North Star 157305 Owner's Manual

1

M157305Y

Owner’s Manual

Electric Hot Water/Steam Pressure Washer

Instructions for Set-up, Operation, Maintenance & Storage

This pressure washer produces cold or hot water high-pressure spray as well as steam spray. Cleaning chemicals

may be incorporated into the spray if desired. The pressure pump is powered by an electric motor and water is

heated by an open flame burner fueled by diesel/kerosene or fuel-. Read and understand this Owner’s Manual

completely before using and keep this manual for review. Failure to properly set up, operate, and maintain could

result in serious injury or death to operator or bystanders.

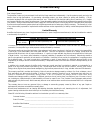

WARNING: SPECIAL HAZARDS

Skin/Eye Injury: High-pressure spray can cause serious skin or eye injury, including injection injury if fluid pierces the skin.

Injection injury can result in blood poisoning and/or severe tissue damage.

Burns: Hot spray can scald and burn skin. Hot surfaces of wand and burner, as well as hot exhaust from the burner can

cause burns.

Slips/Falls: Spray discharge can cause puddles and slippery surfaces. Spray-gun kickback can cause operator loss of

balance and falls.

Flying Debris: High-pressure spray can cause surface damage and flying debris.

Fire/Explosion: Burner sparking can ignite fuel or other flammable liquids or vapors in the vicinity. Hot exhaust from burner

can ignite combustible materials.

Chemical Exposure: Cleaning chemical vapors or contact with skin may be hazardous.

Electric shock: Spray contact with electrical sources can cause electric shock.

Electrocution: Improper connection of the equipment or grounding conductor can result in a risk of electrocution.

CO Poisoning: Exhaust from burner contains carbon monoxide, a poisonous gas that can cause carbon monoxide poisoning

and possible death if inhaled.

Equipment Protection Quick Facts

Inspect Upon Delivery: STOP! Closely inspect to make sure no components are missing or damaged. For missing

or damaged components please contact Product Support at 1-800-270-0810.

Check Pump Oil: Pump is shipped with oil. Check pump oil level before starting.

Water Flow Requirements: Make sure your supply water flow rate is 20% higher than the pressure washer’s flow

rate (3 gal/min preferred), and that your water is clean and particle free.

Chemical Spraying: Use only NorthStar brand or equivalent washer chemicals designed for pressure washer use.

Maintenance Schedule: Pump, burner fuel filter, burner coil and electrodes require periodic checking and servicing

to keep pressure washer functioning efficiently. See “Maintenance & Repair” for frequency of servicing.

Any Questions, Comments, Problems or Parts Orders

Call NorthStar Product Support 1-800-270-0810

ITEM NUMBER: 157305, 157306,

157307, 157308

SERIAL NUMBER: _____________