- DL manuals

- Northern Lights

- Engine

- OL1276

- Operator's Manual

Northern Lights OL1276 Operator's Manual

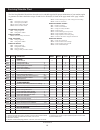

Summary of OL1276

Page 2

Diesel engine exhaust and some of its constitu- ents are known to the state of california to cause cancer, birth defects, and other reproductive harm. — california — proposition 65 warning: northern lights 4420 14th avenue n.W. Seattle, wa 98107 tel: (206) 789-3880 fax: (206) 782-5455 copyright ©201...

Page 3: Operator'S Manual

Ol1276 03/10 3 read this operator's manual thoroughly before starting to operate your equipment. This manual contains information you will need to run and service your new unit. Operator's manual #ol1276 for model l1276a and l1276a2 introduction ....................................................2 ...

Page 4

Ol1276 03/10 4 servicing of marine engines presents unique problems. In many cases boats cannot be moved to a repair facility. Marine engines cannot be compared to the servicing of automobiles, trucks or even farm equipment. Failures often occur in remote areas far from competent assistance. Marine ...

Page 5

Ol1276 03/10 5 caution: this symbol is used throughout this book to alert you to possible danger areas. Please take special notice of these sections. A warranty registration certifi cate is supplied with your set. The extent of coverage is described in the limited warranty statement. We recommend th...

Page 6

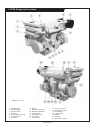

Ol1276 03/10 6 1. Expansion tank 2. Heat exchanger 3. Gear oil cooler 4. Water fill 5. Heat exchanger zinc (2) 6. Crankcase vent 7. Air cleaner 8. Starter 9. Electronic control unit 10. Salt water inlet elbow 11. Lube oil drain 12. Raw water pump 13. Lube oil fill 14. Turbocharger 15. Rocker arm cov...

Page 7

Ol1276 03/10 7 notes.

Page 8

Ol1276 03/10 8 operating procedures before starting 1. Check the water level by removing the pressure cap from the expansion tank. In order to give the cooling water room to expand, the level should be about 1 3/4 in. (4-5 cm) below the fi ller cap sealing surface when the engine is cold. When fi ll...

Page 9

Ol1276 03/10 9 operating procedures note: do not rely on your warning or shutdown system to the exclusion of careful gauge monitoring. Watching your gauges can prevent damage to the unit and dangerous power losses. 2. Do the following when your shutdown system is activated: a. Check the temperature ...

Page 10

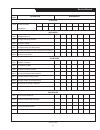

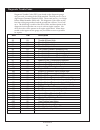

Ol1276 03/10 10 the servicing schedule chart below shows the service schedule required for proper maintenance of your marine engine or generator set. More detailed coverage of each service point (sp) is listed on the page noted in the ‘page’ column. Daily: sp1 check oil level in engine sp7 check pri...

Page 11

Ol1276 03/10 11 service point hours/date service record operation 50 hours sp20 check electrolyte in batteries 250 hours sp2 change engine oil sp3 change lubricating oil fi lters sp4 check air cleaner sp7 change primary fuel fi lter element sp12 check turbocharger air, oil & cooling lines for leakag...

Page 12

Ol1276 03/10 12 lubrication break-in oil 1. Use one of the following during the fi rst 100 hours of operation: a. John deere engine break-in oil b. Api service cc, cd oil c. Acea specifi cation e1 2. Do not use john deere plus-50 oil or engine oils meeting api cf-4, api cg-4, api ch-4, api ci-4, ace...

Page 13

Ol1276 03/10 13 sp6. Valve clearances & electronic unit injector preload 1. Have your deaer adjust intake and exhaust valve clearance and electronic unit injector (eui) preload. This one-time adjustment for all new and overhauled engines is required after the fi rst 2500 hours of operation. Fuels - ...

Page 14

Ol1276 03/10 14 sp7-9. Fuel filters 1. Your engine or generator set should have a primary fuel fi lter installed. We recommend the racor brand of fuel fi lter - water separators. A. Check the primary fuel fi lter daily as recommended by the fi lter manufacturer. Empty the collection bowl as necessar...

Page 15

Ol1276 03/10 15 sp12. Turbocharger 1. Check for air leaks every 250 hours. Air leakage will lower engine output and may cause black exhaust smoke and soot. 2. Listen along air line while engine is running. A whistling or hissing sound indicates leakage. 3. Leakage on the pressure side, between turbo...

Page 16

Ol1276 03/10 16 3. If chlorides, sulfates or total dissolved solids are higher than the above given specifi cation, the water must be distilled, demineralized, or deionized before it is used in a cooling system. 4. If total hardness is higher than 170 ppm and all other parameters are within the give...

Page 17

Ol1276 03/10 17 coolant testing 1. Coolant test kits are available to allow on-site evaluation of the coolant condition. 2. The kits use small strips of paper which are dipped into the coolant. The paper changes color and indi- cates the sca concentration. It also indicates the amount of egc (antifr...

Page 18

Ol1276 03/10 18 sp18. Zinc anodes continued heat exchanger cooled engine: a. Drain the raw water from heat exchanger (see component locations). B. Remove zinc holders from back of the tank and from front and port side of the heat exchanger (see component locations). Keel cooled engines. A. Drain exp...

Page 19

Ol1276 03/10 19 booster batteries caution: battery gas can explode. Keep all fl ames and sparks away from batteries. 1. Before changing or using booster batteries, check battery electrolyte level. Add distilled water. 2. Booster and main batteries must have the same voltage rating. 3. First, connect...

Page 20

Ol1276 03/10 20 if you cannot correct problems with these procedures, see your lugger or northern lights dealer. Valve. See your dealer. Broken piston spray jet: • replace piston spray jet. See your dealer. Clogged oil pump screen or cracked pick-up tube: • remove oil pan and clean screen/ replace p...

Page 21

Ol1276 03/10 21 if you cannot correct problems with these procedures, see your lugger or northern lights dealer. Excessive fuel consumption (continued) engine overloaded : • reduce load on engine. Compression too low: • determine cause of low compression and repair. Leaks in fuel supply: • locate so...

Page 22

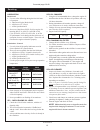

Ol1276 03/10 22 diagnostic trouble codes (dtcs) are found on the diagnostic gauge as 2 part code, according to the j1939 standard. The fi rst part is a 2 to 4 digit suspect parameter number (spn). The second part is a 1 or 2 digit failure mode identifi er (fmi) code. The diagnostic code will be on t...

Page 23

Ol1276 03/10 23 spn fmi description 637 08 crank position input missing 637 10 crank position input pattern error 651 05 cylinder #1 eui circuit open 651 06 cylinder #1 eui circuit shorted 652 05 cylinder #2 eui circuit open 652 06 cylinder #2 eui circuit shorted 653 05 cylinder #3 eui circuit open ...

Page 24

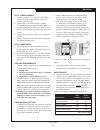

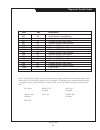

Ol1276 03/10 24 l1276a & l1276a2 marine diesel engines rating high output medium duty continuous duty rpm 2100 1900 1800 engine cylinders 6 6 6 displacement 766 cu in (12.5 l ) 766 cu in (12.5 l ) 766 cu in (12.5 l ) operating cycle 4 4 4 bore 5.0 in (127 mm) 5.0 in (127 mm) 5.0 in (127 mm) stroke 6...

Page 25

Northern lights dc wiring diagram l1276 12 volt standard ground drawing d-4264 ol1276 11-03 26.

Page 26

Northern lights dc wiring diagram l1276 12 volt isolated ground drawing d-4251a ol1276 11-03 27.

Page 27

Northern lights dc wiring diagram l1276 24 volt standard ground drawing d-4030g ol1276 11-03 28.

Page 28

Northern lights dc wiring diagram l1276 24 volt isolated ground drawing d-4026b ol1276 11-03 29.

Page 29

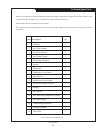

Ol1276 03/10 25 on board spare parts item description qty 1 oil filter 4 2 air filter element 1 3 fuel filter element 4 4 fuel transfer pump 1 5 oil separator element 2 6 injector 1 7 thermostat 2 8 thermostat cover gasket 1 9 speed sensor 1 10 rocker arm cover gasket 1 11 gasket kit, engine overhau...

Page 30

Www.Northern-lights.Com 4420 14th ave. Nw., seattle wa 98107 tel: (206) 789-3880 • 1-800-762-0165 • fax: (206) 782-5455 northern lights and lugger are registered trademarks of northern lights, inc. © 2010 all rights reserved. Litho usa..