- DL manuals

- Northern Industrial

- Garbage Disposal

- JPC-80

- User Instruction Manual

Northern Industrial JPC-80 User Instruction Manual

Summary of JPC-80

Page 1

0 user’s instruction manual for plate compactor model: jpc-80

Page 2

1 the purpose of this user’s instruction manual is to provide safety information and operating instructions in order to protect the user from exposed danger. For your own safety, please read the safety instructions and operating instructions described in this manual thoroughly before use. The inform...

Page 3

2 table of contents page 1. Safety information 3 2. Precautions 3 3. Warnings 3 4. Safety label locations 6 5. Specifications 7 6. Engine 8 7. Operation 9 8. Transportation 11 9. Storage 12 10. Periodic maintenance schedule 13 11. Troubleshooting 13 12. Component and parts list 14 13. Warranty polic...

Page 4

3 1. Safety information the product, plate compactor, is only allowed to be operated under the intended conditions of compacting ground where vibrating roller is unable to compact. It is prohibited to use it for any other purpose. Although the product is designed with special attention to the safety...

Page 5

4 2) do not refuel the engine near inflammables to avoid fire. 3) do not run the engine in an airtight space to avoid exhaust gas poisoning 3.2 to protect the operator 1) when operator feels the fatigue comes from vibration, the operator must stop the machine and take a rest for a while. 2) an airbo...

Page 6

5 by an expert before the initial use and after the essential modification. 15) during the operation, the operator has to monitor other objects within a radius of 20m in case of lighting. 16) the compactor generates mechanical heat so do not touch the body of engine, muffler or other parts during th...

Page 7

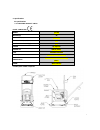

6 4. Safety label locations.

Page 8

7 5. Specifications 5.1 specifications ** ce certified product only** plate compactor model jpc-80 weight(kg) 86 plate size(mm) 540 x 420 travel speed(m/min) 20-25 centrifugal force (kgf) 1,800 engine as required engine oil 10w/30, 600cc fuel unleaded gasoline kw (hp) / rpm 4.0 ~ 4.5 (5.5 ~ 6.0)/3,6...

Page 9

8 5.3 outline configuration 6. Engine 6.1 recommended fuel 1) plate compactor engine requires regular, unleaded gasoline. Use only fresh, clean fuel. Fuel containing water or dirt will damage the fuel system. Consult to engine o wner’s manual for complete fuel specifications. 6.2 before starting 1) ...

Page 10

9 6.3 starting the engine 1) shift the engine on/off switch to “on”. 2) open the fuel valve. Note: if the engine is cold, move the choke lever to “close” position. Note: if the engine is hot, set the choke lever at “open” position. 3) move the throttle lever slightly to the left. 4) pull the starter...

Page 11

10 several different kinds of engines are available upon request for this plate compactor and the followings are for honda gx160 engine made in japan. Please make sure to read the engine instruction manual before operation. Please read the engine and plate compactor user’s manuals before starting or...

Page 12

11 4) pull the starter grip slowly and return it to its original position when resistance is felt. Note: the above operation is necessary to prevent outside moisture air from intruding into the combustion chamber. Caution ** if the engine has been running hard, do not stop it abruptly from the full ...

Page 13

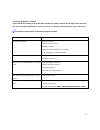

12 10. Periodic maintenance schedule please refer to the following chart for the initial maintenance of plate compactor and its engine. Also please see the enclosed engine manufacturer ’s instruction manual for additional information about engine maintenance. The following chart is based on the norm...

Page 14

13 11. Troubleshooting please check the list below before addressing the problems to servicing personnel including local dealer. If the problem continues after the following troubleshooting, please call your local dealer for future assistance. Failure possible cause remedial measure poor performance...

Page 15

14 12. Components and part list.

Page 16

15 ref description q'ty dimension 1 engine 1 honda gx160/ robin ex17 2 key 1 5 x 5 x 20m/m(square) 3 centrifugal clutch 1 18, 19, 20m/m 4 v-belt 2 a30 5 washer 1 8m/m 6 spring washer 1 8m/m 7 bolt 1 8 x 40m/m 8 engine fitting bolt set 2 8 x 50m/m (specialty steel) 9 flange nut 4 8m/m 10 nut 8 8m/m 1...

Page 17

16 33 engine base ass'y 1 520 x 450 x 110m/m 34 rubber cap 1 * 35 belt cover 1 * 36 flange bolt 4 8 x 20m/m 37 washer 4 8m/m 38 catching rubber 2 * 39 nut 2 * 40 bolt 2 12 x 70m/m 41 washer 4 12m/m 42 rubber isolator "b" 2 * 43 lock nut 2 12m/m 44 handle bracket 1 780 x 375m/m 45 bolt 1 * 46 handle ...

Page 18

17 13. Warranty policy 1) warranty policies for the products are shown on the following table. 2) northern industrial shall supply all necessary parts for the replacement or repair at free of charge, if and only if, when the defects are proved to be derived from mill defect by 3rd party inspection o...