Summary of 155793

Page 2

1 of 15 thank you very much for choosing a northern tool + equipment co., inc. Product! For future reference, please complete the owner's record below: model: _______________ purchase date: _______________ save the receipt, warranty and these instructions. It is important that you read the entire ma...

Page 3

Hazards and should be plugged directly into a properly grounded 3-prong receptacle. Check with a qualified electrician if you are in doubt as to whether the outlet is properly grounded. L extension cord use. A. Use only 'listed' extension cords. If used outdoors, they must be marked “for outdoor use...

Page 4

L before operating the band saw each time, check for alignment of moving parts; binding of moving parts, breakage of parts, mounting and any other conditions that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced. L never leave saw running unatte...

Page 5

Coolant tank preparation use of a water-soluble coolant will increase cutting efficiency and prolong blade life. Do not use black cutting oil as a substitute. Change coolant often and follow manufacturer's instructions as to its uses and precautions. 1.Turn off and disconnect machine from its power ...

Page 6

Vise adjustment warning: do not make any adjustments or load/unload material from vise while machine is running. To set the vise for 0 to 45 degree cutting: 1.Turn off and unplug saw before adjusting. 2.Remove bolt assemblies (c. Fig. 9) 3.Position vise and re-install as pictured in fig. 10. Pay par...

Page 7

Blade selection an 8-tooth per inch, general-use blade is furnished with this metal cutting band saw. Additional blades in 4-, 6-, 8- and 10-tooth sizes are available. The choice of the blade pitch is governed by the thickness of the work to be cut; the thinner the work piece, the more teeth advised...

Page 8

Blade track adjustment 1.Open the blade guard. 2.Remove the blade guide assemblies (top and bottom) 3.Loosen the hex head screw in the tilting mechanism to a point where it is loose but snug. 4.With the machine running, adjust both the set screw and blade tension knob simultaneously to keep constant...

Page 9

Extension cords using extension cords may reduce the life of the motor. Instead, place the machine near a power source. If you must use an extension cord: for 110v, use at least a 12 gauge cord that does not exceed 32.8 feet in length. For 220v, use at least a 16 gauge cord that does not exceed 32.8...

Page 10

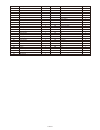

Trouble shooting chart blade is twisting 1.Cut is binding blade 2.Too much blade tension 1.Decrease feed pressure 2.Decrease blade tension symptom possible cause (s) corrective action excessive blade breakage 1.Material loose in vise 2.Incorrect speed or feed 3.Blade teeth spacing too large 4.Materi...

Page 11

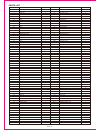

Parts list 10 of 15 part no. 1 6 7 8 14 23 25 26 27 28 29 30 31 32 33 34 35 36 37 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 62.1 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 description base support wheel cutter pin wheel shaft cylinder hex. Hd. Scr...

Page 12

11 of 15 part no. 149 150 151 152 152.1 153 154 155 156 157.1 158 159 160 161 162 163 164 168 169 170 171 172 173 174 175 176 177 description washer key bearing bushing (rear) bear box hex. Hd. Screw ball bearing c-ring oil seal bearing bushing key block plate worm gear gear box gasket gear box cove...

Page 13

Diagram 13 of 15.

Page 14

14 of 15.

Page 15

Manufacturer's limited warranty the limited warranty set forth below is given by northern tool + equipment company inc., (nte) with respect to new merchandise purchased and used in the united states, its possessions and territories. Nte warrants this product against defects in material and workmansh...

Page 16: Warning

Warning some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to the state of california to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are: lead from lead-based paints crystalline silic...