- DL manuals

- Northern Heatpump

- Heat Pump

- RT-SE*

- Installation & Operating Instructions Manual

Northern Heatpump RT-SE* Installation & Operating Instructions Manual

09/29/2010

NI501

Two-Stage Split Geothermal Heat Pump

Installation & Operating Instructions

Model: (RT-SE*)

Application

Retrofit existing forced air installations.

Dual Heat – combine this geothermal unit and A-coil with stand-by gas or oil furnace.

LMC (Load management control) ready.

Information

The air coil furnished with this product has been tested and

certified with this unit. To maintain the specification

performance and product certification, the air coil shipped with

this unit must be used.

This unit is NOT tax credit eligible when a coil other than the

furnished coil is used.

For proper performance, the CFM airflow required in the

specification table must be provided by the installed furnace

blower/air handler.

Since this product requires line sets and air coil installation, an

experienced and licensed refrigeration technician is required.

Domestic Water Heater, Desuperheater

Energy Star promotes the desuperheater and it is standard with this series. However, it only efficiently

produces hot water if the tank temperature is less than 115° F (46° C). Thus, for proper and efficient

application a hot water buffer tank is suggested, see page 17.

Note

The EZGEO control board has a configuration mode dial switch. This must be correctly set during

installation, see EZGEO Controller (HC112) and Field Setup sections.

Drawings:

EC001, HC112, NH501, NR501, NS501, XX029

DO NOT DESTROY THIS MANUAL. PLEASE READ CAREFULLY AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE BY A SERVICE TECHNICIAN.

Summary of RT-SE*

Page 1

09/29/2010 ni501 two-stage split geothermal heat pump installation & operating instructions model: (rt-se*) application retrofit existing forced air installations. dual heat – combine this geothermal unit and a-coil with stand-by gas or oil furnace. lmc (load management control) ready. Informa...

Page 2: Table of Contents

09/29/2010 ni501 table of contents introduction 1 product configurator (nc029) 2 mechanical specifications 3 electrical data 4 product dimensions 5 installation requirements 6 mechanical installation overview 7 mechanical installation source water 9 flushing and filling procedure 11 desuperheater, d...

Page 3

09/29/2010 1 ni501 introduction when used and controlled properly, geothermal heat pumps can save hundreds of dollars in heating and cooling costs per year. Northern heat pump northstar series geothermal heat pumps are designed to provide maximum efficiency, comfort, and reliability. Solid and simpl...

Page 4: Rt-Se-052-1-Cxdx1-Xx-Us

09/17/2010 nc029 northern heat pump configurator rt-se-052-1-cxdx1-xx-us geo source (1) unit type (2) t = two stage unit style (3) s = split refrigerant (4) e = r-410a nominal btu (5, 6, 7) 020 = 1.5-ton 026 = 2.0-ton 033 = 2.5-ton 040 = 3.0-ton 045 = 3.5-ton 052 = 4.0-ton 062 = 5.0-ton country of o...

Page 5

09/29/2010 3 ni501 mechanical specifications – r410a two-stage compressor model rt-se-020 (1.5 ton) rt-se-026 (2 ton) rt-se-033 (2.5 ton) rt-se-040 (3 ton) rt-se-052 (4 ton) rt-se-062 (5 ton) coax & piping water volume – gal .43 .43 .65 .65 1.1 1.1 internal pressure drop (feet) 6.2 6.2 4.2 5.5 6.2 8...

Page 6

09/29/2010 4 ni501 electrical data – single phase voltage compressor desup. Pump loop pump (ext) total min. Model (60 hz) rla lra fla fla fla ampac. Max. Fuse/ hacr 020 208/230-1 10.3 52 .15 4.4 14.9 17.4 30 026 208/230-1 14.1 70 .15 4.4 18.7 22.2 40 033 208/230-1 16.7 82 .15 4.4 21.3 25.4 50 040 20...

Page 7

09/29/2010 5 ni501 product dimensions.

Page 8

09/29/2010 6 ni501 installation requirements 1. All installation work must be performed by trained, qualified contractors or technicians. Northern heat pump, sponsors installation and service schools to assist the installer. Visit our website at www.Electromn.Com for upcoming service schools. Warnin...

Page 9

09/29/2010 7 ni501 mechanical installation overview this nhp series unit cannot produce airflow and cannot correct airflow problems inherent within the existing furnace system. The following items should be carefully considered and properly followed for all installations: examination of the existing...

Page 10

09/29/2010 8 ni501 figure 1 horizontal closed loop the number of “6 inch rounds”. The same would apply to cold air return duct capacity. D. Calculated cfm - by measuring the temperature rise across the existing furnace, the cfm can be approximated. The accuracy of this formula will depend upon the e...

Page 11

09/29/2010 9 ni501 figure 3 p/t adapter mechanical installation source water warning loop design is extremely important for proper heat pump operation. Incorrect loop design will reduce heat pump efficiency, cause poor performance or may render the system unusable. Contact an igshpa or cgc certified...

Page 12

09/29/2010 10 ni501 figure 4 – pressurized closed loop with flow center – typical piping arrangement. Figure 5 – non-pressurized closed loop with flow center – typical piping diagram..

Page 13

09/29/2010 11 ni501 to earth loop from earth loop from flush cart to flush cart step 3 from heat pump to heat pump step 5 to flush cart from flush cart from heat pump to heat pump to earth loop from earth loop step 6b from heat pump to heat pump step 6a from flush cart pressurize loop flushing and f...

Page 14

09/29/2010 12 ni501 using a single water pressure gauge, measure the pressure drop at the pressure/temperature plugs across the heat pump heat exchanger. Compare the measurement with the flow versus the pressure drop table (table#3) and determine the actual flow rate. If the flow rate is low, rechec...

Page 15

09/29/2010 13 ni501 open loop well to well – an open system gets its name from the open discharge of water after it has been used by the heat pump. A well must be available that can supply all of the water requirements of the heat pump along with any other water requirements drawing off that same we...

Page 16

09/29/2010 14 ni501 figure 6: open loop well to well – typical piping diagram. Open loop freeze protection switch – heat pump installations on open loop systems, using a non-antifreeze protected water source during the heating mode require the use of a water coil freeze protection switch. If the wat...

Page 17

09/29/2010 15 ni501 depending on the specific water quality issue, the water coil can be cleaned by the following methods: chlorine cleaning (bacterial growth) 1. Turn thermostat to “off” position. 2. Connect a circulating pump to hose bibs on entering water and leaving waterside of heat exchanger. ...

Page 18

09/29/2010 16 ni501 desuperheater, domestic hot water general all nhp series units are equipped with a desuperheater and an integrated circulating pump (can be a price deduct) that can provide supplemental domestic hot water (sdw). This is done by stripping heat from the superheated gas leaving the ...

Page 19

09/29/2010 17 ni501 figure 7 – desuperheater piping, buffer tank this is the most effective and efficient arrangement and the recommended installation. The buffer tank need not be as big as the standard water heater; 40- gallon size can be very effective. With this two tank system the desuperheater ...

Page 20

09/29/2010 18 ni501 duct system an air filter must always be installed upstream of the air coil on the return air side of the air handler or furnace. If there is limited access to the filter rack for normal maintenance, it is suggested that a return air filter grill be installed. Be sure that the re...

Page 21

09/29/2010 19 ni501 mechanical installation refrigeration overview the nhp series split unit includes pre-charged r-410a, with the filter drier factory installed in the unit. The charge will have to be fine tuned based upon line set length and system performance. Line set lengths of over 25ft (7.6 m...

Page 22

09/29/2010 20 ni501 line set size information 10 feet 20 feet 30 feet model suction liquid suction liquid suction liquid 020 ¾” ⅜” ¾” ⅜” ¾” ⅜” 026 ¾” ⅜” ¾” ⅜” ¾” ⅜” 033 ¾” ⅜” ¾” ⅜” ¾” ⅜” 040 ¾” ⅜” ¾” ⅜” ¾” ⅜” 052 ⅞” ⅜” ⅞” ⅜” ⅞” ⅜” 062 ⅞” ⅜” ⅞” ½” ⅞” ½” see specification chart, page 3, or unit namepl...

Page 23

09/29/2010 21 ni501 condensate drain typical condensate drain installation, shown below. The droop in the internal hose should be considered when planning the drain installation. If there is no nearby floor drain, a condensate drain pump must be used. See accessory parts list in the back of this man...

Page 24

09/29/2010 22 ni501 charging the system – after purging and evacuating the line set, fully open the service valves counterclockwise. Add the previously calculated r-410a(liquid) into the liquid line service port. Never add liquidrefrigerant into the suction side of a compressor. Start the unit and m...

Page 25

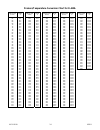

09/29/2010 23 ni501 determining subcooling 1. Measure the temperature of the liquid line on the small refrigerant line (liquid line) feeding the air coil cabinet. 2. Measure the liquid line pressure by attaching refrigerant gauges to the schrader connection on the liquid line service valve. 3. Conve...

Page 26

09/29/2010 24 ni501 pressure/temperature conversion chart for r-410a pressure (psig) temp °f pressure (psig) temp °f pressure (psig) temp °f pressure (psig) temp °f pressure (psig) temp °f 60 62 64 66 68 70 72 74 76 78 80 82 84 86 88 90 92 94 96 98 100 102 104 106 108 110 112 114 116 118 120 122 124...

Page 27

09/29/2010 25 ni501 electrical hookup warning disconnect all electrical power before electrically connecting or servicing the unit. Failure to disconnect the electrical power before working on this product can create a hazard leading to personal injury or death. Line voltage the nameplate and/or ins...

Page 28

09/29/2010 26 ni501 ezgeo controller ezgeo features review attached hc112 helps document which lists the various characteristics and capability of this controller product. Application the ezgeo controller is standard on all northern heat pump models. Even more specific, this model factory default is...

Page 29

09/29/2010 27 ni501 utility load control bottom 2-screw terminal block marked blue and blu/wht. Remove the jumper and extend the two wires to the utility furnished control device. For electric energy operation (off-peak) the two blue wires represent contact closure as shipped. Do not apply external ...

Page 30

09/29/2010 28 ni501 visual example only – the exact connections will depend upon operating mode. The st air supply temperature probe pictured above is not standard equipment on the split unit.. Review previous section – ezgeo controller..

Page 31

09/29/2010 29 ni501 temperature sensors duct sensor (st) – install in the warm air plenum at least 12” (31 cm) above heat pump a-coil. Locate to one side so the air coming through the a-coil passes over the sensor tip. The st sensor does not have an end cap; the small black electronic part just with...

Page 32

09/29/2010 30 ni501 gas furnace hookup – mode d see hookup drawing nh501, the gas furnace wiring is at the ezgeo board bottom left terminal block. Gas furnace (or oil with fan center terminal wiring strip) the control board lower left 6 terminal screw points are used for the furnace interface. Howev...

Page 33

09/29/2010 31 ni501 additional hookup or special system equipment concerns additional room thermostat connection points on the ezgeo board, upper left, are three optional control tabs – w2, e-gas, and y2. These can be used for troubleshooting or emergency full output energy or with a conventional 2h...

Page 34

09/29/2010 32 ni501 field setup or programming it is extremely important the installer properly goes through this section and sets up the various switches to match the installation. Again, refer back to ezgeo controller section for further details on these setups. Warning: power-down reset required ...

Page 35

09/29/2010 33 ni501 switchover temperature (sw over) this switch is shipped from the factory with a square “gas” label. This label should be removed only if a secondary furnace is present and active in the system. The installer should remove the label and adjust this switch only after reading this m...

Page 36

09/29/2010 34 ni501 operation indicators front panel led’s - hi-limit – when the aux el hi-limit probe (automatic reset or manual reset) opens this top red led is on. The electric elements will be interrupted via a safety relay circuit whenever this hl led is illuminated (mode b only). - pwr on – in...

Page 37

09/29/2010 35 ni501 power on, startup before applying power to the heat pump, check the following items: 1. Water supply plumbing to the heat pump is complete and operational. 2. Low voltage wiring of the thermostat and any additional control wiring is complete. 3. Set thermostat to the off position...

Page 38

09/29/2010 36 ni501 operational tips icm board – the icm board performs the functions controlling the compressor operation: system lockout, compressor anti-short cycle, and a five minute delay after power is applied. The control will begin the 5-minute time delay upon a y call from the thermostat. A...

Page 39

09/29/2010 37 ni501 troubleshooting – ezgeo control comment – split, mode d, does not required st sensor. Certain items below only relate to modes b and c. Sensor temperature calibration – both remote sensors are digital electronic and factory calibrated. Normally these do not require field calibrat...

Page 40

09/29/2010 38 ni501 alarm/fault active the status led and alarm output continue until power-off reset. The ezgeo system will attempt to maintain room temperature or prevent freeze-up. - mode a – by definition, no backup, at each roomstat w cycle, compressor will retry. - modes b, c, d – with gas fur...

Page 41

09/29/2010 39 ni501 troubleshooting – general problem possible cause possible solution tripped breaker/blown fuse reset circuit or replace fuse. Always check and use correct size blown controller fuse replace controller fuse. Replace with correct fuse. Low voltage supply contact local power company ...

Page 42

09/29/2010 40 ni501 thermostat improper thermostat location (e.G. Near kitchen). Anticipator should be 1.0 or 1.2 compressor overload defective compressor overload, check and replace if necessary. If the compressor is running hot, it may be due to insufficient refrigerant charge. Blow fuse replace c...

Page 43

09/29/2010 41 ni501 reversing valve does not shift defective solenoid valve not energizing. Replace coil on valve. Reversing valve does not shift, valve is stuck the solenoid valve is de-energized due to incorrect wiring at the unit or thermostat. Replace if valve is tight or frozen and will not mov...

Page 44

09/29/2010 42 ni501 accessories/options part number fault/alarm external annunciator r-al-rs-1 fuse – source loop pump, 10a ufuse1799 fuse – desuperheater pump, 3a ufuse1796 open loop, freeze limit, 39° f (4° c), pipe mounted 6047 sound vibration pad r-pad-2735-1.

Page 45: Electro-Helps Xiii

Electro-helps xiii.

Page 47

09/17/2010 1 hc112 helps – ezgeo controller all functions and definitions will apply to all nhp models, see appropriate model or type. Use installation manual to determine which part of this helps document applies. This electro industries’ exclusive controller provides several installer and user-fri...

Page 48

09/17/2010 2 hc112 heat/cool sequence – reference the figures 1, 2, 3, 4 function sequence charts. These are selected or used based upon the application or setup mode (mode dial switch, back of ezgeo board, see above). Added information for the column headings: stats – represents the 4-wire stat w...

Page 49

09/17/2010 3 hc112 sot time dial switch – this is a 4-position rotary switch which begins counting time with each stat w (heat) or each stat y (cool) input. Depending upon the dial switch setting (chart in installation manual, field setup section) action results after the selected minutes have elaps...

Page 50

09/17/2010 4 hc112 mode a – nhp geo, function sequence, figure 1 sot heat pump blower aux el stat ot start end sb off y1 y2 g y1 y2 stg 1 stg 2-4 gas w sw over alarm el led 1 w > 20 + n/a 2 w + + 3 w 5-20 + + 4 w + + 5 w 5 + + 6 w + + 7 8 w fault t + fault p 9 w t st p 10 11 12 13 14...

Page 51

09/17/2010 5 hc112 mode b – nhp geo, function sequence, figure 2 sot heat pump blower aux el stat ot start end sb off y1 y2 g y1 y2 stg 1 stg 2-4 gas w sw over alarm el led 1 w > 20 + 2 w + + 3 w 5-20 + + 4 w + + 5 w 5 + + Ø 6 w + + Ø 7 w t off 8 9 w lmc t off 10 w fault + + Ø ...

Page 52

09/17/2010 6 hc112 mode c – nhp geo, function sequence, figure 3 sot heat pump blower aux el stat ot start end sb off y1 y2 g y1 y2 stg 1 stg 2-4 gas w sw over alarm el led 1 w > 20 + 2 w + + 3 w 5-20 + + 4 w + + 5 w 5 + + 6 w t off 7 8 w t off 9 w lmc t off 10 w fault + fault p 11 w...

Page 53

09/17/2010 7 hc112 mode d – nhp geo, function sequence, figure 4 sot heat pump blower aux el stat ot start end sb off y1 y2 g y1 y2 stg 1 stg 2-4 gas w sw over alarm el led 1 w > 20 2 w 3 w 5-20 4 w 5 w 5 6 w t off 7 8 w t off 9 w lmc t off 10 w fault t + fault p 11 12 13 14 15 y 80 16 y 1...

Page 56

Txv-c p p p p geo loop field 7/8 1/2 7/8 1/2 txv-h 1/2 lwt ewt air coil comp f/d pt-1 ll pt-2 hl loop- coil sdw- coil dw-rt dw-st rv - - - - - - - - - - - line set - - - - - - - - - - - - - line set - - - bv bv fl bl pt-1a rec t-3 name comp compressor hl pressure high limit ll pressure low limit pt ...

Page 57

Txv-c p p p p geo loop field 7/8 1/2 7/8 1/2 txv-h 1/2 lwt ewt air coil comp f/d pt-1 ll pt-2 hl loop- coil sdw- coil dw-rt dw-st rv - - - - - - - - - - - line set - - - - - - - - - - - - - line set - - - bv bv fl bl pt-1a rec t-3 name comp compressor hl pressure high limit ll pressure low limit pt ...

Page 60: Limited Product Warranty

Page 1 of 2 xx029 northern heat pump residential limited product warranty effective november 1, 2009 northern heat pump, ltd. Warrants to the original owner, at the original installation site, for a period of three (3) years from date of original purchase, that the product and product parts manufact...

Page 61

Page 2 of 2 xx029 conditions and limitations: 1. This warranty is limited to residential, single family dwelling installations only. Any commercial or multi-unit dwelling installations fall under the northern heat pump commercial limited product warranty. 2. Northern heat pump, ltd. Shall not be lia...