- DL manuals

- North Star

- Pressure Washer

- M157593E

- Owner's Manual

North Star M157593E Owner's Manual

M157593E

Owner's Manual

Instructions for Set-up, Operation, Maintenance & Storage

T

RAILER

M

OUNTED

,

H

OT

W

ATER

P

RESSURE

W

ASHER

–

4000

PSI

/

4

GPM

Portable Outdoor-Use Only

This pressure washer produces both cold and hot water high pressure spray. Cleaning chemicals may be

incorporated into the spray if desired. The pressure pump for this equipment is powered by a diesel

engine and the water is heated by a kerosene/fuel-oil fired, open flame burner.

WARNING – READ THIS MANUAL

READ and UNDERSTAND this Owner's Manual and the Engine Owner's Manual completely

before attempting to set up and use the pressure washer!

Failure to properly set up, operate, and

maintain this pressure washer could result in

serious injury or death

to operator or bystanders.

WARNING – SPECIAL HAZARDS

CO Poisoning

Exhaust from both the engine and burner contains carbon monoxide, a

poisonous gas that can cause carbon monoxide poisoning and possible

death if inhaled.

Skin/Eye Injury

High-pressure spray can cause serious skin or eye injury, including injection

injury if fluid pierces the skin. Injection injury can result in blood poisoning

and/or severe tissue damage.

Burns

Hot spray can scald and burn skin.

Hot surfaces of wand, engine and burner, as well as hot exhaust from

both the engine and burner can cause burns.

Slips/Falls

Spray discharge can cause puddles and slippery surfaces.

Spray-gun kickback can cause operator loss of balance and falls.

Flying Debris

High-pressure spray can cause surface damage and flying debris.

Fire/

Explosion

Engine and burner sparking can ignite fuel or other flammable liquids or

vapors in the vicinity.

Hot exhaust from engine and burner can ignite combustible materials.

Chemical Exposure

Cleaning chemical vapors or contact with skin may be hazardous.

Electric shock

Spray contact with electrical sources can cause electric shock.

Trailer tipover

Sudden stopping or turning while towing the pressure washer with a

filled water tank can result in driving instability and/or trailer tip over.

A summary of important safety information is provided at the end of the manual.

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar Product Support 1-800-270-0810

ITEM NUMBER: 157593

SERIAL NUMBER: _____________

®

Summary of M157593E

Page 1

M157593e owner's manual instructions for set-up, operation, maintenance & storage t railer m ounted , h ot w ater p ressure w asher – 4000 psi / 4 gpm portable outdoor-use only this pressure washer produces both cold and hot water high pressure spray. Cleaning chemicals may be incorporated into the ...

Page 2

Hazard signal word definitions equipment protection quick facts inspect upon delivery stop! Closely inspect to make sure no components are missing or damaged. See the "assembly and initial set-up" section for instructions on whom to contact to report missing or damaged parts. Fill with engine oil st...

Page 3

Table of contents 3 about your pressure washer ........................................................................................ 4 specifications .................................................................................................................... 5 component identification ......

Page 4: Read This Manual

About your pressure washer 4 thank you for purchasing a northstar hot water pressure washer! Your machine is designed for long life, dependability, and the top performance you demand. This pressure washer is designed to: 1) produce a high-pressure spray of heated or unheated water (up to 4 gallons p...

Page 5

Specifications 5 model model # 157593 flow output pressure rating 4000 psi flow rate 4 gpm maximum temperature 210 f dimensions / components length 142" width 76" height 61" weight 1460lbs. – dry 3400lbs. – water tank full pump type northstar nsrw4540 engine horsepower 18.8 hp high pressure discharg...

Page 6

Component identification 6 ref # description ref # description ref # description 1 pressure relief valve 10 ball valve (city tap water) 18 pressure switch 2 unloader 11 engine key switch 19 water outlet 3 inlet plumbing 12 water inlet (city tap water) (trailer models use hose reel) 20 heat switch 4 ...

Page 7: Reference Guide

Component identification 7 reference guide 1. Pressure relief valve valve that opens to relief pressure in the event of system over pressurization. 2. Unloader valve that regulates pressure and directs flow into bypass when trigger is closed. 3. Inlet plumbing means of connecting garden hose to pump...

Page 8: On-Product Warning Labels

Safety labeling 8 always make sure safety labels are in place and in good condition. If a safety label is missing or not legible, order new labels or unsafe operation could result. To order replacement safety labels , call northstar product support at 1-800-270-0810. On-product warning labels part n...

Page 9

Special equipment safety features 9 high pressure relief valve warning-if the high-pressure relief valve ever discharges water, turn the engine off and do not use the machine. The valve will no longer function properly. See a dealer or call product support at 1-800-270- 0810. This unit is equipped w...

Page 10

Assembly and initial set-up 10 steps for assembly / initial set-up step 1. Unpacking & delivery inspection step 2. Trailer assembly step 3. Initial pump & engine preparation step 4. Battery installation each of these steps is discussed in the below: step 1. Unpacking & delivery inspection find and s...

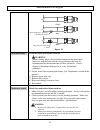

Page 11

Assembly and initial set-up 11 figure 3 – hardware bag contents 5/16 flat washer qty-8 part # 82099 1/2” flat washer qty-2 part # 82122 1/2” class g nut qty-3 part # 82291 1/2 x 5” bolt qty-1 part # 82119 1/2 x 4” bolt qty-2 part # 82250 5/8 x 1-1/2” bolt qty-4 part # 82251 5/8” class g nut qty-4 pa...

Page 12

Assembly and initial set-up 12 step 2. Trailer assembly warning: the pressure washer is heavy. It can crush and cause serious injury if it rolls out of control or tips over. Follow all assembly instructions exactly as presented below. 1.) remove the top and four sides of the steel crate. 2.) remove ...

Page 13

Assembly and initial set-up 13 step 2. Trailer assembly (continued) 14.) attach coupler to a-frame with two 1/2x4" bolts and class g lock nuts. Tighten each bolt to 90ft.-lbs. Use a torque wrench. 15.) attach safety cables to the a-frame with 1/2" x 5" bolt and class g lock nut. Place a flat washer ...

Page 14

Assembly and initial set-up 14 step 3. Initial pump & engine preparation prepare water pump verify pump oil level . Note: the pump is shipped with oil. 1. Verify that oil level is half way up the sight glass (or at the indicator line on the dip stick). 2. If oil level is low, fill using the type of ...

Page 15

Assembly and initial set-up 15 step 4. Battery installation install a 12-volt battery (group 22nf) with a minimum 55 amp-hour rating. The engine will run but the burner will not fire unless a battery is installed. The battery is to be supplied by the customer and should be installed in the protectiv...

Page 16

Moving and towing 16 warning the filled pressures washer is heavy. It can crush and cause serious injury if it rolls out of control or tips over. Always keep the jack cranked down to help balance the trailer when it is not connected to a vehicle hitch. Follow all the instructions below for safely co...

Page 17

Moving and towing 17 attach safety cables two safety cables must be used while towing . Cross safety cables under the coupler, allowing only enough slack for vehicle turns. Plug in lights plug light pin connector into vehicle . Raise the jack always crank the jack into the up position before towing....

Page 18

Before each use 18 follow the steps below prior to each use of the pressure washer. Steps to follow before each use step 1. Check equipment step 2. Add fuel(s) step 3. Select suitable worksite step 1. Check equipment check/add pump oil check/add pump oil . Caution: never run the pump without suffici...

Page 19

Before each use 19 never attempt to repair a high-pressure hose or component – always replace it with a part that is rated at or above the pressure rating of this machine. 1) check hoses, fittings, wand, trigger gun and connections for signs of wear, cracks, looseness, or leaks. Replace as required....

Page 20

Before each use 20 note: a running or still-hot engine or burner is hot enough to ignite fuel. 2) fill fuel tank outdoors – never indoors. Fuel vapors can ignite if they collect inside and enclosure and explosion can result. 3) stay away from all sources of heat, sparks, and flames. Do not smoke. 4)...

Page 21

Before each use 21 step 3. Select suitable outdoor worksite before using the pressure washer, you must understand the criteria for selecting a suitable location for operation. Note that this pressure washer is for outdoor use only. Warning : you must choose a suitable site for operating your pressur...

Page 22

Before each use 22 2. Away from combustible dust, liquids, or vapors do not locate and use the pressure washer in the presence of flammable vapors, dust, gases, or other potentially combustible materials. Burner is an open flame, which can ignite airborne dusts and flammable vapors. Operate only whe...

Page 23

Operation 23 after you have checked and fueled the equipment and positioned it in a suitable worksite, it is time to start your pressure washer. The following are the procedures necessary for safe, successful operation of your pressure washer. Warning carefully read and follow all instructions and s...

Page 24

Operation 24 connect your water supply if using tap water: follow these instructions when supplying water from a pressurized source such as city tap water: acquire a suitable garden hose and attach to the water supply: 1. Acquire a suitable garden hose: a. The water supply garden hose must have an i...

Page 25

Operation 25 if using water tank: follow these instructions when supplying water from the feed tank: 1. Ensure that you have the tank feed ball valve open, and the city tap water ball valve closed, as indicated in the diagram below. 2. Make sure the water in your tank is clean. Debris can cause exce...

Page 26

Operation 26 3. Release the collar, making sure it springs back and re-seats to its original (non-retracted) position. (figure 8b). Check the connection by pulling on the hose to ensure a positive connection. Figure 8b select spray nozzle your pressure washer is equipped with four high-pressure nozz...

Page 27

Operation 27 1. Make sure the engine is off and the hose line depressurized. 2. To install the nozzle, pull the collar back and twist the nozzle firmly into the coupler on the end of the wand. (figure 9a) figure 9a 3. Release the collar, making sure it springs back and re-seats to its original (non-...

Page 28

Operation 28 low pressure adhere better to the surface being cleaned, allowing the formula time to react and remove dirt more effectively. Note: an external chemical injector pump is not recommended for use with this pressure washer. Warning : chemical spraying never spray acids, corrosives, or abra...

Page 29

Operation 29 4. Submerge the suction strainer connected to the braided chemical hose into a bucket containing the chemical solution. See figure 10. Step 3. Spraying safety rules for operation before starting the pressure washer, review the following general safety rules for operation: conditions for...

Page 30

Operation 30 connections could fail and result in catastrophic high pressure release of fluid as well as hose whipping. Avoid sharp objects . Keep hose away from sharp objects. Bursting hoses may cause injury. No load bearing . Do not use the pump to support other items of equipment that impose unac...

Page 31

Operation 31 hoses, water supply, and nozzle"). Purge air from the water supply hose by squeezing the trigger until a steady stream of water flows out of the nozzle at low pressure. (air in the hoses can cause damage to the pump, so always make sure all the air is out of the hoses before starting th...

Page 32

Operation 32 water stream. 3. You can apply chemicals with either warm or cold water. Check chemical label. If warm water is specified, start burner according to instructions provided below. 4. Apply chemicals by squeezing the spray gun trigger. The chemical injector will draw the chemical into the ...

Page 33

Operation 33 "oil burner adjustment instructions" step in the "set-up" section of this manual. 5. When the trigger is released, a pressure switch automatically turns the burner off. Also, when the temperature setting is reached, the thermostat automatically turns the burner off. Warning : it is impo...

Page 34

Operation 34 pressure first and follow instructions for attaching a nozzle). 2. Clear the cleaning area of all persons. Keep children and pets away. 3. Hold the spray gun firmly with two hands and a sturdy stance -- gun kicks back when triggered. Caution : spray gun metal gets extremely hot when usi...

Page 35

Operation 35 9. If temporarily interrupting spraying, rotate trigger safety latch downward to the locked position to guard against accidental trigger release. 10. Always turn off the engine and activate spray gun trigger to relieve system pressure when: the sprayer is unattended, or disconnecting ho...

Page 36

Storage 36 storage when you are finished using the pressure washer, you must prepare the sprayer for storage and store it in a proper location. Note: o if you will be storing the sprayer in freezing conditions , follow the instructions for preparing the sprayer for storage in freezing conditions. O ...

Page 37

Storage 37 remove the spray gun from the hose. 3. Using a wrench, disconnect the plumbing that connects to the heating coil inlet. The water will flow out of the heating coil. This will protect the coil from freeze damage. 4. Open both water inlet ball valves and remove the cap from the water filter...

Page 38

Storage 38 prepare pressure washer for storage prepare the pressure washer for storage. 1. Disconnect the battery, remove it from the battery compartment, and store it indoors. 2. Make sure the engine start switch is off. 3. Disconnect the high-pressure hose, garden hose, and spray gun. Move pressur...

Page 39

Burner adjustment 39 oil burner adjustment (only needed if white exhaust smoke appears) the oil burner is preset and performance tested at the factory (elevation 1100 feet). Different altitudes may require a one-time initial burner adjustment. Caution: if white smoke appears from the burner exhaust ...

Page 40

Burner adjustment 40 5. Slowly open the air band until white smoke just starts to appear. 6. Turn air band halfway back to the black smoke position previously noted. Tighten the locking screw. 7. Now fine tune the burner air by adjusting the shutter: a. Locate the shutter as shown in figure 14 below...

Page 41

Maintenance & repair 41 inspect and maintain your pressure washer as specified below in order to keep it in safe and optimal working order. Follow all safety rules and recommended maintenance instructions. Warning always shut off water supply, bleed water pressure, turn off engine and disconnect the...

Page 42

Maintenance & repair 42 0810. Replacement parts . If a part needs replacement, only use factory approved repair parts. Replacement parts that do not meet specifications may result in a safety hazard or poor operation of the pressure washer and will void the warranty. Keep pressure washer clean keep ...

Page 43

Maintenance & repair 43 clean water filter clean the water filter before each use. Warning : when cleaning filters, check whether dangerous chemicals have been used with the filter and take any precautions that may be recommended by the manufacturer of these chemicals. Always dispose of hazardous fl...

Page 44

Maintenance & repair 44 recharge and maintain battery inspect, recharge, and maintain battery according to your battery manufacturer's instructions. Do not store with battery charger always connected. Batteries that are over- charged can boil themselves dry and produce excessive amounts of hydrogen,...

Page 45

Maintenance & repair 45 filter bowl water drain maintain burner's fuel filter/water separator drain water from burner's filter bowl as needed, and replace filter after every 500 hours of use or as needed. 1) after each use of the burner, visually check the filter bowl. If any water has accumulated, ...

Page 46

Maintenance & repair 46 6) run the pressure washer in cold mode for 1 to 3 hours, recirculating the cleaning solution. Caution: do not run the burner. 7) dispose of the cleaning solution where it is not harmful to animals or the environment. 8) flush with fresh water and clean the inlet strainer whe...

Page 47

Maintenance & repair 47 inspect electrodes inspect electrodes yearly and make adjustments as needed. 1) remove the 4 nuts that attach the burner to the heating chamber. You do not have to disconnect the fuel lines or the electric cords. Figure 20 2) pull the burner out from underneath the heat excha...

Page 48

Maintenance & repair 48 drive belt maintenance check drive belt tension after first 24 hours of running and then routinely with each oil change. Tighten or replace belts as needed . Always tighten belts if slipping. Warning: belt slippage can cause static electricity build-up, which may result in sp...

Page 49

Maintenance & repair 49 note to commercial users: all mechanical equipment, no matter how well designed, will need maintenance and repairs. A northstar pressure washer is no exception. At times, a northstar pressure washer may become inoperable because repairs are required. Northstar product support...

Page 50

Troubleshooting 50 any questions, comments, problems, or parts orders call northstar product support 1-800-270-0810 engine will not start causes solutions low oil shutdown fill engine with the adequate amount of oil. No fuel add diesel to diesel tank, bleed engine fuel line(see engine owner's manual...

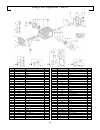

Page 51

Parts explosion m157593 – rev e 51.

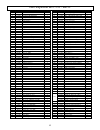

Page 52

Parts explosion m157593 – rev e 52 ref part # description qty ref part # description qty 1 787796 belt guard back plate 1 76 777723 quick couple nipple, 3/8" npt f 1 2 787794 belt guard cover 1 77 777904 quick coupler, 1/4" npt f 1 3 786485 northstar rw4540 pump 1 78 777396 hose, 50ft, includes #76 ...

Page 53

Parts explosion m157593 – rev e 53 ref part # description qty ref part # description qty 129 783427 hose reel 2 150 50csc128 3/4" –1/2" reducer 1 131 30198 200 gal tank 1 40 30048 1/2" – 3/8" reducer 1 132 777707 tank strap 2 50 777338 3/8" – 1/4" reducer 1 133 82080 eye bolt, 1/4" 4 60 777340 1/4" ...

Page 54

Pump parts explosion – rev e 54 ref part # description qty ref part # description qty 1 n/a screw 8 37 n/a washer 3 2 n/a plug 1 38 co0202002200 ceramic bushing 3 3 n/a pump manifold 1 39 n/a washer 3 4 n/a washer 1 40 n/a o-ring 3 5 n/a plug 1 41 n/a anti-extrusion ring 3 6 n/a washer 1 42 n/a pist...

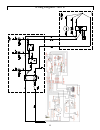

Page 55

Wiring diagram – rev e 55.

Page 56

Summary of important safety information 56 this section provides a summary of the various safety procedures and measures that have been presented throughout the manual. Keep this summary handy and refer to it to refresh your memory about how to safely use your pressure washer. Warning carefully read...

Page 57

Summary of important safety information 57 o when connecting the battery, connect the red cable to the positive terminal first. O when disconnecting the battery, disconnect the black cable from the negative terminal first acid/skin contact. If battery acid contacts skin or clothing, flush immediatel...

Page 58

Summary of important safety information 58 hitch trailer properly. Follow all instructions for hitching trailer to towing vehicle. Make sure hitched trailer sits level jack. Keep jack cranked down to help balance the trailer when it is not connected to a vehicle hitch. Crank jack up before towing. R...

Page 59

Summary of important safety information 59 check sprayer nozzle . Sprayer nozzle can become a projectile and cause serious personal injury or property damage if not properly connected to the spray gun. Check to ensure the nozzle has been properly attached to the spray gun before using the pressure w...

Page 60

Summary of important safety information 60 never pull by hose . Do not move this machine by pulling on the hose. Hose or connections could fail and result in catastrophic high-pressure release of fluid as well as hose whipping. Avoid sharp objects . Keep hose away from sharp objects. Bursting hoses ...

Page 61: Limited Warranty

Limited warranty 61 dear valued customer: the northstar product you just purchased is built with the finest material and craftsmanship. Use this product properly and enjoy the benefits from its high performance. By purchasing a northstar product, you show a desire for quality and durability. Like al...

Page 62

62 manufactured by northern tool + equipment co., inc. Burnsville, mn 55306 northerntool.Com ®.