7366546 (rev. B 1/24/18) systems tested and certified by the water quality association against csa b483.1. Systems tested and certified by nsf international against nsf/ansi standard 44 for hardness reduction and efficiency, and certified to nsf/ansi standard 372. In st al la tio n an d o pe ra tio ...

2 table of contents page specifications & performance claims . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

3 specifications & performance claims model nst30ed nst45ed1 nst70ed1 model code sr30 sr45 sr70 rated softening capacity (grains @ salt dose) 11,800 @ 2.3 lbs. 25,300 @ 7.4 lbs. 30,200 @ 12.5 lbs. 13,300 @ 2.6 lbs. 35,700 @ 9.9 lbs. 45,300 @ 17.2 lbs. 20,800 @ 4.1 lbs. 55,100 @ 15.2 lbs. 70,000 @ 26...

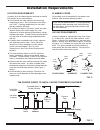

4 18" dia. 39" c 14" 3-3/4" o u tl e t in le t inlet - outlet a b fig. 1 dimensions in le t o ut le t inlet - outlet 18” dia. 39” a b c d = the water softener requires a minimum water flow of 3 gallons per minute at the inlet. Maximum allowable inlet water pressure is 125 psi. If your house water pr...

5 the proper order to install water treatment equipment fig. 3 pressure tank city water supply well water supply well pump or optional sediment filter water heater water softener untreated water to outside faucets hot water to house cold water to house location requirements consider all of the follo...

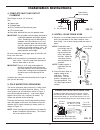

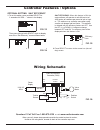

6 fig. 4 soft water hard water hard water to outside faucets crossover use if water supply flows from the left. Include single or 3-valve bypass. Main water p ipe hard water soft water to softener inlet from softener outlet 1” npt sweat adaptor (2) not included 1” npt installation adaptor (2) * o-ri...

7 1. Turn off water supply a . Close the main water supply valve near the well pump or water meter. B . Shut off the electric or fuel supply to the water heater. C . Open high and low faucets to drain all water from the house pipes. 2. Install bypass valve and/or plastic installation adaptors: a . I...

8 installation instructions 4. Complete inlet and outlet plumbing pipe fittings must be 3/4” minimum. Use: = copper pipe = threaded pipe = pex (crosslinked polyethylene) pipe = cpvc plastic pipe = other pipe approved for use with potable water important: do not solder with plumbing attached to insta...

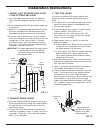

9 nozzle/ venturi ferrule nut brine valve tubing brinewell grommet hose adaptor to drain overflow drain hose brinewell cover brine tank resin tank fig. 13 8. Connect brine tubing a . Route the tubing attached to the brine valve assem- bly out of the brine tank through the hole provided in the tank s...

10 installation instructions 10. Add water and salt to the salt storage tank a . Using a container, add about three gallons of clean water into the salt storage tank. B . Add salt to the storage tank. Use nugget, pellet or coarse solar salts with less than 1% impurities. 11. Plug in the power supply...

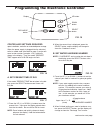

11 programming the electronic controller controller settings required upon installation, and after an extended power outage. When the power supply is plugged into the electrical outlet, a model code (see table on page 3) and a soft- ware version number (example: j3.9), are briefly shown in the displ...

12 optional recharge controls sometimes a manually initiated regeneration (re - charge) may be desired or needed. Two examples: = you have used more water than usual (guests, extra washing, etc.) and you may run out of soft water before the next scheduled regeneration. = you did not refill the stora...

13 optional setting: salt efficiency 1. To set this option, press and hold select for 3 seconds until “000 - -” shows in the display. Then press (do not hold) select again to display one of the “salt efficiency” screens shown below. Salt efficiency: when this feature is on, the water softener will o...

14 fig. 27 broom handle pencil mark 1” - 2” salt salt bridge water level push tool into salt bridge to break fig. 28 cap o-ring seal screen support screen gasket *flow plug (hvdc) housing ferrule nut cone screen *flow plug *install with lettered side up, concave side down. Cleaning the nozzle & vent...

15 troubleshooting guide problem cause correction no soft water no salt in the storage tank. Add salt and then initiate a “recharge now”. Salt is “bridged” (a layer of salt in the salt storage tank has hardened). Break salt bridge, as described on the previous page, and then initiate a “recharge now...

16 troubleshooting automatic electronic diagnostics the electronic controller has a self-diagnostic function for the electrical system (except input power and water meter). The computer monitors the electronic components and circuits for correct operation. If a malfunction occurs, an error code appe...

17 fig. 33 this check verifies proper operation of the valve motor, brine tank fill, brine draw, regeneration flow rates, and other controller functions. Always make the initial checks, and the manual initiated diagnos- tics. Note: the electronic control display must show a steady time (not flashing...

18 softener exploded view (all models) valve assembly see pages 20-23 for parts 5 6 7 8 9 10 11 13 12 4 3 2 18 17 19 27 25 20 21 22 23 26 24 15 16 1 14.

19 key no. Part no. Description 1 7351054 power supply, 24v dc 2 7309358 repl.Electronic control board (pwa) 3 7180291 faceplate cover, nst30ed (also order following decal) 7260554 faceplate cover, nst45ed1 & nst70ed1 (also order following decal) ¢ 7267344 faceplate decal, nst30ed 7366083 faceplate ...

20 valve exploded view (nst30ed) 50 51 52 54 53 55 56 57 58 59 60 61 62 63 64 65 66 68 67 69 70 71 wear strip seal cross-section view 74 72 73 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 91 96.

21 valve parts list (nst30ed) key no. Part no. Description 50 7070412 screw, #4-24 x 1-1/8”, flat head 51 7325702 spacer, motor mount 52 7030713 switch 53 7342657 screw, #10-14 x 2”, pack of 5 – 7331266 valve cover assembly (includes key nos. 54 & 55) 54 á expansion pin 55 á valve cover 56 7082087 w...

22 valve exploded view (nst45ed1 & nst70ed1) wear strip seal cross-section view 100 101 102 103 104 105 106 107 108 109 110 111 112 117 118 140 113 114 115 119 120 116 127 121 145 123 121 122 123 124 125 126 128 129 131 130 132 133 134 135 136 137 138 139 141 142 143 144.

23 valve parts list (nst45ed1 & nst70ed1) key no. Part no. Description 100 7224087 screw, #8-32 x 1” (2 req.) 101 7286039 motor (incl. 2 ea. Of key no. 100) 102 7231393 motor plate 103 0900857 screw, #6-20 x 3/8” (3 req.) 104 7171250 bearing 105 7283489 cam & gear – 7331169 drain hose adaptor kit, n...