• allen wrench set (inch) • center punch • flat blade screwdriver (potentiometer & terminal size) • wire stripper • screwdriver (phillips size 2) • #7 drill 1/4-20 tap (metal frame install) • tape ruler Ø3/8 drill (door sex bolt install) • power drill ! Tools required: use screw pack and hardware pr...

Note: flags included in this instruction sheet show a pull side installation instead of a push side installation. Use video segments for reference only. For assistance, contact norton technical product support at 800-438-1951 ext 4706. 3000 highway 74 east • monroe, nc 28112 tel: 800-438-1951 ext 47...

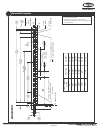

Notes: • all dimensions are given in inches. • thickness recommended for reinforcements in hollow metal doors and frames is charted at the left of this page. • do not scale drawing. • this template information based upon use of 5" maximum width butt hinges. • maximum frame reveal is 4-3/4" for 6060 ...

Edge of frame or of hinge c l “a” 21-5/16” 5/16” frame rabbet door opening angle dim “a” 4-1/8” 3-1/2” 2-7/8” 2-3/8” 2-0” 1-5/8” 85° 90° 95° 100° 105° 110° initial frame holes 1b left hand door illustrated. A. Using template, locate and prepare holes in the frame. B. Drill #7 and tap 1/4-20 machine ...

Page 5 assa abloy initial wall prep 1c back plate mounting 2a i ii i ii a. Install (2) 1/4-20 x 1” screws into holes drilled in step 1b. Leave 1/8” gap between bottom of screw head and frame. B. I) install back plate assembly over screws in step 2a and ii) slide back plate toward latch edge of door....

See page 24 for removable template. Remaining back plate screws 3 a. B. Install (7) 1/4-20 x 1” screws into holes drilled in step 3a. Leave 1/4” gap between bottom of screw head of screws marked “closer” and frame. C. Support between back plate and wall is required. Drill #7 and tap 1/4-20 machine s...

Prep door for shoe 6 mount adjusting tube and shoe assembly on door 7 a. B. Orient shoe with long side of snubber shoe toward hinge and adjusting rod toward the top of the door as shown in illustration. Install (2) 1/4-20 x 1” screws thru shoe and into sex bolts installed in step 7a. Install sex bol...

Assemble arm to pinion 8 secure arm to pinion 9 a. Secure main arm to pinion with provided screw. B. Tighten arm screw with 7/16” wrench. Secure adjusting rod and arm slide tube 10 a. Rotate main arm away from hinge until adjusting rod and arm slide tube are perpendicular (at 90 degrees) with the do...

Closer spring force adjustment 11 mechanical closer adjustments 12 slowly increase closer power until door closes consistently. Note: a closer set to the ada required 5 lbs opening force may not be strong enough to close the door due to latching hardware, air pressure, or frame issues. - + stronger ...

Page 10 assa abloy incoming power connection 13 controller interface 14 lcd screen joystick see page 13 for controller adjustment options. A. To power unit, flip switch on end cap furthest from the hinge from “off” to “on” position. B. To scroll thru menu items, push up or down on joystick. C. To ch...

Install cover and label 17 ½ left hand door right hand door a. If using surface mount power input only, remove appropriate shaded area from cover, see illustration below. Repaint cut edges as necessary to prevent corrosion. B. Place cover over unit and secure with (6) 6-32 screws taken out previousl...

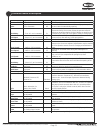

Controller error codes error code description short circuit a short was sensed on the motor outputs temperature trip power module reached 200°f or greater (too much load in too hot ambient condition) over voltage line voltage has reached 145vac or greater under voltage line voltage has dropped below...

Page 13 assa abloy controller interface description screen display adjustments default description mount: push or pull pull side of opening operator is mounted on push: off or pushngo off turn on or off push n go feature.If on, a slight push or pull of the door starts it automatically opening. Obst ...

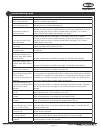

Factory pre-wiring of connections basic wiring diagrams using factory pre-wired connection standard function with switches Ÿ doors are normally closed. Ÿ activating either switch will open both doors. Door will close after hold open time delay has expired. Wall switch, card reader, key switch, etc. ...

Fail safe electric strike or electromagnetic lock 24vdc wiring change factory pre-wiring from illustration a to illustration b (more no to nc) a) b) - 24vdc electric strike (fail secure) wall switch, card reader, key switch, etc. (normally open momentary dry contacts) + fail safe electric strike 24v...

Electric dogging exit device wiring change factory pre-wiring from illustration a to illustration b (more no to nc) a) b) electric dogging exit device wiring Ÿ doors are normally closed and latched. Ÿ turning key switch on will apply power to the exit device. Ÿ the first depression on the device tou...

Electric latch retraction exit device wiring change factory pre-wiring from illustration a to illustration b a) b) electric latch retraction exit device wiring Ÿ doors are normally closed and latched. Ÿ activating switch will retract exit device latch bolt and operator will open the door. Ÿ the door...

Radio frequency standard function wiring (can be ordered pre-wired to this rf wiring) if installing in the field, change factory pre-wiring from illustration a to illustration b a) b) radio frequency standard function Ÿ doors are normally closed. Ÿ activating wireless switch or hand held wireless tr...

Page 19 assa abloy this page left blank copyright © 2015 yale security inc., an assa abloy group company. All rights reserved. Reproduction in whole or in part without the express written permission of yale security inc. Is prohibited. 80-9360-1003-020 (08-15).

Vestibule function wiring gnd +24 nc com no nc com no aux1 gnd pres det gnd aux2 gnd door toggle gnd aux1 aux3 gnd aux2 no conn blow open gnd +24 nc com no nc com no aux1 gnd pres det gnd aux2 gnd door toggle gnd aux1 aux3 gnd aux2 no conn blow open wall switch, card reader, key switch, etc. (normal...

Troubleshooting guide issue seen solution door closing too fast 1) adjust latch and/or sweep valves on closer clockwise or 2) decrease closing speed on controller (see page 10) door closing too slow 1) adjust latch and/or sweep valves on closer counterclockwise or 2) increase closing speed on contro...

Troubleshooting r4 red led blue led antenna wire learn w/o delay button delay potentiometer (time adjustment) learn w/ delay button dip switch terminal strip problem: the led on my receiver is just flickering and i’m unable to program and/or it won’t work. Solution: you have a push plate stuck or fa...

Page 23 assa abloy this page left blank copyright © 2015 yale security inc., an assa abloy group company. All rights reserved. Reproduction in whole or in part without the express written permission of yale security inc. Is prohibited. 80-9360-1003-020 (08-15).

“ b ” 4-1/8 (105) 1-13/16 (46) 5/8 (16) 3/8 (10) 4.0 (102) 13-1/4 (337) 21-5/16 (541) 27-7/8 (708) 30 (762) 3/8 (10) 1-1/4 (32) 1/4-20 machine scre ws or no . 14 w ood scre ws (7 places) f or concealed wired units only (2 places) 3/8 dia. Se x nuts (2 places) door f rame rab bet f rame stop/soffit 5...