1 tm m1108d item number : 1108, 1109, 1114 serial number : _____________________ owner’s manual instructions for assembly, testing, operation, servicing, & storage 22, 30, 37-ton log splitters: outdoor hydraulic powered machine that splits wood logs. Warning read and understand this manual completel...

Hazard signal word definitions 2.

Table of contents 3 about your log splitter 4 safety label locations 5 machine components identification 7 initial set-up 8 optional 4-way wedge wings 10 moving & towing to the job site 11 before each use: step one: inspection/maintenance 14 step two: refueling 17 step three: work site selection & s...

About your log splitter 4 thank you for purchasing your northstar log splitter! About your log splitter: this log splitter is a machine designed to split wood logs using a hydraulically powered moving wedge. The log splitter’s gasoline engine is used to pressurize the hydraulic system . This log spl...

Safety label locations 5 reference number part number description 1 39259 warning decal 2 777887 splitter operating instruction decal 3 777890 fire hazard warning decal 4 777891 hydraulic fluid warning decal 5 777892 moving/towing decal 6 778593 outrigger leg decal 7 778597 horizontal lock decal 8 7...

Safety label locations 6 pn 778714 vertical lock poisonous gas this product's use gives off carbon monoxide, an odorless gas that can kill you. Only use outdoors and away from air intakes. Never use inside homes, garages, or sheds. Even if you run a fan or open doors and windows. See product manual ...

Machine component identification 7 ref description ref description 1 2” ball coupler 11 endplate 2 horizontal lock 12 outrigger legs 3 lifting handle 13 engine 4 cylinder 14 hydraulic tank 5 hydraulic oil dipstick 15 suction strainer 6 split control lever 17 safety chains 7 control valve 18 vertical...

Initial set-up 8 important! Engine is shipped without oil. Do not start the engine before adding oil. See assembly instructions section of this manual to assemble the log splitter before set-up. Step one: inspect log splitter components. Closely inspect all log splitter components. (see machine comp...

Initial set-up 9 step four: lubricate keepers pump grease into grease zerks found under each keeper . This will help prevent wear between the keepers and beam. Grease zerk fig 02408 keeper beam wedge.

Optional 4-way wedge wings 10 4-way wedge wings wing assembly 1. Unbox and identify components 2. Insert nylon nuts into hex cutouts in wing 3. Position wings into proper locations on the wedge and bolt into position using supplied bolts 4. Tighten the bolts with a 3/8 ” hex wrench • 4-way wings cre...

Moving and towing to the job site 11 warning the log splitter is heavy. It can crush and cause serious injury if it rolls out of control or tips over. Follow the instructions below for safely moving and towing the log splitter. Moving the log splitter: 1. Place in horizontal position make sure the l...

Moving and towing to the job site 12 towing: 1. Read instructions review towing safety instructions in your vehicle manual. 2. Check tires make sure tires are fully inflated and in good repair. Warning: • do not over-inflate tires. Serious injury can occur if tire explodes. • when seating a bead aft...

Moving and towing to the job site 13 6. Tow to desired location tow log splitter carefully to desired work site. (see before each use section on selecting an appropriate work site) important safety instructions : • added length . Be aware of the added length of the splitter. • speed limit . Never to...

Before each use-inspection / maintenance 14 step one: inspect and maintain log splitter before each use if the log splitter has been used previously, it must be inspected and maintained before each subsequent use. Warning always shut off the engine, disconnect the spark plug, and relieve system pres...

Before each use-inspection / maintenance 15 5. Hydraulic system check the hydraulic system carefully: 1. Visually inspect all hoses, tubing, clamps/fittings, pump, and cylinder for cracks, fraying, kinks, or other damage. 2. Check all components for oily residue, which may indicate a leak. Do not op...

Before each use-inspection / maintenance 16 9. Tires make sure tires are fully inflated and in good repair if you will be towing the splitter. See tire sidewall for recommended tire pressure. Warning: • do not over-inflate tires. Serious injury can occur if tire explodes. • when seating a bead after...

Before each use - fueling 17 step two: fueling warning gasoline is highly flammable and explosive. You can be burned or seriously injured when handling fuel. Use extreme care when handling gasoline. 1. Engine off / cool the engine must be off and allowed to cool at least two minutes before adding fu...

Before each use – work site selection & set-up 18 step three: work site selection and log splitter set-up warning it is important to select an appropriate work site and properly set up the log splitter in order to minimize the risk of slips and falls, equipment rolling or tipping over, carbon monoxi...

Before each use – work site selection & set-up 19 4. Lock both outrigger legs down lock both the outrigger legs in the “down” position. 5. Block wheels block the wheels to prevent unintended movement of the log splitter. 6. Apply grease apply grease into grease zerks located under both keepers. Lock...

Splitting operation 20 warning before starting this log splitter, review the following instructions and safety information for safe operation of the log splitter. Failure to follow these rules may result in serious injury to the operator or bystanders from moving parts that crush, cut, or entangle f...

Splitting operation 21 1. Put on protective clothing / gear wear the following protective clothing and safety gear: 1) eye protection . Always wear safety glasses or goggles when operating the machine. Pieces of log may fly out and serious eye injury can occur. 2) boots . Falling logs can crush feet...

Splitting operation 22 b) set to vertical position 1) lock rear outrigger leg in down position. 2) pull out horizontal lock catch pin, grasp lifting handle and lift beam until it rotates into vertical position. Warning : crush hazard. The beam is heavy – do not let it just drop. It could crush finge...

Splitting operation 23 fig02218 5. Load log load log onto beam with a cut end against the endplate – positioned for a lengthwise cut. Notes: a) the log splitter is designed only for cutting lengthwise with the grain, not for cutting across the grain. B) this log splitter is designed for cutting logs...

Splitting operation 24 split control lever operation split control lever operation 6. Extend wedge move split control lever toward endplate to extend wedge and split log. Important safety instructions: • operator position . Always operate the log splitter from the manufacturer’s indicated operator p...

Splitting operation 25 split control lever operation warning: never attempt to remove a stuck log by: • modifying the splitter. • adding attachments to the splitter. Personal injury could result from log or metal pieces flying out at high speed toward the operator or bystanders, or the splitter coul...

Storage 26 warning gasoline vapors can ignite and cause a fire. Select a well-ventilated storage away from sources of heat, flame, or sparks. Follow the instructions below for storing your log splitter between uses . 1. Retract wedge retract the wedge completely to keep the rod protected from corros...

Periodic maintenance 27 in addition to the maintenance performed with each use, periodic maintenance should also be performed according to the following schedule. Warning always shut off the engine, disconnect the spark plug, and relieve system pressure before cleaning, adjusting, or repairing the s...

Periodic maintenance 28 7. Dispose of used oil at an oil recycling center. Used hydraulic oil is hazardous waste. 8. Extend and retract wedge 5 (five) times to purge air from the system. 9. Check hydraulic oil level and fill if necessary. 3. Spark arrestor muffler as specified in spark arrestor muff...

Troubleshooting 29 warning before troubleshooting or attempting to service, read the following safety instructions to avoid serious injury to the operator or bystanders from moving parts that can crush or cut, burns, fire or explosion, or escaping high pressure hydraulic fluid. Important safety inst...

Specifications 30 1108, 1109, 1114 hydraulic fluid type…………. 10wt aw32, asle h-150, or iso32 coupler size…………………… 2” ball maximum towing speed……… 45 mph maximum log length ............... 25 in hydraulic cylinder stroke ......... 24 in overall dimensions ................... 89”l x 43”w x 41”h 1108 1...

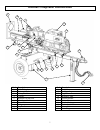

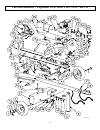

Parts breakdown – exploded view 1108, 1109, 1114 – rev d 31 fig. 02415.

Parts breakdown – exploded view 1108, 1109, 1114 – rev d 32 item part no. Description qty. Model item part no. Description qty. Model 1 82140 1/8” x 2” cotter pin 4 all 3005 ¾” coupling 1 1108, 1109 2 124a dust cap 2 all 31 3007 1” coupling 1 1114 3 777124 axle nut 2 all 32 3009 coupling insert 1 al...

Summary of important safety information for operation 33 warning carefully read and make sure you understand the following safety information before using the log splitter. Improper use or maintenance of the log splitter can result in serious injury to the operator or bystanders from moving parts th...

Summary of important safety information for operation 34 ● tires. Be sure the tires are fully inflated and in good repair before towing the log splitter. When adding air to the tires, do not over-inflate – serious injury could occur if tire explodes. ● added length. Be aware of the added length of t...

Summary of important safety information for operation 35 o stop the engine, disconnect the spark plug, and move all control valve handles back and forth to relieve pressure before changing or adjusting hydraulic system components such as hoses, tubing, fittings or other components. O if injured by e...

Summary of important safety information for operation 36 safety – during use general safety during use warning : before starting this log splitter, review the following rules for safe operation. Failure to follow these rules may result in serious injury to the operator or bystanders. • safety equipm...

Summary of important safety information for operation 37 • note for vertical position loading : place the log on the endplate and turn it until it leans against the beam and is stable. If the log is too big or oddly shaped, stabilize the log with wooden shims between the log and endplate or ground. ...

Assembly instructions 38 closely inspect all log splitter components. If you have missing components, contact customer service at 1-800-270-0810. If you have damaged components, contact the freight company that delivered the unit and file a claim. Caution! Heavy lifting required. Some of the compone...

Assembly instructions 39.

Assembly instructions 40 step 1 remove shipping crate if there are rubber boots on the axles, remove and discard them slide wheel onto axle with valve stem facing out slide outer bearing onto axle (outer bearing may be shipped loose in parts bag or loose inside wheel) outer bearing taper points into...

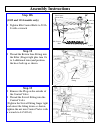

Assembly instructions 41 towbar outrigger leg bolt catch pin fig 02419 step 4 connect an outrigger leg to front of towbar using (1) outrigger leg bolt and (1) outrigger leg nut (already in place) use wrench to tighten nut until snug then back off ½ turn insert catch pin to lock in vertical position ...

Assembly instructions 42 step 7 fasten horizontal beam lock to beam using (2) beam bolts and (2) beam nuts tighten bolts to 37 lb-ft with a wrench fasten handle to beam as shown using (2) beam bolts and (2) beam nuts tighten bolts to 37 lb-ft step 8 lower beam to horizontal position as described in ...

Assembly instructions 43 step 10 slightly loosen hose clamp on loose end of suction hose slide suction hose onto the bottom fitting of the pump secure the suction hose with the hose clamp step 11a (1109 and 1114 models only) attach idle control plate to idle control mount plate on the beam using (2)...

Assembly instructions 44 step 11b (1109 and 1114 models only) tighten idle control bolts to 20 lb- ft with a wrench idle control plate idle control mount plate fig 02431 step 12 thread the return line fitting into the filter (finger tight plus turn 1½ to 3 additional turns)and position the hose barb...

Assembly instructions 45 step 14 raise beam to vertical position as described in the splitting operation section of the manual slightly loosen hose clamp on to the loose end of the return line slide the loose end of the return line onto the return line fitting tighten hose clamp step 15 install loos...