North Star 1572041 Owner's Manual

M1572041G.1

157

Owner’s Manual

Cold Water, Belt Drive Pressure Washer

(For Portable Outdoor Use only)

Instructions for Installation/Set-up, Operation, Maintenance, & Storage

This pressure washer produces cold water high pressure spray. Cleaning chemicals may be incorporated into the

spray if desired. The pressure pump for this equipment is powered by a gasoline internal combustion engine.

WARNING: SPECIAL HAZARDS

CO Poisoning:

Exhaust from engine contains carbon monoxide, a poisonous gas that can cause carbon monoxide

poisoning and possible death if inhaled. ONLY run pressure washer OUTDOORS and at least 20 feet from the home, away

from windows, vents and air intakes, to allow proper ventilation. If you start to feel sick, dizzy, or weak while using the

pressure washer, shut off the engine and get to fresh air RIGHT AWAY.

Injection Injury

: High-pressure spray can pierce skin and underlying tissues, leading to serious injury and possible

amputation. Such an injection injury can result in blood poisoning and/or severe tissue damage.

Flying Debris

: High-pressure spray can cause flying debris and possible surface damage.

Electric shock

: Operating equipment in wet conditions or near water can cause electric shock.

Chemical Exposure:

Cleaning chemical vapors or contact with skin may be hazardous.

Fire/Explosion:

Engine sparking can ignite fuel or other flammable liquids or vapors in the vicinity. Hot exhaust from engine

can ignite combustible materials.

Burns

: Pressure Washer pump and engine are hot surfaces that can cause burn injuries.

Detailed safety

information about these hazards appears throughout this manual.

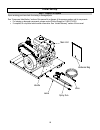

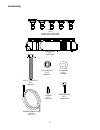

Equipment Protection Quick Facts

Inspect Upon Delivery:

FIRST! Inspect for missing or damaged components. See

“Initial Set-Up”

section for where

to report missing or damaged parts.

Add Engine Oil:

Engine is shipped

without oil

. See engine manual for instructions on capacity and viscosity

recommendations.

Replace Temporary Pump Oil Plug:

Pump is shipped

with

oil but with temporary shipping plug. Check pump oil

level before starting and replace temporary shipping plug with permanent oil fill plug provided within plastic bag

containing this Owners’s Manual.

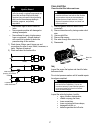

Water Flow Requirements:

Make sure your supply water flow rate is 20% higher than the pressure washer's flow

rate (see "Operations", section for detail), and that your water is clean and particle free.

Chemical Spraying:

Use only approved pressure washer chemicals designed for high-pressure use. Use chemical

adjustment knob to regulate cleaning power (on select units).

Storage:

Do not allow water to freeze in the pump, hose, or spray gun(s). See “Storage” for more information.

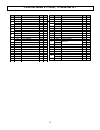

Maintenance Schedule:

Engine and pump require periodic inspection and servicing to keep pressure washer

functioning efficiently. See “

Maintenance Schedule Summary

” for frequency of servicing.

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar Product Support 1-800-270-0810

ITEM NUMBER: 1572041, 1572042

SERIAL NUMBER: _____________