1 pump is shipped with oil. - remove shipping tape from pump oil fill cap. (cat pumps) - remove shipping plug and install vented fill cap. (comet pumps) - see pump oil cap section of this manual. Closely inspect all components. -if you have damaged components: contact the freight company that delive...

Hazard signal word definitions 2.

Table of contents 3 important safety instructions………………………....4-5 warning label locations……………………………...6 assembly instructions…………………………………….7-9 machine component identification………………………10 pump oil cap and pump component identification…..11 operation instructions………………………………....11-15 water supply………...

Important safety instructions 4 warning -risk of injection or injury to persons - do not direct discharge stream at persons. - do not use a hose if exterior damage is evident. -risk of explosion. - do not spray flammable liquids. - do not operate in a flammable environment. Caution -gun kicks back. ...

Grounding instructions 5 this product must be grounded. If it should malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electrical shock. This product is equipped with a cord having an equipment-grounding conductor and a grounding plug....

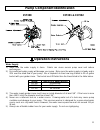

Warning label locations 6 gun kicks back. Hold with both hands. Risk of injection or injury to persons. Do not direct discharge stream at persons. Risk of fire and explosion. Do not spray flammable liquids. To reduce the risk of injury, read owner's manual carefully before using. © 2005 nt+e co. 800...

Machine component identification 7 i.) unpack your pressure washer is shipped in one box. Separate and identify the components found in both boxes. Pressure hose any questions, comments, problems or parts orders call northstar customer service 1-800-270-0810 * figures shown are for representation on...

Machine component identification 8 ii.) hardware bag hose hook – qty 3 part # 38510 gun hook – qty 2 part # 38509 flange nut – qty 8 part # 82019 carriage bolt - qty 2 part # 82233 t-handle – qty 2 part # 38578 grommet – qty 5 part # 35198 nozzle – qty 2 part # 778150 washer – qty 2 part # 82021 loc...

Machine component identification 9 nozzles grommets gun hooks flange nuts hose hook handle hook detail flange nut top hook detail lock nut and washer t-handle knob carriage bolt iii.) handle assembly 1.) attach handle to base with two carriage bolts and t-handle knobs. 2.) spin a flange nut backward...

Machine component identification 10 1.) handle. Designed for easy cart movement. 2.) hose hook. Store hose on hook. 3.) pressure hose. Attach quick couplers to gun and water outlet. 4.) chemical hose. Submerge in cleaning solution. 5.) water pump. Inspect for loose/broken parts prior to each use. 6....

Pump component identification 11 operation instructions water supply 1.) make sure the water supply is clean. Debris can cause excess pump wear and reduce performance. 2.) an insufficient water supply will damage your pump. Make sure the water supply is steady and is 20% over the rated flow of your ...

Operation instructions 12 start-up instructions 1. Attach garden hose. 2. Attach pressure hose. 3. Attach gun and lance. 4. Turn water supply on. 5. Squeeze trigger to purge air from pump. 6. Insert nozzle. 7. Plug in power cord 8. Reset the gfci button on the cord 9. Start motor. Shut-down instruct...

Operation instructions 13 spray gun safety lock when not spraying, use the spray gun safety lock to prevent accidental high pressure discharge. Attaching the lance tighten spin-on coupler hand tight. Note: the o-rings make the seal so there is no need to tighten with a wrench. Spray gun spray gun sa...

Operation instructions 14 flying objects. Make sure nozzle is secure before squeezing trigger. If nozzle is not secure it will become a projectile. Serious injury can occur. Warning installing nozzles to install a nozzle pull back the collar and push the nozzle into the coupler. Once the connection ...

Operation instructions 15 applying chemicals 1.) install the black nozzle when applying chemicals onto the cleaning surface. 2.) start the pressure washer according to the start-up instructions. 3.) submerge the chemical hose in cleaning solution. 4.) squeeze the spray gun trigger. The chemical inje...

Maintenance and storage 16 maintenance mode before performing any maintenance on the pressure washer, it must be placed in maintenance mode. 1.) turn off motor and unplug cord. 2.) turn off water supply. 3.) squeeze trigger to relieve system pressure. Maintenance schedule what to check when to check...

Maintenance and storage 17 sight glass drain plug fill cap cat 3dx25gsi pump fill cap comet bxd 1617e pump oil capacity: 4.3oz. (.13l) oil capacity: 8.5 oz. (.25l) fig01854 oil capacity: 8.5 oz. (.25l) drain plug sight glass fill cap cat 2dx20es pump drain plug sight glass pump oil change 1.) place ...

Maintenance and storage 18 winter storage protect your pump, hose and gun from freezing. Items needed: 12” piece of garden hose or equivalent, funnel and rv antifreeze (approximately 6 oz.) 1.) follow the storage instructions listed above. 2.) make sure the motor start switch is off. 3.) attach the ...

Troubleshooting 19 problem motor will not start solution: a,b low/surging pressure or no water flow solution: c,d,e,f,g,h no chemical injection solution: i,j,k,l cause solution a- tripped gfci cord reset gfci cord b- tripped motor relay reset motor c- insufficient water supply see water supply secti...

Specifications 20 157300 157301 psi (bar) 1700 (117) psi (bar) 2000 (138) gpm (l/min) 1.5 (5.7) gpm (l/min) 1.5 (5.7) max water temp 140 °f (60°c) max water temp 140 °f (60°c) dimensions l x w x h 33.5” x 20.9” x 38.6” ( 851mm x 531mm x 980mm) dimensions l x w x h 33.5” x 20.9” x 38.6” (851mm x 531m...

Wiring diagram 21.

Part explosion m157300 rev e 22 item part# description qty models item part# description qty models 1 38509 threaded gun hook 2 all 778128 electric control box cover 1 157300 2 778065 northstar decal 1 all 23 778132 electric control box cover 1 157301,2 3 35198 7/16 id grommet 5 all 778140 gfci cord...

23.