- DL manuals

- Norton

- Saw

- BBL13247

- Owner's Manual

Norton BBL13247 Owner's Manual

Summary of BBL13247

Page 1

Owners manual block buster large masonry saw models: bbl547 bbl527 bbl5247 bbl7247 bbl1347 bbl1327 bbl13247 form bbl527-1327 manual rev 12-2010

Page 2: Warranty

Warranty norton construction products warrants all products manufactured by it against defects in workmanship or materials for a period of one (1) year from the date of shipment to the customer. The responsibility of norton construction products under this warranty is limited to replacement or repai...

Page 3: Table of Contents

Table of contents section page i. Preparation a. Safety precautions 3 dust and silica warning 4 b. Assembly 5 c. Assembly conveyor cart & guide a cut 5-6 d. Bbl series masonry saw specifications 7 e. Electrical connections 8 f. Wiring diagram 9 g. Gasoline engine 11 ii. Operation a. How to mount the...

Page 4: I. Preparation

3 i. Preparation a. Safety precautions important! The following safety precautions must always be observed. Hazard symbols fuel (gasoline) is extremely flammable and its vapors can explode if ignited. Store gasoline only in approved containers, in well- ventilated, unoccupied approved areas, and awa...

Page 5: Dust and Silica Warning

4 dust and silica warning grinding/cutting/drilling of masonry, concrete, metal and other materials can generate dust, mists and fumes containing chemicals known to cause serious or fatal injury or illness, such as respiratory disease, cancer, birth defects or other reproductive harm. If you are unf...

Page 6: I. Preparation

5 i. Preparation b. Assembly 1. Remove machine from skid. 2. Remove the conveyor cart and guide-a-cut from the carton and place on the pan. 3. Remove the drain plug from carton and place in drain opening in bottom of pan. 4. Check the owner’s manual for wiring connection and proper electrical connec...

Page 7: I. Preparation

6 i. Preparation c. Assembly conveyor cart & guide-a-cut conveyor cart assembly: remove the conveyor cart and back stop from the saws water pan, and the wing nuts, carriage bolts, washers, and cart stop from the plastic bag. Slide one (1) carriage bolt thru each of the three (3) square holes located...

Page 8: I. Preparation

7 i. Preparation d. Bbl series masonry saw specifications dimensions/weight length 41” (1041mm) width 26” (660mm) height (electric) 54” (1372mm) height (gas) 57” (1448mm) weight (electric) uncrated 440lbs (970kg) weight (gas) uncrated 460lbs (1014kg) electric motor motor mfg. Baldor motor type tefc,...

Page 9: I. Preparation

8 i. Preparation e. Electrical connections important beforeconnecting the motor leads to the power supply, be sure that the voltage, cycles and phase shown on the nameplate of the motor correspond to the available power supply. Both the 5 h.P. And 7-1/2 h.P. Motors have overload protectors and are e...

Page 10: I. Preparation

9 i. Preparation f. Wiring diagram 5hp 230v single phase for any electric motor service, warranty, or technical related questions contact your nearest baldor service center: baldor electric company corporate headquarters 5711 r.S. Boreham, jr. St. P.O. Box 2400 fort smith, ar 72901 phone: (501) 646-...

Page 11

10 f. Wiring diagram 5hp & 7-1/2 hp 230-460v three phase for any electric motor service, warranty, or technical related questions contact your nearest baldor service center: baldor electric company corporate headquarters 5711 r.S. Boreham, jr. St. P.O. Box 2400 fort smith, ar 72901 phone: (501) 646-...

Page 12: I. Preparation

11 i. Preparation g. Gasoline engine prior to attempting to operate the engine, read the information contained in the engine owner's manual. An engine owner’s manual is supplied with every gasoline powered concrete saw. 1. Check oil: add oil if low. Refer to the engine owner's manual for the recomme...

Page 13: II. Operation

12 ii. Operation a. How to mount blade be sure blade shaft collars and arbor are free of dirt and all foreign material before mounting blade on the arbor shaft. Tightening blade against an uneven surface can cause fracture of an abrasive blade or cause to run-out of alignment, causing excessive blad...

Page 14: II. Operation

13 ii. Operation b. How to use " step cutting " with abrasive blades use "step cutting" without exception when cutting wet or dry with abrasive blades. "jam cutting", which is discussed and illustrated in the section following, is to be used only with wet and dry cutting diamond blades. 1. Clamp and...

Page 15: II. Operation

14 1. To lock the head into position, tighten the lever nut at the back of the saw. 2. "step" cutting with diamond blades is done by applying more pressure to the blade. Unlike "step" cutting with abrasive blades, "step" cutting with diamond blades requires only a few passes through the material. 3....

Page 16: III. Maintenance

15 4. Use "step" cutting as explained previously when using abrasive blades. 5. Use "jam" or "step" cutting when using dry cutting diamond blades. E. How to use saw for wet cutting water may be supplied either by filling the water pan to within a half-inch of the top (for continuous use of the same ...

Page 17: III. Maintenance

16 4. Check belt tension frequently during the first day of operation. Check belt tension periodically thereafter and make any necessary adjustments. 5. The two most common causes of misalignment are shown in the drawing. A). The engine drive shaft pulley and the blade shaft are not parallel. See fi...

Page 18: III. Maintenance

17 b. Engine 1. Refer to the engine owner’s manual for complete maintenance. A. Pre-cleaner: every 25 operating hours, more often in dusty or dirty conditions, wash and oil the pre-cleaner. B. Paper element: every 100 operating hours, more often under dusty or dirty conditions, clean the paper eleme...

Page 19: V. Parts List Section

18 lubrication of sealmaster bearings shaft sizes maximum grease capacity of bearing chamber in ounces 1/2" to 3/4" .09 7/8" to 1-3/16" 1/4 1-1/4" to 1-1/2" 3/8 1-11/16" to 1-15/16" 3/4 2” to 2-3/16" 1-1/8 d. Pump the submersible pump require no lubrication for gasoline powered machines mechanically...

Page 20: V. Parts List Section

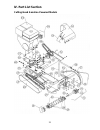

19 v. Parts list section frame all models.

Page 21: IV. Part List Section

20 iv. Part list section frame all models item part number description 1 76146 frame bbl 2 73276 bearing with bushing 3 83830 connecting bar 4 76548 pin kit, connecting bar 5 83728 split bearing 6 76097 water pump fixation spring 7 73266 stay-level arm 8 76039 kit stay-level arm pin 9 76597 cam kit,...

Page 22: IV. Part List Section

21 iv. Part list section cutting head gasoline powered models.

Page 23: IV. Part List Section

22 iv. Part list section cutting head gasoline powered models item part number description 26 76124 cutting head bbl 20” models only 232182 cutting head bbl 24" models only 27 76111 protection for bearings and shaft 28 73418 bearings (set of 2) 29 76060 support for blade shaft bearing (set of 2) 30 ...

Page 24

23 item part number description 58 80568 spray nozzle (set of 2) 59 75280 water pump fixing screw 60 83746 switch support 61 83745 emergency stop switch 62 76015 eyebolt with hardware (1).

Page 25: IV. Part List Section

24 iv. Part list section cutting head electric models.

Page 26: IV. Part List Section

25 iv. Part list section cutting head electric models item part number description 26 76124 cutting head bbl 20” models only 232182 cutting head bbl 24" models only 27 76111 protection for bearings and shaft 28 73418 bearings (set of 2) 29 76060 support for blade shaft bearing (set of 2) 30 73220 bu...

Page 27: IV. Part List Section

26 iv. Part list section electric motor item part number description 62 232088 motor assembly w/switch 5hp 230v/60/1 phase 232099 motor assembly w/switch 5hp 230-460v/60/3 phase 232100 motor assembly w/switch 7-1/2hp 230-460v/60/3 phase 63 232092 receptacle 64 232090 terminal box large -na- 232091 c...

Page 28: IV. Part List Section

27 iv. Part list section cutting table (common all bbl) item part number description 70 83777 conveyor cart complete 71 75333 wheel kit, conveyor cart (set of 4) w/hardware 27282 carriage bolt m10 x 30 din 603 (sold each, 3 required) 27508 washer 10.5 din 9021 (sold each, 3 required) 27040 wing nut ...

Page 29: IV. Part List Section

28 iv. Part list section guide-a-cut assembly (common all bbl) item no description part number -na- guide-a-cut assembly 83892.

Page 30

29.

Page 31

30

Page 32: Saint-Gobain Abrasives

31 saint-gobain abrasives 2770 west washington stephenville, tx 76401 phone: 254-918-2310 fax: 254-918-2312.