- DL manuals

- North Star

- Pressure Washer

- 1577543

- Owner's Manual

North Star 1577543 Owner's Manual

TM

M1578112K

Owner’s Manual

Pressure Washer:

Machine that cleans dirty

surfaces with high pressure water.

Any Questions, Comments, Problems or Parts Orders

Call NorthStar Product Support 1-800-270-0810

Engine is shipped without oil.

- Before starting engine, fill engine oil.

- See engine manual for engine oil requirements.

Pump is shipped with oil.

- Remove shipping plug and install vented fill cap. (Comet Pumps)

- Remove shipping tape from pump oil fill cap. (Cat Pumps)

- See pump oil cap section of this manual.

Closely inspect all components.

-If you have damaged components then: Contact the freight company that

delivered the unit and file a claim.

-If you have missing components then: Contact Customer Service at

1-800-270-0810.

Read this manual.

Serious injury or death can result if safety instructions are not followed.

WARNING

ITEM NUMBERS:

1578112, 1578172

1578182, 1578152,

1578202, 1578203,

1578173, 1577543,

1577544

Summary of 1577543

Page 1

Tm m1578112k owner’s manual pressure washer: machine that cleans dirty surfaces with high pressure water. Any questions, comments, problems or parts orders call northstar product support 1-800-270-0810 engine is shipped without oil. - before starting engine, fill engine oil. - see engine manual for ...

Page 2

Hazard signal word definitions 2.

Page 3: Table Of Contents

Table of contents 3 important safety rules ......................................…. 4,5 warning label locations ...................................…. 6 assembly instructions…………………………………... 7-9 machine component identification……………………. 10 pump oil cap and pump component identification… 11 operation ...

Page 4: Important Safety Rules

Important safety rules 4 save these instructions 1.) read owner's manual completely. Serious injury or death can result if safety instructions are not followed. You must be 16 or older to operate this machine. Keep untrained people away. 2.) skin puncture hazard. High pressure fluid can inject under...

Page 5: Important Safety Rules

Important safety rules 5 5.) risk of exposure to dangerous chemicals. Serious injury or death can result if chemical manufacturer instructions are not followed. -wear protective gloves when handling and cleaning with chemicals. -understand all safety hazards and first aid for all chemicals being use...

Page 6: Warning Label Locations

Warning label locations 6 start-up instructions 1. Attach garden hose. 2. Attach pressure hose. 3. Attach gun and lance. 4. Turn water supply on. 5. Squeeze trigger to purge air from pump. 6. Insert nozzle. 7. Start engine. 2008 northern tool + equipment 800-270-0810 warning part no. 38570 1.) skin ...

Page 7: Assembly Instructions

Assembly instructions 7 i.) unpack your pressure washer is shipped in two boxes except for models 1577543 and 1577544 which are shipped in one box. Separate and identify the components found in the box/boxes. * depending in model, components may appear differently than illustrated any questions, com...

Page 8: Assembly Instructions

Assembly instructions 8 ii.) hardware bag hose hook – qty 1 part # 779761 flange nut – qty 2 part # 82019 carriage bolt – qty 2 part # 82233 vented fill cap 1578112, 1577543,1577544 vented dipstick 1578152, 1578173, 1578203 gun hook – qty 1 part # 38509 t- handle knob – qty 2 part # 38578 nozzle – q...

Page 9: Assembly Instructions

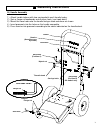

Assembly instructions 9 iii.) handle assembly 1.) attach handle to base with two carriage bolts and t-handle knobs. 2.) spin a flange nut backwards onto the gun hook. (see hook detail) 3.) mount the hose hook onto the handle and gun hook onto base as shown. 4.) insert grommets into the holes on the ...

Page 10

Machine component identification 10 1.) handle . Designed for easy cart movement. 2.) hose hook . Store hose on hook. (position depends on model, see assembly instructions section.) 3.) pressure hose. Attach quick couplers to gun and water outlet. 4.) chemical hose. Submerge in cleaning solution. 5....

Page 11

Pump oil cap and pump component identification 11.

Page 12: Operation Instructions

Operation instructions 12 water supply 1.) make sure the water supply is clean. Debris can cause excess pump wear and reduce performance. 2.) an insufficient water supply will damage your pump. Make sure the water supply is steady and is 20% over the rated flow of your pump. Use a stopwatch to time ...

Page 13: Operation Instructions

Operation instructions 13 start-up instructions 1. Attach garden hose to water inlet. 2. Attach pressure hose to water outlet and gun. 3. Attach spray gun to lance. 4. Turn water supply on. 5. Squeeze trigger to purge air from pump. 6. Insert nozzle. 7. Start engine. Shut-down instructions 1. Turn e...

Page 14: Operation Instructions

Operation instructions 14 spray gun safety lock when not spraying, use the spray gun safety lock to prevent accidental high pressure discharge. * note: depending on model, gun may appear differently. Attaching the lance tighten spin-on coupler hand tight. Note: the o-rings make the seal so there is ...

Page 15: Operation Instructions

Operation instructions 15 flying objects. Make sure nozzle is secure before squeezing trigger. If nozzle is not secure it will become a projectile. Serious injury can occur. Warning pump hose spray gun installing nozzles to install a nozzle pull back the collar and push the nozzle into the coupler. ...

Page 16: Operation Instructions

Operation instructions 16 risk of exposure to dangerous chemicals. Serious injury or death can result if chemical manufacturer instructions are not followed. -wear protective gloves when handling and cleaning with chemicals. -understand all safety hazards and first aid for all chemicals being used. ...

Page 17: Maintenance And Storage

Maintenance and storage 17 maintenance mode before performing any maintenance on the pressure washer, it must be placed in maintenance mode. 1.) turn off engine. 2.) turn off water supply. 3.) squeeze trigger to relieve system pressure. 4.) shut off fuel valve. 5.) unplug spark plug wire from spark ...

Page 18: Maintenance And Storage

Maintenance and storage 18 pump oil change 1) place a suitable container below the pump to catch the used oil. Vrx: remove the bolts that connect the pump to the engine. Remove fill cap and rotate pump upside down. All other pumps: remove drain plug. 2) allow the used oil to drain completely. Vrx: r...

Page 19: Maintenance And Storage

Maintenance and storage 19 long term storage follow the engine owner’s manual for storing the engine. Winter storage protect your pump, hose, and gun from freezing. Items needed: 12” piece of garden hose or equivalent, funnel and rv antifreeze (approximately 6 oz.) 1.) follow the storage instruction...

Page 20: Troubleshooting

Troubleshooting 20 problem engine will not start solution: a,b low/surging pressure or no water flow solution: c,d,e,f,g,h no chemical injection solution: i,j,k,l cause solution a- low oil shutdown see engine manual for oil requirements b- engine starting instructions not followed see engine manual ...

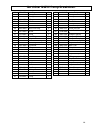

Page 21: Specifications

Specifications 21 1578112 1578172 psi (bar) 3000 (207) psi (bar) 3000 (207) gpm (l/min) 2.5 (9.4) gpm (l/min) 2.5 (9.4) max water temp 140 f (60 c) max water temp 140 f (60 c) noise level 78 db noise level 78 db dimensions l x w x h 34” x 21” x 38” (864mm x 534mm x 965mm) dimensions l x w x h 34” x ...

Page 22: Parts Exploded View

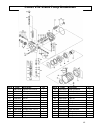

Parts exploded view 22 * depending on model, components may appear differently. Item numbers: 1578112,1578172, 1578173,1578182, 1578152,1578202, 1577543, 1577544, 1578203 revision k.

Page 23: Parts Exploded View

Parts exploded view 23 ref# part# description qty model 1 38509 gun hook 1 all 2 779826 decal 1 all 3 35198 grommet 5 all 4 780223 handle 1 all 5 779761 hose hook 1 all 6 38578 knob 2 all 7 779924 base 1 all 8 2278 wheel 2 all 9 305200 wheel retainer 2 all 10 38525 50’ pressure hose 1 1578112, 8172,...

Page 24: Pump Exploded View

Pump exploded view 24 779828 a1578172 779827 a1578182 781211 781209 a1578202 781210

Page 25: Pump Exploded View

Pump exploded view 25 ref# part# description qty model 26 779828 comet bxd 2530g pump 1 1578112 1577544 38518 cat 3dnx pump 1578172 781209 northstar nszw pump 1578203 777654 cat 3spx pump 1578182 781211 comet awd pump 1578152 38520 cat 66dx pump 1578202 779827 comet vrx 2528g pump 1577543 781210 nor...

Page 26

Comet bxd 2530g pump breakdown 26.

Page 27

Comet bxd 2530g pump breakdown 27.

Page 28: Cat 3Dnx Pump Breakdown

Cat 3dnx pump breakdown 28.

Page 29

Northstar nszw pump breakdown 29 part # code description qty part # code description qty 1 3218 0424 brass pump manifold kit 1 52 3200 0007 cap 1 2 3202 0018 plug 1 54 2811 0084 washer 1 3 3609 0014 screw 8 56 2811 0086 washer 1 4 1210 0046 o-ring 6 72 0204 0072 bushing 1 5 3009 0087 suct. /del. Val...

Page 30

Northstar nszw pump breakdown 30 22 0009 0223 back ring 3 92 3410 0297 injector body 1 23 1241 0030 packing 3 93 1210 0398 o-ring 1 24 0009 0222 packing retainer 3 94 1210 0402 o-ring 1 25 1210 0223 o-ring 3 95 1802 0197 spring 1 26 0019 0095 oil seal 3 96 2409 0122 check valve 1 27 0600 0048 specia...

Page 31: Cat 3Spx Pump Breakdown

Cat 3spx pump breakdown 31.

Page 32: Comet Awd Pump Breakdown

Comet awd pump breakdown 32 part # code description qty part # code description qty 1 3218 0413 brass manifold 1 63 1210 0040 o-ring 1 2 3609 0099 screw 8 64 1210 0049 o-ring 1 4 1210 0415 o-ring 6 65 1802 0197 spring 1 5 3009 0170 suct. /del. Valve seat 6 66 2409 0086 check valve 1 6 3604 0028 suct...

Page 33: Comet Awd Pump Breakdown

Comet awd pump breakdown 33 19 0403 0195 pump crankcase 1 82 0009 0205 ring 1 20 1241 0105 packing + ring 3 83 0009 0207 spring spacer 1 23 1241 0057 packing 3 84 1802 0182 spring (wire Ø3, 25) 1 24 0009 0374 packing retainer 3 85 3622 0030 stop adjustable nut 1 25 1210 0333 o-ring 3 86 1227 0022 ri...

Page 34: Cat 66Dx Pump Breakdown

Cat 66dx pump breakdown 34.

Page 35

Comet vrx 2528g pump breakdown 35 ref # code description qty ref # code description qty 1 2801 0079 thermo valve cover 1 39 2432 0018 pump crankcase 1 2 1210 0218 o-ring 1 40 1802 0213 piston spring 3 3 0424 0402 thermal valve body 1 41 2409 0099 piston 3 4 1210 0475 o-ring 1 42 0009 0267 ring 3 5 3...

Page 36

Comet vrx 2528g pump breakdown 36 14 1802 0219 regulation valve spring 1 52 1410 0322 detergent injector kit 1 15 2811 0117 washer 1 53 0204 0051 bushing 1 16 3605 0104 special screw 1 54 1802 0216 spring 1 17 1210 0392 o-ring 1 55 3003 0033 ball 1 18 1210 0470 o-ring 1 56 1210 0466 o-ring 1 19 0009...

Page 37

Northstar nslw pump breakdown 37 part # code description qty part # code description qty 1 3218 0424 brass pump manifold kit 1 54 2811 0084 washer 1 2 3202 0018 plug 1 55 3200 0007 cap 1 3 3609 0014 screw 8 56 2811 0086 washer 1 4 1210 0046 o-ring 6 72 0204 0072 bushing 1 5 3009 0087 suct. /del. Val...

Page 38

Northstar nslw pump breakdown 38 20 0009 0196 packing head ring 3 90 1215 0403 reg. Valve kit + seat 1 21 1241 0065 packing 3 91 1817 0064 pressure knob 1 22 0009 0223 back ring 3 92 3410 0288 injector body 1 23 1241 0030 packing 3 93 1210 0398 o-ring 1 24 0009 0222 packing retainer 3 94 1210 0402 o...

Page 39: Limited Warranty

Limited warranty 39 dear valued customer: the northstar product you just purchased is built with the finest material and craftsmanship. Use this product properly and enjoy the benefits from its high performance. By purchasing a northstar product, you show a desire for quality and durability. Like al...

Page 40

40 manufactured by northern tool + equipment co., 2800 southcross drive west p.O. Box 1499 burnsville, mn 55337-0499 tm.