- DL manuals

- Northern Heatpump

- Heat Pump

- NorthStar RD-WE-096

- Installation & Operating Instructions Manual

Northern Heatpump NorthStar RD-WE-096 Installation & Operating Instructions Manual

09/11/2014

NI701

Water to Water Geothermal Heat Pump

Installation & Operating Instructions

Model: RA-WE* (Single Compressor)

RD-WE* (Dual Compressor)

Application

Geo source loop or ground water fluid

Load water heat/cool output

Low temperature, radiant floor heating

Air handler larger water coil, heat/cool

Tested to UL Standards 1995 and CSA Standards C22.2

3-Phase Models

Also see and use NI704

Domestic Water Heater, Desuperheater

Energy Star promotes the desuperheater; however, it

only efficiently produces hot water if the tank

temperature is less than 115° F (46° C). A hot water

buffer tank is suggested for proper and efficient

application, see page 19.

Drawings:

NR701, NR705, NR706, UAW701, UAW705, XX029

DO NOT DESTROY THIS MANUAL. PLEASE READ CAREFULLY AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE BY A SERVICE TECHNICIAN.

Northern Geo LLC

75 West Veum

Appleton, MN 56208

320-297-9100

www.northernheatpump.com info@northerngeo.com

Summary of NorthStar RD-WE-096

Page 1

09/11/2014 ni701 water to water geothermal heat pump installation & operating instructions model: ra-we* (single compressor) rd-we* (dual compressor) application geo source loop or ground water fluid load water heat/cool output low temperature, radiant floor heating air handler larger water coil, he...

Page 2

09/11/2014 ni701 table of contents introduction 1 product configurator (nc028) 2 mechanical specifications 3 single compressor 3 dual compressor 4 electrical data 5 single compressor 5 dual compressor 5 product dimensions 6 installation requirements 9 mechanical installation overview 10 mechanical i...

Page 3

09/11/2014 1 ni701 introduction when used and controlled properly, geothermal heat pumps can save hundreds of dollars per year. Northstar series geothermal heat pumps are designed to provide maximum efficiency, comfort, and reliability. Solid and simple electric controls allow for low maintenance an...

Page 4

09/11/2014 2 ni701.

Page 5

08/19/2014 3 ni701 ra-we – mechanical specifications – r410a single stage compressor model ra-we-036 (3 ton) ra-we-050 (4 ton) ra-we-060 (5 ton) ra-we-072 (6 ton) source & load gpm – heating 12 16 15 18 source & load gpm – cooling 12 16 15 20 factory charge r410a 3 lbs. 14 oz. 4 lbs. 8 oz. 6 lbs. 6 ...

Page 6

08/19/2014 4 ni701 rd-we – mechanical specifications – r410a dual compressor model rd-we-096 (8 ton) rd-we-120 (10 ton) rd-we-144 (12 ton) source & load gpm – heating 16 20 24 source & load gpm – cooling 16 20 24 factory charge r410a* 4 lbs. 2 oz. X (2*) 4 lbs. 2 oz. X (2*) 4 lbs. 2 oz. X (2*) sourc...

Page 7

08/19/2014 5 ni701 ra-we – electrical data – single phase model voltage compressor load pump desup. Pump source pump total min. Max. Fuse/ hacr (60 hz) rla lra fla fla fla fla ampac. Ra-we-036 208/230-1 17.9 112 1.8 .15 4.4 24.3 28.7 40 ra-we-050 208/230-1 26.4 134 1.8 .15 4.4 33.3 39.2 60 ra-we-060...

Page 8

08/19/2014 6 ni701 product dimensions – ra-we-036 & ra-we-050

Page 9

08/19/2014 7 ni701 product dimensions – ra-we-060 & ra-we-072.

Page 10

08/19/2014 8 ni701 product dimensions – rd-we.

Page 11

08/19/2014 9 ni701 installation requirements 1. All installation work must be performed by trained, qualified contractors or technicians. Northern heat pump, sponsors installation and service schools to assist the installer. Visit our website at www.Northernheatpump.Com for upcoming service schools....

Page 12

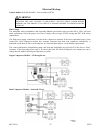

08/19/2014 10 ni701 figure 1 horizontal closed loop mechanical installation overview this northstar series unit cannot heat or cool energy by itself. Heat pumps use the fluid in the source loop as the energy source. Thus the design and installation of the source fluid system may be the most importan...

Page 13

08/19/2014 11 ni701 mechanical installation source water warning loop design is extremely important for proper heat pump operation. Incorrect loop design will reduce heat pump efficiency, cause poor performance or may render the system unusable. Contact an igshpa or cgc certified geothermal loop con...

Page 14

08/19/2014 12 ni701 figure 3 p/t adapter pressure/temperature (p/t) plugs – should be installed in the adaptor elbow on the entering and leaving water line of the heat pump on a closed system. (figures 3 and 4) a thermometer can be inserted into the p/t ports to check entering and leaving water temp...

Page 15

08/19/2014 13 ni701 figure 4 – pressurized closed loop with flow center – typical piping arrangement.* figure 5 – non-pressurized closed loop with flow center – typical piping diagram.* *4-ton model shown, for water connection locations on other models reference product dimension pages..

Page 16

08/19/2014 14 ni701 to earth loop from earth loop from flush cart to flush cart step 3 from heat pump to heat pump step 5 to flush cart from flush cart from heat pump to heat pump to earth loop from earth loop step 6b from heat pump to heat pump step 6a from flush cart pressurize loop flushing and f...

Page 17

08/19/2014 15 ni701 step 10 using a single water pressure gauge, measure the pressure drop at the pressure/temperature plugs across the heat pump heat exchanger. Compare the measurement with the flow versus the pressure drop table (table#3) and determine the actual flow rate. If the flow rate is low...

Page 18

08/19/2014 16 ni701 open loop/well – an open system gets its name from the open discharge of water after it has been used by the heat pump. A well must be available that can supply all of the water requirements of the heat pump along with any other water requirements drawing off that same well. The ...

Page 19

08/19/2014 17 ni701 figure 6: open loop well – typical piping diagram. Rd-we series, freeze protection – this heat pump is equipped with freeze protection temperature sensors used to monitor source side entering water temperature and load side leaving water temperature. The sensors are connected to ...

Page 20

08/19/2014 18 ni701 desuperheater, domestic hot water general all nhp series units can be equipped with a desuperheater and an integrated circulating pump that can provide supplemental domestic hot water (sdw). This is done by stripping heat from the superheated gas leaving the compressor. Fuses – 3...

Page 21

08/19/2014 19 ni701 figure 7 – desuperheater piping, buffer tank* this arrangement is the most effective and efficient and the recommended installation. The buffer tank need not be as big as the standard water heater; 40-gallon size can be very effective. With this two tank system the desuperheater ...

Page 22

08/19/2014 20 ni701 hydronic (load), space water heating, installation plumbing the geo unit load circuit is basically a heat exchanger with piping ports for out and in flow. There are no pumps within the unit. Use standard water heating loop parts/components and piping/plumbing best practices as if...

Page 23

08/19/2014 21 ni701 buffer tank controller – hp-btc or hp-btc-24 this add-on optional electro industries controller is suggested to improve and easily take care of the buffer tank, up to 6 zone pumps/valves, 4-wire stat for cooling, cooling fan coil pump, etc. In addition, a major feature of this co...

Page 24

08/19/2014 22 ni701 electrical hookup 3-phase models (both 208 and 480) – also see and use ni704. Warning disconnect all electrical power before electrically connecting or servicing the unit. Failure to disconnect the electrical power before working on this product can create a hazard leading to per...

Page 25

08/19/2014 23 ni701 disconnect – field provided external safety disconnect is required, see nameplate max amps. Grounding – route and install the proper size ground conductor between the ground lug above the compressor contactor and the building service entrance panel ground bus. This must be a cond...

Page 26

08/19/2014 24 ni701 operation indicators external monitor lights the two monitor lights indicate control power and/or fault indicator. Icm board – the icm board performs the functions controlling the compressor operation: system lockout, compressor anti-short cycle, and a five minute delay after pow...

Page 27

08/19/2014 25 ni701 causing it to lockout the compressor(s). If the icm board shows a low pressure fault code and the low pressure switch is closed. Check the two leds on the freeze protection board. Setup – this control contains a jumper peg that configures the sensors to operate either at open loo...

Page 28

08/19/2014 26 ni701 troubleshooting guide for water to water geo “heating” head pressure subcool suction pressure superheat compressor amp draw load temp differential source temp differential undercharged system low low low high low low low overcharged system high high high low high high high low lo...

Page 29

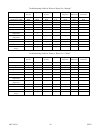

08/19/2014 27 ni701 unit operating conditions – heat model stage source temp source temp Δ source gpm load temp Δ load gpm total amps 240 discharge pressure discharge temp sub cool at txv suction pressure at bulb suction temp at bulb super- heat at bulb n/a 32 2.3-4.3 8 4.4-6.4 8.0 10.4-11.4 397-417...

Page 30

08/19/2014 28 ni701 unit operating conditions – cool model stage source temp source temp Δ source gpm load temp Δ load gpm total amps (240) discharge pressure discharge temp sub cool at txv suction pressure at bulb suction temp at bulb super- heat at bulb n/a 50 7.1-9.1 8 6.1-8.1 8 4.0-5.0 183-203 9...

Page 31

08/19/2014 29 ni701 preventive maintenance source coil maintenance –in closed loop systems, water coil maintenance is generally not needed. However, if a dirty installation or deterioration of the piping has caused debris to accumulate in the system, the water coil should be cleaned using standard c...

Page 32

08/19/2014 30 ni701 accessories/options part number fault/alarm external annunciator r-al-fd-1 fuse – source loop pump, 10a ufuse1799 fuse – desuperheater pump, 3a ufuse1796 nhp digital 4-wire thermostat (pre-programmed) 5021 open loop, freeze limit, 39° f (4° c), pipe mounted 6047 sound vibration p...

Page 33

08/19/2014 31 ni701.

Page 34

08/19/2014 32 ni701.

Page 35

08/19/2014 33 ni701.

Page 36

08/19/2014 34 ni701.

Page 37

08/19/2014 35 ni701.

Page 38

08/19/2014 36 ni701.

Page 39

08/19/2014 37 ni701.

Page 40

08/19/2014 38 ni701.

Page 41

08/19/2014 39 ni701.

Page 42

08/19/2014 40 ni701.