- DL manuals

- Northern Lights

- Portable Generator

- M864W and M864W3

- Operator's Manual

Northern Lights M864W and M864W3 Operator's Manual

Summary of M864W and M864W3

Page 2

Diesel engine exhaust and some of its constitu- ents are known to the state of california to cause cancer, birth defects, and other reproductive harm. — california — proposition 65 warning: northern lights 4420 14th avenue n.W. Seattle, wa 98107 tel: (206) 789-3880 fax: (206) 782-5455 copyright ©201...

Page 3: Operator'S Manual

Om864w 12/13 1 proprietary information this publication is the property of northern lights, inc. It may not be reproduced in whole or in part without the written permission of northern lights, inc. © northern lights, inc. All rights reserved. Litho u.S.A. Publication number om864w 12/13 read this op...

Page 4

Om864w 12/13 2 the servicing of marine engines and generator sets presents unique problems. In many cases, boats cannot be moved to a repair facility. Marine engines cannot be compared to the servicing of automobiles, trucks, or even farm equipment. Failures often occur in remote areas far from comp...

Page 5

Om864w 12/13 3 a warranty registration certifi cate is supplied with your set. It entitles the original purchaser of our equipment to a warranty covering material or assembly faults. The extent of coverage is described in the limited warranty statement. We recommend that you study the statement care...

Page 6

Om864w 12/13 4 safety rules added 11-21-11 always stop engine before fueling machine. Always fi ll portable fuel tank outdoors. Never fuel a hot engine. Prevent accidental discharge of starting fl uids by storing all cans in a cool, safe place, away from sparks or open fl ame. Store with cap securel...

Page 7

Om864w 12/13 5 safety rules (continued) revised 7-9-12 install all safety guards direct contact with rotating fans, belts, pulley and drives can cause serious injury. Keep all guards in place at all times during engine operation. Wear close-fi tting clothes. Stop the engine and be sure all fans, bel...

Page 8

Om864w 12/13 6 safety rules (continued) added 11-21-11 slowly loosen cap to relieve pressure before opening fully. Avoid high pressure fluids relieve pressure prior to disconnecting pressurized lines. Escaping fl uid under pressure can penetrate the skin causing serious injury. Always relieve pressu...

Page 9

Om864w 12/13 7 safety rules (continued) added 11-21-11 use proper lifting equipment and techniques lifting heavy components incorrectly can cause severe injury or damage to machinery. Avoid unbalanced loads. Do not use lifting eyes. Lift the generator set using lifting bars inserted through the lift...

Page 10: Caution

Om864w 12/13 8 general policy to avoid dangerous or hazardous situations, refrain from any of the following: • removing or bypassing a guard or other safety device • placing any part of your body in a position where you could be caught by moving machinery. • cleaning or oiling machinery when in oper...

Page 11

Om864w 12/13 9 notes.

Page 12

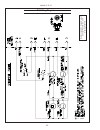

Om864w 12/13 10 figure 2: m864w service side 1. Dc circuit breaker 2. Ac circuit breaker 3. Air filter 4. Secondary fuel filter 5. Fuel system bleed point 6. Lube oil fill 7. Intake manifold 8. Coolant fill 9. Expansion tank 10. Heat exchanger 11. Heat exchanger raw water drain and zinc 12. Heat exc...

Page 13

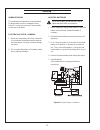

Om864w 12/13 11 m864w generator component locations figure 3: m864w non-service side 1. Expansion tank 2. Coolant fill 3. Exhaust manifold 4. Lube oil fill 5. Wet exhaust elbow 6. Manifold drain 7. Oil pan 8. Raw water pump 9. Heat exchanger raw water drain and zinc 10. Heat exchanger 1 10 9 8 4 3 5...

Page 14

Om864w 12/13 12 figure 2: m864w service side 1. Dc circuit breaker 2. Ac circuit breaker 3. Air filter 4. Secondary fuel filter 5. Fuel system bleed point 6. Lube oil fill 7. Intake manifold 8. Coolant fill 9. Expansion tank 10. Heat exchanger 11. Heat exchanger raw water drain and zinc 12. Heat exc...

Page 15

Om864w 12/13 13 m864w generator component locations figure 3: m864w non-service side 1. Expansion tank 2. Coolant fill 3. Lube oil fill 4. Exhaust manifold 5. Wet exhaust elbow 6. Manifold drain 7. Oil pan 8. Raw water pump 9. Heat exchanger raw water drain and zinc 10. Heat exchanger pre-2012 basef...

Page 16

Om864w 12/13 14 figure 4-b: series 3 generator control panel figure 4-a: series 1-b generator control panel 1. Preheat/ shutdown bypass this switch serves two functions: a. Preheats engine before beginning the starting process. Press switch for 10-20 seconds before attempting startup. B. Bypasses th...

Page 17

Om864w 12/13 15 before starting 1. Check the water level by removing the pressure cap from the expansion tank. In order to give the cooling water an opportunity to expand, the level should be about 1 in. (2.5 cm) below the fi ller cap sealing surface when the engine is cold. Caution: use protective ...

Page 18

Om864w 12/13 16 operating 1. Units with series 3 and series 4 control panels: check gauges often. Oil pressure must be above 15 psi. The d.C. Voltmeter should read between 11 and 15 volts at 80° f (25° c) ambi- ent temperature. The water temperature gauge must be below 200° f (94° c). Check the a.C....

Page 19

Om864w 12/13 17 shutdowns and alarms 1. Your unit is fi tted with a system to protect it from high water temperature or low oil pressure. A. Generator sets have shutdown systems to stop the engine. They have no warning horns. B. Other alarms and shutdowns are available as optional equipment. Note: i...

Page 20

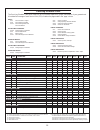

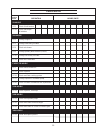

Om864w 12/13 18 the servicing schedule chart below shows the service schedule required for proper maintenance of your generator set. More detailed coverage of each service point (sp) is listed on the page noted in the ‘page’ column. Daily: sp1 check oil level in engine sp8 check primary fuel fi lter...

Page 21

Om864w 12/13 19 service point hours/ date service record operation 50 hours sp5 check v-belt tension sp19 check electrolyte in batteries 200 hours sp2 change engine oil sp3 change lubricating oil fi lters sp4 check air cleaner sp8 change primary fi lter element (racor) sp10 change secondary fuel fi ...

Page 22

Om864w 12/13 20 servicing lubrication - general 1. Use only clean, high quality lubricants stored in clean containers in a protected area. 2. These lubricants are acceptable: a. Api service cc/cd/ce single viscosity oils. B. Api service cc/cd/sf multi-viscosity oils. 3. Use the proper weight oil for...

Page 23

Om864w 12/13 21 sp5. V-belts 1. Check the tension and wear on the v-belt after every 50 hours. 2. Use your thumb to press on the belt at the midpoint between the crankshaft and alternator pulleys. The tension is correct if the belt can be depressed about 3/8 in. (10 - 15 mm) with 22 lbs. (10 kg) for...

Page 24

Om864w 12/13 22 sp7. Valve clearances 1. Readjust valve clearance after fi rst 50 hours of operation. Adjust valves every 750 hours thereafter. 2. Warm up the engine to 167° f - 185° f (75° c - 85° c). Shut off fuel and battery. 3. Rotate the crankshaft in a clockwise direction to set cylinder no. 1...

Page 25

Om864w 12/13 23 fuels - general 1. Use only clean, high quality fuels of the following specifi cations, as defi ned by astm designation d975 for diesel fuels: a. Use grade no. 2 diesel at ambient temperatures above freezing 32° f (0° c). B. International fuel specifi cations: iso-8217-dma bs 2869 pa...

Page 26

Om864w 12/13 24 sp11. Bleeding the fuel system caution: escaping diesel fuel under pressure can penetrate skin causing serious personal injury. Before disconnecting lines be sure to relieve all pressure. Before applying pressure, be sure all connections are tight and lines, pipes and hoses aren't da...

Page 27

Om864w 12/13 25 sp12. Injector service 1. Injectors should be checked every 750 hours. This check should be made by a northern lights dealer or local injection repair station. To insure that your engine stays in compliance with applicable epa and carb emission standards, the following maintenance pr...

Page 28

Om864w 12/13 26 sp13. Injection pump 1. Since operating conditions may vary considerably, it is diffi cult to give a defi nite interval for checking the injection pump. But as a rule, pump settings, maxi- mum speed, idle speed and exhaust smoke should be checked after every 2400 hours of operation. ...

Page 29

Om864w 12/13 27 4. Injection pump removal: caution: escaping diesel fuel under pressure can have suffi cient force to penetrate the skin, causing serious personal injury. If injured by escaping diesel fuel, see a doctor at once. A. Clean the injection pump, hoses, and area around the pump with a cle...

Page 30

Om864w 12/13 28 cooling system - general note: be sure to close the sea-cock before working on the engine cooling system. Caution: the cooling water in the engine reaches extremely high temperatures. You must use extreme caution when working on hot engines to avoid burns. Allow the engine to cool be...

Page 31

Om864w 12/13 29 sp16. Heat exchanger 1. Clean the heat exchanger core once a year or after 2400 hours of operation. 2. Drain the expansion tank and heat exchanger. 3. Remove the heat exchanger end covers. 4. Clean the inside of the exchanger core tubes using a metal rod. Flush, inspect, and clean ag...

Page 32

Om864w 12/13 30 generator end the maintenance and operation recommendations for the generator end are in a separate owner's manual. If you do not have one of these manuals, contact your local dealer. Electrical system - general 1. Never switch the battery switch off or break the circuit between the ...

Page 33

Om864w 12/13 31 sp19-20. Battery care 1. Check the electrolyte level every 50 hours, or once a month. Add distilled water to the manufacturer's recommended level. 2. Batteries, cables, and cable terminals should be checked and cleaned every 100 hours. Clean corrosion with a water and baking soda sol...

Page 34

Om864w 12/13 32 if you cannot correct problems with these procedures, see your northern lights dealer. Troubleshooting dc electrical system problem possible cause recommendation(s) battery will not charge loose or corroded connections • clean and tighten battery connections. Sulfated or worn out bat...

Page 35

Om864w 12/13 33 engine problem possible cause recommendation(s) engine hard to start improper starting procedure • see starting section of this manual. Take or will not start special note of bypass switch operation. No fuel • check level of fuel in fuel tank. Low battery condition • check electrolyt...

Page 36

Om864w 12/13 34 engine problem possible cause recommendation(s) engine overheats engine overloaded • reduce the electrical load. Low coolant level • fill tank or radiator to proper level. • check hoses for loose connections and leaks. Keel cooling tubes (marine sets) • remove paint from tubes. Have ...

Page 37

Om864w 12/13 35 engine problem possible cause recommendation(s) high oil consumption break-in period • oil consumption decreases after break in. Crankcase oil too light • use proper viscosity oil. Oil leaks • check for leaks in lines around gaskets and drain plug. Crankcase over full • remove excess...

Page 38

Om864w 12/13 36 specifi cations and dimensions rated rpm/frequency 1800/60 hz 1500/50 hz kilowatt rating 25 kw 20 kw general information cylinders in-line 4 in-line 4 displacement 151.7 cid (2.49 l ) 151.7 cid (2.49 l ) cycle 4 4 bore x stroke 3.39 in (86 mm) x 4.21 in (107 mm) 3.39 in (98 mm)x 4.21...

Page 39

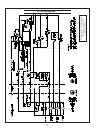

Om864w 12/13 37 northern lights dc wiring diagram – model m864w 12v standard ground drawing c-9956a dc wiring diagram revised 11-21-11.

Page 40

Om864w 12/13 38 dc wiring diagram northern lights dc wiring diagram – m864w 12v isolated ground drawing c-5658.

Page 41

Om864w 12/13 39 dc wiring diagram northern lights dc wiring diagram – control panel s-1b, 12v drawing a3170 added 11-21-11.

Page 42

Om864w 12/13 40 dc wiring diagram northern lights dc wiring diagram – control panel s-3c, 12v drawing a12572b added 11-21-11.

Page 43

Om864w 12/13 41 revised 7-9-11 northern lights dc wiring diagram – m864w 24v standard ground drawing b-9878c dc wiring diagram.

Page 44

Om864w 12/13 42 northern lights dc wiring diagram – m864w 24v isolated ground drawing b-9901a dc wiring diagram revised 11-21-11.

Page 45

Om864w 12/13 43 northern lights dc wiring diagram – control panel s-1b, 24v drawing a-4792 dc wiring diagram added 11-21-11.

Page 46

Om864w 12/13 44 northern lights dc wiring diagram – control panel s-3c, v iewline m864 drawing a-12647 st ar t st ar t yell ow/red ye ll o w /r ed redre d gra y gr ay whitew h it e purplepu rp le bla ck bl ac k bl ue bl ue st op st o p bla ck bl ac k redre d control p anel co n tr o l pa n el panelp...

Page 47

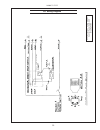

Om864w 12/13 45 northern lights ac wiring diagram – 4 lead generator , dst -100-2f ak v oltage regulator , drawing b-9724c ac wiring diagram revised 11-21-11.

Page 48

Om864w 12/13 46 northern lights ac wiring diagram – 12 lead generator , dst -100-2f ak v oltage regulator , drawing b-9723c ac wiring diagram added 11-21-11.

Page 49

4420 14th ave. Nw., seattle wa 98107 tel: (206) 789-3880 • 1-800-762-0165 • fax: (206) 782-5455 northern lights and lugger are registered trademarks of alaska diesel electric, inc. © 2013 all rights reserved. Litho usa..