Summary of CT601MP

Page 1

Ct 601 mp operating instructions.

Page 2

2.

Page 3: Declaration Of Conformity

3 the undersigned manufacturer: saint - gobain abrasives s.A. 190, bd j.F. Kennedy l- 4930 bascharage declares that this product: power float : ct 601 mp code: 70184629945 is in conformity with the following directives: • european machinery directive 2006/42/ec pierre mersch business manager machine...

Page 4

4.

Page 5: Ct601Mp

5 ct601mp operating instructions and spare parts list 1 basic safety instructions 6 1.1 symbols 6 1.2 machine plate 6 1.3 safety instructions for particular operating phases 7 2 machine description 7 2.1 short description 7 2.2 purpose of use 7 2.3 layout 8 2.4 technical data 9 3 assembly and commis...

Page 6

6 1 basic safety instructions the ct601mp is exclusively designed for the finishing of wet concrete floors mainly on construction sites. Uses other than the manufacturer's instructions shall be considered as contravening the regulations. The manufacturer shall not be held responsible for any resulti...

Page 7

7 1.3 safety instructions for particular operating phases before commencing work • read the present operator’s instructions booklet carefully. • before commencing work, make yourself familiar with the working environment at the place of use. The working environment includes: obstacles in the area of...

Page 8

8 2.3 layout handle (1) jig welded steel construction including 2 rubber grips. A dead-man handle (7) allows the operator to work safely and to stop the machine at any moment. The angle of the machine arm can be adjusted to operate the machine comfortably. Pitch of the blades (2) the pitch of the bl...

Page 9

9 2.4 technical data engine honda gx120, 4 strokes, 1 cylinder, 4hp (2,9kw) filter dual filter fuel regular unleaded oil honda 4-stroke, or equivalent high detergent, premium quality motor oil certified to meet or exceed u.S. Automobile manufacturer’s requirement for service classification sg, sf. (...

Page 10

10 3.3 starting the machine turn the fuel valve to the on position. Fully press the dead-man handle against the main handle. Move the choke lever to the closed position. Note: do not use the choke if the engine is warm or the air temperature is high. Move the throttle control lever slightly to the l...

Page 11

11 4 transport and storing 4.1 securing for transport before transporting the machine, always remove the blades and the plate. 4.2 transport procedure conform yourself to work regulations, in order to transport the machine safely. To lift the machine, use the lifting eye. Make sure that your lifting...

Page 12

12 • to the right (iv), push down the handle. Tilting the blades floating the slab is done with the blades nearly flat on the surface of the concrete; however it is recommended that the blades are just slightly tilted to avoid the suction and drag created in normal operation of float blades on wet c...

Page 13

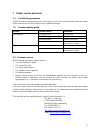

13 6 maintenance and servicing 6.1 maintenance of the machine to ensure a long-term quality from the use of the ct601mp, please follow the maintenance plan below: b e g in o f th e d a y d u ri n g t h e c h a n g in g o f to o l e n d o f th e d a y o r m o re o ft e n i f re q u ir e d e v e ry w ...

Page 14

14 6.2 maintenance of the engine regular service period perform at every indicated month or operating hour interval, whichever comes first e a c h u s e f ir s t m o n th o r 2 0 h o u rs e v e ry 3 m o n th s o r 5 0 h o u rs e v e ry 6 m o n th s o r 1 0 0 h o u rs check level engine oil change ch...

Page 15

15 • paper element: tap element lightly several times on a hard surface to remove excess dirt or blow compressed air lightly through the filter from the inside out. Never brush the dirt off; brushing will force dirt into the fibres. • foam element: clean in warm soapy water, rinse and allow to dry t...

Page 16

16 • install the plug fingertight to seat the washer, then tighten with a plug wrench (an additional ½ turn if a new plug) to compress the sealing washer. If you are reusing a plug, tighten 1/8- 1/4 turn after the plug seats. Fuel line to service the fuel line, follow these instructions: • drain the...

Page 17

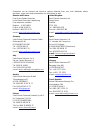

17 7 faults: causes and cures 7.1 fault-finding procedures should any fault occur during the use of the machine, turn it off. Any works dealing with the engine of the machine can only be carried out by a qualified technician. 7.2 trouble-shooting guide trouble possible source resolution not enough f...

Page 18

18 guarantee can be claimed and technical support obtained from your local distributor where machines, spare parts and consumables can be ordered as well: benelux and france: from saint-gobain abrasives in the grand-duché de luxembourg free telephone numbers: belgium : 0 800 18951 france: 0 800 90 6...

Page 19

19.

Page 20

20 saint-gobain abrasives 190, bd. J. F. Kennedy l-4930 bascharage luxembourg tel.: ++352 50401-1 fax: ++352 501633 e-mail: sales.Nlx@saint-gobain.Com www.Construction.Norton.Eu 18.02.2009.