the positi...

Page 91

91 appendixes 12.2 wiring diagram c olor c ode b o r w y bk br gy : blue : o range : red : whit e : y ello w : black : br o w n : gr een/y ello w if an y of the orig inal wir es as supplied the boiler must be replac ed , they must be r eplac ed their equivalent. Fm fan m o to r yb k r o w cn 8 cn17 ...

Page 92

92 appendixes 12.3 ladder diagram.

Page 93

93 appendixes 12.4 component assembly diagrams and parts lists 12.4.1 case assembly 1 3 4 2 8 7 9 9 5 6 9 10 1 2.

Page 94

94 appendixes # description part # remark 1 case 20030085a nhb-110/150 20030088a nhb-055/080 2 cover 30013463a 3 pcb 30013044a 4 front panel 30013041a 5 exhaust pipe assembly 30008673a 6 intake air duct assembly 30008662b 7 intake air fillter 20007667a 8 air pressure sensor 30010238a 9 rubber ring 2...

Page 95

95 appendixes 12.4.2 heat exchanger and waterway assembly 13 12 11 7 7 2 5 4 23 16 6 7 3 3 18 3 21 6 2 22 1 9 14 15 12 12 10 12 12 12 7 23-1 7 20 12 7 12 2 19 17 12 12 8 7.

Page 96

96 appendixes # description part # remark 1 heat exchanger assembly 30014219a nhb-150 30013575a nhb-110 30014060a nhb-080 30014218a nhb-055 2 o-ring (p29) 20032163a nhb-110/150 o-ring (Φ17.5x2.7t) 20003022a nhb-055/080 3 fastener 20017724a nhb-110/150 20007853a nhb-055/080 4 high limit switch 300025...

Page 97

97 appendixes 12.4.3 combustion parts assembly 1 2 3 4 5 16 15 15 18 17 10-3 10-2 19 11 15 12 13 7 6 7 8 9 10-1 14.

Page 98

98 appendixes # description part # remark 1 ignition transformer 30010455a 2 mixed chamber 20030041a nhb-110/150 20030049a nhb-055/080 3 chamber packing 20022743a nhb-110/150 20027108a nhb-055/080 4 burner 30010246a nhb-110/150 30011854a nhb-055/080 5 burner packing 20021677a nhb-110/150 20027105a n...

Page 99

99 appendixes 12.5 outdoor temperature sensor outdoor temperature sensor installation 1. Pull out the sensor body from the cap. 2. Attach the body to the wall using the screws/anchors provided with the device. 3. Run the wires into the device body through the grommet opening. 4. Connect the wires to...

Page 100

100 appendixes 12.6 outdoor reset control the outdoor reset control feature may be used to enhance energy efficiency while maintaining optimal heating performance. With the outdoor reset control, the space heating temperature setting automatically changes according to the outdoor temperature and the...

Page 101: Memo

Memo.

Page 102

Getting service if your boiler requires service, you have several options for getting service: contact technical support at 1-800-519-8794 or on the website: www.Navien.Com. For warranty service, always contact technical support first. Contact the technician or professional who installed your boiler...