- DL manuals

- Northern Lights

- Portable Generator

- M673L3

- Operator's Manual

Northern Lights M673L3 Operator's Manual

Summary of M673L3

Page 2

Diesel engine exhaust and some of its constitu- ents are known to the state of california to cause cancer, birth defects, and other reproductive harm. — california — proposition 65 warning: northern lights 4420 14th avenue n.W. Seattle, wa 98107 tel: (206) 789-3880 fax: (206) 782-5455 copyright ©201...

Page 3: Operator'S Manual

Read this operator's manual thoroughly before starting to operate your equipment. This manual contains information you will need to run and service your new unit. Operator's manual for models m673l 3 and m673ld 3 table of contents introduction ....................................................2 mo...

Page 4

Om673l3 11/13 2 servicing of marine engines and generator sets presents unique problems. In many cases boats cannot be moved to a repair facility. Marine engines cannot be compared to the servicing of automobiles, trucks or even farm equipment. Failures often occur in remote areas far from competent...

Page 5: Warning

Om673l3 11/13 3 a warranty registration certificate is supplied with your set. It entitles the original purchaser of our equipment to a warranty covering material or assembly faults. The extent of coverage is described in the limited warranty statement. We recommend that you study the statement care...

Page 6: Caution

Om673l3 11/13 4 safety rules revised 3-12-12 operating equipment requires the full attention of the operator. Do not use radio or music headphones while operating machinery. Practice safe maintenance ! Caution understand all service procedures before starting work. Keep area clean and dry. Never lub...

Page 7: Warning

Om673l3 11/13 5 safety rules (continued) revised 3-12-12 install all safety guards ! Warning direct contact with rotating fans, belts, pulley and drives can cause serious injury. Keep all guards in place at all times during engine operation. Wear close-fitting clothes. Stop the engine and be sure al...

Page 8: Caution

Om673l3 11/13 6 safety rules (continued) revised 3-12-12 read and understand the msds for each chemical before you start any job that includes it. Follow the procedures and use appropriate equipment exactly as recommended. Contact your northern lights dealer or northern lights factory for msds’s use...

Page 9: Warning

Om673l3 11/13 7 safety rules (continued) revised 3-12-12 material containing asbestos. Keep all bystanders away from any area where asbestos dust may be generated. Use proper lifting equipment and techniques ! Warning lifting heavy components incorrectly can cause severe injury or damage to machiner...

Page 10: Caution

Om673l3 11/13 8 general policy to avoid dangerous or hazardous situations, refrain from any of the following: • removing or bypassing a guard or other safety device • placing any part of your body in a position where you could be caught by moving machinery. • cleaning or oiling machinery when in ope...

Page 11

Om673l3 11/13 9 notes.

Page 12

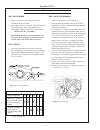

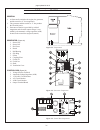

Om673l3 11/13 10 revised 5-12-11 1. Heat exchanger end cap 2. Coolant fill/pressure cap 3. Heat exchanger/expansion tank/exhaust manifold 4. Lube oil fill- top 5. Wet exhaust elbow 6. Generator junction box 7. Control panel plug-in 16. Dc circuit breaker 17. Air filter housing 18. Secondary fuel fil...

Page 13

Om673l3 11/13 11 1. Heat exchanger end cap 2. Coolant fill/pressure cap 3. Heat exchanger/expansion tank/exhaust manifold 4. Lube oil fill- top 5. Wet exhaust elbow 6. Generator junction box 7. Control panel plug-in 16. Dc circuit breaker 17. Air filter housing 18. Fuel filter 19. Fuel injector 20. ...

Page 14

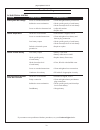

Om673l3 11/13 12 figure 5: series 3 generator control panel figure 4: series 1-b generator control panel figure 6: series 4 generator control panel 1. Shutdown bypass-preheat switch this switch serves two functions: 1. Preheats glowplugs before beginning the starting process. Press switch for 10-20 ...

Page 15

Om673l3 11/13 13 break-in period 1. The first 100 hours on a new or reconditioned engine are critical to its life and performance. 2. Operate the engine under various conditions, particularly heavy loades with minimal idling, to help seat engine components properly. 3. Constantly check the engine te...

Page 16

Om673l3 11/13 14 operating procedures shutdowns and alarms 1. Generator sets have shutdown systems to stop the engine in the event of high water temperature or low oil pressure. A. Other alarms and shutdowns are available as optional equipment. Note: do not rely on your warning to the exclusion of c...

Page 17

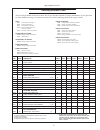

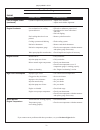

Om673l3 11/13 15 the servicing schedule chart below shows the service schedule required for proper maintenance of your generator set. More detailed coverage of each service point (sp) is listed on the page noted in the ‘page’ column. Daily: sp1 check oil level in engine sp5 check v-belt tension sp7 ...

Page 18

Om673l3 11/13 16 service record notes.

Page 19

Om673l3 11/13 17 servicing lubrication - general 1. Use only clean, high quality lubricants stored in clean containers in a protected area. 2. These lubricants are acceptable: a. Api service cc/cd/ce single viscosity oils. B. Api service cc/cd/sf multi-viscosity oils. 3. Use the proper weight oil fo...

Page 20

Om673l3 11/13 18 servicing sp4. Air cleaner 1. Inspect air cleaner every 250 hours. In dusty conditions check more often. 2. Inspect the element. If it is dirty, wash the element in soapy water. Rinse and dry thoroughly before re-installing. Replace if necessary. Part number is: m673l3 & ld3 - #24-2...

Page 21

Om673l3 11/13 19 servicing fuels - general 1. Use only clean, high quality fuels of the following specifications, as defined by astm designation d975 for diesel fuels: a. Use grade no. 2 diesel at ambient temperatures above freezing 32°f (0°c). B. Use grade no. 1 at ambient temperatures below freezi...

Page 22

Om673l3 11/13 20 servicing figure 12: m673 fuel system. Sp10. Bleeding the fuel system caution: escaping diesel fuel under pressure can penetrate skin causing serious personal injury. Before disconnecting lines be sure to relieve all pressure. Before applying pressure, be sure all connections are ti...

Page 23

Om673l3 11/13 21 servicing sp11. Injector service 1. Injectors should be checked every 1000 hours, or more often as necessary. Check should be made by a northern lights dealer or local injection repair station. Caution: escaping diesel fuel under pressure can have sufficient force to penetrate the s...

Page 24

Om673l3 11/13 22 servicing water quality 1. Distilled, deionized, soft water is preferred for use in cooling systems. Bottled distilled water from a food store or water supplier is recommended. Tap water often has a high mineral content. Tap water should neverbe put in a cooling system unless first ...

Page 25

Om673l3 11/13 23 servicing figure 13: remove delivery line flare nuts. Figure 14: remove delivery lines. Figure 15: cover lines, inlets and injection pump outlets. Figure 16: remove return line nuts. Figure 18: unscrew injector. Figure 19: remove and replace copper sealing washer. Figure 20: reinsta...

Page 26

Om673l3 11/13 24 servicing sp14. Cooling system flushing 1. Flush the cooling system every 2500 hours or every 12 months, whichever comes first. A. Remove expansion tank cap and drain engine block. B. Leave all drains open. C. Pour clean water into expansion tank until water coming from drains is fr...

Page 27

Om673l3 11/13 25 glow plugs 1. Each cylinder is supplied with a glow plug which serves to heat the combustion chamber for starting. 2. To check the glow plugs, loosen the current carrying flat wire between the plus-poles of the glow plugs ( figure 21 ). Connect a d.C. Test bulb between the plus-pole...

Page 28

Om673l3 11/13 26 general 1. A generator set includes the engine, the generator, and the control or “j” box ( figure 23 ). 2. The generator and the control or “j” box produce the electrical power. 3. Generator excitation is provided by residual magnetism and electrical output voltage is con- trolled ...

Page 29

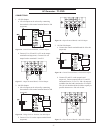

Om673l3 11/13 27 connections 1. 120 volt output: a. 120 volt output can be selected by connecting the terminals of the control terminal board to 120 ( figure 26 ). Figure 26: control terminal board, 120 volt output b. Connect u1 to u2 and v1 to v2 on the output terminal board ( figure 27 ). Connect ...

Page 30

Om673l3 11/13 28 ac generator - tf-276d operation in order to ensure a long, trouble-free life, the generator must be operated properly and the specified maintenance must be performed. Operating environment always keep electrical equipment clean. Moisture, salt, dust, and oil will damage the generat...

Page 31

Om673l3 11/13 29 9. Parts: see parts book for complete list a. Bearing part #22-68305 b. Brush assembly part #22-68304 10. Test specifications: see wiring diagram(s) a. Resistance of j-k 16.6 ohm at 20°c (68°f) b. Resistance of a-b 0.25 ohm at 20°c (68°f) c. Resistance of u1-v2 0.56 ohm at 20°c (68°...

Page 32

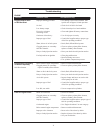

Om673l3 11/13 30 if you cannot correct problems with these procedures, see your northern lights dealer. Troubleshooting dc electrical system problem possible cause recommendation(s) battery will not charge loose or corroded connections • clean and tighten battery connections. Sulfated or worn out ba...

Page 33

Om673l3 11/13 31 troubleshooting engine problem possible cause recommendation(s) engine hard to start improper starting procedure • see starting section of this manual. Take or will not start special note of bypass switch operation. No fuel • check level of fuel in fuel tank. Low battery output • ch...

Page 34

Om673l3 11/13 32 troubleshooting engine problem possible cause recommendation(s) lack of engine power cylinder compression pressure low • adjust valve clearance. (continued) • adjust nozzle holder alignment. Engine overheats low coolant level or cooling • fill tank or radiator to proper level. Syste...

Page 35

Om673l3 11/13 33 troubleshooting engine problem possible cause recommendation(s) low oil pressure low oil level • fill crankcase to proper level. Clogged filter and strainer or • repair or replace. Worn bearings and oil pump improper type of oil • drain and fill crankcase with correct oil. Partially...

Page 36

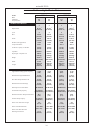

Om673l3 11/13 34 northern lights marine data model: m673l3 m673ld3 rpm 1800 1500 1800 1500 kw rating 6.0 5.0 5.0 4.5 frequency (hz) 60 50 60 50 general information cylinders 3 3 3 3 displacement 46.4 in 3 46.4 in 3 46.4 in 3 46.4 in 3 (0.761 ltr) (0.761 ltr) (0.761 ltr) (0.761 ltr) cycle 4 4 4 4 bor...

Page 37

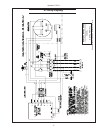

Om673l3 11/13 35 ac wiring diagrams wiring diagrams are subject to change without notice. Ac engine w iring diagram 100-120/ 200-240 v olts ac 50/60 hz drawing #b-6103j updated 6-22-11.

Page 38

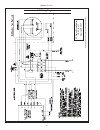

Om673l3 11/13 36 ac wiring diagrams wiring diagrams are subject to change without notice. Ac engine w iring diagram 200-240 volts ac drawing #b-6104f updated 6-22-11.

Page 39

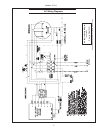

Om673l3 11/13 37 ac wiring diagrams wiring diagrams are subject to change without notice. Ac engine w iring diagram 120 volts ac drawing #b-6105g updated 4/9/12.

Page 40

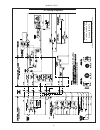

Om673l3 11/13 38 dc wiring diagrams wiring diagrams are subject to change without notice. Dc engine w iring diagram 12 v olts dc standard ground drawing #b-9873 updated 6-22-11.

Page 41

Om673l3 11/13 39 dc wiring diagrams wiring diagrams are subject to change without notice. Dc engine w iring diagram 12 v olts dc isolated ground drawing #b-8247a updated 6-22-11.

Page 42

Om673l3 11/13 40 dc wiring diagrams wiring diagrams are subject to change without notice. Dc engine w iring diagram s-1b 12 v olt drawing #a-3170 added 6-22-11.

Page 43

Om673l3 11/13 41 dc wiring diagrams wiring diagrams are subject to change without notice. Dc engine w iring diagram s-3c 12 v olt drawing #a-12616 updated 4-9-12.

Page 45

4420 14th ave. Nw., seattle wa 98107 tel: (206) 789-3880 • 1-800-762-0165 • www.Northern-lights.Com northern lights and lugger are registered trademarks of northern lights, inc. © 2013 all rights reserved. Litho usa..