- DL manuals

- North Star

- Cutter

- 49157

- Owner's Manual

North Star 49157 Owner's Manual

Summary of 49157

Page 1

Save these instructions 163cc concrete cutter owner’s manual warning: read and understand all instructions, warnings, and cautions before using this product. Failure to follow the instructions, warnings, and cautions may result in serious personal injury and/or property damage. Item #49157.

Page 2

Page 2 of 30 thank you very much for choosing a north star product! For future reference, please complete the owner’s record below: serial number/lot date code: ________________________________ purchase date: ____________________________________________ save the receipt, warranty, and this manual. T...

Page 3

Page 3 of 30 table of contents intended use .......................................................................................................................................... 4 technical specifications .............................................................................................

Page 4

Page 4 of 30 intended use this concrete cutter is designed to cut concrete, asphalt, or both at the same time. (the cutter is not designed to cut through concrete with rebar however.) the rotating handle adjusts the cutting depth from 3.9 in. To 4.7in. The cutter includes a built-in water distributi...

Page 5

Page 5 of 30 some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to the state of california to cause cancer, birth defects, or other reproductive harm. Some examples of these chemicals are: - lead from lead-based paints, - crysta...

Page 6

Page 6 of 30 equipment can tip over when moving, causing injury. Persons not operating should be at least 10 feet away while equipment is in use. Engine exhaust contains carbon monoxide. This is a poison you cannot see or smell. Never use in doors. Do not operate without guards in place. Keep feet c...

Page 7

Page 7 of 30 specific operation warnings to avoid fatal accident stop the engine before refueling and be careful not to spill fuel during the refueling. Spilled fuel may ignite causing a fire. Do not refuel the engine near flammable objects to avoid fire. Do not run the engine in enclosed areas to p...

Page 8

Page 8 of 30 do not insert hands or fingers between pulley cover and engine during operation, this will cause injury. Do not transport the concrete cutter with fuel in its fuel tank by the motor vehicle. Do not lift the concrete cutter by a person when putting on and off from vehicle. Always use a p...

Page 9

Page 9 of 30 13 elevate bar.

Page 10

Page 10 of 30 before each use engine recommended fuel the cutter engine requires fresh, clean, regular, unleaded gasoline . Fuel containing water or dirt will damage the fuel system. Consult to engine owner’s manual for complete fuel specifications. Danger: adding fuel to the tank should be done onl...

Page 11

Page 11 of 30 operating the concrete cutter operators must be trained in the use of the concrete cutter and maintain practiced skill. It is dangerous to operate this machine improperly or by an untrained person. An operator should read and understand the manual and follow its directions. Do not stop...

Page 12

Page 12 of 30 after each use cleanup check that the cutter engine is turned off and cooled before attempting any maintenance, cleaning, or inspection to avoid an accidental start and possible injury. Remove foreign substances from the saw blade and rinse it with water. Remove foreign substances such...

Page 13

Page 13 of 30 maintenance check that the concrete cutter engine is turned off and cooled before attempting any maintenance, cleaning, or inspection. Performing maintenance on an operating concrete cutter can cause injury. Maintain the concrete cutter by adopting a program of conscientious repair and...

Page 14

Page 14 of 30 installing the saw blade check that the cutter engine is turned off and cooled before attempting any maintenance, cleaning, or inspection to avoid an accidental start and possible injury. Note: the saw blade is not supplied. Diamond saw blade specifications diameter (a): 14-inch arbor ...

Page 15

Page 15 of 30 see figure 3. 5. Remove counterclockwise nut (06) with the supplied 36mm wrench (07). If the shaft spins, hold it in place with the supplied 32mm wrench (08). 6. Remove the blade holder outer (09). Figure 3 see figure 4. 7. Install the saw blade (11) on the blade shaft (10) making sure...

Page 16

Page 16 of 30 see figure 5. 8. Replace the blade holder outer (09) and nut (06). 9. Tighten nut (06) to approximately 45-50 ft. Lb. (61-68 n/m). Figure 5 10. Replace the blade cover and hose by performing steps 1 – 4 in reverse order..

Page 17

Page 17 of 30 setting the saw blade depth check that the cutter engine is turned off before making adjustments to the cutter to avoid an accidental start and possible injury. Use the procedure below to adjust the gauge pin correctly to zero depth (ground level). Once the pin is set, an accurate dept...

Page 18

Page 18 of 30 changing the v-belt check that the concrete cutter engine is turned off and cool before attempting to change the v-belt. Changing the v-belt while the cutter is still hot or operating will cause injury. 1. Remove the four bolts (02) and lift off the belt cover (01). 2. Remove the v-bel...

Page 19

Page 19 of 30 parts diagram engine mount.

Page 20

Page 20 of 30 engine mount ref. Parts no. Description qty. Remark 1 gx-160s engine 1 honda gx160 2 ca110-000 inner belt cover 1 3 qky-5x5x50 key 1 50x50x50l 4 ca040-25.4 engine pulley 1 5 qws-spm8 plain washer 1 m8-large 6 qws-sm8 spring washer 1 m8 7 qbl-m8x35 bolt 1 m8x35l 8 pa130-001 belt cover 1...

Page 21

Page 21 of 30 blade shaft.

Page 22

Page 22 of 30 blade shaft ref. Parts no. Description qty. Remark 1 qbl-m12x110 bolt 1 m12x110l 2 qws-sm12 spring washer 1 m12 3 qws-pm12 plain washer 2 m12 4 ca090-000b blade cover 1 5 qnt-m10 nut 1 m10 6 qbl-m10x30 bolt 1 m10x30l 7 qbl-m12x45 bolt 4 m12x45l 8 qws-pm12 plain washer 2 m12 9 qbr-ucp20...

Page 23

Page 23 of 30 adjust handle.

Page 24

Page 24 of 30 adjust handle ref. Parts no. Description qty. Remark 1 ca050-000b adjust mount 1 2 qws-pm12 plain washer 4 m12 3 qbl-m12x35 bolt 2 m12x35l 4 ca070-001 handle 1 5 qws-om12 plain washer 1 m12 6 qnt-nm12 nylon nut 1 m12 7 qhd-100 height adjust handle 1 8 qnt-m12 nut 1 m12 9 ca130-005 adju...

Page 25

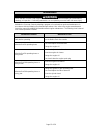

Page 25 of 30 wheel shafts ref. Parts no. Description qty. Remark 1 ca080-000 wheel shaft 1 2 qbr-ucfl205 unit bearing 2 ucfl205 3 ca130-002 rear wheel 2 4 qws-pm10 plain washer 3 m10 5 qws-spm10 spring washer 2 m10 6 qbl-m10x25 bolt 2 m10x25l 7 qbl-m12x35 bolt 4 m12x35l 8 qws-pm12 plain washer 4 m1...

Page 26

Page 26 of 30 frame & water tank ref. Parts no. Description qty. Remark 1 pp700-002 water tank cap 1 2 pc700-001b water tank 1 3 ca030-000 frame 1 4 qbl-m12x35 bolt 4 m12x35l 5 qws-sm12 spring washer 4 m12 6 qws-pm12 plain washer 4 m12 7 qbv-pt1/4bs ball valve/pt1/4(bs) 1 8 qpt-8x12x300 water hose/Ø...

Page 27

Page 27 of 30 troubleshooting problem possible cause solution poor performance (cutter does not develop its full speed.) engine throttle control does not open completely. Throttle control not adjusted correctly. Open the engine throttle control completely. Adjust the throttle control correctly. Conc...

Page 28

Page 28 of 30 replacement parts for replacement parts and technical questions, please call customer service at 1-800-222-5381. Not all product components are available for replacement. The illustrations provided are a convenient reference to the location and position of parts in the assembly sequenc...

Page 29

Page 29 of 30 limited warranty northern tool and equipment company, inc. ("we'' or '"us'') warrants to the original purchaser only ("you'' or “your”) that the north star product purchased will be free from material defects in both materials and workmanship, normal wear and tear excepted, for a perio...

Page 30

Page 30 of 30 distributed by northern tool and equipment company, inc. Burnsville, minnesota 55306 northerntool.Com made in korea.