M2851701c.3 owner's manual instructions for assembly, testing, operation, servicing, and storage tow behind sprayers: for outdoor use with agricultural pesticides and other liquids** warning read and understand the owner's manual completely before using this sprayer. Assemble, test, and use only in ...

Hazard signal word definitions 2.

Table of contents 3 intended use ............................................................................................................................................................... 4 summary of important safety information ....................................................................

Intended use 4 the sprayer is intended for use in spraying agricultural pesticides and other non- flammable liquids. Spraying pesticides: pesticides are hazardous chemicals that must be handled with caution as directed throughout this manual and on the pesticide label. Pesticides are regulated by th...

Summary of important safety information 5 warning read and understand this owner's manual completely before using the sprayer. Read each chemical label's instructions before handling the chemical. Improper use of the sprayer or handling of chemicals could result in serious injury or illness for the ...

Summary of important safety information (continued) 6 see troubleshooting section of this manual before attempting any repairs. Wear personal protective equipment and follow safety instructions. After spraying clean sprayer immediately after use according to the directions provided in this manual. D...

Warning label location 7 warning read and understand the owner's manual completely before using this sprayer. Assemble, test, and use only in accordance with the owner's manual instructions. Read and follow chemical label instructions. Pesticides are hazardous chemicals which must be handled careful...

Unpacking 8 closely inspect all contents in the shipping carton. Note that some parts are shipped inside the tank. If you have missing or damaged components, please contact northstar product support at 1-800-270-0810. Sprayer cart base 778190 tongue 778038 axle 778192 boom supports (qty 2) 37698 boo...

Unpacking the manual bag 9 the following items are found in the manual bag. Remote switch 777493 drain cap 37680 rubber washer 5232 lance clip (qty 2) 52034 #10 x ¼” screw (qty 2) 82057 5/16 x 1” bolt (qty 2) 82091 5/16 x ¾” carr. Bolt (qty 12) 82088 5/16 x ½” flange bolt (qty 1) 82014 5/16 flange n...

Assembly 10 rubber washer drain cap step one: attach gun clips to tank fasten the two gun clips to the sprayer tank with screws. Step two: attach drain cap to tank 1. Press the rubber washer into the drain cap with your finger. 2. Thread the drain cap onto the tank. Screw gun clip.

Assembly 11 step three: attach gun hose to pump 1. Install hose clamp on hose. I) slide hose clamp over the end of the hose. Ii) push the hose onto the hose barb. Iii) slide the hose clamp over the hose barb. Iv) tighten the hose clamp. 2. Attach one end of the gun hose to the pump hose barb. Step f...

Assembly (continued) 12 step five: attach gun hose to spray gun 1. Install hose clamp on hose. I) slide hose clamp over the end of the hose. Ii) push the hose onto the hose barb. Iii) slide the hose clamp over the hose barb. Iv) tighten the hose clamp. 2. Attach the end of the gun hose to the gun ho...

Assembly (continued) 13 step eight: attach the cart base to the sprayer note: to protect the pump from damage, place two wood planks or spacers under the sprayer to keep the pump from resting on the ground. Using (4) flat washers, loosely thread (4) 5/16 x 3/4" flange bolts into the inserts in the b...

Assembly (continued) 14 boom bracket cart base carriage bolt flange nut boom support flange nut boom support carriage bolt step nine: attach wheels to cart base 1. Slide axle into holes on bottom of cart base. 2. Slide the tires and wheel retainers onto the axle. 3. Tighten wheel retainers with supp...

Assembly (continued) 15 step eleven: attach boom arms to the boom bracket 1. Attach the boom arms to the boom bracket with (2) bolts, (2) nyloc nuts, and (4) flat washers. 2. Tighten nuts until the boom arms do not move freely. (they should still be loose enough to move up and down.) step twelve: co...

Assembly (continued) 16 boom valve hose clamp 6” hose hose clamp boom hose barb hose clamp 19” hose left nozzle fitting 19” hose hose clamp right nozzle fitting hose clamp installation instructions 1. Slide hose clamp over the end of the hose 2. Push the hose onto the hose barb 3. Slide the hose cla...

Assembly (continued) 17 nozzle retaining nut boom nozzle hitch pin (not included) step fourteen: attach sprayer to vehicle 1. Secure the sprayer to the tow vehicle with a hitch pin (not included, call 800.270.0810 and order item# 2501946). 2. Make sure both boom nozzles are pointed toward the ground...

Assembly (continued) 18 step fifteen: connect remote switch to vehicle battery warning batteries are hazardous because they contain caustic acid, can emit explosive gases, and can cause electric shock. Caution must be exercised when making connections to a battery to avoid shock and contact with the...

Assembly (continued) 19 5. Attach remote switch to vehicle using supplied velcro pad, affix remote switch to vehicle in a position that is easily reached from the driver's seat. 6. Disconnect after use after each use, disconnect power to the sprayer by disconnecting the sprayer's pump cord from the ...

Machine components 20 1. Remote switch. The remote switch connects the battery to the pump power cord and allows the operator to turn the sprayer pump on and off. 2. Hitch mount. The hitch mount connects the vehicle hitch to the sprayer. 3. Sprayer tank. The sprayer tank holds the chemical. 4. Fill ...

Operation – important safety information 21 now that you have completed and tested your assembly, there is some important safety and health information you need to know with regard to handling and spraying chemicals, as well as vehicle handling with the sprayer attached. Warning carefully read and m...

Operation – important safety information (continued) 22 chemical application safety: warning caution must be used when spraying chemicals to avoid unsafe exposure to humans and the environment . Heed the warnings below and follow all instructions carefully. Before spraying sprayer prep. Always inspe...

Operation – important safety information (continued) 23 towing/hauling safety: warning the filled sprayer is very heavy. It can crush and cause serious injury if it rolls out of control or tips over. Follow the instructions below for safely towing the sprayer. Read vehicle instructions. Review towin...

Operation – important safety information (continued) 24 sprayer leak in the event that the sprayer develops a leak while spraying chemicals, you must immediately stop spraying. Turn off power to the sprayer and follow the directions below, as applicable. Bodily chemical contact personal contaminatio...

Operation – preparing the sprayer for each use 25 fill cap suction strainer (inside tank) if the sprayer has been used previously, it must be prepared before each subsequent use. Warning read instructions below carefully for inspecting and preparing the sprayer. Damaged or clogged equipment could re...

Operation – using the sprayer 26 step one: assess wind conditions and clear work area. Before you decide to spray, you must determine whether wind conditions are suitable. You must also restrict access to the work area to ensure the safety of bystanders. Warning do not spray if wind speeds are great...

Operation - using the sprayer (continued) 27 step two: fill the sprayer. Warning always wear personal protective equipment as directed on the chemical label when handling pesticides. Long pants and sleeves, chemical resistant gloves, and eye protection are strongly recommended. Additional protective...

Operation - using the sprayer (continued) 28 drain cap 7. Check drain cap before filling tank, ensure drain cap is securely tightened. 8. Fill tank add pesticide to tank through fill cap: a) confirm the chemical/water dilution ratios specified on the chemical label. B) determine chemical and water v...

Operation - using the sprayer (continued) 29 closed boom valves step 3: operate the sprayer. Warning always wear personal protective equipment as directed on the chemical label when spraying. Long pants and sleeves, chemical-resistant gloves, and eye protection are strongly recommended. Additional p...

Operation - using the sprayer (continued) 30 retaining nut spray nozzle open desired boom valves 6. Squeeze trigger & adjust nozzle to spray, squeeze the gun trigger. - twist the spray nozzle to adjust from a straight stream to hollow cone spray pattern, as recommended on the chemical label for prop...

Operation - using the sprayer (continued) 31 c. Ensure correct spray pattern make sure both boom nozzles are pointed toward the ground. If they are not, loosen the nozzle retaining nut, orient the opening of the boom nozzle to point straight down, then retighten the nozzle retaining nut. Important: ...

Operation - using the sprayer (continued) 32 step four: clean sprayer and decontaminate after use. When done using the sprayer, it is important to clean the sprayer and decontaminate yourself. Do not store the sprayer with chemicals in the tank, as it is unsafe and could also result in damage to the...

Storage 33 prepare the sprayer for end-of-season storage by running rv antifreeze through the system. This will keep internal parts lubricated, protect against corrosion, and keep the unit from freezing. Caution the sprayer will be damaged if it freezes. Protect the sprayer from freezing during stor...

Specifications 34 warning before troubleshooting or attempting to service, read the following safety rules to avoid accidental exposure to chemical and also risk of electric shock. Note: a reserve, clean container capable of holding at least 16 gallons (model # 2851701) or 26 gallons (model # 285180...

Specifications 35 electrical system requirements electrical connection………...… 12 vdc amp draw from pump…………. 8 amps sprayer specifications maximum gpm………………... 2.2 gpm (8.3 liters/min.) maximum pressure………..…… 70 psi (4.8 bar) tank maximum capacity model #2851701….….………… 16 gallons (61 liters) model...

Exploded view – 2851701/2851801 – rev c.3 36.

Exploded view – 2851701/2851801 – rev c.3 37 ref# part# description model qty 1 779769 spray gun all 1 2 30746 hose clamp all 8 3 779768 gun hose all 15.5 ft 4 35082 hose barb all 2 5 5377 tee w/ gauge port all 1 6 777848 pressure gauge all 1 7 787195 pump fitting all 1 8 791392 2.2gpm northstar pum...

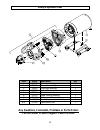

Pump exploded view 38 ref# part# description qty 1 788005 motor assembly 1 2 786945 base plate assembly 1 3 786981 diaphragm assembly 1 4 778279 valve plate assembly 1 5 787015 quick connect clip 2 6 787011 upper housing assembly 1 7 786948 pressure switch assembly 1 8 a2682272 complete pump head as...

Appendix a –broadcast spray calibration tables models 2851701 and 2851801 39 below are some guidelines to help you calibrate your tow behind broadcast sprayer. This is a very important step in operating the tow behind broadcast sprayer such that too much or too little chemical may be applied. 1.Usin...

40 this page has intentionally been left blank..

Limited warranty 41 dear valued customer: the northstar product you just purchased is built with the finest material and craftsmanship. Use this product properly and enjoy the benefits from its high performance. By purchasing a northstar product, you show a desire for quality and durability. Like al...

42 manufactured by northern tool + equipment co., burnsville, mn 55306 northerntool.Com.