- DL manuals

- NC

- Utility Vehicle

- SW9

- Operator's Instruction Manual

NC SW9 Operator's Instruction Manual

1

SW9 Site Dumper

SW9 Site Dumper

SW9 Site Dumper

SW9 Site Dumper

OPERATORS

OPERATORS

OPERATORS

OPERATORS

INSTRUCTION

INSTRUCTION

INSTRUCTION

INSTRUCTION

MANUAL

MANUAL

MANUAL

MANUAL

NC ENGINEERING (HAMILTONSBAWN) LTD

2 Killyrudden Road, Hamiltonsbawn, Co Armagh, BT61 9SF

Tel: 028 38871970 Fax: 028 38870362

email:

sales@nc-engineering.com

www.nc-engineering.com

REVISION B

ORGINALINSTRUCTIONS

Summary of SW9

Page 1

1 sw9 site dumper sw9 site dumper sw9 site dumper sw9 site dumper operators operators operators operators instruction instruction instruction instruction manual manual manual manual nc engineering (hamiltonsbawn) ltd 2 killyrudden road, hamiltonsbawn, co armagh, bt61 9sf tel: 028 38871970 fax: 028 3...

Page 2

2.

Page 3

3 dear customer even if you have operated this type of equipment before, it is very important that your new equipment operations and instructions are explained to you by a dealer representative following delivery of your equipment. This will explain the operating controls and enable you to gain maxi...

Page 4

4.

Page 5: Pre Handover Check List

5 pre handover check list return form to nc engineering (hamiltonsbawn) ltd 2 killyrudden road hamiltonsbawn co armagh bt61 9sf delivery on this machine has been completed, including the following items. Tick check box when each item is completed. 1. Operator handbook delivered with equipment and ...

Page 6

6 at delivery point with customer explain parts book explain all warning labels on equipment show location of all serial numbers on equipment lubrication & maintenance explain maintenance requirements, fuel & lubricant specifications instruct how to use service schedules of maintenance han...

Page 7: Contents

7 contents declaration of conformity 9 noise level declaration 10 vibration declaration 11 post delivery checks 12 machine data 13 skip & loading information 13 steering 14 transmission 14 brakes 14 engine 14 vehicle identification plate - vin 14 safety decals and descriptions 15 safety information ...

Page 8: Contents

8 contents page no. Safe operating instructions 30 visibility 30 climbing / descending gradients 31 crossing gradients 31 rops bar 32 towing loads 33 transportation 33.

Page 9: Engineering

9 engineering (hamiltonsbawn) ltd. Manufacturers of agricultural and industrial equ i pment 2 killyrudden road, hamiltonsbawn, tel: 028 38871970 richhill, co. Armagh. Fax: 028 3887 0362 northern ireland. E.Mail: info@nc engineering.Com 8t619sf www.Nc-engineering.Com ec – declaration of conformity ma...

Page 10: Noise Level Declaration

10 noise level declaration the noise levels are measured according to iso6395:1998 the noise level of this machine is l wa 104db ( a ) l pa 85db ( a ) l wa :- a - weighted sound power level. L pa :- a - weighted sound pressure level..

Page 11: Vibration Declaration.

11 vibration declaration. The absence of a harmonised test code together with variable conditions under which this equipment may be used allows only representative figures to be quotes. Whole body vibration level : a w (m/s²) = 0.25 hand / arm : a ha ( m/s² ) ≤ 2.4 the above figures are for referenc...

Page 12: Post Delivery Checks

12 post delivery checks • check the condition of the machine and make sure it has not been damaged during delivery. • tightness of wheel nuts. • check the following oil levels in engine, gearbox and axles. Hydraulic oil and fuel levels. Brake fluid level in the reservoir. Coolant level. Battery liqu...

Page 13: Machine Data

13 machine data skip & loading information the machine is fitted with a load carrying skip which is able to swivel to the left and right of the machine. Capacities max. Safe load: 9000 kg heaped: 4427 litres struck: 3126 litres water: 2492 litres never attempt to load the skip beyond its rated capac...

Page 14: Machine Data

14 machine data steering steering of the dumper is by an ‘orbital’ hydrostatic steering unit, that articulates the centre of the machine using a hydraulic cylinder which in turn gives a steering motion. Transmission the dumper is fitted with a torque converter transmission coupled to a four speed sh...

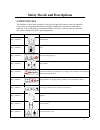

Page 15: Safety Decals

15 safety decals and descriptions safety decals the machine is fitted with a number of safety decals placed in areas to draw the attention of the users. It is important that before using the machine theses decals are read and un- derstood. The decals must be clean and readable at all times, if they ...

Page 16

16 safety decals and descriptions part no. Symbol. Descriptions. Dec~1920-013 don’t operate controls until operators manual has been read. Dec~1920-014 recommended brake fluid. Dec~1920-015 recommended brake fluid ( circular ) dec~1920-016 no repairs to rops. Dec~1920-017 stay clear of pinch points....

Page 17: Safety Information

17 safety information for safety & protection read the following both operators and maintenance personnel must read the following safety notice. The information below is given for your own safety. They must be read before operating or carrying out any maintenance to the machine. Local site rules mus...

Page 18: Safety Information

18 safety information this machine is designed to transport free flowing materials. If used in the correct manner it shall provide a efficient and safe means of transport and meet all performance standards. The operator of the machine must be an able bodied adult fully trained in its operation. Alwa...

Page 19: Safety Information

19 safety information roll over protection structure (rops) fatigue and finite life problems with rops. Rops on the whole are maintenance free but in the unlikely event of a failure it is usually due to the operator not inspecting or periodically checking the rops for cracks, loose bolts, damage or ...

Page 20: Safety Information

20 safety information seat belt information • improper inspection of the seat belt could cause serious injury or loss of life in the event of an accident. • in the event of an accident the entire seat belt system must be replaced. • if needed the seat belt must be replaced throughout the life of the...

Page 21: Seat Adjustment

21 seat adjustment horizontal adjustment the seat can be adjusted horizontally or fore-aft direction by pushing the lever marked (a) and sliding the seat back or forward to the required position so that the operator has full control of the foot pedals and steering column. When the lever is released ...

Page 22: Safety Information

22 safety information battery isolator the battery isolator is to be used when ever maintenance is being performed on the machine to stop accidental engine start up. The isolator switch can also be used in the event of long periods of the dumper being unattended e.G. Meal breaks, overnight etc. This...

Page 23: Safety Information

23 safety information warning others the dumper is fitted with a number of devices to warn others nearby of impending danger from the machine. Horn the horn can be activated from either of two locations by pressing the appropriate button (a) or (b). Once the button is released the horn will stop. Be...

Page 24: Safety Information

24 safety information checklist common rail (tier 3) specific in addition to the general safety notices and general good workshop practices issued in this section and throughout the manual, there are specific points to note when completing maintenance on tier 3 equipment. Diesel fuel quality importa...

Page 25: Safety Information

25 safety information common rail safety checklist the following safety checklist is intended to help remind you of safety procedures and practices relating to a common rail engine. Safety is your responsibility - do make sure the engine and surrounding area has been thoroughly cleaned prior to comp...

Page 26: Engine Canopy

26 engine canopy opening access to the engine area is gained by lifting the engine canopy upwards. This is done by: • ensure button (b) of handle (a) is in the unlocked position. • press button (b) to release the canopy latch. • lifting the canopy, using handle (a). The gas struts will hold the cano...

Page 27: Driving Controls

27 driving controls starting procedure ensure handbrake (a) is on and neutral is selected on the column lever (b). The engine will not start if the fnr selector lever is in either forward or reverse. The starter switch has four stages 1. Off 2. On 3. Engine heat 4. Engine start to start the engine t...

Page 28: Driving Controls

28 driving controls acceleration to make the vehicle go faster depress the accelerator pedal (a) with your right foot , this will increase the revs of the engine. To increase speed select a higher gear, press the red button on the side of the gear selector lever select the gear required by pushing t...

Page 29: Dashboard Warning Lights

29 dashboard warning lights attention engine failure / malfunction . Low hydraulic oil (optional) if hydraulic oil drops below a minimum level this light will illuminate. Dumper should be filled to the correct level before continuing with work. Handbrake this light will stay on when ever the handbra...

Page 30: Visibility Around Dumper

30 safe operating instructions visibility around dumper take care when driving the dumper. Before moving off always ensure there are no persons in areas of low visibility. Sound the horn to warn others of your approach. Don’t move off until you are sure no persons are obstructing your path. If in do...

Page 31: Crossing Gradients

31 safe operating instructions climbing / descending gradients when ascending or descending a gradient, especially when the skip is loaded, the skip must always face the incline. To the right is a diagram for the correct and incorrect ways to ascend and descend gradients. Never exceed the maximum st...

Page 32: Rops Bar

32 safe operating instructions rops bar the dumper is fitted with a folding rops bar, which can be lowered for transportation purposes. Lowering • to lower the rops remove the linch key in the pin (a). These are located on both sides of the rops. • push rops bar backwards until holes (b) and (c) lin...

Page 33: Transportation

33 safe operating instructions using the dumper for towing loads this dumper is not designed as a towing vehicle, but if the machine has to be used for towing an implement make sure the weight of any trailer and its load does not exceed half the rated payload of the dumper. It is important that if t...