- DL manuals

- NorthStar

- Power Tool

- 49162

- Owner's Manual

NorthStar 49162 Owner's Manual

SAVE THESE INSTRUCTIONS

163cc Reversible Plate Compactor

Owner’s Manual

WARNING:

Read and understand all instructions, warnings, and cautions before using this

product. Failure to follow the instructions, warnings, and cautions may result in serious personal

injury and/or property damage.

Item #49162

Summary of 49162

Page 1

Save these instructions 163cc reversible plate compactor owner’s manual warning: read and understand all instructions, warnings, and cautions before using this product. Failure to follow the instructions, warnings, and cautions may result in serious personal injury and/or property damage. Item #4916...

Page 2

Page 2 of 28 thank you very much for choosing a northstar product! For future reference, please complete the owner’s record below: serial number/lot date code: ________________________________ purchase date: ____________________________________________ save the receipt, warranty, and this manual. Th...

Page 3

Page 3 of 28 table of contents intended use .......................................................................................................................................... 4 technical specifications .............................................................................................

Page 4

Page 4 of 28 intended use the reversible plate compactor produces low amplitude high frequency vibrations, designed to com- pact granular soil, cable and water trenches, marginal strips as well as all those compaction jobs for which the use of large machines is not convenient. It is equipped with a ...

Page 5

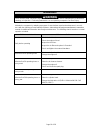

Page 5 of 28 technical specifications compactor weight 202.8 ~ 209.4 lbs. (92 ~ 95 kg) centrifugal force 4046 lbs. (1835 kgf) vibration frequency 100 hz (6000 vpm) travel speed (depending on soil) 82 ft./min (25 m/min) grade ability 20% compacted area (depending on soil) 6781.2 ft 2 /hr (630 m 2 /hr...

Page 6

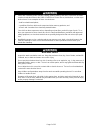

Page 6 of 28 some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to the state of california to cause cancer, birth defects, or other repro- ductive harm. Some examples of these chemicals are: - lead from lead-based paints, - crys...

Page 7

Page 7 of 28 personal safety stay alert, watch what you are doing, and use common sense when operating the tool. Do not use the tool while you are tired or under the influence of drugs, alcohol, or medication. Dress properly. Do not wear loose clothing, dangling objects, or jewelry. Keep your hair, ...

Page 8

Page 8 of 28 compactor use and care do not force the product. Products do a better and safer job when used in the manner for which they are designed. Plan your work, and use the correct product for the job. Check for damaged parts before each use. Carefully check that the product will operate proper...

Page 9

Page 9 of 28 specific operation warnings to avoid fatal accident stop the engine before refueling and be careful not to spill fuel. Spilled fuel may ignite. Do not refuel the engine near flammable objects to avoid fire. Do not run the engine in enclosed areas to prevent carbon monoxide poisoning. To...

Page 10

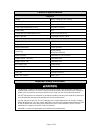

Page 10 of 28 main parts of plate compactor 01 handle 02 handle bar 03 hydraulic oil refill bolt 04 frame 05 engine air filter 06 engine fuel tank 07 accelerator lever 08 hand pump piston 09 engine base plate 10 vibrator plate 11 hydraulic hose 12 isolated rubber 13 engine muffler 14 pulley cover 15...

Page 11

Page 11 of 28 before each use engine recommended fuel the compactor engine requires fresh, clean, regular, unleaded gasoline. Fuel containing wa- ter or dirt will damage the fuel system. Consult to engine owner’s manual for complete fuel specifications danger: adding fuel to the tank should be don...

Page 12

Page 12 of 28 operating instructions operation principle vibrating for ground compacting is accomplished occurred by a vibrator (a) that is installed on the bottom plate (b) for tamping. There are two shafts in the vibrator for forward and reverse. One shaft has two centrifugal vibrators. One of the...

Page 13

Page 13 of 28 engine speeds and machine performance the engine speed influences to the centrifugal force produced by the vibrator and therefore the vibra- tion produced. A fast engine speed results in a strong centrifugal force. A slow engine speed greatly reduces the centrifugal force. Operating on...

Page 14

Page 14 of 28 2) to drive the compactor forward, push the travel lever to the forward position (see below). 3) to drive the compactor backward, pull the lever to the reverse position. Do not move the travel lever with excessive force when engine is turn-off. The lever should move easil y when the en...

Page 15

Page 15 of 28 after each use remove foreign substances such as soil, stone or dirt from compactor and engine. Clean the engine cylinder cooling fins. Clean or replace the air filter. Check the general condition of the compactor. Storage in case of storing the plate compactor for a long period of tim...

Page 16

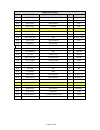

Page 16 of 28 maintenance check that the plate compactor engine is turned off and cooled before attempting any maintenance, cleaning, or inspection. Performing maintenance on an operating compactor can cause injury. Maintain the compactor by adopting a program of conscientious repair and maintenance...

Page 17

Page 17 of 28 changing the v-belt check that the plate compactor engine is turned off and cool before attempting to change the v-belt. Changing the v-belt while the compactor is still operating may cause injury. 1. Loose the four flange bolts (02) to remove the belt cover (01). 2. Loose the three so...

Page 18

Page 18 of 28 parts diagram compactor assembly.

Page 19

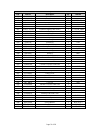

Page 19 of 28 compactor assembly ref. Part no. Description qty remark a01 pm040-000 vibrator plate assembly 1 jpc-940r a02 pa130-002 shock absorber 1 a03 qws-pm10 plain washer 1 m10 a04 qnt-cm10 cap nut 1 m10 a05 pl070-000b handle bar 1 a06 qws-pm12 plain washer 4 m12(10.9t) a07 qws-sm12 spring wash...

Page 20

Page 20 of 28 vibrator plate.

Page 21

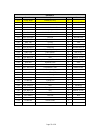

Page 21 of 28 vibratory plate ref. Part no. Description qty remark b01 pl010-000 vibrator plate 1 b02 pl040-002 top cover 1 b03 qws-pm8 plain washer 27 m8 (10.9t) b04 qws-sm8 spring washer 27 m8(10.9t) b05 qbl-hm8x25 bolt 24 m8x25l(10.9t) b06 pl040-011 vibrator cylinder cover 1 b07 qfu-pt,pf 1/4 hyd...

Page 22

Page 22 of 28 handle bar.

Page 23

Page 23 of 28 handle bar ref. Part no. Description qty remark c01 pl071-000b handle bar ass'y 1 c02 qnt-m16 nut 2 m16 (10.9t) c03 qws-pm16 plain washer 2 m16 (10.9t) c04 pl050-002 handle bar bracket(r) 1 c05 qcws-sm16 conical spring washer 2 m16 c06 pl050-000 handle bar bracket(l) 1 c07 qbl-m16x180h...

Page 24

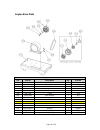

Page 24 of 28 engine base plate engine base plate ref. Part no. Description qty remark d01 pl100-000 centrifugal clutch assembly 1 d02 qky-5x5x50 key 1 5x5x50l d03 qws-pm8 plain washer 1 m8 (Ø35) d04 qws-sm8 spring washer 1 m8 (10.9t) d05 qbl-m8x40 bolt 1 m8x40l d06 qbt-a28 v-belt 1 a28 d07 qws-pm8 ...

Page 25

Page 25 of 28 troubleshooting use the table below to troubleshoot problems before contacting service personnel or your local dealer. If the problem continues after troubleshooting, call your local dealer for assistance. Problem possible cause solution travel lever: no movement or hard switching bloc...

Page 26

Page 26 of 28 replacement parts for replacement parts and technical questions, please call customer service at 1-800-222-5381. Not all product components are available for replacement. The illustrations provided are a con- venient reference to the location and position of parts. When ordering parts,...

Page 27

Page 27 of 28 limited warranty northern tool and equipment company, inc. ("we'' or '"us'') warrants to the original purchaser only ("you'' or “your”) that the north star product purchased will be free from material defects in both ma- terials and workmanship, normal wear and tear excepted, for a per...

Page 28

Page 28 of 28 distributed by northern tool and equipment company, inc. Burnsville, minnesota 55306 northerntool.Com made in korea.