- DL manuals

- Northern Lights

- Engine

- OM844W3

- Operator's Manual

Northern Lights OM844W3 Operator's Manual

Summary of OM844W3

Page 2

Diesel engine exhaust and some of its constitu- ents are known to the state of california to cause cancer, birth defects, and other reproductive harm. — california — proposition 65 warning: northern lights 4420 14th avenue n.W. Seattle, wa 98107 tel: (206) 789-3880 fax: (206) 782-5455 copyright ©201...

Page 3: Operator'S Manual

Om844w3 11/13 1 read this operator's manual thoroughly before starting to operate your equipment. This manual contains information you will need to run and service your new unit. Proprietary information this publication is the property of northern lights, inc. It may not be reproduced in whole or in...

Page 4

Om844w3 11/13 2 serial numbers introduction unit identification servicing of marine engines and generator sets presents unique problems. In many cases boats cannot be moved to a repair facility. Marine engines cannot be compared to the servicing of automobiles, trucks or even farm equipment. Failure...

Page 5: Warning

Om844w3 11/13 3 warranty revised 3/13/12 a warranty registration certificate is supplied with your set. The extent of coverage is described in the limited warranty statement. We recommend that you study the statement carefully. Note: if the warranty is to apply, the servicing instructions outlined i...

Page 6: Caution

Om844w3 11/13 4 safety rules revised 3/13/12 operating equipment requires the full attention of the operator. Do not use radio or music headphones while operating machinery. Practice safe maintenance ! Caution understand all service procedures before starting work. Keep area clean and dry. Never lub...

Page 7: Warning

Om844w3 11/13 5 safety rules (continued) revised 3/13/12 install all safety guards ! Warning direct contact with rotating fans, belts, pulley and drives can cause serious injury. Keep all guards in place at all times during engine operation. Wear close-fitting clothes. Stop the engine and be sure al...

Page 8: Caution

Om844w3 11/13 6 safety rules (continued) revised 3/13/12 read and understand the msds for each chemical before you start any job that includes it. Follow the procedures and use appropriate equipment exactly as recommended. Contact your northern lights dealer or northern lights factory for msds’s use...

Page 9: Warning

Om844w3 11/13 7 safety rules (continued) revised 3/13/12 material containing asbestos. Keep all bystanders away from any area where asbestos dust may be generated. Use proper lifting equipment and techniques ! Warning lifting heavy components incorrectly can cause severe injury or damage to machiner...

Page 10: Caution

Om844w3 11/13 8 general policy to avoid dangerous or hazardous situations, refrain from any of the following: • removing or bypassing a guard or other safety device • placing any part of your body in a position where you could be caught by moving machinery. • cleaning or oiling machinery when in ope...

Page 11

Om844w3 11/13 9 notes.

Page 12

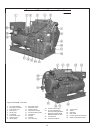

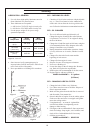

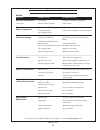

Om844w3 11/13 10 1. Dc circuit breaker 2. Coolant recovery tank 3. Secondary fuel filter 4. Fuel return line 5. Fuel injector 6. Oil fill (top) 7. Coolant fill 8. Fresh water pump 9. Injection pump marine generator component locations 19. Oil filter 20. Lube oil drain 21. Fuel lift pump 22. Control ...

Page 13

Om844w3 11/13 11 1. Dc circuit breaker (not visible. Callout for approximate location) 2. Coolant r ecovery tank 3. Secondary fuel filter 4. Fuel return line 5. Fuel injector 6. Oil fill (top) 7. Coolant fill 8. Fresh water pump marine generator component locations 19. Oil filter 20. Lube oil drain ...

Page 14

Om844w3 11/13 12 commercial generator component locations 1. Dc circuit breaker 2. Secondary fuel filter 3. Fuel return line 4. Fuel injector 5. Oil fill (top) 6. Coolant fill 7. Fresh water pump 8. Injection pump 9. Oil fill (side) 19. Control panel plug-in 20. Ac circuit breaker for automatic volt...

Page 15

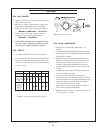

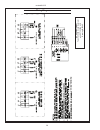

Om844w3 11/13 13 control panels figure 3-b: series 3 generator control panel figure 3-a: series 1-b generator control panel figure 3-c: series 4 generator control panel 1. Shutdown bypass-preheat switch two functions are built into this switch: the preheat- ing of the engine, and bypassing of the en...

Page 16

Om844w3 11/13 14 break-in period 1. The first 100 hours on a new or reconditioned engine are critical to its life and performance. 2. Operate the engine under various conditions, particularly heavy loades with minimal idling, to help seat engine components properly. 3. Frequently check the engine te...

Page 17

Om844w3 11/13 15 shutdowns and alarms 1. Your unit is fitted with a system to protect it from high water temperature or low oil pressure. A. Generator sets have shutdown systems to stop the engine. They have no warning horns. B. Other alarms and shutdowns are available as optional equipment. Note: d...

Page 18

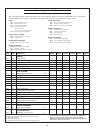

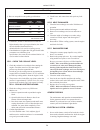

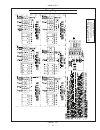

Om844w3 11/13 16 the servicing schedule chart below shows the service schedule required for proper maintenance of your generator set. More detailed coverage of each service point (sp) is listed on the page noted in the ‘page’ column. Daily: sp1 check oil level in engine sp5 check v-belt tension sp7 ...

Page 19

Om844w3 11/13 17 service record notes.

Page 20

Om844w3 11/13 18 servicing lubrication - general 1. Use only clean, high quality lubricants stored in clean containers in a protected area. 2. These lubricants are acceptable: a. Api service cc/cd/ce single viscosity oils. B. Api service cc/cd/sf multi-viscosity oils. 3. Use the proper weight oil fo...

Page 21

Om844w3 11/13 19 sp4. Air cleaner 1. Inspect air cleaner every 250 hours. In dusty condi- tions, check more often. 2. Marine sets: if dirty, wash element in soapy water. Rinse and dry thoroughly before re-installing. Replace if necessary. The element part number is: m844 w3 and m844 lw3 – #24-23100 ...

Page 22

Om844w3 11/13 20 servicing fuels - general 1. Use only clean, high quality fuels of the following specifications, as defined by astm designation d975 for diesel fuels: a. Use grade no. 2 diesel at ambient temperatures above freezing 32°f (0°c). B. Use grade no. 1 at ambient temperatures below freezi...

Page 23

Om844w3 11/13 21 servicing sp10. Bleeding the fuel system caution: escaping diesel fuel under pressure can penetrate skin causing serious personal injury. Before disconnecting lines be sure to relieve all pressure. Before applying pressure, be sure all connections are tight and lines, pipes and hose...

Page 24

Om844w3 11/13 22 figure 11: remove delivery line flare nuts. Figure 12: remove delivery lines. Figure 13: cover lines, inlets and injection pump outlets. Figure 15: remove return line. Figure 16: unscrew injector. Figure 17: remove and replace copper sealing washer. Figure 18: reinstall injector. To...

Page 25

Om844w3 11/13 23 sp11. Injector service 1. Injectors should be checked every 1000 hours. Check should be made by a northern lights dealer or local injection repair station. Have your dealer check the fuel injection nozzle spray pattern with injection nozzle tester. If the starting pressure is too hi...

Page 26

Om844w3 11/13 24 servicing 2. Here are acceptable water quality specifications: 3. If chlorides, sulfates or total dissolved solids are higher than the above given specification, the water must be distilled, demineralized, or deionized before it is used in a cooling system. 4. If total hardness is h...

Page 27

Om844w3 11/13 25 2. Do not reverse the polarity of battery cables when installing the battery. 3. If welding on the unit, disconnect the regulator and bat- tery. Isolate the leads. 4. Disconnect the battery cables when servicing the d.C. Alternator. 5. Never test with a screwdriver, etc., against an...

Page 28

Om844w3 11/13 26 if you cannot correct problems with these procedures, see your northern lights dealer. Troubleshooting dc electrical system problem possible cause recommendation(s) battery will not charge loose or corroded connections • clean and tighten battery connections. Sulfated or worn out ba...

Page 29

Om844w3 11/13 27 troubleshooting engine problem possible cause recommendation(s) engine hard to start improper starting procedure • see starting section of this manual. Take or will not start special note of bypass switch operation. No fuel • check level of fuel in fuel tank. Low battery output • ch...

Page 30

Om844w3 11/13 28 troubleshooting engine problem possible cause recommendation(s) lack of engine power (continued) overheated engine • see “engine overheats” in next category. Below normal engine temperature • remove and check thermostat. Improper valve clearance • reset valves. Best done by dealer. ...

Page 31

Om844w3 11/13 29 troubleshooting engine problem possible cause recommendation(s) high fuel consumption fuel leakage • improper installation or tightening. (continued) excessive load on engine • check loads. Below normal thermostat not working properly • check thermostat. Engine temperature temperatu...

Page 32

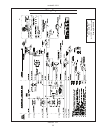

Om844w3 11/13 30 wiring diagrams ac w iring diagram taiyo px300k2 4 lead generator with dst -102f ak a vr drawing b-9724c revised 8/6/12.

Page 33

Om844w3 11/13 31 wiring diagrams ac w iring diagram taiyo px300k2 12 lead generator with dst -100-2f ak avr drawing b-9723a added 9-19-11.

Page 34

Om844w3 11/13 32 wiring diagrams ac w iring diagram avr sx460 with stamford 4 and 12 wire drawing b-5703l revised 6/8/12.

Page 35

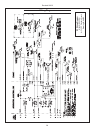

Om844w3 11/13 33 wiring diagrams dc w iring diagram m844, m20cr w for 12 vdc standard ground drawing b-9902b revised 9-19-11.

Page 36

Om844w3 11/13 34 wiring diagrams dc w iring diagram m844w3, m844l w3, m20cr w3 for 12 vdc isolated ground drawing b-101 11a.

Page 37

Om844w3 11/13 35 wiring diagrams dc w iring diagram control panel s-1b drawing a-3170 added 9-19-11.

Page 38

Om844w3 11/13 36 wiring diagrams panel w iring diagram s-3c oceanline / v iewline panels 12v drawing a-12572b added 9-19-11.

Page 39

Om844w3 11/13 37 wiring diagrams panel w iring diagram s-3c v iewline panels 12v drawing a-12645a added 6/8/12.

Page 40

Om844w3 11/13 38 wiring diagrams dc w iring diagram m844w , m20cr w for 24 vdc standard ground drawing b-9907c revised 6/8/12.

Page 41

Om844w3 11/13 39 wiring diagrams dc w iring diagram m844w , m20cr w for 24 vdc isolated ground s-1b drawing b-9906b revised 6/8/12.

Page 42

Om844w3 11/13 40 wiring diagrams dc w iring diagram control panel for 24 vdc isolated ground drawing a-4792 added 9-19-11.

Page 43

Om844w3 11/13 41 wiring diagrams panel w iring diagram s-3c oceanline / v iewline panels 24v drawing a-12594b added 9-19-11.

Page 45

4420 14th ave. Nw., seattle wa 98107 tel: (206) 789-3880 • 1-800-762-0165 • www.Northern-lights.Com northern lights and lugger are registered trademarks of northern lights, inc. © 2013 all rights reserved. Litho usa..