- DL manuals

- Northern Lights

- Marine Equipment

- OWN-ADV

- Installation And User Manual

Northern Lights OWN-ADV Installation And User Manual

Summary of OWN-ADV

Page 2

Northern lights 4420 14th avenue n.W. Seattle, wa 98107 tel: (206) 789-3880 fax: (206) 782-5455 copyright ©2012 northern lights, inc. All rights reserved. Northern lights™, and the northern lights logo are trademarks of northern lights, inc. Printed in u.S.A. Part no.: wavenet 1/12.

Page 3: User Manual

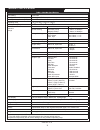

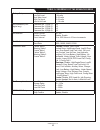

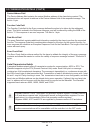

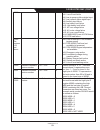

Own-adv 01/12 1 5.4.2 shutdown sequence ........................ 35 5.5 digital output setup ..................... 35 - 37 5.6 digital input setup ............................... 38 5.7 battery setup ...................................... 38 5.8 password setup .................................. 39 5...

Page 4

Own-adv 01/12 2 table 1: wavenet specifi cations vdc rating 12/24 vdc standby current consumption 50 ma @ 12 vdc load equivilancy number (len) wavenet: 1 / wavenet remote:2(nmea 2000® spec. : 1 len=50ma) operating temp -40oc to +85oc (-40of to +185of) lcd operating temp. ** -20oc to +70oc (-4of to +...

Page 5

Own-adv 01/12 1. Wavenet controller series 3 wavenet front view wavenet back view the wavenet is designed for use on generator sets with mechanical engines. It can monitor analog data from senders on the engine and generator such as oil pressure, coolant temperature, current, voltage, engine speed a...

Page 6

Own-adv 01/12 4 a shipping label affi xed to the shipping box includes a variety of product and shipping information, such as items and customer numbers. Make certain that this information matches your order .... Information. Each wavenet controller is packaged in its own box. Do not discard the pac...

Page 7

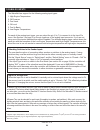

Own-adv 01/12 the following general safety precautions should be headed: 1. The wavenet may carry high voltage/current which can cause serious injury or death. Extreme caution must be exercised when connections are being installed to or from the controller. All wiring connections must be de-energize...

Page 8

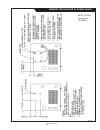

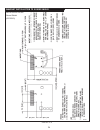

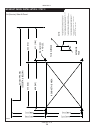

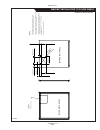

Figure 1 - general wavenet system wiring diagram 6 wavenet is connected on a nmea 2000 network. Installation must be made by an nmea 2000 certifi ed technician. Updated 1-17-12.

Page 9

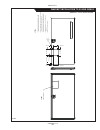

7 figure 2 - digital io example w avenet digital inputs and outputs. Wavenet is connected on a nmea 2000 network. Installation must be made by an nmea 2000 certifi ed technician. Updated 1-17-12.

Page 10

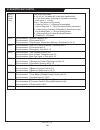

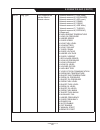

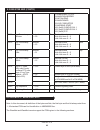

Own-adv 01/12 table 2 table 2: wavenet terminal details quick fit terminals terminal wire size (awg) current max* functions crank 12 40a crank output terminal battery + 3 12 40a positive battery terminal battery - 3 12 40a negative battery terminal fuel 12 40a fuel output terminal extra relay 1 12 4...

Page 11

Own-adv 01/12 table 2 (continued) digital inputs terminal detail terminal location wire size (awg) current max. Function 10 10 18 7ma n/a ground 11 18 7ma ground ground 12 18 7ma ground 1 ground input to generate logic high. 2 tie input to battery + to generator logic high 3 see table 13 on page 38 ...

Page 12

Own-adv 01/12 table 2 (continued) ac current sensing terminal detail terminal location wire size (awg) current max. Function phase a 1 18 5a phase a current sensing ct - phase b 2 18 5a phase b current sensing ct - phase c 3 18 5a phase c current sensing ct - phase a 4 18 5a phase a current sensing ...

Page 13

Own-adv 01/12 4.1 power-up 4.2 controller alarming 4.3 emergency stop 4 wavenet operation & basic user configuration if the emergency stop input of the digital input terminal is not connected to ground the controller will alarm and display “emergency stop” when powered. Emergency stop also forces th...

Page 14

Own-adv 01/12 4.4 controller states 12 the wavenet incorporates 3 primary modes of operation: 1. Off mode 2. Auto mode 3. Run mode 1. Off mode – when the wavenet is set to the off mode, automatic starting will be disabled. No automatic controls will be initiated. The off mode may be initiated when n...

Page 15

Own-adv 01/12 when in the run mode the wavenet lcd screen can be locked to display a particular parameter group. To do this press the up and down keys to scroll to the parameter group you wish to view and then press the enter key to lock the screen. You will see a lock symbol displayed on the top ri...

Page 16

Own-adv 01/12 4.5 wavenet start / stop behavior (cont’d) when the controller is in the auto mode the three manual start conditions above can be used to start the generator. When the controller is in the run mode it will display the reason for start on the screen (nmea 2000 run, manual run). Stopping...

Page 17

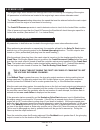

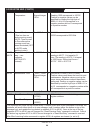

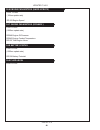

Own-adv 01/12 when you press the enter key in the off mode you will enter the basic menu which includes the clock setup, basic setup, advanced setup, and failure history submenus. 1. Clock setup 2. Basic setup 3. Advanced setup 4. Failure history 4.8 wavenet menu system operation table 3: basic menu...

Page 18

Own-adv 01/12 the wavenet internal clock information can remain “in memory” for approximately 2 weeks when no dc power is supplied to the controller. Two week memory storage is available in a completely charged controller clock. Dc power is required to be supplied continually to the wavenet for appr...

Page 19

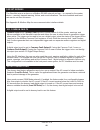

Own-adv 01/12 4.9.2 basic setup (cont’d) 4.9.3 event history log 17 table 5 – basic setup menu menu selection and range contrast adjust 5-95 % page roll delay 1-10 s state roll delay 1-10 (1 is shortest delay, 10 is longest) sleep delay 10-600s. Shorter is ideal to extend the backlighting life. Main...

Page 20

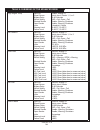

Own-adv 01/12 table 6: event log entries an “*” beside the event entry indicates the event is a wavenet event. All other events are failures. (see page section 4.12 on page 21) event entry description adc switch failure these are internal wavenet failures. Try power cycle the wavenet. If failure occ...

Page 21

Own-adv 01/12 event entry description low oil level see section 5.1 on page 28. Low oil pressure see section 5.1 on page 28. Maintenance needed * the generator requires maintenance. See section 5.9 on page 39 maintenance performed * maintenance has been preformed on the generator (i.E. The maintenan...

Page 22

Own-adv 01/12 some industry standard failures, warnings, and events on the wavenet are indicated by a series of leds on the left side of the controller. Specifi c led indicators will be illuminated depending upon the condition of the controller. The wavenet led indicators allow a quick check of the ...

Page 23

Own-adv 01/12 table 7: wavenet lamp indication meanings (cont’d) led description led color led status indication over speed red yellow solid red solid yellow a solid red illuminated led represents an over speed failure condition. A solid yellow illuminated led represents an over speed warning condit...

Page 24

Own-adv 01/12 when a failure occurs (although most failures only occur in the run mode, the low fuel level and low coolant level failures occur in any state including off and auto) the controller exits the run mode and goes to the failure mode – turning off the fuel output and other outputs on or of...

Page 25

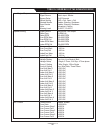

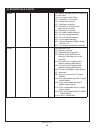

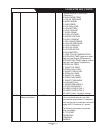

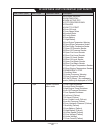

Own-adv 01/12 table 8: advanced menu layout summary menu layout description advanced menu (password protected) high engine temp analog inputs: these control all aspects of the specifi c analog input listed in the left column such as whether it is a switch, sender, or obtained from nmea2000. You can ...

Page 26

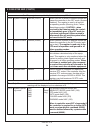

Own-adv 01/12 table 9: submenus of the advanced menu 24 high engine temp input pin signal source bypass delay switch setting shorted sender open sender units warning level failure level disable, analog 2-7 switch input, sender 1, 2, or 3 10-60 seconds gnd = fail, open = fail disable, warning, shutdo...

Page 27

Own-adv 01/12 table 9: submenus of the advanced menu 25 low engine temp input pin signal source bypass delay switch setting shorted sender open sender units warning level reserve, analog 2-7 switch input, sender 10-60 seconds gnd = fail, open = fail disable, warning, shutdown disable, warning, shutd...

Page 28

Own-adv 01/12 table 9: submenus of the advanced menu a/c current over current warn 4 over current fail 4 hi wye current cur warn latch 0-6500 a 0-6500 a 100%, 50% disable, enable engine logic delay to start glowplug time crank time midheat time crank rest time crank attempts fuel crank rest false re...

Page 29

Own-adv 01/12 table 9: submenus of the advanced menu battery setup low warn level low fail level high warn level high fail level low vol incrank 7-24 volts 7-24 volts 12-32 volts 12-32 volts 4 – 18 volts set password (four digits long) password no. 1 (digit 1) password no. 2 (digit 2) password no. 3...

Page 30

Own-adv 01/12 the wavenet has support for the following analog input types: 1. High engine temperature 1 2. Oil pressure 3. Fuel level 4. Oil level 5. Fuel in basin 6. Low engine temperature 2 for each of the analog input types, you can select the pin (2 to 7) to connect to in the input pin menu. Se...

Page 31

Own-adv 01/12 each of the analog types support warnings and/or failures (senders only). In the case of high engine temperature, if the data from the sender exceeds the value set the controller will give a warning or failure. For the other analog input types, the data from the source must drop below ...

Page 32

Own-adv 01/12 table 10 - default sender tables position 1 position 2 position 3 high engine temperature / low engine temperature front panel menu name datcom 1 vdo 2 murphy 1 sender utility name datcon 330f 491 ohm vdo 266f 488 ohm murphy 368f 4880 ohm sender part # datcom 2202-00, 02024-00 and 0202...

Page 33

Own-adv 01/12 for the magnetic pickup and generator output options you must select the rated frequency and rated speed. The wavenet uses these values together to calculate the engine speed from the magnetic input or generator output. The rated speed is the speed (in revolutions per minute, rpm) the ...

Page 34

Own-adv 01/12 5.3.2 ac voltage (cont’d) voltage group 4 has an option (the group 4 setting submenu under the ac voltage menu) for four wire delta or three phases (default). The two different confi gurations are shown in figure 4. The three wire delta requires three voltage transformers to create the...

Page 35

Own-adv 01/12 5.3.2.1 voltage select inputs (cont’d) table 11: voltage select inputs voltage confi guration digital inputs volt select 1 volt select 2 voltage group 1 (single phase) 1 phase, 3-wire (2-wire option also selectable) open circuit open circuit voltage group 2 3 phase, 4-wire wye active *...

Page 36

Own-adv 01/12 the engine logic menu contains the settings that control the starting and stopping of the engine. All parameters in bold below are located in the engine logic menu unless otherwise noted. The crank disconnect setting determines the speed that must be attained before the crank output is...

Page 37

Own-adv 01/12 the wavenet has a safety feature where a locked rotor condition will be detected. To disable this feature set the crank oil pressure in the engine logic menu to 0. The crank oil pressure is the oil pressure usually seen while the engine is cranking. During the cranking, if the oil pres...

Page 38

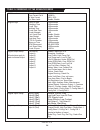

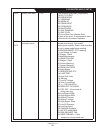

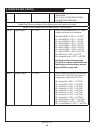

Own-adv 01/12 name description high temp failure this turns on the digital output if the high engine temperature failure is activated. See section 5.1 for more details. High temp warning this turns on the digital output if the high engine temperature warning is activated. See section 5.1 for more de...

Page 39

Own-adv 01/12 over voltage warning this turns on the digital output when the ac over voltage warning is activated (section 5.3.2). Over current warning this turns on the digital output when the ac over current warning is activated (section 5.3.3). Fuel in basin warning this turns on the digital outp...

Page 40

Own-adv 01/12 38 5.6 digital input setup there are eight digital inputs. Each input can be selected to any of the features given in table 13 below. Table 13 – digital input selections name description low air pressure this input generates a low air pressure failure when active only in crank. It is i...

Page 41

Own-adv 01/12 39 the wavenet allows a 4 digit password to be entered to protect the advanced setup menu from any unauthorized changes. This password will be needed to perform any changes to the advanced setup. If the password is entered incorrectly, the controller will allow 3 more tries before the ...

Page 42

Own-adv 01/12 40 the wavenet acts as a slave on a modbus rs-485 network and can – on request by the master device – remotely transmit warning, failure, and event indications. The device address and baud rate can be set from this menu. See appendix b: modbus map for more communication interface detai...

Page 43

Own-adv 01/12 the user can select the engine instance and manual stop confi rmation disable/enable. 41 engine instance - the engine instance range is from 0 to 252, the devices in the nmea2000 network can use engine instance as unique identity to recognize others. Stop confi rmation disable/enable -...

Page 44

Own-adv 01/12 42 there are 3 main display pages for remote unit: the remote unit settings page, on-line genset status page and on-line genset parameters page. When the wavenet remote unit powers on, it will go to the on-line genset status page. Up to three gensets can communicate on the nmea 2000 ne...

Page 45

Own-adv 01/12 43 run - the local wavenet panel is running and the genset can be stopped from any enlisted wavenet remote by pressing the stop key. This state includes some sub-states like “cranking, preheat, warm-up, running, idle-running, cooling down,etc.” the detail sub-state messages will show o...

Page 46

Own-adv 01/12 44 updated 1-20-12 access this mode by pressing the info key from the on-line genset status page. Press info or hold stop to return to the on-line genset status page. On the remote unit settings page, there are 3 settings menus. The clock setup, basic setup and advanced setup will allo...

Page 47

Own-adv 01/12 table 15 – wavenet wiring harness part list harness description part number ac harness assembly 22-40541/22-40619/22-40651 dc harness assembly 22-40612 673 ac wire harness 22-40575/22-40651 673 dc wire harness 22-40570 wavenet nmea panel connector 22-40598 8 appendix a: accessory list ...

Page 48

Own-adv 01/12 current transformers are required for display of ac current. One ct is required for each phase to be displayed. The wiring for ct’s is as follows: in single phase applications: • phase a to terminals phase a* • phase b to terminals phase b* in three phase applications: • phase a to ter...

Page 49

Own-adv 01/12 output relays are protected by onboard 40a fuse protection. Smaller amperage fuses from many automotive stores may be used in place of the higher current 40a. If installing lower amperage fuse protection be certain that current draw does not exceed the fuse current limit. 8.5 wavenet f...

Page 50

Own-adv 01/12 device address field the device address fi eld contains the unique modbus address of the slave being queried. The addressed slave will repeat its address in the device address fi eld of the response message. This fi eld is 1 byte. Function code field the function code fi eld in the que...

Page 51

Own-adv 01/12 9.2 modbus commands wavenet supports two modbus commands “0x03 read holding register (4x)” and “0x06 write single register” to make the communication work, user need to setup something in wavenet setting to correspond- ing with the rsa unit. In the wavenet advanced menu, there is a men...

Page 52

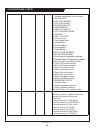

Own-adv 01/12 9.3 register map (cont’d) 40003 - 40010 (read only) each event uses 5bits, b4, b3, b2, b1, b0 where b0 is the least signifi cant bit. B0 = the event status (warning or shutdown occurring) 0 = not active, 1 = active b2-b1 = the severity of the event 0 = take no action, 1 = warning/ackno...

Page 53

Own-adv 01/12 2nd generation modbus register support basic modbus functions 1. Controller information (read only) 40080 wavenet front panel led status 0 = off, 1 = on r bit0: over crank failure (red) bit1: over crank warning (amber) bit2: high engine temp. Failure (red) bit3: high engine temp. Warn ...

Page 54

Own-adv 01/12 40083 bit0: battery low and high level warning bit1: not used bit2: low coolant level failure bit3 : controller is not in auto bit4: failure has occurred bit5 : cranking rest active bit6: controller is in run mode (after crank success) bit7: controller is cranking bit10: ac under volta...

Page 55

Own-adv 01/12 40085 bit0 to bit4: (reserved) bit5 : low oil level failure bit6: low air pressure failure digital input bit7: low hydraulic failure digital input bit8: auxiliary input failure bit9: low battery level failure bit10: high battery level failure bit11: ac over voltage failure bit12: ac un...

Page 56

Own-adv 01/12 2. Start/stop control and command start/stop registers are polled by the controller every 250ms. 40098 system disable 0x5da2 (23970) w when 0x5da2 is written to address 40098 this places the controller in the off mode (system disabled). The register is read in all control- ler operatin...

Page 57

Own-adv 01/12 40101 system sub-state 0 ~ 40 r the controller sub-mode (if applicable): 19 dly to start 20 preheating 21 cranking 22 warm up 23 crank rest 25 cooldown 26 shutdown 27 idle running 31 idle cool 33 front panel run (manual run) 0 none of the above. 0 corresponds to none of the above sub m...

Page 58

Own-adv 01/12 9.3 register map (cont’d) 56 34 lock mark symbol (screen locked when in run mode) 35 not in auto 36 off for silence 37 off for alarm 38 power on ecm... 39 waiting ecm... 40 new active dtc 41 dtc process down 43 failure 45 wait to start 46 low oil level 47 low speed warn 48 locked rotor...

Page 59

Own-adv 01/12 8 internal reserved 8 ( eeprom ) 9 (reserved ) 10 high engine temp 11 low oil pressure 12 under speed 13 over speed 14 low fuel level 15 low battery 16 low coolant 17 over crank 18 over voltage 19 under voltage 20 over current 21 eps loads error 22 low air pressure 23 low hydraulic 24 ...

Page 60

Own-adv 01/12 9.3 register map (cont’d) 58 crank rest cooldown idle cool (cooldown in idle) low battery prelarm 4. Digital i/o and analog inputs (read only) allows the status of the digital inputs and outputs to be read. Digital i/o and analog input will update every 1 second once. 40110 digital inp...

Page 61

Own-adv 01/12 9.3 register map (cont’d) 59 advanced modbus register support 1. Engine-generator parameters (read only) running parameters will update every 1 second. The engine speed, high engine temperature, low engine temperature, oil pressure, and fuel level parameters display 0xff01 if not avail...

Page 62

Own-adv 01/12 9.3 register map (cont’d) 60 40175 pcb board temperature -55 ~ 130 signed integer 16 bit r 1 bit 0.1c reading 1000 corresponds to 100.0c positive or negative values can be identifi ed by reading the high byte of msb. A 1 in bit 15 corresponds to a negative number while a 0 corresponds ...

Page 63

Own-adv 01/12 9.3 register map (cont’d) 61 40131 log type only supports the values listed in format column. R 1 internal reserved 1 ( ade read ) 2 internal reserved 2 ( keyboard) 3 internal reserved 3 ( adc read ) 4 internal reserved 4 ( rs485 ) 5 internal reserved 5 ( rs232 ) 6 internal reserved 6 ...

Page 64

Own-adv 01/12 9.3 register map (cont’d) 62 51 emergency stop 54 maintain needed 55 initializing 56 maintained 62 log corrupted 63 modbus start 162 (0xa2) config fail 1 163 (0xa3) config fail 2 233 (0xe9) dtc 40132 log time stamp minutes decimal 0 ~ 59 r decimal format high 4-bit tens 0 ~ 5 low 4-bit...

Page 65

Own-adv 01/12 63 table 21 - pgn 130818 start position (byte) data length parameter name description 1.1 11 bits manufacturer code northern lights 374 2.4 2 bits reserved bits set to all ‘1’ 2.6 3 bits industry group marine: 4 3 1 byte proprietary identity checksum on transmitting side: the local sou...

Page 66

Own-adv 01/12 64 start position (byte) data length parameter name description 5 1 byte genset controller sub-state 21 cranking (remote unit displays “cranking”) 22: warm up (remote unit displays “warm-up”) 23: crank rest (remote unit displays “crank rest”) 24: nmea2000 running (remote unit displays ...

Page 67

Own-adv 01/12 10.1 northern lights proprietary (fast packet) 65 start position (byte) data length parameter name description 38 power on ecm... 39 waiting ecm... 40 new active dtc 41 dtc process down 43 failure 45 wait to start 46 low oil level 47 low speed warn 48 locked rotor 49 fuel in basin 50 l...

Page 68

Own-adv 01/12 10.1 northern lights proprietary (fast packet) 66 start position (byte) data length parameter name description 9 1 byte genset controller failure code 18 loss of ecm (failure) 19 eps supplying load (failure) 20 user text 1 (failure) 21 user text 2 (failure) 0 no failure 10 2 bytes trip...

Page 69

Own-adv 01/12 10.1 northern lights proprietary (fast packet) 67 start position (byte) data length parameter name description 14 4 bytes genset control- ler led status bit19: glow plug on (green) bit20: failure is active (red failure led) bit21 to bit31: (reserved) bit20: failure is active (red failu...

Page 70

Own-adv 01/12 68 pgn: 127488 (100ms update rate) dd129 engine speed 10.6 engine parameters (rapid update) pgn: 127489 (1000ms update rate) dd049 engine oil pressure dd043 engine coolant temperature dd132 total engine hours 10.7 engine parameters (dynamic) pgn: 127508 (1500ms update rate) dd136 batte...

Page 71

69 this page intentionally blank.

Page 72

11 appendix d: additional drawings own-adv 01/12.

Page 74

This page intentionally blank.

Page 75

Own-adv 01/12 71 wavenet installation to sound shield b-9802a m673l/tf276d sound shield (05-78000).

Page 76

Own-adv 01/12 72 wavenet installation to sound shield b-9917 m673l3/ld3/tf276d sound shield (05-78010).

Page 77

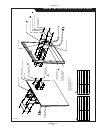

Own-adv 01/12 wavenet installation in sound shield panel co nnec tion harness module encl osure module encl osure c over [4x] #6 st ainless helical l ock wa sher [4x] 6-32 x 1/2" l ong pa n head st ainless steel ma chine scre ws. Pa nel mount nmea recept acle. (inst alls from inside) [2x] strain rel...

Page 78

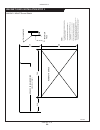

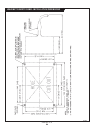

Own-adv 01/12 wavenet installation to sound shield 74 added 8-4-11 b-9947 4. L o ca te hole centers and cut out c orners using centerpunch. 5. Deburr holes, break sharp edges. 3. La yout area to be cut out using dimensions as shown. Dimensions are taken from the outer p anel edge. 1. P anel surf ace...

Page 79

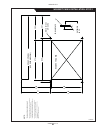

Own-adv 01/12 wavenet installation to sound shield 75 added 8-4-11 b-10057 140.0 [5.51] 184.0 [7.24] 245.3 [9.66] 30.8 [1.21] 279.4 [11.00] 146.1 [5.75] 57.2 [2.25] 114.3 [4.50] 8.0 [0.31] 162.0 [6.38] 55.5 [2.19] 117.6 [4.63] Ø4.0 [ Ø0.16] 4 holes. Panel stiffener edge 2. Using a bo x cut ter with ...

Page 80

Own-adv 01/12 wavenet installation to sound shield 76 added 8-4-11 b-9948 4. L oca te hole centers and cut out c orners using centerpunch. 5. Deburr holes, break sharp edges. 3. La yout area to be cut out using dimensions as shown. Dimensions are taken from the outer p anel edge. 1. P anel surf ace ...

Page 81

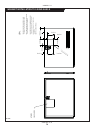

Own-adv 01/12 wavenet panel installation: step 1 77 added 8-4-11 b-9973 2. Secure templa te to p anel surf ace with m asking tape. 3. Using a bo x cut ter with fresh blade, m ake cut foll owing lines. Use of straight edge to guide blade 4. M ake initial cut shall ow , down to the fo am barrier. 1. W...

Page 82

Own-adv 01/12 78 added 8-4-11 b-9974 wavenet panel installation: step 2 m844l / 844 sound shield, rh (service) side aft panel. 4. Secure templa te to p anel surf ac e with m asking tape. 5. L o ca te hole centers and cut o ut c o rners using centerpunch. 6. Deburr holes, break sharp edges. 3. Align ...

Page 83

Own-adv 01/12 wavenet installation to sound shield 79 added 8-4-11 b-9949 4. L o ca te hole centers and cut out c orners using centerpunch. 5. Deburr holes, break sharp edges. 3. La yout area to be cut out using dimensions as shown. Dimensions are taken from the outer p anel edge. 1. P anel surf ace...

Page 84

Own-adv 01/12 wavenet panel installation step 1 b-9728a 2. Secure templa te to p anel surf ac e with m asking tape. 3. Using a bo x cut ter with fresh blade, m ake cut foll o wing lines. Use of str aight edge to guide blade 4. M ake initial cut shall o w , down to the fo am barrier. 1. With the inte...

Page 85

Own-adv 01/12 81 wavenet panel installation: step 2 b-9729a 4. Secure templa te to p anel surf ac e with m asking tape. 5. L o ca te hole centers and cut out c o rners using centerpunch. 6. Deburr holes, break sharp edges. 3. Align the outer edge of this dr aw ing with upper right hand c o rner, to ...

Page 86

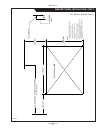

Own-adv 01/12 82 added 8-4-11 b-10058 2. Using a bo x cut ter with fresh blade, m ake cut foll owing lines. Use of straight edge to guide blade 4. M ake initial cut shall ow , down to the fo am barrier. 1. With the interior (sound fo am) side f acing yo u, la y out the area to be removed as shown wi...

Page 87

Own-adv 01/12 wavenet installation to sound shield 83 added 8-4-11 b-10059 146 [5.75] 76.2 [3.00] 8.0 [.31] 162 [6.38] 42.4 [1.67] 114.3 [4.50] 40.8 [1.61] 117.6 [4.63] Ø4.0 [ Ø.16] 4 holes step 2. Step 1. Ex terior f ace (p anel) interior f ace (fo am) 4. L o ca te hole centers and cut out c orners...

Page 88

Own-adv 01/12 84 wavenet remote panel installation dimensions b-9829.

Page 91

Www.Northern-lights.Com 4420 14th ave. Nw., seattle wa 98107 tel: (206) 789-3880 • 1-800-762-0165 • fax: (206) 782-5455 northern lights and lugger are registered trademarks of northern lights, inc. © 2012 all rights reserved. Litho usa..