- DL manuals

- NorthStar

- Air Compressor

- 53009

- Owner's Manual

NorthStar 53009 Owner's Manual

READ & SAVE THESE INSTRUCTIONS

8-Gallon Electric Air Compressor

Owner’s Manual

WARNING:

Read carefully and understand all ASSEMBLY AND OPERATION

INSTRUCTIONS before operating. Failure to follow the safety rules and other basic safety

precautions may result in serious personal injury or property damage.

Item #53009

Summary of 53009

Page 1

Read & save these instructions 8-gallon electric air compressor owner’s manual warning: read carefully and understand all assembly and operation instructions before operating. Failure to follow the safety rules and other basic safety precautions may result in serious personal injury or property dama...

Page 2

Page 2 of 24 thank you very much for choosing a northstar ™ product! For future reference, please complete the owner’s record below: serial number/lot date code: ________________________________ purchase date: ____________________________________________ save the receipt, warranty, and this manual. ...

Page 3

Page 3 of 24 table of contents intended use .......................................................................................................................................... 4 packaging contents ...................................................................................................

Page 4

Page 4 of 24 intended use the northstar 8-gallon electric air compressor provides compressed air used primarily for operating air tools and pressuring other objects that require high air pressure, such as tires. Do not use for low- pressure objects such as balloons, air mattresses, and sport balls, ...

Page 5

Page 5 of 24 this equipment for a purpose for which it was not intended. Industrial or commercial applications must follow osha requirements. ⚠warning this product may contain chemicals known to the state of california to cause cancer, birth defects, or other reproductive harm. Some dust created by ...

Page 6

Page 6 of 24 stay alert, watch what you are doing, and use common sense when operating the compressor. Do not use the tool while you are tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating the tool may result in serious personal injury. Dress proper...

Page 7

Page 7 of 24 specific operation warnings ⚠warning moisture in supply air when compressed will form into droplets as it leaves air compressor pump and enters receiver tank. When humidity is high or when a compressor is in continuous use for an extended period of time, a significant amount of moisture...

Page 8

Page 8 of 24 ⚠warning flying objects hazard always wear the proper protective equipment including ansi z87.1 compliant eye protection. Air-powered equipment and power tools are capable of propelling items (metal chips, fasteners, and particulates) at high speed into the air and could result in injur...

Page 9

Page 9 of 24 ⚠warning explosion and fire hazard do not use the compressor in the presence of gasoline, solvents, flammable liquids, or flammable vapors. This compressor can produce sparks which can ignite flammable liquids and vapors, causing fire or explosion. Abrasive tools such as grinders, drill...

Page 10

Page 10 of 24 double insulated tools: tools with two-prong plugs tools marked double insulated do not require grounding. They have a special double insulation system which satisfies osha requirements and complies with the applicable standards of underwriters laboratories, inc., the canadian standard...

Page 11

Page 11 of 24 make sure your extension cord is properly wired and in good electrical condition. Always replace a damaged extension cord or have it repaired by a qualified electrician before using it. Protect your extension cords from sharp objects, excessive heat, and damp or wet areas. Main parts o...

Page 12

Page 12 of 24 6. Regulator: the air coming from the air tank is controlled by the regulator knob. Turn the regulation knob clockwise to increase discharge pressure, and counter-clockwise to decrease discharge pressure. Follow tool operating instruction for recommended pressure range. 7. Asme safety ...

Page 13

Page 13 of 24 ref. 2: wheel set 1. Attach the tank wheels to the tank frame using the tank wheel bolts and o-rings in mounting structure. 2. The convex side of the wheel rims has to face inwards toward the air tank. ⚠warning the convex side of wheel rim has to face inwards to the air tank otherwise ...

Page 14

Page 14 of 24 operating instructions ⚠caution break in period before initial use, open the drain valve and run the compressor without air tools attached and through open air for 20 minutes to break-in pump parts. 1. Verify that the pressure switch is in the off position. 2. Turn regulator counter cl...

Page 15

Page 15 of 24 when operating the air compressor, make sure all other people and animals maintain a safe distance. Do not move the air compressor when the air tank is under pressure. Never use the air hoses to pull or move the air compressor. For use on a hard, level surface capable of sustaining the...

Page 16

Page 16 of 24 vapors. This compressor can produce sparks which can ignite flammable liquids and vapors, causing fire or explosion. Abrasive tools such as grinders, drills and other tools are capable of making sparks that can ignite flammable materials, liquids and vapors causing fire or explosion. A...

Page 17

Page 17 of 24 maintenance ⚠warning always disconnect, lock out, and tag the main power supply and then release air pressure from the air tank before cleaning, adjusting, or servicing the compressor. Make sure all guards and shields are replaced before re-starting. Maintain the product by adopting a ...

Page 18

Page 18 of 24 inspect air filter. Inspect the compressor ’s air filter on a weekly basis. A dirty air filter will not allow the air compressor to operate at full capacity. Clean air filter if dirty and restricted air flow. Replace the air filter every 12 months or 1000 hours. Note: do not operate wi...

Page 19

Page 19 of 24 failure possible cause corrective action loose piping tighten as required foreign material on piston clean piston compressor over heated undersized unit for air requirements contact your compressor distributor air leaks in the system fix leaks restricted air filter clean or replace fil...

Page 20

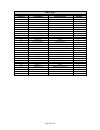

Page 20 of 24 parts list reference part number part description quantity 1 3401x034b air tank 1 2 2405012 drain valve 1 3 3433013-a rubber pad set 2 4 2b20-fm08 hexagon head nut 2 5 2402054 tank wheel 2 6 2n52-30*12 o-ring 2 7 2418001 tank wheel bolt 2 8 2414025 check valve 1 9 2n06-01t02h unloading...

Page 21

Page 21 of 24 parts diagram- pump.

Page 22

Page 22 of 24 parts list reference part number part description quantity 1 3101-we11 cylinder head 2 2 2b00-m06*065 hexagon socket set bolt 12 3 2g01-we11 cylinder head seal 2 4 3b13-we11 in. & ex. Valve assembly 2 5 2g03-we11 valve seat seal 2 6 3201-we11 cylinder 2 7 2214-we06 piston ring plate 2 ...

Page 23

Page 23 of 24 limited warranty northern tool and equipment company, inc. ("we'' or "us'') warrants to the original purchaser only ("you'' or "your") that the northstar product purchased will be free from material defects in both materials and workmanship, normal wear and tear excepted, for a period ...

Page 24

Page 24 of 24 distributed by: northern tool & equipment company, inc. Burnsville, minnesota 55306 www.Northerntool.Com made in taiwan.