- DL manuals

- Northern Lights

- Portable Generator

- Lugger OM944W

- Operator's Manual

Northern Lights Lugger OM944W Operator's Manual

Summary of Lugger OM944W

Page 2

Www.Northern-lights.Com 4420 14th ave. Nw., seattle wa 98107 tel: (206) 789-3880 • 1-800-762-0165 • fax: (206) 782-5455 northern lights and lugger are registered trademarks of northern lights, inc. © 2006 all rights reserved. Litho usa. Diesel engine exhaust and some of its constitu- ents are known ...

Page 3: Operator'S Manual

Om944w 06/06 3 proprietary information this publication is the property of northern lights, inc. It may not be reproduced in whole or in part without the written permission of northern lights, inc. © northern lights, inc. All rights reserved. Litho u.S.A. Publication number om944w 06/06 read this op...

Page 4

4 om944w 06/06 the servicing of marine engines and generator sets presents unique problems. In many cases, boats cannot be moved to a repair facility. Marine engines cannot be compared to the servicing of automobiles, trucks, or even farm equipment. Failures often occur in remote areas far from comp...

Page 5

Om944w 06/06 5 a warranty registration certifi cate is supplied with your set. It entitles the original purchaser of our equipment to a warranty covering material or assembly faults. The extent of coverage is described in the limited warranty statement. We recommend that you study the statement care...

Page 6

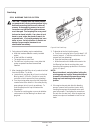

6 om944w 06/06 figure 2: m944w service side with px-300k2 series generator end. M944w generator set component locations 1. Expansion tank 2. Coolant fill 3. Rocker arm cover 4. Intake manifold 5. Lube oil fill 6. Air filter 7. Junction box 8. Fuel filter 9. Vibration mounts 10. Lube oil dipstick 11....

Page 7

Om944w 06/06 7 m944w generator set component locations figure 3: m944w non-service side with px-300k2 series generator end. 18. Ac circuit breaker 19. Dc circuit breaker 20. Wet exhaust elbow 21. Exhaust manifold 22. Heat exchanger 23. Raw water pump 24. Belt guard 25. Oil pan 26. Alternator 27. Sta...

Page 8

8 om944w 06/06 control panels figure 4-b: series 3 generator control panel figure 4-a: series 1-b generator control panel 1. Preheat/ shutdown bypass this switch serves two functions: 1. Preheats air before beginning the starting process. Press switch for 10-20 seconds before attempting startup. 2. ...

Page 9

Om944w 06/06 9 operating procedures before starting 1. Check the water level by removing the pressure cap from the expansion tank. In order to give the cooling water an opportunity to expand, the level should be about 1 in. (2.5 cm) below the fi ller cap sealing surface when the engine is cold. Caut...

Page 10

10 om944w 06/06 operating 1. Units with series 3 and series 4 control panels: check gauges often. Oil pressure must be above 15 psi. The d.C. Voltmeter should read between 11 and 15 volts at 80° f (25° c) ambient temperature. The water temperature gauge must be below 200° f (94° c). Check the a.C. V...

Page 11

Om944w 06/06 11 shutdowns and alarms 1. Your unit is fi tted with a system to protect it from high water temperature or low oil pressure. A. Generator sets have shutdown systems to stop the engine. They have no warning horns. B. Other alarms and shutdowns are available as optional equipment. Note: i...

Page 12

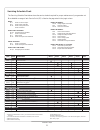

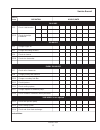

12 om944w 06/06 the servicing schedule chart below shows the service schedule required for proper maintenance of your generator set. More detailed coverage of each service point (sp) is listed on the page noted in the ‘page’ column. Daily: sp1 check oil level in engine sp8 check primary fuel fi lter...

Page 13

Om944w 06/06 13 service point hours/ date service record operation 50 hours sp5 check v-belt tension sp19 check electrolyte in batteries 250 hours sp2 change engine oil sp3 change lubricating oil fi lters sp4 check air cleaner sp18 check zinc electrodes every 500 hours sp7 check valve clearances sp8...

Page 14

14 om944w 06/06 servicing lubrication - general 1. Use only clean, high quality lubricants stored in clean containers in a protected area. 2. These lubricants are acceptable: a. Api service cd, ce, and cf-4 single viscosity oils. B. Api service cd, ce, and cf-4 multi-viscosity oils. 3. Use the prope...

Page 15

Om944w 06/06 15 sp3. Changing lube oil filter 1. Change the lube oil fi lter every 250 hours. 2. Use a fi lter wrench to remove old fi lter. Dispose of fi lter in approved manner. 3. Make sure the gasket from the old fi lter is removed and discarded. Clean mount face. 4. Spread a thin fi lm of engin...

Page 16

16 om944w 06/06 servicing sp7. Valve clearances 1. Readjust valve clearance after fi rst 50 hours of operation. Check valves every 500 hours thereafter. 2. Check the valves when the engine is cold. 3. Rotate the crankshaft in a clockwise direction in the front 180 0 to bring each piston to the top d...

Page 17

Om944w 06/06 17 fuels - general 1. Use only clean, high quality fuels of the following specifi cations, as defi ned by astm designation d975 for diesel fuels: a. Use grade no. 2 diesel at ambient temperatures above freezing 32° f (0° c). B. Use grade no. 1 at ambient temperatures below freezing. C. ...

Page 18

18 om944w 06/06 sp11. Bleeding the fuel system caution: escaping diesel fuel under pressure can penetrate skin causing serious personal injury. Before disconnecting lines be sure to relieve all pressure. Before applying pressure, be sure all connections are tight and lines, pipes and hoses aren't da...

Page 19

Om944w 06/06 19 servicing sp12. Injector service 1. Injectors should be checked every 500 hours. This check should be made by a northern lights dealer or local injection repair station. Caution: escaping diesel fuel under pressure can have suffi cient force to penetrate the skin causing serious pers...

Page 20

20 om944w 06/06 sp13. Injection pump 1. Since operating conditions may vary considerably, it is diffi cult to give a defi nite interval for checking the injection pump. But as a rule, pump settings, maximum speed, idle speed and exhaust smoke should be checked after every 2000 hours of operation. Se...

Page 21

Om944w 06/06 21 servicing cooling system - general note: be sure to close the sea-cock before working on the engine cooling system. Caution: the cooling water in the engine reaches extremely high temperatures. You must use extreme caution when working on hot engines to avoid burns. Allow the engine ...

Page 22

22 om944w 06/06 sp16. Heat exchanger 1. Clean the heat exchanger core once a year or after 2000 hours of operation. 2. Drain the expansion tank and heat exchanger. 3. Remove the heat exchanger end covers. 4. Clean the inside of the exchanger core tubes using a metal rod. Flush, inspect, and clean ag...

Page 23

Om944w 06/06 23 generator end the maintenance and operation recommendations for the generator end are in a separate owner's manual. If you do not have one of these manuals, contact your local dealer. Electrical system - general 1. Never switch the battery switch off or break the circuit between the ...

Page 24

24 om944w 06/06 sp19-20. Battery care 1. Check the electrolyte level every 50 hours, or once a month. Add distilled water to the manufacturer's recommended level. 2. Batteries, cables, and cable terminals should be checked and cleaned every 100 hours. Clean corrosion with a water and baking soda sol...

Page 25

Om944w 06/06 25 if you cannot correct problems with these procedures, see your northern lights dealer. Troubleshooting dc electrical system problem possible cause recommendation(s) battery will not charge loose or corroded connections • clean and tighten battery connections. Sulfated or worn out bat...

Page 26

26 om944w 06/06 troubleshooting engine problem possible cause recommendation(s) engine hard to start improper starting procedure • see starting section of this manual. Take or will not start special note of bypass switch operation. No fuel • check level of fuel in fuel tank. Low battery condition • ...

Page 27

Om944w 06/06 27 troubleshooting engine problem possible cause recommendation(s) lack of engine power low compression pressure • consult dealer. (continued) (worn piston rings, etc...) engine overheats engine overloaded • reduce the electrical load. Low coolant level • fill tank or radiator to proper...

Page 28

28 om944w 06/06 engine problem possible cause recommendation(s) high oil consumption break-in period • oil consumption decreases after break in. Crankcase oil too light • use proper viscosity oil. Oil leaks • check for leaks in lines around gaskets and drain plug. Crankcase over full • remove excess...

Page 29

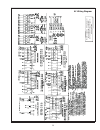

Om944w 06/06 29 northern lights ac wiring diagram – models m944w and m30cw dst -100-2f ak v oltage regulator drawing b-8280d ac wiring diagram.

Page 30

30 om944w 06/06 northern lights dc wiring diagram – models m944w and m30cw 12 v olt standard ground drawing c-6050 dc wiring diagram drawings subject to change without notice..

Page 31

Om944w 06/06 31 northern lights dc wiring diagram – models m944w and m30cw 12 v olt isolated ground drawing c-6051 dc wiring diagram drawings subject to change without notice..

Page 32

32 om944w 06/06 northern lights dc wiring diagram – models m944w and m30cw 24 v olt standard ground drawing c-6052 dc wiring diagram drawings subject to change without notice..

Page 33

Om944w 06/06 33 dc wiring diagram northern lights dc wiring diagram – model m944w 24 v olt isolated ground drawing c-6053 drawings subject to change without notice..

Page 34

34 om944w 06/06.

Page 35

Www.Northern-lights.Com 4420 14th ave. Nw., seattle wa 98107 tel: (206) 789-3880 • 1-800-762-0165 • fax: (206) 782-5455 northern lights and lugger are registered trademarks of northern lights, inc. © 2006 all rights reserved. Litho usa..