- DL manuals

- NCR

- Scanner

- 74 OFX (7874)

- User Manual

NCR 74 OFX (7874) User Manual

Summary of 74 OFX (7874)

Page 1

Ncr realscan 74 ofx (7874) release 1.1 user guide 25315 b005-0000-1822 issue c.

Page 2

The product described in this book is a licensed product of ncr corporation. Ncr is a registered trademark of ncr corporation. Ncr realpos, ncr realprice, ncr realscan, ncr easypoint and ncr fastlane are either registered trademarks or trademarks of ncr corporation in the united states and/or other ...

Page 3: Preface

I preface audience this book is written for hardware installer/service personnel, system integrators, and field engineers. Notice: this document is ncr proprietary information and is not to be disclosed or reproduced without consent. References • ncr scanner programming tags (bst0 ‐ 2121 ‐ 74) • ncr...

Page 4: Table of Contents

Ii table of contents chapter 1: product information available models.............................................................................................................1-2 features and options......................................................................................................

Page 5

Iii no side rails .........................................................................................................2-8 realscan checkstand wiring ..................................................................................2-9 power considerations...........................................

Page 6

Iv special host terminal connections............................................................................3-36 scanner connected to ibm terminals..................................................................3-36 sni beetle host terminal ........................................................

Page 7

V multiple reads ........................................................................................................4-10 operating instructions..................................................................................................4-11 turning the realscan 74 on and off .................

Page 8

Vi program parameter descriptions................................................................................5-18 communications protocol .....................................................................................5-18 ibm slot scanner.......................................................

Page 9

Vii scans required....................................................................................................5-29 overlap characters.............................................................................................5-29 minimum segment size............................................

Page 10

Viii codabar stitch.....................................................................................................5-39 number of codabar scans required ...............................................................5-39 bar codes–7 .................................................................

Page 11

Ix dual cable interface ...............................................................................................5-54 avery scale emulation.......................................................................................5-54 programming worksheets ...........................................

Page 12

X code 39 minimum and maximum length .....................................................5-74 interleaved 2 of 5 tone length .........................................................................5-74 interleaved 2 of 5 tone frequency .................................................................

Page 13

Xi ignore rs232 commands from pos................................................................5-84 enable upc ns5 coupon..................................................................................5-85 gs1 databar ai 8110 coupons .................................................................

Page 14

Xii firmware flashing procedure...............................................................................5-98 realscan flash drive support ...................................................................................5-101 ncr realscan flash drive prep application ............................

Page 15: Revision Record

Xiii revision record issue date remarks a may 23, 2008 release 1.1 b sept. 19, 2008 various artwork updates updated shift test and decreasing load test information c december 19, 2008 updated scanner dimensions, checkstand cutout dimensions, and scale calibration test procedures safety and regulator...

Page 17: Product Information

Chapter 1: product information the ncr realscan 74 ofx is a state ‐ of ‐ the ‐ art bi ‐ optic scanner. Its primary use is in high ‐ performance checkout areas of food distribution and general merchandise sales. The realscan 74 can read bar codes on all six sides of the product as it passes through t...

Page 18: Available Models

1-2 chapter 1: product information available models 25319 ncr realscan 74 scanner/scale ncr realscan 74 scanner only the ncr realscan 74 is available in six rohs ‐ compliant models. The following table identifies the major models along with a brief description of each. Model description realscan 787...

Page 19

Chapter 1: product information 1-3 the realscan 74 vertical scan window is mounted to a tower that rises above the checkstand surface. The upper console is designed to withstand constant impact from items being scanned. The horizontal scan window is flush–mounted to a part plastic, part steel top pl...

Page 20: Communications Protocol

1-4 chapter 1: product information communications protocol the realscan 74 communicates with the host terminal through: • rs232 • usb • ibm 46xx • dual ‐ cable rs232 autodiscrimination the realscan 74 can decode a variety of bar codes. The ability to discriminate among the different bar code types i...

Page 21: Remote Compact Display

Chapter 1: product information 1-5 remote compact display 16217 ncr e = d = 0.01 1b max 30.00 lb min 0.2 lb n max 3000 iii the realscan 74 scanner/scale units are available with no weight display or with a remote post mounted display. When no display is used, scale information is sent to the host te...

Page 22

1-6 chapter 1: product information special programming is required for each peripheral device using a peripheral port. The connector is wired as follows. Auxiliary rs232 peripheral port pin number signal name 1 +5 vdc 2 nc 3 gnd 4 txd 5 rxd 6 +12 vdc 7 cts 8 rts the realscan 74 auxiliary rs232 perip...

Page 23: Usb

Chapter 1: product information 1-7 the two auxiliary rs232 ports are both located at the back of the unit. Port 1 (located on the right side when facing the rear of the unit) is the most convenient port for connecting a hand–held scanner. Each peripheral device using a peripheral port requires speci...

Page 24: Operator Interface

1-8 chapter 1: product information refer to the “firmware flashing” section in chapter 5 for more information on firmware flashing. Operator interface there is very little interface required between the operator and the realscan 74. Messages are sent from the realscan 74 to the operator through stat...

Page 25: Power Supply

Chapter 1: product information 1-9 power supply 23756 a green light at the corner of the power supply indicates that the power supply is on. The optional power supply provides the necessary 12v dc voltage required by the realscan 74 if power is not supplied from the pos terminal. The power cord plug...

Page 26

1-10 chapter 1: product information pacesetter plus pacesetter plus determines what is wrong with a bar code label, fixes the data, and then transfers the information to the host terminal. It provides information on possible bar code printer problems but is not a bar code specification conformity ve...

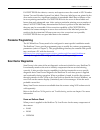

Page 27: Parameter Programming

Chapter 1: product information 1-11 pacesetter iii also detects, corrects, and reports errors discovered in upc number system two and number system four labels. These two label types are printed in the store and account for a significant number of unreadable labels due to failures of the in–store pr...

Page 28: Soft Power Down/power Up

1-12 chapter 1: product information • spinner motor • scale board • laser diodes • fpga • scale hardware if scan doctor finds a problem hindering proper operation of the realscan 74, it disables the unit; otherwise the problem is identified and operation continues. Ongoing wellness check scan doctor...

Page 29: Site Preparation

Chapter 2: site preparation customer responsibilities the ncr customer is responsible in preparing the site for installation of the ncr realscan 74. The following information is provided to help with this task. The customer must do or provide the following. • when required by ncr, provide the ncr cu...

Page 30: Preparing The Site

2-2 chapter 2: site preparation preparing the site this document contains information necessary for the preparation of a site conforming to ncr specifications. It is important that the site complies with the requirements specified in this document because, once the equipment has been installed, defi...

Page 31: Weight

Chapter 2: site preparation 2-3 weight the weight of the realscan 74 depends on the model. The following are the installed weights of basic models. Note: weight of the power supply and power cord are not included. With top plate without top plate model kilograms pounds kilograms pounds realscan 7874...

Page 32: Checkstand Cutout

2-4 chapter 2: site preparation checkstand cutout when cutting the checkstand hole, be careful to maintain the specified dimensions. The checkstand must be designed to drain large spills of liquids away from the base of the scanner. Ncr recommends that an adjustable plate be placed between the leadi...

Page 33

Chapter 2: site preparation 2-5 realscan 7874-3000/4xxx/5xxx (15.7 inch) realscan 7874-3000 when third-party scale attached note: see scale vendor for final dimensions where avery or bizerba scale is used. 40.1 cm 15.8 in 13.0 cm 5.1 in 10.2 cm 4.0 in 29.5 cm 11.6 in 25884 3.2 cm 1.3 in 3.2 cm 1.3 i...

Page 34

2-6 chapter 2: site preparation realscan 7874-4xxx/5xxx with f030 / k002 (40.6 cm / 16 inch) 40.9 cm 16.1 in 10.2 cm 4.0 in 29.5 cm 11.6 in 25883 3.2 cm 1.3 in 3.2 cm 1.3 in 3.2 cm 1.3 in 29.5 cm 11.6 in 40.9 cm 16.1 in note: always treat the scanner's profile under the checkstand as a rectangular p...

Page 35

Chapter 2: site preparation 2-7 realscan 7874-4xxx/5xxx with 7874-k200 (50.8 cm / 20 inch) with side rails 13.0 cm 5.1 in 10.2 cm 4.0 in 31.0 cm 12.2 in 25886 note: always treat the scanner's profile under the checkstand as a rectangular prism (a flat-sided box) when measuring the checkstand for a f...

Page 36

2-8 chapter 2: site preparation no side rails 13.0 cm 5.1 in 10.2 cm 4.0 in 29.52 cm 11.6 in 25885 note: always treat the scanner's profile under the checkstand as a rectangular prism (a flat-sided box) when measuring the checkstand for a fit. Do not take advantage of voids or angles in the design o...

Page 37: Realscan Checkstand Wiring

Chapter 2: site preparation 2-9 realscan checkstand wiring feeder wiring and insulated ground from main service panel to distribution panel to be run in metal conduit. The electrical wiring must meet all electrical codes, laws, and regulations. Note: circuit breakers ncr circuits should be run in se...

Page 38: Power Considerations

2-10 chapter 2: site preparation power considerations the realscan 74 receives power from an external dc power supply or from +12v dc supplied by the pos terminal . The power supply mounts in a remote location close to the realscan 74. The ncr supplied power supply is a 40 ‐ watt switching power sup...

Page 39: Service Clearance

Chapter 2: site preparation 2-11 service clearance although many of the realscan 74 components are accessed without removing the unit from the checkstand, service clearance must be provided. Clearance is also required for cleaning the unit. Refer to the following illustration for the required cleara...

Page 40: Environmental Considerations

2-12 chapter 2: site preparation environmental considerations the realscan 74 operates in most standard working environments. Temperature ranges permitted are greater when the realscan 74 is in storage or transit. The realscan 74 can operate up to one hour at extreme temperatures without suffering d...

Page 41

Chapter 2: site preparation 2-13 realscan 25 compact display dimensions the following are dimensions of the realscan 25 compact display. The holes are spaced to align with those of the older realscan 25 remote post display and with some competitor models. 24173 e f g h c i j k a b d a 115.31 mm b c ...

Page 43: Installation

Chapter 3: installation installing the realscan 74 consists of eight main steps. Sometimes additional information is required depending on the installation. Information about enabling special functions is provided in programming chapter. 3.

Page 44: Installation Steps

3-2 chapter 3: installation installation steps the following are the eight installation steps for installing the realscan 74. 1. Verify installation preparation (scanner and checkstand) 2. Cable installation preparation 3. Install sensormatic® or checkpoint antenna (optional) 4. Connect cables 5. Pu...

Page 45

Chapter 3: installation 3-3 step 2: cable installation preparation note: before attempting to install the realscan 74, the site must be prepared in accordance with the requirements described in site preparation chapter. Note: the realscan 74 ships complete from the factory and requires no operator a...

Page 46

3-4 chapter 3: installation step 3: sensormatic® coil installation to install the sensormatic® coil, perform the following procedure. 1. Position the realscan 74 facing the operator. 2. Remove the top plate. A) hold the front edge of the top plate between your fingers. B) lift the top plate to remov...

Page 47

Chapter 3: installation 3-5 b) lift the bezel up and set aside. 25572 5. Install the sensormatic® coil. A) connect the horizontal coil cable and the vertical coil cable as shown. 25692 b) route the coil cable at the bottom of the tower as shown and press the strain relief into the notch. 25691.

Page 48

3-6 chapter 3: installation c) lay the horizontal coil down and around the horizontal window. 25690 d) install the three screws to hold the horizontal coil in place. 25659 e) route the horizontal coil cable on the tower as shown. 25693.

Page 49

Chapter 3: installation 3-7 f) attach the vertical coil around the vertical window and route the vertical coil cable on the tower as shown. 25657 6. Replace the bezel. A) align the top edge of the tower cabinet with the top edge of the front bezel. 25571 b) ensure to route the horizontal coil wires ...

Page 50

3-8 chapter 3: installation c) press the bottom–left and bottom–right corners of the front bezel towards the tower cabinet to latch it in place. 25512 7. Replace the top plate. A) holding the front edge of the top plate, lay the back edge on the two rear support posts on the realscan 74. B) lay the ...

Page 51: Step 4: Cable Connection

Chapter 3: installation 3-9 step 4: cable connection 25505 realscan 74 interface cable host terminal ac power cord dc power cable power supply rs-232 peripheral note: ensure that the power is off before connecting or disconnecting cables. If the scanner is powered by a pos terminal, turn off the pos...

Page 52

3-10 chapter 3: installation c) route the checkpoint cable as shown below. 25695 tape may be used to hold the loop in place d) route the cable out the left side of the unit. 25696 2. If used, connect the optional dc power cable from the power supply to the dc power connector. 3. Connect the interfac...

Page 53

Chapter 3: installation 3-11 8. If used, connect the sensormatic® ac power cord. 9. If used, connect the checkpoint® interlock cable. 10. Turn on the scanner by turning on the pos terminal or by turning on the ac power of the scanner. Note: some peripherals are limited to which port they can use. St...

Page 54: Step 7: Scale Calibration

3-12 chapter 3: installation step 6: top plate alignment verification verify the final alignment of the top plate with the top of the checkstand. The side edges of the top plate must not be higher than the top surface of the checkstand. • for installation of a realscan 74 scanner only, skip to “step...

Page 55

Chapter 3: installation 3-13 the realscan 74 maintains an audit trail of scale calibration and weighs parameter setting. The audit trail consists of two even counters. Display the audit trail count by pressing and holding the scale zero button on the operator display panel. The display alternates be...

Page 56

3-14 chapter 3: installation calibrating and exercising the realscan 74 1. Determine the type of weight set to use for calibration. There a two weight sets, kilograms and pounds. • for the kilogram weight set, you must have a calibrated kg weight set, 12.5 kg total. Weight combinations 2.5kg, 7.5kg,...

Page 57

Chapter 3: installation 3-15 ii. Unscrew the green sealing screw and pull up on the cover to access the blue calibration switch button. 25917 25915 iii. Press the small blue calibration switch button ( this button is very small and very recessed). When you press the button, the scanner speak s “ pre...

Page 58

3-16 chapter 3: installation note: you must replace the calibration switch cover and top plate, and complete the scale exercise procedure within 90 seconds. If not, the scanner will report a ‘calibration error code 8’ and you will see 1 blue and 1 green led on the light bar. 25688 blue green off off...

Page 59

Chapter 3: installation 3-17 ii. As you press on the scale deck, an increasing number of leds will turn on indicating the amount of pressure you are applying. 25689 orange off off off off orange off orange off orange orange increasing pressure off off orange orange off orange orange orange orange ii...

Page 60

3-18 chapter 3: installation iv. At the highest pitch, with all 5 leds on, you must continue pressing down with continuous consistent pressure until the 5 leds turn solid red and the scanner beeps four times. 25795 red red red red red v. Finally, the scanner will say “complete” and all the 5 leds wi...

Page 61

Chapter 3: installation 3-19 4. Once the exercising is complete (press ‐ down done twice), the scanner will require a delay before continuing with calibration. It will say “please wait 20 seconds…15 seconds…10 seconds…five seconds…complete”. There is a countdown shown on the 7825 remote display if o...

Page 62

3-20 chapter 3: installation d. Scanner speaks “place 30 pounds on deck then press scale zero”. Add 15 more pounds to make 30 lb on the scale then press scale zero. Wait. E. Scanner speaks “place zero pounds on deck then press scale zero”. Take all the weights off the scale then press scale zero. Wa...

Page 63

Chapter 3: installation 3-21 after calibrating the scale, the accuracy must be verified to assure it meets the government requirements. This consists of a series of four tests that must be run in the continuous sequence given. 1. Increasing load test 2. Over ‐ capacity test 3. Decreasing load test 4...

Page 64

3-22 chapter 3: installation place additional weight on the center of the top plate as shown in the following table. Use the weight that corresponds to the realscan 74 weight feature. The display shows a series of dashes to indicate an over ‐ capacity condition. 24180 step weight feature add weight ...

Page 65

Chapter 3: installation 3-23 shift test this test involves moving a weight off the center point of the top plate to check for continued accuracy. 25344 test pattern 1. Place an appropriate test load weight for each weight feature on each of the four circles individually. The display must show the sa...

Page 66

3-24 chapter 3: installation securing the calibration switch after performing a scale calibration, attach a seal to the scale calibration security cover. Depending on the local laws, weights and measures officials may be required to attach the seal. Note: in the united states and canada, the audit t...

Page 67

Chapter 3: installation 3-25 4. Seal the calibration switch security cover with one of the following seals: • lead/wire seal (ncr part number: 603 ‐ 8001097) using a lead/wire seal press (ncr part number: 603 ‐ 9000157) • film/paper seal (obtain locally—must meet the requirements of the local govern...

Page 68

3-26 chapter 3: installation step 8: sensormatic® deactivation setup sensormatic tag deactivation connect the sensormatic® tag deactivation system to the rs232 auxiliary port, which is port 2. If a hand ‐ held scanner is used, connect the hand ‐ held to port 1. When the realscan 74 scanner reads a t...

Page 69

Chapter 3: installation 3-27 cashier sign in offline alert there is a feature to alert the cashier of the eas system state at sign in. When the sign in occurs and the scanner is enabled if the eas system is offline the “eas offline message will be spoken”. There is a programmable time limit on how l...

Page 70

3-28 chapter 3: installation scan the following sequence of programming tags to change the tone frequency of the realscan 74. 1. Program mode —puts scanner in programming mode. 2. Hex 5, hex 8, hex b —increments to the next frequencies. Continue scanning hex b to get the desired frequency. There are...

Page 71

Chapter 3: installation 3-29 scanning this tag is a toggle function. The number of beeps indicates how the function is set. • 1 beep—manual deactivation function is disabled • 2 beeps—manual deactivation function is enabled—factory default • 3 beeps—function is enabled plus 048589999977 bar code sen...

Page 72

3-30 chapter 3: installation • 2 beeps—bar code label hold ‐ off function is enabled—factory default after enabling or disabling the bar code label hold ‐ off function, scan the following reset tag to make the setting permanent in the realscan 74. Audible detection the audible detection function pro...

Page 73

Chapter 3: installation 3-31 scan the following eas communications function tag to set the eas communication function. The function changes each time this tag is scanned. The number of beeps indicates how the function is set. • 1 beep—eas communications function is disabled—factory default • 2 beeps...

Page 74

3-32 chapter 3: installation after setting the eas optional communication function and the error bar code timer, scan the following reset tag to make the setting permanent in the realscan 74. Reset bar code error, detect, and manual deactivation bar codes the following are the error, detect, and man...

Page 75

Chapter 3: installation 3-33 • realscan 74 deactivation button = enabled • realscan 74 detection clicking = enabled 2. Turn on the sensormatic® amb9010 controller. This system is programmed at the factory with default settings for proper operation. 3. After the realscan 74 and the sensormatic® amb90...

Page 76

3-34 chapter 3: installation next, obtain a security tag that has not been deactivated. Scan a bar code and immediately pass the security tag through the deactivation zone. The good read tone should sound indicating a good read of the bar code and deactivation of the security tag. Refer to the “sens...

Page 77: Flash Latest Firmware

Chapter 3: installation 3-35 realscan 74 power-on wellness check if an error occurs during the power ‐ on wellness check, the realscan 25 remote display (if the unit has one) displays an error code, and if enabled, the realscan 74 emits an audible description of the error and what action to take. Th...

Page 78: Sni Beetle Host Terminal

3-36 chapter 3: installation special host terminal connections scanner connected to ibm terminals the scanner and scanner interface to any ibm system is basically plug ‐ and ‐ play, assuming the realscan unit is programmed for ibm communications (refer to the “programming worksheets” section on chap...

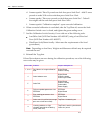

Page 79: Peripheral Connections

Chapter 3: installation 3-37 25592 label identifiers ean13 ean8 upc-e upc-a code 39 i 2 of 5 code 128 ucc/ean128 = "a" (41h) = "b" (42h) = "c" (43h) = "a0" (41h 30h) (upc-a is expanded into ean13 = "m" (4dh) = "i" (49h) = "k" (4bh) = "p" (50h) (ucc/ean128 label id is enabled codabar pharmacode = "n"...

Page 80

3-38 chapter 3: installation programming the metrologic hand-held scanner if connected through the auxiliary rs232 port scan the following sequence of tags with the metrologic hand ‐ held scanner. If the scanner encounters problems reading these tags, use the tags printed in the metrologic installat...

Page 81

Chapter 3: installation 3-39 ³ 1 1 6 6 1 7 upc prefix id ³ 2 1 6 6 3 2 cr-lf on ³ 8 0 7 5 1 3 0 0 upc format.

Page 82

3-40 chapter 3: installation ³ 8 0 6 7 0 9 8 0 itf "b" ³ 8 0 6 0 0 9 7 0 code 39 "a" ³ 8 0 6 1 1 0 2 0 code 128 "f" ³ 9 9 9 9 9 9 exit config mode.

Page 83

Chapter 3: installation 3-41 programming the realscan 74 when installing a metrologic hand ‐ held scanner, certain programming options must be set in the realscan 74. Program these options as follows. There are four options that must be programmed on the realscan 74. Scan the following tags to set t...

Page 84: Scanner

3-42 chapter 3: installation ncr realscan 2357 and hand-held products (honeywell) type hand-held scanner these instructions apply to all hand ‐ held products scanners and 7837 models (except the 7837 ‐ 1000 specifically), including the 3800g and 4600 series imagers. When connecting a realscan 2357 h...

Page 85

Chapter 3: installation 3-43 programming the realscan 74 there are four options that must be programmed on the realscan 74. Scan the following programming tags to set these options. These must be the first tags scanned after applying power to the realscan 74. Hand-held processing selection programmi...

Page 86

3-44 chapter 3: installation programming realscan 2357 hand-held scanner if connected through the usb peripheral port prerequisites: firmware levels: • 7874, 497 ‐ 0461146 ‐ usb hh (pdf417 support not available) programming: use the following programming sequence if you want to make the scanner beep...

Page 87

Chapter 3: installation 3-45 ncr realscan 2356 and symbol (motorola) type hand-held scanner a realscan 2356 hand ‐ held scanner can be connected to one of the auxiliary rs232 ports on the ncr realscan 74. If the realscan 2356 ‐ 4208 is the only peripheral device, it can be connected to either port. ...

Page 88

3-46 chapter 3: installation rts/cts option 2 host: low rts auto-discriminate supplementals programming the realscan 74 there are four options that must be programmed on the realscan 74. Scan the following programming tags to set these options. These must be the first tags scanned after applying pow...

Page 89

Chapter 3: installation 3-47 programming realscan 2356 hand-held scanner if connected through the usb peripheral port prerequisites: firmware levels: • 7874, 497 ‐ 0461146 ‐ usb hh (pdf417 support not available) programming: use the following programming sequence if you want to make the scanner beep...

Page 90

3-48 chapter 3: installation if it is desired to scan pdf 417 (2d) bar codes with the hand ‐ held, you can enable the realscan 74 to allow the pass ‐ through of the data without the realscan 74 itself having the capability to read that type of bar code. The following programming sequence is only for...

Page 91

Chapter 3: installation 3-49 ncr realscan 2356-4278 wireless hand-held scanner a realscan 2356 wireless hand ‐ held scanner can be connected to one of the auxiliary rs232 ports on the ncr realscan 74. If the realscan 2356 wireless hand ‐ held scanner is the only peripheral device, it can be connecte...

Page 92

3-50 chapter 3: installation even parity rts/cts option 2 host: low rts after scanning the last tag, remove power from the realscan 2356 wireless hand ‐ held scanner by unplugging the cable, then plugging it back in. Programming the realscan 74 there are four options that must be programmed on the r...

Page 93: Operation

Chapter 4: operation the ncr realscan 74 requires very little attention during operation. It is designed to reduce the amount of bar code orientation prior to scanning an item. Most people become proficient in a very short time because of the bi ‐ optic design and the pacesetter functionality. 4.

Page 94: System Components

4-2 chapter 4: operation system components 25893 a - manual deactivation b - volume adjust button c - scale zero button d - motion detector e - speaker f- remote compact display g - vertical scan window h - top plate i - horizontal scan window j - scan adviser status indicator g h f a b c d i e j op...

Page 95

Chapter 4: operation 4-3 the motion detector is located at the upper ‐ right of the operator display panel. The laser diodes and spinner motor turn off after a user selectable period of operator inactivity. This prolongs the life of the realscan 74. The default non ‐ active time is fifteen (15) minu...

Page 96

4-4 chapter 4: operation other interfaces can also disable the scanner under software control, resulting in all five leds on the scan adviser indicator turning dim red. When the scanner is disabled, no bar codes can be read. Scale zero button the scale zero button is the top most button on the opera...

Page 97

Chapter 4: operation 4-5 • controlling speaker volume –volume is controlled by pressing and then releasing the button. The speaker emits a sound for each press/release of the button. • controlling speaker frequency –frequency is controlled by continuous pressing of the button. The speaker emits a so...

Page 98: Remote Compact Display

4-6 chapter 4: operation remote compact display normally, the scale automatically re–zeros itself when there is no weight on the top plate. If the realscan 25 remote compact display (if fitted) is blank or indicates a weight other than zero, yet no weight is currently on the scale, pressing the scal...

Page 99

Chapter 4: operation 4-7 scan adviser led scanner state indicators scanner state led color brightness activity number of leds idle (enabled) green dim solid 3 center enabled and in sleep mode green dim solid 1 center led good scan green bright solid 5 leds disabled and awake red bright solid 5 leds ...

Page 100: Speaker

4-8 chapter 4: operation speaker a tone can be programmed to sound when the realscan 74 accurately reads a bar code. The tone provides a means of determining a good read without having to observe the status indicator. The good read tone can be enabled or disabled through programming. If the tone is ...

Page 101: Top Plate

Chapter 4: operation 4-9 top plate the ruggedized plastic and steel top plate contains the horizontal scan window. Items being scanned are passed from the checkstand, across the top plate, and back onto the checkstand. The checkstand construction permits the items to be slid along the surface withou...

Page 102: Label Orientation

4-10 chapter 4: operation label orientation because the realscan 74 produces an omni ‐ directional scan pattern, bar code labels can be read from many different angles. The realscan 74 reads the labels on the leading side of a package, the trailing side, the bottom side, the top side, the side oppos...

Page 103: Operating Instructions

Chapter 4: operation 4-11 operating instructions the realscan 74 is extremely easy to operate. However, there are certain functions and procedures that the operator needs to understand in order to be proficient at operating the realscan 74. Turning the realscan 74 on and off the realscan 74 does not...

Page 104: Scanning Procedure

4-12 chapter 4: operation scanning procedure 25507 to scan items with the ncr realscan 74, use the following procedure. 1. Verify the scanner is ready (scan adviser’s 3 center leds are green). 2. Pass the item across the realscan 74 lower window. Slide the item from the checkstand, across the top pl...

Page 105

Chapter 4: operation 4-13 note: if 0.000 kg (0.00 lb) is not displayed, reset the scale by pressing the scale zero button. If this does not work, turn the scanner circuit breaker off and then on . 2. Pick up the item and place it in the center of the top plate. Note: make sure the item does not over...

Page 106: Adjusting The Good Read Tone

4-14 chapter 4: operation note: as the security tag goes through the sensormatic® deactivation zone, the sensormatic® system deactivates the security tag and the deactivation tone is produced by the scanner. If the security tag is not deactivated, a clicking tone is generated. Both options can be ch...

Page 107: Not-On-File Error

Chapter 4: operation 4-15 permanent changes to tone length, tone volume, and tone frequency require changes through programming. To adjust the tone length, volume, or frequency, refer to the following table: settings programming steps expected behavior increment good tone length repeatedly scan/ente...

Page 108: Cleaning Instructions

4-16 chapter 4: operation cleaning instructions the realscan 74 should be kept in good operating condition by performing the following routine maintenance. Keeping the scan windows clean helps keep the read rate exceptionally high. During normal operation of the realscan 74, the horizontal scan wind...

Page 109: Programming

Chapter 5: programming the realscan 74 can be programmed to meet most installation requirements. This includes communications with the host terminal and various realscan 74 features and functions. 5.

Page 110: Programming Description

5-2 chapter 5: programming programming description the realscan 74 can be remotely programmed from its attached pos with no local intervention. To achieve this, special pos software must be purchased from ncr. This section describes programming a scanner with special bar code tags. Programming the r...

Page 111: Programming Tags

Chapter 5: programming 5-3 save the program 1. Scan the save and reset tag . When the save and reset tag is scanned, the scanner saves all programming parameters entered. This becomes the new scanner program. The scanner goes through initial startup and operates using the new program. 2. Save progra...

Page 112

5-4 chapter 5: programming indication–in program mode • scan adviser status indicator is initially 3 center leds dim green and then flashes bright green (5 leds) showing the tag was read. Scanner will reboot and perform power up sequence (the scan adviser turns off momentarily, then comes on with 5 ...

Page 113

Chapter 5: programming 5-5 end function this tag ends certain input sequences. Since the parameter program determines the end of most sequences, this tag is not used often. Indication • scan adviser status indicator is initially 3 center leds dim green and then flashes bright green (5 leds) showing ...

Page 114: Speak Scanner Serial Number

5-6 chapter 5: programming save and reset function this tag instructs the realscan 74 to save and start using the programming data. It is used in the program mode. Indication • scan adviser leds flashes five leds red twice, then scanner will reboot and perform power up sequence (the scan adviser tur...

Page 115: Program Entry Procedure

Chapter 5: programming 5-7 • if the scanner says “scanner s n 0 0 0 0 0 0 0 0 0 0”, then the actual serial number is not stored in memory. • the scanner beeps when it is done speaking the serial number. Program entry procedure enter all parameters to enter all parameters in a parameter program, scan...

Page 116

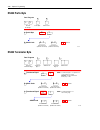

5-8 chapter 5: programming 11722 program mode code 39 bar codes - 2 full ascii minimum characters allowed check digit present transmit check digit 4 1 allow 1- or 2-character tags parameter program 1 0 disable enable 0 1 disable enable 0 1 disable enable 1 0 disable enable 2-f 0 1 disable enable.

Page 117

Chapter 5: programming 5-9 program entry procedure the following example is a typical program entry procedure. 1. Disconnect scanner from pos. 2. Apply power to the realscan 74 (or scan the reset tag). 3. Scan the program mode tag. 4. Scan the two hex tags corresponding to the worksheet number. 5. S...

Page 118

5-10 chapter 5: programming 11723 program mode 4 1 code 39 full ascii minimum characters allowed check digit present transmit check digit a b c d e 1 0 disable enable 0 1 disable enable 1 0 disable enable 2- f 0 1 disable enable f 0 1 disable enable allow 1- or 2-character tags bar codes - 2 paramet...

Page 119: Parameter Defaults

Chapter 5: programming 5-11 program entry procedure (shortcut method) the following example is a typical program entry procedure. 1. Disconnect scanner from pos. 2. Apply power to the realscan 74 (or scan the reset tag). 3. Scan the program mode tag. 4. Scan the two hex tags corresponding to the wor...

Page 120

5-12 chapter 5: programming programming mode program parameters default setting upc/ean enable unused disable extend upc–a to ean–13 disable extend upc–e to upc–a disable periodical codes disable periodical code extension no default value send data data as decoded bar codes ‐ 1 set 2 tag label off c...

Page 121

Chapter 5: programming 5-13 programming mode program parameters default setting interleaved 2 of 5 disable bar code length range specific value 1 0 8 value 2 1 6 check digit present disable transmit check digit disable interleaved 2 of 5 tone disable tone length 75 milliseconds tone frequency 1071 h...

Page 122

5-14 chapter 5: programming programming mode program parameters default setting codabar decoding disable codabar length range check 4 ‐ 36 codabar specific length check 4 ‐ 36 codabar check digit disable codabar check digit transmission enable codabar tone length 75 ms codabar tone frequency 1071 he...

Page 123

Chapter 5: programming 5-15 programming mode program parameters default setting baud rate 9600 parity odd stop bits and character length 1 stop bit and 7–bit length rs232 parameters ‐ 1 hand shake rts high, wait for cts bcc options disable—scanner ‐ only models enable— scanner/scale models interface...

Page 124

5-16 chapter 5: programming programming mode program parameters default setting model number no default value ibm address address 6e set by selecting ibm 468x on communications protocol worksheet vibration filter normal vibration filter scale parameters display mode argentina cero display mode host ...

Page 125: Programming Tips

Chapter 5: programming 5-17 programming tips the following are some tips to help when programming the realscan 74. • turn the host terminal off or disconnect all interface cables to the realscan 74 before entering the program. Some host terminals can corrupt the program if they are running and are c...

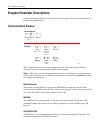

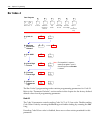

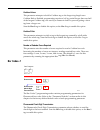

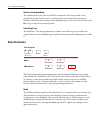

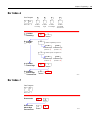

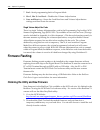

Page 126: Communications Protocol

5-18 chapter 5: programming program parameter descriptions within the program mode are several parameter programs. Each of these has specific programming parameters. Communications protocol 24036 protocol your program ibm slot scanner 3 ibm hand-held bar code reader 4 rs-232 5 ibm usb d ncr (rs-232)...

Page 127: Good Read Tone

Chapter 5: programming 5-19 note: two programming tags must be scanned to enable this parameter: hex e followed by hex 0 . Rs232 rs232 is used to connect the realscan 74 to almost any rs232 type of communications device. This protocol uses 7 ‐ bit ascii by default to send tag data to the device. Goo...

Page 128

5-20 chapter 5: programming tone on/off the hex a tag selects the tone on/off programming parameter, which offers two options, on and off. The hex 0 tag turns the good read tone off and the hex 1 tag turns the good read tone on. Tone frequency (hertz) the hex b tag sets the frequency of the good rea...

Page 129

Chapter 5: programming 5-21 not-on-file volume the hex e tag sets the volume of the not–on–file tone by listening to it as the hex e tag is repeatedly scanned. The new tone sounds for two seconds. End this mode by scanning the end tag or another valid hex tag. The not ‐ on ‐ file tone goes off when ...

Page 130: Timers

5-22 chapter 5: programming timers note: ncr suggests that you do not set the active time parameter to 0. Leaving the laser light on all the time reduces its life expectancy. Lockout time (milliseconds) a 350 8 450 0 600 1 750 2 900 3 1050 4 1200 5 1350 6 1500 7 restart lockout timer b active time (...

Page 131

Chapter 5: programming 5-23 restart lockout timer the restart lockout timer parameter controls restarting the lockout timer each time the scanner reads the same bar code. Turning on the restart lockout timer option has the following effect. If a bar code moves out of the scan pattern after being rea...

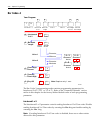

Page 132: Bar Codes–1

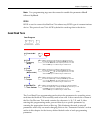

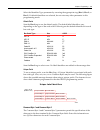

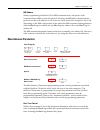

5-24 chapter 5: programming bar codes–1 upc/ean your program 0 disable 24037 a upc/ean a 1 enable c extend upc-a to ean-13 0 disable 1 enable d extend upc-e to upc-a 0 disable 1 enable e periodical codes 0 disable 1 enable periodical code extension 0 2-digit only 1 5-digit only 2 2-digit & 5-digit s...

Page 133

Chapter 5: programming 5-25 if reading upc/ean bar codes is disabled, there are no other entries allowed for this parameter. However, if reading upc/ean bar codes is enabled, the remaining parameters can be programmed. Extend upc–a to ean–13 the extend upc–a to ean–13 parameter determines whether to...

Page 134: Bar Codes–2

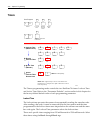

5-26 chapter 5: programming bar codes–2 code 39 a 0 disable 1 enable minimum characters allowed b 8 2 - f default full ascii c 0 disable 1 enable check digit present d 0 disable 1 enable transmit check digit e 0 disable 1 enable allow 1- or 2-character tags f 0 disable 1 enable your program 24174 co...

Page 135

Chapter 5: programming 5-27 minimum characters the minimum characters allowed parameter defines how many characters in a bar code must be read the same by two separate scans before determining a valid read has occurred. This option should be set to the number of characters in a typical tag which ens...

Page 136

5-28 chapter 5: programming tone length the tone length parameter permits you to set the length of the code 39 tone. Set this parameter by scanning the appropriate hex tag ( hex 0 to hex f ). Each hex tag is incremented by 15 milliseconds. For example, hex 0 = 0 ms, hex 1 = 15 ms, hex 2 = 30 ms, hex...

Page 137

Chapter 5: programming 5-29 code 39 stitch check digit this parameter permits tag lengths containing a code 39 check digit to be stitched if code 39 stitch enable is active. Check digit length1 and length2 these check digit lengths are programmed to permit specific length of code 39 tag to require a...

Page 138: Bar Codes–3

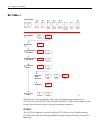

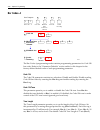

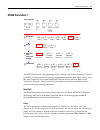

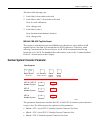

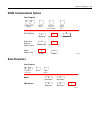

5-30 chapter 5: programming bar codes–3 25788 a b interleaved 2 of 5 bar code length c check digit present d 1 0 disable enable 0 - 3 1 0 range check specific check character minimum character maximum 1 0 disable enable 1 0 disable enable 0 - 3 0 - 9 0 - 9 transmit check digit character 1 character ...

Page 139

Chapter 5: programming 5-31 bar code length the bar code length parameter selects the method for determining if an interleaved 2 of 5 bar code is a valid length. The range check method identifies a length range by specifying the minimum and maximum number of characters. The specific check method ide...

Page 140

5-32 chapter 5: programming interleaved 2 of 5 tone this parameter permits you to enable or disable the interleaved 2 of 5 tone. Scan hex 0 to disable the tone (default) or hex 1 to enable it. If disabled, the interleaved 2 of 5 tone is under control of the upc tone control (general good read tone)....

Page 141

Chapter 5: programming 5-33 interleaved 2 of 5 check digit length2 interleaved 2 of 5 check digit length2 sets the number of data characters defining the tag length2 that requires a check digit. This tag length could be outside the normal specific length or range of tag lengths programming for inter...

Page 142: Bar Codes–4

5-34 chapter 5: programming bar codes–4 22766 code 128 a 0 disable 1 enable minimum data characters allowed b 1 2 3 4 5 ean/ucc 128 c 0 disable 1 enable your program bar codes - 4 1 7 a code 128 b minimum data characters allowed c ucc 128 partial decoding f 0 disable 1 enable f partial decoding the ...

Page 143

Chapter 5: programming 5-35 tone frequency this parameter permits you to set the frequency of the code 128 tone. Set this parameter by scanning the appropriate hex tag ( hex 0 to hex 7 ). Hex tag frequency in hertz hex 0 702 hz hex 1 781 hz hex 2 868 hz hex 3 961 hz hex 4 1071 hz hex 5 1187 hz hex 6...

Page 144: Bar Codes–5

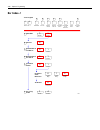

5-36 chapter 5: programming bar codes–5 24952 gs1 databar enable scans required on gs1 databar 14 b a disable 0 enable gs1 databar 14 only 1 1 scan 1 2 scans 2 3 scans 3 4 scans 4 1 8 your program bar codes - 5 gs1 databar enable a enable gs1 databar e only 2 enable gs1 databar 14 & gs1 databar e 3 ...

Page 145: Bar Codes–6

Chapter 5: programming 5-37 scans required on gs1 databar–e this parameter sets the number of scans required to read a gs1 databar–e bar code. Increasing the number of scans can improve reading nominal bar codes. There are four settings: 1 scan, 2 scans, 3 scans, and 4 scans. Set this parameter by s...

Page 146

5-38 chapter 5: programming codabar check digit the codabar check digit parameter permits control of codabar check digit requirement. Scan the appropriate hex tag (hex 1 to hex 0) to enable or disable the check digit. The default is hex 0—disable codabar check digit. Codabar check digit transmission...

Page 147: Bar Codes–7

Chapter 5: programming 5-39 codabar halves this parameter attempts to build a codabar tag on the longest tag length seen. Codabar halves enabled programming requires a half tag partial longer than one ‐ half of the longest codabar tag ever seen by a scanner in order to prevent getting a short tag fr...

Page 148: Label Identifiers

5-40 chapter 5: programming label identifiers identifier type default prefix 25514 a common byte 1 b common byte 2 c bar code type d common byte unique identifier 0 - 7 5 default hex character (ascii code chart) 0 - f hex character (ascii code chart) 0 - 7 default hex character (ascii code chart) 0 ...

Page 149

Chapter 5: programming 5-41 select the identifier type parameter by scanning the appropriate tag ( hex 0 , hex 2 , or hex 3 ). If default identifiers are selected, do not enter any other parameter in this programming mode. Default prefix scan the hex 0 tag to use the default prefix. The default labe...

Page 150

5-42 chapter 5: programming note: refer to the ascii code chart for the hex characters; however, values of 20 to 7e are recommended. Do not use the same characters as the terminator byte or the message may terminate too soon. Also, a common byte cannot be 00. If not using a common byte, scan any hex...

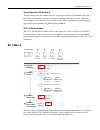

Page 151: Rs232 Parameters 1

Chapter 5: programming 5-43 rs232 parameters 1 22772 baud rate a 0 300 1 600 2 1200 3 2400 4 4800 5 9600 6 19200 parity b stop bits and character length c handshake d 0 odd 1 even 4 none 0 1 stop bit 7-bit character 1 1 stop bit 8-bit character 2 2 stop bits 7-bit character 3 2 stop bits 8-bit chara...

Page 152

5-44 chapter 5: programming stop bits and character length the stop bits and character length parameter contains four selections: 1 stop bit and 7 ‐ bit character length, 1 stop bit and 8 ‐ bit character length, 2 stop bits and 7 ‐ bit character length, and 2 stop bits and 8 ‐ bit character length. ...

Page 153: Rs232 Parameters 2

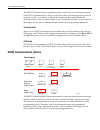

Chapter 5: programming 5-45 rs232 parameters 2 24041 bcc options a interface control b check digit c 0 disable 1 enable 0 none 1 ack/nak 2 xon/xoff 3 ack/nak & xon/xoff 0 disable upc-a disable ean-8 disable ean-13 disable upc-e 1 enable upc-a enable ean-8 enable ean-13 disable upc-e 2 disable upc-a ...

Page 154: Rs232 Prefix Byte

5-46 chapter 5: programming interface control the interface control parameter permits control of the transfer of data between the scanner and the host terminal. The options are none, enable ack/nak, enable xon/xoff, and enable both ack/nak and xon/xoff. If enable ack/nak is selected, each message se...

Page 155: Rs232 Terminator Byte

Chapter 5: programming 5-47 the rs232 prefix byte programming mode controls the use of prefix bytes. If an rs232 prefix byte is used, it is the leading character in each message sent to the host terminal. Following it is the message data. Refer to the “parameter defaults” section earlier in this cha...

Page 156: Rs232 Communications Options

5-48 chapter 5: programming the rs232 terminator byte programming mode controls the use of terminator bytes. If an rs232 terminator byte is used, it goes at the end of the message sent to the host terminal. If a bcc is included, it follows the terminator byte and includes the terminator byte in the ...

Page 157

Chapter 5: programming 5-49 message delay the message delay option sets the minimum time the firmware waits before sending the next message. This permits lowering cts by the host terminal to inhibit data from the scanner. This option was not available on previous scanners. Messages can be delayed as...

Page 158: Scale Parameters

5-50 chapter 5: programming normal or eavesdrop mode the normal mode is used for most rs232 connections. Eavesdrop mode is also available to permit another device to monitor the communications between the realscan 74 and the host terminal. Scan the hex 6 tag to select the normal mode or the hex 7 ta...

Page 159: Miscellaneous Parameters

Chapter 5: programming 5-51 ibm address when programming a realscan 74 for ibm communications, the proper scale communications address must be selected. Selecting the ibm 468x communications protocol sets the scale address to 6e; however, it may need to be changed to 6a or 6b, depending on the ibm c...

Page 160

5-52 chapter 5: programming ibm retransmit control when an ibm terminal is used and the scale detects a bad message from the terminal, this parameter controls how the original message gets retransmitted. If enable is selected by scanning the hex 7 tag, the scale retransmits the original message thre...

Page 161

Chapter 5: programming 5-53 the three clerk messages are: 1. Scale failed, clean under scale deck 2. Scale failed, code 5, clean under scale deck next, do scale calibration next, change scale 3. Scale failed, code 4 stop checkstand mechanical vibration next, change scale ibm–485 / ibm–usb tag data f...

Page 162: Dual Cable Interface

5-54 chapter 5: programming • hex 5 —upc–e number system character sent • hex 6 —upc–a number system character not sent • hex 7 —upc–a number system character sent dual cable interface the dual cable interface programming mode identifies the scale type to the host terminal. The scale type normally d...

Page 163: Programming Worksheets

Chapter 5: programming 5-55 programming worksheets the programming worksheets provide a convenient method of defining the realscan 74 program before loading it into the unit. Each worksheet relates to a parameter program. The programming worksheets permit the exact sequence of tags to scan for each ...

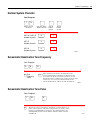

Page 164: Good Read Tone

5-56 chapter 5: programming good read tone tone on/off a off 0 on tone frequency (hertz) tone volume tone length (milliseconds) not-on-file tone volume when entering tone frequency, the adjustment can be incremented upward by scanning the hex b tag. Each time you scan the hex b , the tone frequency ...

Page 165: Timers

Chapter 5: programming 5-57 timers note: ncr suggests that you do not set the active time parameter to 0. Leaving the laser light on all the time reduces its life expectancy. Lockout time (milliseconds) a 350 8 450 0 600 1 750 2 900 3 1050 4 1200 5 1350 6 1500 7 restart lockout timer b active time (...

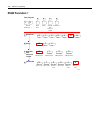

Page 166: Bar Codes–1

5-58 chapter 5: programming bar codes–1 upc/ean your program 0 disable 24037 a upc/ean a 1 enable c extend upc-a to ean-13 0 disable 1 enable d extend upc-e to upc-a 0 disable 1 enable e periodical codes 0 disable 1 enable periodical code extension 0 2-digit only 1 5-digit only 2 2-digit & 5-digit s...

Page 167: Bar Codes–2

Chapter 5: programming 5-59 bar codes–2 code 39 a 0 disable 1 enable minimum characters allowed b 8 2 - f default full ascii c 0 disable 1 enable check digit present d 0 disable 1 enable transmit check digit e 0 disable 1 enable allow 1- or 2-character tags f 0 disable 1 enable your program 24174 co...

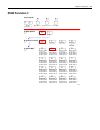

Page 168: Bar Codes–3

5-60 chapter 5: programming bar codes–3 25788 a b interleaved 2 of 5 bar code length c check digit present d 1 0 disable enable 0 - 3 1 0 range check specific check character minimum character maximum 1 0 disable enable 1 0 disable enable 0 - 3 0 - 9 0 - 9 transmit check digit character 1 character ...

Page 169: Bar Codes–4

Chapter 5: programming 5-61 bar codes–4 22766 code 128 a 0 disable 1 enable minimum data characters allowed b 1 2 3 4 5 ean/ucc 128 c 0 disable 1 enable your program bar codes - 4 1 7 a code 128 b minimum data characters allowed c ucc 128 partial decoding f 0 disable 1 enable f partial decoding.

Page 170: Bar Codes–5

5-62 chapter 5: programming bar codes–5 24952 gs1 databar enable scans required on gs1 databar 14 b a disable 0 enable gs1 databar 14 only 1 1 scan 1 2 scans 2 3 scans 3 4 scans 4 1 8 your program bar codes - 5 gs1 databar enable a enable gs1 databar e only 2 enable gs1 databar 14 & gs1 databar e 3 ...

Page 171: Bar Codes–6

Chapter 5: programming 5-63 bar codes–6 25515 codabar decoding a 0 disable 1 enable codabar length b 0 1-36 1-36 codabar check digit c 0 disable 1 enable your program bar codes - 6 1 a a codabar decoding b codabar legth c codabar check digit codabar check digit transmission d 0 disable 1 enable d co...

Page 172: Label Identifiers

5-64 chapter 5: programming label identifiers identifier type default prefix 25514 a common byte 1 b common byte 2 c bar code type d common byte unique identifier 0 - 7 5 default hex character (ascii code chart) 0 - f hex character (ascii code chart) 0 - 7 default hex character (ascii code chart) 0 ...

Page 173: Number System Character

Chapter 5: programming 5-65 number system character 24040 not sent 0 sent upc-a & upc-e number system 1 your program not sent 4 sent upc-e number system 5 1 9 number system character upc-a & upc-e number system not sent 6 sent upc-a number system 7 upc-e number system upc-a number system sensormatic...

Page 174: Rs232 Parameters 1

5-66 chapter 5: programming rs232 parameters 1 22772 baud rate a 0 300 1 600 2 1200 3 2400 4 4800 5 9600 6 19200 parity b stop bits and character length c handshake d 0 odd 1 even 4 none 0 1 stop bit 7-bit character 1 1 stop bit 8-bit character 2 2 stop bits 7-bit character 3 2 stop bits 8-bit chara...

Page 175: Rs232 Parameters 2

Chapter 5: programming 5-67 rs232 parameters 2 24041 bcc options a interface control b check digit c 0 disable 1 enable 0 none 1 ack/nak 2 xon/xoff 3 ack/nak & xon/xoff 0 disable upc-a disable ean-8 disable ean-13 disable upc-e 1 enable upc-a enable ean-8 enable ean-13 disable upc-e 2 disable upc-a ...

Page 176: Rs232 Prefix Byte

5-68 chapter 5: programming rs232 prefix byte 22774 prefix byte a ascii code b 0 disable 1 enable 0 - 7 hex character (ascii code chart) 0 - f hex character (ascii code chart) 0 default 2 your program prefix byte a rs-232 prefix byte 2 2 ascii code b rs232 terminator byte 25786 terminator byte 1 a a...

Page 177: Rs232 Communications Options

Chapter 5: programming 5-69 rs232 communications options 22779 no delay 0 1 0 1 0 1 0 1 0 1 2 10 milliseconds 50 milliseconds rs-232 delay scanner only 4 scanner / scale scanner or scanner / scale format disable 8 1 9 enable good weigh tone 5 1 2 4 communication options rs-232 delay scanner or scann...

Page 178: Miscellaneous Options

5-70 chapter 5: programming miscellaneous options miscellaneous parameters host tone control your program miscellaneous parameters disable 3 enable 4 3 2 host tone control speech toggle between enable and disable speech d ibm retransmit control ibm retransmit control 3 times 7 forever 8 22813 ibm-48...

Page 179

Chapter 5: programming 5-71 code 128 tone frequency 24468 selection programming tag sequence programming mode, hex 7, hex 4, hex 1, hex 1, save and reset 702 hz programming mode, hex 7, hex 4, hex 1, hex 0, save and reset 781 hz programming mode, hex 7, hex 4, hex 1, hex 3, save and reset 868 hz pro...

Page 180

5-72 chapter 5: programming code 39 tone length 24385 selection programming tag sequence programming mode, hex 7, hex 0, hex 3, hex 2, save and reset 30 ms 45 ms programming mode, hex 7, hex 0, hex 3, hex 3, save and reset 60 ms programming mode, hex 7, hex 0, hex 3, hex 4, save and reset 75 ms prog...

Page 181

Chapter 5: programming 5-73 code 39 quiet zone 24389 selection programming tag sequence disable programming mode, hex 7, hex 0, hex 5, hex 2, save and reset enable programming mode, hex 7, hex 0, hex 5, hex 3, save and reset code 39 intercharacter gap check 24390 selection programming tag sequence e...

Page 182

5-74 chapter 5: programming code 39 cd length2 24455 code 39 minimum and maximum length 25787 interleaved 2 of 5 tone length 24456 selection programming tag sequence programming mode, hex 7, hex 0, hex 6, hex 2, save and reset 30 ms 45 ms programming mode, hex 7, hex 0, hex 6, hex 3, save and reset ...

Page 183

Chapter 5: programming 5-75 interleaved 2 of 5 tone frequency 25901 selection programming tag sequence 702 hz 781 hz 868 hz 961 hz 1071 hz 1187 hz 570 hz 633 hz setting default programming mode, hex 7, hex 0, hex 7, hex 2, save and reset programming mode, hex 7, hex 0, hex 7, hex 3, save and reset p...

Page 184

5-76 chapter 5: programming interleaved 2 of 5 cd length2 24461 interleaved 2 of 5 scans required 25645 selection programming tag sequence programming mode, hex 6, hex b, hex 5, hex 3, save and reset 3 scans 4 scans programming mode, hex 6, hex b, hex 5, hex 4, save and reset 1 scan programming mode...

Page 185

Chapter 5: programming 5-77 interleaved 2 of 5 minimum segment size selection programming tag sequence programming mode, hex 6, hex b, hex e, hex 4, save and reset programming mode, hex 6, hex b, hex e, hex 5, save and reset 2 segment size programming mode, hex 6, hex b, hex e, hex 2, save and reset...

Page 186

5-78 chapter 5: programming gs1 databar tone frequency 25902 selection programming tag sequence programming mode, hex 7, hex 4, hex 1, hex 1, save and reset 702 hz programming mode, hex 7, hex 4, hex 1, hex 0, save and reset 781 hz programming mode, hex 7, hex 4, hex 1, hex 3, save and reset 868 hz ...

Page 187

Chapter 5: programming 5-79 gs1 databar–e ai 95 to interleaved 2 of 5 tag data conversion 24958 selection programming tag sequence programming mode, hex 7, hex 0, hex 9, hex b, save and reset disable programming mode, hex 7, hex 0, hex 9, hex a, save and reset enable setting default codabar tone len...

Page 188

5-80 chapter 5: programming codabar tone 25324 selection programming tag sequence programming mode, hex 7, hex 4, hex 5, hex 1, save and reset disable programming mode, hex 7, hex 4, hex 5, hex 0, save and reset enable setting default codabar halves 25325 selection programming tag sequence programmi...

Page 189

Chapter 5: programming 5-81 codabar start/stop transmission 25322 25327 selection programming tag sequence programming mode, hex 6, hex b, hex 1, hex 2, save and reset tn*e tn*e programming mode, hex 6, hex b, hex 1, hex 3, save and reset abcd programming mode, hex 6, hex b, hex 1, hex 0, save and r...

Page 190

5-82 chapter 5: programming number of coupon scans required 24462 selection programming tag sequence programming mode, hex 6, hex b, hex 0, hex 2, save and reset 2 scans 3 scans programming mode, hex 6, hex b, hex 0, hex 3, save and reset 4 scans programming mode, hex 6, hex b, hex 0, hex 4, save an...

Page 191

Chapter 5: programming 5-83 number of code 128 scans required 24466 selection programming tag sequence programming mode, hex 6, hex b, hex 7, hex 3, save and reset 3 scans 4 scans programming mode, hex 6, hex b, hex 7, hex 4, save and reset 1 scan programming mode, hex 6, hex b, hex 7, hex 1, save a...

Page 192

5-84 chapter 5: programming number of minimum interleaved 2 of 5 characters in interleaved 2 of 5 partial selection programming tag sequence programming mode, hex 6, hex b, hex e, hex 4, save and reset 4 characters 5 characters programming mode, hex 6, hex b, hex e, hex 5, save and reset 2 character...

Page 193

Chapter 5: programming 5-85 enable upc ns5 coupon 24964 selection programming tag sequence programming mode, hex 7, hex 1, hex d, save and reset enable programming mode, hex 7, hex 1, hex c, save and reset disable setting default gs1 databar ai 8110 coupons gs1 databar 8110 specific disable 25590 se...

Page 194: Ascii Code Chart

5-86 chapter 5: programming checkpoint interlock 25685 scanner power-on state 27079 selection programming tag sequence programming mode, hex 8, hex 0, hex 0, save and reset disable programming mode, hex 8, hex 0, hex 1, save and reset enable default setting ascii code chart 70 71 72 73 74 75 76 77 7...

Page 195: Special Programming

Chapter 5: programming 5-87 special programming some of the realscan 74 features require programming that is somewhat different than the normal programming. The following sections describe the special programming options. Set current parameters to default values the realscan 74 comes from the factor...

Page 196: Check Digits On Price Fields

5-88 chapter 5: programming convert upc–e tags to ean–13 tags upc–e tags can be converted directly to ean–13 tags. This function is only needed if upc–a tags are not to be converted to ean–13 tags. The default is to disable this function. • enable converting upc–e to ean–13— program mode, hex 4, hex...

Page 197: Good Read Tone

Chapter 5: programming 5-89 enable/disable code–128 partials when decoding code 128 using partial scans, sometimes a decode error is generated. However, several conditions must occur to cause the misread. If having problems reading code 128 bar codes, try disabling partials. • disable code 128 parti...

Page 198: Gs1 Databar

5-90 chapter 5: programming gs1 databar gs1 databar, formerly reduced space symbology (rss) permits more data to be recorded in a smaller physical space. This is accomplished by encoding the data in large symbol characters rather than encoding each data character separately. Also, no quiet zone is r...

Page 199

Chapter 5: programming 5-91 gs1 databar–expanded gs1 databar–expanded is a variable length linear symbology. It can encode 74 numeric or 41 alpha characters. Rss expanded can be scanned and decoded in up to 22 segments and then reconstructed 19256 9987 6543 2101 2345 6789 8888 gs1 databar–expanded s...

Page 200

5-92 chapter 5: programming terminal coupon interface parameters certain parameters must be set to permit the unit to transmit coupon data to the host terminal. These are in addition to the general parameters that are required for other scanner functions. Note: selection of optional add ‐ on bar cod...

Page 201

Chapter 5: programming 5-93 terminal coupon select 2 1. Scan the program mode tag. 2. Scan the hex 3 and hex d tags to select this parameter. 3. Scan a hex 0 through hex 7 tag to set a coupon select 2 parameter: coupon select 2 parameter disable enable coupon and p5 or 128 optional (ean ‐ 99) hex 0 ...

Page 202: Voice Volume

5-94 chapter 5: programming clerk messages off 1. Program mode 2. Hex 3 3. Hex 3 4. Hex 0 5. Save and reset note: because the clerk messages are a subset of the voice messages, disabling all voice messages disables the clerk messages also. All voice messages must be enabled for the clerk messages to...

Page 203

Chapter 5: programming 5-95 volume levels there are eight standard volume settings in the realscan 74. However, there is a programming sequence which activates eleven. This gives the operator greater flexibility in selecting the appropriate volume of the good read tone. This parameter does not have ...

Page 204: Firmware Flashing

5-96 chapter 5: programming 7. End —sends programming back to program mode 8. Hex 3 , hex e , then hex 0 —disables the volume adjust button 9. Save and reset tag—stores the good read tone and volume adjust button settings, and then resets the scanner single volume adjust bar code there is a single v...

Page 205: Firmware Version

Chapter 5: programming 5-97 firmware download tools for all sa and pxa scanners release number release date download 2.0.1.4 build 40 13 jun 2007 readme.Doc 2.0.1.4 build 40 13 jun 2007 ncrflashlimited.Exe (install tool) 2.0.1.4 build 40 13 jun 2007 ncrflashlimitedsilent.Exe (install tool) pxa scann...

Page 206: Firmware Flashing Procedure

5-98 chapter 5: programming firmware flashing procedure perform the following procedure to flash firmware on the realscan 74: 1. Apply power to the realscan 74. 2. Connect the scanner to the pc terminal using an rs232 cable or usb cable appropriate for realscan 74 scanner. The rs232 cable is part nu...

Page 207

Chapter 5: programming 5-99 note: ensure that the 7874 scanner tab is in front. This displays the realscan 74 settings. 4. See what firmware is under the heading “firmware update flags”. Select the modify ini file button on the right side. 5. Use the pull ‐ down menu under “firmware level” to point ...

Page 208

5-100 chapter 5: programming 9. Scan the firmware flashing tag. Ensure the scanner motor is off, the orange leds on the side of the bezel are on, and the scan adviser on top turns pink and may flash depending on the firmware already in the unit. Firmware flashing 24984 this flash mode tag is also in...

Page 209: Realscan Flash Drive Support

Chapter 5: programming 5-101 realscan flash drive support the realscan 74 supports a flash drive to provide convenient and economic means of scanner service upgrades and initial installations. The flash drive support capabilities are similar to the capabilities currently provided by the realscan rem...

Page 210

5-102 chapter 5: programming 2. Select setup.Exe to run the installer. The following window displays. 3. After the progress bar completes, the following window displays..

Page 211

Chapter 5: programming 5-103 4. Select next . The following window displays. 5. Select i agree and select next . The following window displays..

Page 212

5-104 chapter 5: programming 6. If desired, change the target folder where the prep application is to be installed. Select everyone from the options to select who uses the application and then select next . The following window displays. 7. Select next . The flash drive prep application installs. Th...

Page 213

Chapter 5: programming 5-105 8. Select close to exit. The installer places an icon on the desktop. The following is a sample image of the icon. The following window displays after selecting the flash drive prep tool icon. The application automatically detects the flash drive upon inserting it in the...

Page 214

5-106 chapter 5: programming 3. Select submit . The following window displays. 4. Select ok . The following window displays. 5. On the target scanner tab, select 7874 as the target scanner..

Page 215

Chapter 5: programming 5-107 6. On the clone/memory dump tab select the memory dump checkbox under the dumps groupbox. 7. Select the prep flash drive button. The application then preps the flash drive. The following message box displays after a successful flash drive prep. 8. Right ‐ click the safel...

Page 216

5-108 chapter 5: programming 9. Plug the flash drive in the scanner ʹ s usb peripheral port. The scanner gives off a triple beep of ascending frequency, which indicates that the usb peripheral port recognized the flash drive and was able to enumerate. The triple beep sounds off regardless of the con...

Page 217

Chapter 5: programming 5-109 4. Select ok . The following window displays. 5. On the target scanner tab, select 7874 as the target scanner. 6. On the parameters groupbox, select the update scanner with: checkbox. 7. Select the eeprom from the dropdown menu. Note: if the extract from scanner to: grou...

Page 218

5-110 chapter 5: programming 8. Select the prep flash drive button. The application then preps the flash drive. The following message box displays after a successful flash drive prep. The down arrow of the 2nd line in the scanner configuration preview panel under 7874 highlights. 9. Right ‐ click th...

Page 219

Chapter 5: programming 5-111 parameters download this function downloads the scanner configuration from the flash drive to the scanner. This is similar with the flash tool except that the eeprom image comes from the flash drive instead of from the pc. 1. Select the ncr realscan flash drive prep tool...

Page 220

5-112 chapter 5: programming 4. Select ok . The following window displays. 5. On the target scanner tab, select 7874 as the target scanner. 6. On the parameters groupbox, select the extract from scanner to: checkbox. 7. Enter a filename. Ensure that the filename must have a .Bin file extension or el...

Page 221

Chapter 5: programming 5-113 note: if the update scanner with: groupbox is enabled upon selecting the extract from scanner to: checkbox, the following error message displays. 8. Select the prep flash drive button. The application then preps the flash drive. The following message box displays after a...

Page 222

5-114 chapter 5: programming a triple beep of ascending frequency follows. The scanner then sounds off a low frequency triple beep, which indicates that the flash drive can be safely removed. Unplug the flash drive from the scanner ʹ s usb peripheral port. Firmware upload this function uploads the s...

Page 223

Chapter 5: programming 5-115 4. Select ok . The following window displays. 5. On the target scanner tab, select 7874 . 6. On the firmware groupbox, select the extract from scanner to: checkbox. 7. Enter a filename. Ensure that the filename must have a .Bin file extension or else an error exclamation...

Page 224

5-116 chapter 5: programming the following is a sample filename with the correct file extension. Note: if the update scanner with: groupbox is enabled upon selecting the extract from scanner to: checkbox, the following error message displays. 8. Select the prep flash drive button. The application th...

Page 225

Chapter 5: programming 5-117 10. Plug the flash drive in the scanner ʹ s usb peripheral port. The following lists the different actions the scanner initiates: the scanner gives off a triple beep of ascending frequency, which indicates that the usb peripheral port recognized the flash drive and was a...

Page 226

5-118 chapter 5: programming 4. Select ok . The following window displays. 5. On the target scanner tab, select 7874 . 6. On the firmware groupbox, select the checkbox under update scanner with: . 7. Select the firmware from the dropdown menu..

Page 227

Chapter 5: programming 5-119 note: if the extract from scanner to: groupbox is enabled upon selecting the update scanner with: checkbox, the following error message displays. 8. Select the prep flash drive button. The application then preps the flash drive. The following message box displays after a...

Page 228

5-120 chapter 5: programming the scanner speaks ʺ load program in 3 seconds...2...1...0... ʺ . The scanner resets after this message. The scanner beeps and a triple beep of ascending frequency follows. The leds blink from left to right while in flash mode. The scanner reboots after a successful firm...

Page 229

Chapter 5: programming 5-121 4. Select ok . The following window displays. 5. On the target scanner tab, select 7874 as the target scanner..

Page 230

5-122 chapter 5: programming 6. On the clone/memory dump tab, select the memory dump checkbox. This enables the clear tallies afterward checkbox under the dumps groupbox. 7. Select the clear tallies afterwards checkbox. 8. Select the prep flash drive button. The application then preps the flash driv...

Page 231

Chapter 5: programming 5-123 10. Plug the flash drive in the scanner ʹ s usb peripheral port. The scanner gives off a triple beep of ascending frequency, which indicates that the usb peripheral port recognized the flash drive and was able to enumerate. The triple beep sounds off regardless of the co...

Page 232

5-124 chapter 5: programming 5. Select ok . The following window displays. 6. On the target scanner tab, select 7874 as the target scanner..

Page 233

Chapter 5: programming 5-125 7. On the clone/memory dump tab, under the clone mode groupbox, select the parameters to be cloned. In this procedure, select either or both firmware and eeprom checkboxes, which means either or both firmware and eeprom of the gold unit, are cloned to the target scanner....

Page 234

5-126 chapter 5: programming the following window displays after selecting eeprom . 8. Select ok . The confirm button is now enabled. 9. Select confirm . The following window displays. The following window displays if eeprom was previously selected. Note: all other settings; including settings in ot...

Page 235

Chapter 5: programming 5-127 12. Plug the flash drive in the scanner ʹ s usb peripheral port. The scanner gives off a triple beep of ascending frequency, which indicates that the usb peripheral port recognized the flash drive and was able to enumerate. The triple beep sounds off regardless of the co...

Page 236

5-128 chapter 5: programming scanner cloning using programming tags the scanner has some programming sequences that let you clone a unit if you did not get a chance to run the flash drive prep application before going to the site. This requires programming tags. Follow these steps to perform scanner...

Page 237

Chapter 5: programming 5-129 3. Select submit . The following window displays. 4. Select ok . The following window displays. 5. On the target scanner tab, select 7874 as the target scanner..

Page 238

5-130 chapter 5: programming 6. Select the file viewer tab. The following window displays. 7. Select which file to work with using the dropdown menu in either scanner logs or scanner memory dump . 8. Select view to view the file (wordpad format), delete to delete the file, or delete all to delete al...

Page 239

Chapter 5: programming 5-131 after selecting delete , the following window displays. Note: this is a sample window if the scanner logs delete button is selected. If delete all is selected, the following window displays. This is a sample window if the scanner memory dump delete all button is selected...

Page 241: Troubleshooting

Chapter 6: troubleshooting this chapter contains troubleshooting charts that are designed for locating and correcting certain problems without the aid of a trained technician. If the problem cannot be corrected using these charts, a trained technician can use scan doctor to help identify a faulty co...

Page 242: Scale Diagnostics

6-2 chapter 6: troubleshooting realscan 74 diagnostics and troubleshooting there are two kinds of diagnostics that run on each scanner unit. The level 0 diagnostics run every time the scanner unit is powered up. This determines if the unit is operational. The operational diagnostics continuously che...

Page 243: Scale Troubleshooting Codes

Chapter 6: troubleshooting 6-3 scale troubleshooting codes note: led 1 is the first led from the bottom of the scan adviser. Possible cause corrective action out of range calibration error 1. Calibrate scale. 2. If error code persists, check: scale cables and power supply digital board scale assembl...

Page 244: Scanner Diagnostic Codes

6-4 chapter 6: troubleshooting scanner diagnostic codes level 0 diagnostics are run every time the realscan 74 is powered up. This diagnostic determines if the unit is operational. Level 0 diagnostics are also run when the unit is in base programming mode and when the default , save and reset , or a...

Page 245

Chapter 6: troubleshooting 6-5 isolating sensormatic® problems possible cause corrective action sensormatic ® scanmax ™ pro controller not turned on check the on/off switch on the scanmax ™ pro controller if it is turned on. 24859 problem does not deactivate tags replace sensormatic ® interlock cabl...

Page 247: Ncr Scanner Programming Tags

Appendix a: ncr scanner programming tags scanner programming tags bst0-2121-74 release o 27064 volume adjustment 11817 a.

Page 248

A-2 appendix a: ncr scanner programming tags reset 11818 default r0046 programming mode r0042.

Page 249

Appendix a: ncr scanner programming tags a-3 end r0043 save and reset r0044 abort r0045.

Page 250

A-4 appendix a: ncr scanner programming tags diagnostic mode r0041 speak scanner serial number available with firmware version 497 -0433606 or later. 22786 speak barcodes currently enabled available with firmware version 497-0433606 or later. 22785.

Page 251

Appendix a: ncr scanner programming tags a-5 mode 1 slot scanner (pacesetter plus) 11500 mode 2 slot scanner (pacesetter plus) 11501 reset tallies slot scanner (pacesetter plus) 11502.

Page 252

A-6 appendix a: ncr scanner programming tags firmware flashing super asic models 20600 hex 0 r0048 hex 1 r0049.

Page 253

Appendix a: ncr scanner programming tags a-7 hex 2 r0050 hex 3 r0051 hex 4 r0052.

Page 254

A-8 appendix a: ncr scanner programming tags hex 5 r0053 hex 6 r0054 hex 7 r0055.

Page 255

Appendix a: ncr scanner programming tags a-9 hex 8 r0056 hex 9 r0057 hex a r0058.