- DL manuals

- Norton

- Saw

- C3120

- Owner's Manual

Norton C3120 Owner's Manual

Summary of C3120

Page 1

Owners manual large concrete saws models: c3120 c6120 c3126 c6126 c3130 c6130 c6136 form c6120 7/07 model serial numbers are in a yr/mo/day/ number built sequence ex: 070211007 means it was built feb 11 2007 7th saw bulit.

Page 2: Warranty

2 warranty norton warrants all products manufactured by it against defects in workmanship or materials for a period of one (1) year from the date of shipment to the customer. The responsibility of norton under this warranty is limited to replacement or repair of defective parts at norton's indianapo...

Page 3: Table of Contents

3 table of contents contents page i. Preparation a. Safety precautions 4-6 b. Assembly 7 c. C31xx specifications 8 c61xx specifications 9 ii. Operation a. Blade installation 10-13 changing blade side 12 multiple mounted blades 13 b. Aligning the pointer 13-14 c. Controls and functions 15-17 d. Water...

Page 4: I. Preparation

4 i. Preparation a. Safety precautions important! The following safety precautions must always be observed. Hazard symbols fuel (gasoline) is extremely flammable and its vapors can explode if ignited. Store gasoline only in approved containers; in well ventilated; unoccupied areas approved; and away...

Page 5: Dust and Silica Warning

5 dust and silica warning grinding/cutting/drilling of masonry, concrete, metal and other materials can generate dust, mists and fumes containing chemicals known to cause serious or fatal injury or illness, such as respiratory disease, cancer, birth defects or other reproductive harm. If you are unf...

Page 6

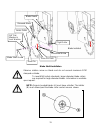

6 a. Safety precautions 1. Before mounting any blade on the saw: the blade should be inspected for any damage which might have occurred during shipment, handling or previous use. 2. The blade collars and arbors should be cleaned and examined for damage before mounting the blade. 3. The blade must be...

Page 7: I. Preparation

7 i. Preparation b. Assembly norton concrete saws are shipped partially assembled to protect parts of the saw which are subject to damage in transit. To prepare the saw for operation the following procedure is required. 1. Inspect the saw for shipping damage. If any damage is found, contact the ship...

Page 8

8 c. C31xx concrete saw specifications dimensions/weight c61xx length (transport) 58 inch(1,473 mm) width 36 inch (914 mm) height 55 inch (1,397 mm) weight crated 1,530 lbs (694 kg) weight uncrated 1,420 lbs (644 kg) engine engine mfg. Deutz model f2l2011 spec no. 7483 number of cylinders 2 engine t...

Page 9

9 c. C61xx concrete saw specifications dimensions/weight c61xx length (transport) 58 inch(1,473 mm) width 39-3/4 inch (1,010 mm) height 55 inch (1,397 mm) weight crated 1,590 lbs (721 kg) weight uncrated 1,540 lbs (700 kg) engine engine mfg. Deutz model bf3l2011 spec no. 7482 number of cylinders 3 e...

Page 10: II. Operation

10 ii. Operation read and understand this manual before running or using the machine! A. Installing the blade 1. Insure that the ignition power key switch is in the off position and then insert the blade shaft locking pin into the blade shaft locking hole. 2. Remove the blade shaft screw, (note: ope...

Page 11

11 blade shaft installation observe rotation arrow on blade and do not exceed maximum rpm stamped on blade. To meet ansi safety standards, larger diameter blade collars are required for large diameter blades. Information is available upon request. Note: organic bonded blades (a) must have a blotter....

Page 12

12 changing the blade side: 1. Insure that the ignition power key switch is in the off position and then insert the blade shaft locking pin into the blade shaft locking hole. 2. Remove the blade shaft screw, (note: operator’s right side is a left hand thread and the operator’s left side is right han...

Page 13

13 9. Attach the blade guard by sliding the blade guard attachment loop over the bayonet mount, attach the blade guard lock pin, and close the hinged blade guard nose. 10. Attach the blade guard by sliding the blade shaft guard attachment loop over the blade guard bayonet mount and then attach the b...

Page 14

14 4. Align the front pointer rod by with the straight line by loosening the front pointer rod retaining screws and moving the front pointer rod. 5. Retighten the front pointer rod retaining screws. 6. To expand the front pointer frame, remove the wing nuts and pull the front pointer extension out w...

Page 15

15 c. Controls and functions prior to attempting to operate the engine, read the information contained in the engine owner's manual. An engine owner’s manual is supplied with every gasoline powered concrete saw. 1. Check oil: add oil if low. Refer to the deutz engine owner's manual for the recommend...

Page 16

16 insure that the operator is familiar with the control and gauge locations and functions before proceeding: control and gauge locations and function chart item type function engine control module w/hour meter control starts engine, led warning indicators and will shut the engine down in the event ...

Page 17

17 item type function 12-volt power point switch control activates the 12-volt power point volt meter gauge displays the charging status of the alternator tachometer gauge displays the engine rpm oil pressure gauge displays the engine oil pressure in psi 5. Starting the engine: a. Insure that the bl...

Page 18

18 m. Allow the engine to warm to operating temperature before use. N. To adjust the engine speed either: a. Press the small button located in the center of the vernier throttle control and pull the large knob of the vernier throttle control towards the rear of the machine to increase the engine spe...

Page 19

19 jackshaft drive 61hp: blade diameter engine rpm engine pulley diameter blade shaft rpm blade shaft pulley diameter blade collar diameter 42 inch (1067mm) 2800 4.0 inch (102 mm) 890 6 inch (152mm) 8 inch (203mm) 48 inch (1219mm) 2500 4.0 inch (102 mm) 800 6 inch (152mm) 8 inch (203mm) d. Water sup...

Page 20

20 lethal exhaust: gas use only in well ventilated areas. Engine exhaust gases contain poisonous carbon monoxide which is odorless, colorless, and can cause death if inhaled. Avoid inhaling exhaust fumes, and never run the engine in a closed building or confined area. Use approved: eye protection he...

Page 21

21 8. If wet cutting turn on the water supply at the source and then open the water valves on the saw. Make sure that there is a minimum of 5 to 8 gallons per minute of water flow!! If using the water pump turn the pump control switch to the “on” position. 9. Be sure that the engine is running at fu...

Page 22

22 11. Transmission engage/disengage lever by fully to the engage position and slowly push the forward/reverse lever forward until the desired speed is reached. Note: the further the forward/reverse lever is moved the faster the machine will move in that direction. If the engine begins to stall or t...

Page 23

23 f. Cutting technique the machine is equipped with depth gauge and a depth stop to help with the sawing process. Depth gauge the depth gauge shows the depth of cut in inches and centimeters. Each time the blade is changed the depth gauge must be reset. To set the depth gauge: 1. Do not start the e...

Page 24

24 depth lock the depth lock allows the operator to set the cutting depth. When the depth lock is used the machine will not lower below the operator preset depth of cut. To set the depth lock: 1. Follow the instructions in sections d. Operating the sawpages 9 to 21 and e. Cutting technique subsectio...

Page 25

25 xx). Do not force the blade in to the cut!! Step cutting provides the best performance (fastest cut and longest blade life). Never saw deeper than 4” per pass as deeper passes will shorten the blade life and places higher stresses on the saw. Never twist, rotate, or bend the blade while in the cu...

Page 26

26 never operate saw with nose guard up. Never stand directly in front or in back of blade, either in or out of the cut. Never operate the saw without the blade guard and blade guard retaining pin in proper position. Use the pointers as a guide. Never exert side press or twist the blade in the cut. ...

Page 27

27 • if the saw stalls in the cut, immediately stop the forward speed and raise the blade out of the cut. If this is not done the belts can fail or the blade may be damaged. • go slowly with a new blade until it opens up, that is, until the diamonds can be seen and felt. • if the saw leads off exces...

Page 28

28 hand side. If the blade is to be used on the operator’s left hand side the lead off will need to be reset. A good starting point is to set the lead off to 1 foot (305mm) movement to the opposite side of the blade in 25 feet (762cm) of forward movement of the saw. Warning: adjustments to the lead ...

Page 29: III. Maintenance

29 iii. Maintenance a: engine always refer to the deutz engine operation manual for complete detailed instructions and latest information. If you do not have your original deutz engine operation manual, contact the deutz corporation for a replacement. Deutz corporation 3883 steve reynolds blvd norcr...

Page 30

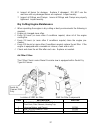

30 locations of engine components: deutz engine components ‡ 1. Oil filler neck 2. Charge-air line 3. Fan w/integrated generator 4. Narrow v-belt 5. Tractive electromagnet 6. Wheel-house cover 7. V-belt pulley on crankshaft 8. Oil pan 9. Shut-off lever 10. Speed control lever 11. Oil dip stick 12. O...

Page 31

31 oil: checking the oil ‡: 1. Fill oil into oil pan up to the “max” mark on the engine dipstick. The engine dipstick is located on the rear of the engine, between the engine and the console. Use either of the two (2) oil filler necks one is located on top of the engine, the other is located on the ...

Page 32

32 oil specifications: oil type (shipped from factory): sae 20w20 oil change quantity with filter: 8.45 qt (8 liters) oil quality grade: lube oils are differentiated by deutz according to their performance and quality class. Oils of other comparable specifications can be used. If you have any questi...

Page 33

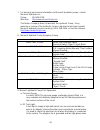

33 oil change intervals ‡: lube oil grade deutz lube oil quality class dqc i dqc ii dqc iii ace specification e2-96 e3-96/e5-02 e4-99 api specification cf/cf-4 cg-4/ch-4 -na- world wide specification -na- dhd-1 -na- standard lube oil code for building equipment and non- road vehicles eo eo a eo b eo...

Page 34

34 winter fuel grades: waxing may occur at lower temperatures which will clog the fuel system and reduce the engines efficiency. If the ambient temperature is less than 32°f (0°c) a winter grade fuel (suitable to 5°f (-15°c) should be used. If the temperature is below 5°f to -4°f (-15°c to -20°c) ke...

Page 35

35 engine service: for engine service and maintenance schedule and service and maintenance information see the deutz operation manual or contact your local deutz service center for service information. The following trouble shoot chart is taken from the deutz operation manual. Fault measures hard st...

Page 36

36 b. Air filter assembly: please note that the air filter assembly for the 31hp and 61hp engines are different and do not interchange. The c31xx units are equipped with a 31hp deutz diesel engine see section air filter c31xx on page 37 for details. The c61xx units are equipped with a 61hp deutz tur...

Page 37

37 6. Inspect all hoses for damage. Replace if damaged. Do not use the machine until any damaged hoses are replaced. Inspect weekly. 7. Inspect all fittings and clamps. Insure all fittings and clamps are properly tightened. Inspect weekly. Dry cutting engine maintenance 9 when operating the engine i...

Page 38

38 air filter c61xx: the c61xx classic series diesel concrete saw is equipped with three (3) stages of air filtration: the first is a sy-klone pre-filter; the next two is a donaldson air cleaner with a primary (outer) and secondary (inner) air filters. In addition the system is equipped with a filte...

Page 39

39 c. Bearings all of the bearings on norton saws are equipped with a hydraulic grease fitting (known as a grease zerk) for the easy of re-lubrication. The proper amount of lubrication in the bearing is extremely important. Both excessive and inadequate lubrication may cause a bearing failure. The b...

Page 40

40 d. "v" belts warning: never make adjustments to belts or pulleys while engine is running! 1. The best tension for a belt drive is the lowest tension at which the belts will not slip under full load. 2. Simply take up the drive until the belts are snug in the grooves. Run the drive for about 15 mi...

Page 41

41 1. Remove the hydraulic pump cover from the console. 2. Locate the check valve adjusting screw as shown below: 3. Turn the check valve adjusting screw clockwise to increase the raise speed and counterclockwise to decrease the raise speed. 4. Replace the hydraulic pump cover. The lowering speed ca...

Page 42

42 3. Adjust the inline flow control valve in small increments unit the desired lowering speed is meet. 4. Replace the hydraulic pump cover. Hydraulic pump maintenance: 1. Hydraulic pump maintenance and trouble shooting part number: 149001: manufacturer monarch model m-319-0110 all monarch pumps are...

Page 43

43 7. For warranty and service information on monarch hydraulic pumps, contact monarch hydraulics at: phone: 616-458-1306 web site: http://www.Monarchhyd.Com/ the norton company does not warranty the hydraulic pump. If any warranty or service of the hydraulic pump is required contact your nearest mo...

Page 44

44 the probe comes in contact with "hot" electrical component. They are easily obtained from automotive jobbers or discount stores. C. Continuity light: continuity light is like a test light but contains its own battery power source. It is used for testing electrical circuits when the components are...

Page 45

45 to form sludge), foaming and water settling to the bottom of the reservoir. Fifth, the oil must be able to pour or flow at the lowest expected temperature so that the oil can reach or get into the pump. For all of the reasons just listed, automatic transmission fluid (atf dextron b) was found in ...

Page 46

46 b. On systems that fail to prime or lose their prime, check for the following: 1. Correct unit mounting position in the case of a pump motor combination. It is either horizontal or vertical and failure to mount in proper manner could mean pump cannot prime (pick up oil) because the suction tube i...

Page 47

47 c. Cause for low voltage 1. Battery capacity too small. 2. Cable ends not electricity secure to battery cable. (solder them if necessary.) 3. Battery cable size too small for load and length of run. Copper #1 automotive battery cable is the recommended minimum size. (the wire core diameter of #1 ...

Page 48

48 3. Place a few drops of oil on felt liner in head assembly. 4. Check brush set for wear and replace if necessary. 5. Blow dirt and dust out of motor housing and check for shorts, burnt wires, or open circuits in the field coil assembly. 6. Check armature and commentator for shorts or open circuit...

Page 49

49 2. Use a circuit "test light" to test switch. (see test equipment section) 3. Remove the wires from the switch and "touch" them together in the proper order to operate system. Note: all switch control stations subjected to the weather should be mounted so that the cord exits the bottom to prevent...

Page 50

50 the ground wire du e to the construction of the motor solenoid switch (see electrical switches). Likely spots for "faults" are the same as shorts see above. J. Solenoid coils coils are used in solenoid start switches. Failures can be caused by vibration, water, improper voltage or corrosion. The ...

Page 51

51 label). On the "inline" style relief valve the return lines, threaded into the back, will have to be removed in order to reach the adjusting screw. The "internal" relief valve is adjusted with a screw driver and the "inline" relief is adjusted with a 1/4" alien key. B. Relief valve pressure too l...

Page 52

52 1. Symptom: in most cases a check valve will fail such that the load will drift down when the unit is in the "hold" position. Note: check cylinder for leakage past piston seals. A bad piston seal will give the same symptom. 2. Repair procedures • remove the spring retainer. • remove spring. • rem...

Page 53

53 fluid, check the fan and accessory belts, clean the cooling fins, and also check for any fluid leakage. Do not pressure wash the transmission! 3. Use only the proper viscosity and type of fluid. At normal operating temperatures, the optimum viscosity range is between 80-180 sus (16-40 cs) and it ...

Page 54

54 1. Speed control lever: the operator’s right hand lever is the forward/reverse lever. The forward/reverse lever is used to control the speed and direction of the machine. The machine is equipped with a neutral lockout which prevents the forward/reverse lever from accidentally being moved from the...

Page 55

55 too move the machine: when the transmission engage/disengage lever is engaged, pushing the forward/reverse lever slowly forward will increase the forward speed of the saw. Pulling it to the center will place the saw in neutral. The machine is equipped with a neutral lockout. To operate the forwar...

Page 56

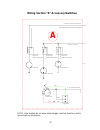

56 h. Electrical system a d c b see section “letter” for details “a” accessory/switches “b” controls/instruments “c” wiring harness connector “d” engine.

Page 57

57 wiring section “a” accessory/switches 3 2 7 3 2 7 3 2 7 syl. + - + - toggle switch 20a 12 volt single pole single throw m a toggle switch 20a 12 volt single pole single throw toggle switch 20a 12 volt single pole single throw connects to 15 amp fuse connects to red/deep sea control panel connecti...

Page 58

58 wiring section “b” controls/instruments 1 2 3 4 6 7 8 deep sea 701hc control panel 9 5 10 amp s + 4 + - red red s brown/black black/red volt meter gage yellow/black gage oil press tachometer 3 2 + s key switch 15 amp kill switch bush to break on off vdo-tachometer dip switch b + - - -.

Page 59

59 wiring section “c” wiring harness connector control/instrument side 9 6 5 4 3 2 1 bro w n bl ack red black brown re d yello w bl ue ora n g e ye llo w orang e blue 7 8 10 11 12 c /red /b la c k /black /black /blac k /b lac k engine side.

Page 60

60 wiring section “d” engine starter motor alternator crank solenoid green/yellow fuel solenoid 86 87 87a 85 30 fuel shut-off solenoid relay g wk n.C. Oil pressure sensor switch g wk sensor switch oil temperature n.O. Red battery yellow orange brown (auxiliary shutdown) blue re d blac k re d/ b l a ...

Page 61: IV. Parts List Section

61 iv. Parts list section a. Ordering information 1. List model number and serial number of machine. 2. List part number and serial number of part not the item number. 3. All positions on the machine are from the operator’s position when running the machine 4. Wherever alternate parts are shown due ...

Page 62: Decals For

Decals for c31xx, c61xx diesel saw part part number 70184628678 237446 decal console 227264 108713 227238 227237 227235 212196 227243 108850 108847 227240 108934 227234 227241 70184629168 237444 decal raise/lower 70184629169 237445 decal depth control 70184629170 237245 decal diesel fuel.

Page 67

62 b: blade guard conversion chart straight drive (non-jackshaft models only) blade size 14" 20" 26" 30" 36" engine pulley p/n 237219 237219 237219 237219 237219 engine pulley od 4" x 2" 11g 3vx 4" x 2" 11g 3vx 4" x 2" 11g 3vx 4" x 2" 11g 3vx 4" x 2" 11g 3vx engine speed (rpm) 2,800 rpm 2,700 rpm 2,...

Page 68

63 c: service parts main frame group 31hp and 61hp.

Page 69

64 main frame group 31hp and 61hp item description part no. Item description part no. 1 eng. Base weldment 237338 27 battery clip 237380 2 washer 5/8 sae 8172013 28 nut 1/4-20 hex lock 8160001 3 nut 5/8-11 hex lock 8160007 29 cover plate 237362 4 nut 5/8-11 hex 8142007 30 scr 10-24 x 1 socket hd 804...

Page 70

65 main frame group 31hp and 61hp 52 shaft cover 61 hp 237398 56 nut 3/8-16 hex 8142003 52 shaft cover 31 hp 237397 57 scr 3/8-16 x 2 1/2 hex hd cap 8041056 53 console rear cover 61 hp 237392 58 scr 1/4-20 x 1-1/4 socket hd cap 9048093 53 console rear cover 31 hp 237393 59 rope cleat 237267.

Page 97

90 saint-gobain abrasives, inc. 2270 west washington street stephenville, tx 76401-3798 phone: 800-554-8003 254-918-2310 fax: 800-443-1092 254-918-2312.