1 owner's manual instructions for assembly, testing, operation, servicing, & storage log splitter: outdoor hydraulic machine that splits wood logs. Warning read and understand this manual completely before using log splitter. All operators of this equipment must read and completely understand all sa...

Hazard signal word definitions 2.

Table of contents 3 about your log splitter................................................................................................................... 4 attention: all rental companies and private owners who loan this equipment to others! ............ 4 safety label locations ..................

About your log splitter 4 thank you for purchasing your northstar log splitter! About your log splitter: this log splitter is a machine designed to split wood logs using a hydraulically powered moving ram which pushes the log against a splitting wedge. The log splitter's gasoline engine is used to p...

Safety label locations 5 reference # part number description 1 777335 warning decal 2 777890 fire hazard warning decal 3 777335 kill switch/ wedge control decal 4 777891 hydraulic fluid warning decal 5 777892 moving/towing decal 6 305546 hot muffler decal 7 777335 lift and split control decal 8 7778...

Safety label locations 6 pn 777335 pn 777335 pn 777891 ©2005 northern tool + equipment co. 1-800-270-0810 escaping high pressure hydraulic fluid hazard high fluid pressures and temperatures are developed in the hydraulic system. Hydraulic fluid escaping through even a pin-size hole opening can punct...

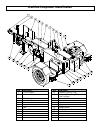

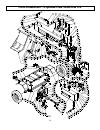

Machine component identification 7 ref description ref description 1 2" ball coupler 13 hydraulic tank fill cap 2 jack 14 hydraulic temp gauge/oil level indicator 3 4-way wedge 15 hydraulic tank 4 lift & split control 16 engine fuel tank 5 beam 17 light kit 6 log lifter 18 engine kill switch 7 ram 1...

Initial unpacking & set-up 8 important! Engine is shipped without oil. Do not start the engine before adding oil. Step one: add oil to engine add oil to the engine. Using a funnel, add sae 10w-30 oil up to the full mark on the dipstick. (see engine owner's manual for oil capacity and location of fil...

Connecting battery to engine 9 your log splitter's engine is equipped with an electric starter, which requires the installation of a 12-volt lawn tractor size battery (group u1-7). The battery should have a minimum rating of 18 amp-hour. The battery is to be supplied by the customer and should be in...

Moving and towing to the job site 10 warning the log splitter is heavy. It can crush and cause serious injury if it rolls out of control or tips over. Follow the instructions below for safely moving and towing the log splitter. Moving the log splitter 1. Lock log lift in up position raise the log li...

Moving and towing to the job site 11 5. Move log splitter to work site or tow hitch roll the splitter by hand either directly to chosen work site or to vehicle hitch for towing. (see instructions on p. 19 on selecting a work site.) important safety instructions: hills. Do not move the log splitter u...

Moving and towing to the job site 12 4. Lock log lift in up position secure log lift into the up (vertical) position using the travel pin. Locate the travel pin stored behind the crank jack and use it to secure the log lift in the vertical position. 5. Turn engine off turn engine off. Never move the...

Moving and towing to the job site 13 9. Put jack and tow bar leg up. To provide adequate ground clearance while towing, secure both the jack and tow bar leg in the "up" position. 10. Tow to desired location tow log splitter carefully to desired work site. (see instructions on pg.17 on selecting an a...

Before each use – step one inspection / maintenance 14 step one: inspect and maintain log splitter before each use. If the log splitter has been used previously, it must be inspected and maintained before each subsequent use. Warning always shut off the engine, disconnect the spark plug, and relieve...

Before each use – step one inspection / maintenance 15 ● stop the engine, disconnect the spark plug, and move all control valve handles back and forth to relieve pressure before changing or adjusting hydraulic system components such as hoses, tubing, fitting or other components. ● never check for le...

Before each use – step three work site selection & set-up 16 step two: fueling warning gasoline is highly flammable and explosive. You can be burned or seriously injured when handling fuel. Use extreme care when handling gasoline. 1. Engine off / cool the engine must be off and allowed to cool at le...

Before each use – step three work site selection & set-up 17 step three: work site selection and log splitter set-up. Warning it is important to select an appropriate work site and properly set up the log splitter in order to minimize the risk of slips and falls, equipment rolling or tipping over, c...

Splitting operation 18 warning before starting the log splitter, review the following instructions and safety information for safe operation. Failure to follow these rules may result in serious injury to the operator or bystanders from moving parts that crush, cut, or entangle; from flying objects, ...

Splitting operation 19 1. Put on protective clothing / gear wear the following protective clothing and safety gear. 1) eye protection. Always wear safety glasses or goggles when operating the machine. Pieces of log may fly out and serious eye injury can occur. 2) boots. Falling logs can crush feet. ...

Splitting operation 20 instructions for operating the power log lift: warning: crush hazard operator position. Stay in the designated operator position while operating log lift control. Second person. If a helper is assisting in loading logs to be split, do not actuate log lift control until the hel...

Splitting operation 21 warning: always keep hands and feet away from the ram, wedge, and partially split logs while loading, operating and unloading the log splitter. Important safety instructions: hold bark side. Hold the bark side of logs when loading or positioning, never the ends. Never place yo...

Splitting operation 22 7. Extend ram move split control lever toward wedge to extend ram and split log. Important safety instructions: operator position. Always operate the log splitter from the manufacturer's indicated operator position. (see diagram above.) other positions are unsafe because they ...

Splitting operation 23 1) retract ram fully. 2) turn engine off. 3) remove stuck log from the wedge manually with a pry bar or a sledgehammer. Important: be extremely careful as log pieces may fly off as they separate from the wedge. Make sure bystanders are clear and wear safety goggles. 4) do not ...

Storage 24 warning gasoline vapors can ignite and cause a fire. Select a well-ventilated storage area away from sources of heat, flame, or sparks. Follow the instructions below for storing your log splitter between uses. 1. Retract wedge retract the wedge completely to keep the rod protected from co...

Periodic maintenance 25 in addition to the maintenance performed with each use, periodic maintenance should also be performed according to the following schedule. Warning always shut off the engine, disconnect the spark plug, and relieve system pressure before cleaning, adjusting, or repairing the s...

Troubleshooting 26 warning before troubleshooting or attempting to service, read the following safety instructions to avoid serious injury to the operator or bystanders from moving parts that can crush or cut, burns, fire or explosion, or escaping high pressure hydraulic fluid. Important safety inst...

Specifications 27 maximum pressure ................... 3000 psi maximum flow ......................... 28 gpm hydraulic fluid capacity........... 28 gallons hydraulic fluid type………… 10 wt aw32, asle h-150, or iso32 coupler size…………………… 2" ball maximum towing speed……… 45 mph maximum log length .........

Parts breakdown – exploded view 11960 rev u.1 28.

Parts breakdown – exploded view 11960 rev u.1 29 item part# description qty item part# description qty 1 39164 3/4" npt x jic #12 elbow 4 53 38613 protective sleeve 2.5 ft. 2 82140 1/8"x 2" cotter pin 10 54 790391 hydraulic tank 1 3 38981 1-1/2 " x 7-3/4" pin 1 55 39188 suction strainer 1 4 82240 3/...

Summary of important safety information for operation 30 warning carefully read and make sure you understand the following safety information before using the log splitter. Improper use or maintenance of the log splitter can result in serious injury to the operator or bystanders from moving parts th...

Summary of important safety information for operation 31 safety during towing read instructions. Review towing safety instructions in your towing vehicle manual. Securely attached. Be sure the log splitter is securely attached to the towing vehicle before towing. Tires. Be sure tires are fully infla...

Summary of important safety information for operation 32 engine debris. Debris on a hot engine can be a fire hazard. With the engine off, clean debris and chaff from engine cylinder head, cylinder head fins, blower housing rotating screen, and muffler areas. Avoid contact with hot muffler. Other deb...

Summary of important safety information for operation 33 on skin / clothes. If gasoline is spilled on your skin or clothes, change clothes and wash skin immediately. Gasoline storage. Store gasoline in a cool, dry place in an ul approved, tightly sealed container. Safety in work site selection / set...

Summary of important safety information for operation 34 safety in loading, operating, and unloading square log ends. Logs that are not cut square can slide out while splitting and become a safety hazard or cause excessive force to log splitter components. Use a chainsaw to cut logs square on each e...

Summary of important safety information for operation 35 log stuck on wedge. A log can become stuck to the wedge if the wedge becomes embedded in the log and the log doesn't split and separate. This can happen if the log is too stringy or tough to split completely. If this happens, follow the direct...

36 this page has intentionally been left blank..

Limited warranty 37 dear valued customer: the northstar product you just purchased is built with the finest material and craftsmanship. Use this product properly and enjoy the benefits from its high performance. By purchasing a northstar product, you show a desire for quality and durability. Like al...

38 manufactured by northern tool + equipment co. 2800 southcross drive west p.O. Box 1499 burnsville, mn 55337-0499 made in the usa.