- DL manuals

- Norton

- Saw

- GC25E

- Owner's Manual

Norton GC25E Owner's Manual

Summary of GC25E

Page 1

Owners manual multiple application concrete saw model: gc55 and gc25e form.

Page 2: Warranty

2 warranty norton warrants all products manufactured by it against defects in workmanship or materials for a period of one (1) year from the date of shipment to the customer. The responsibility of norton under this warranty is limited to replacement or repair of defective parts at norton's stephenvi...

Page 3: Table of Contents

3 table of contents contents page i. Preparation a. Safety precautions 4-6 b. Assembly 7 c. Gc55 and gc25e series concrete saw specifications 8-9 d. Engine gc55 models 10 e. Electrical connections gc25e 11-12 wiring diagram gc25e 12 ii. Operation a. Installing the blade 12-13 b. Starting the engine ...

Page 4: I. Preparation

4 i. Preparation a. Safety precautions important! The following safety precautions must always be observed. Hazard symbols fuel (gasoline) is extremely flammable and its vapors can explode if ignited. Store gasoline only in approved containers, in well-ventilated, unoccupied approved areas, and away...

Page 5: Dust and Silica Warning

5 dust and silica warning grinding/cutting/drilling of masonry, concrete, metal and other materials can generate dust, mists and fumes containing chemicals known to cause serious or fatal injury or illness, such as respiratory disease, cancer, birth defects or other reproductive harm. If you are unf...

Page 6

6 1. Before mounting any blade on the saw, the blade should be inspected for any damage which might have occurred during shipment, handling or previous use. 2. The blade collars and arbors should be cleaned and examined for damage before mounting the blade. 3. The blade must be properly fitted over ...

Page 7: I. Preparation

7 i. Preparation b. Assembly the gc55 and gc25e compact concrete saws are shipped completely assembled and ready for use except for diamond blade, gasoline, oil, and handle bar position for the gc55 and diamond blade, electrical extension cord, and power supply for the gc25e. Inspect the saw for shi...

Page 8

8 c. Gc55 and gc25e series concrete saw specifications dimensions/weight gc55 gc25e length (working) 42-23/32” (1,090mm) 42-23/32” (1,090mm) length (transport) 32” (813mm) 32: (813mm) width 18-1/8" (460mm) 18-1/8" (460mm) height 42-23/32” (1,090mm) 42-23/32” (1,090mm) frame width 18-1/8” (460mm) 18-...

Page 9

9 the gc55 and gc25e concrete saws where designed from the ground up to be a high performance multiple application saw. The gc55 and gc25e are capable of cutting green concrete (early entry), cured concrete, asphalt, and decorative concrete. Being able to cut more than just green gives the gc55 and ...

Page 10

10 d. Engine gc55 models prior to attempting to operate the engine, read the information contained in the engine owner's manual. An engine owner’s manual is supplied with every gasoline powered concrete saw. 1. Check oil: add oil if low. Refer to the engine owner's manual for the recommended sae vis...

Page 11

11 e. Electrical connections gc25e important-before connecting the motor leads to the power supply be sure that the voltage, cycles and phase shown on the nameplate of the motor correspond to the available power supply. Voltage selection for the gc25e 3 hp motor is single phase saw motors witch have...

Page 12: II. Operation

12 wiring diagram gc2e only thermal reset: if the thermal reset engages this is a sign that the motor is over heating. Continued over heating will damage the motor. The thermal reset will reset it’s self once the motor is cooled. Do not force the thermal reset as it will damage the reset and motor. ...

Page 13

13 4. Clean off any foreign particles on the clamping surfaces of both collars and on the mounting surface of the blade. 4. Position the blade beneath the cutting head and slide the blade into the blade guard (slide the blade under the blade guard at an angle will simplify the installation process)....

Page 14

14 5. To start the machine a. Gc55: follow the instructions for starting the engine found in the engine manual. I. Verify that the emergency stop switch is in the up position ii. Turn engine on/off switch to the on position iii. Turn the fuel control to the on position iv. Engage choke as necessary ...

Page 15

15 10. When moving the saw to a new location, be sure the blade is not touching the ground. Always pay close attention to where you are moving and where the blade is at all times. D. Cutting technique lower the blade into the concrete to the required depth by turning the hand wheel clockwise. Push t...

Page 16

16 green concrete cutting important considerations green concrete is concrete that is still in a plastic state that is the concrete still has a lot of moisture in it, in other words it is not fully cured or dry. As the concrete starts to hydrate (dry or cure), the concrete will change slightly in vo...

Page 17

17 surface. When the blade meets the concrete surface at a 90° angle (perpendicular) less side drag is created on the blade. When the blade is not perpendicular side drag is create that will cause the concrete to chip or spall. 3. Blade that is designed for green concrete cutting. The gmax blade has...

Page 18: III. Maintenance

18 2. Check blade specification. The improper blade specification will create additional spalling or chipping of the concrete. For best results use a norton gmax series blade. The norton gmax series have unique features to improve the green concrete cut quality and the overall efficiency of the blad...

Page 19

19 nearest honda service center, or from the internet: http://www.Honda- engines.Com/home.Htm honda engine (refer to owner's manual for complete maintenance.) check the engine oil level before each use when the engine is cool and the engine is level. Add oil if the level is low. The oil level should...

Page 20

20 always refer to the engine manual for more detailed information on checking the oil, changing oil, and oil capacity, air filter changes, and fuel type to use. Use only honda air filters. Do not clean the air filter with gasoline or other flammable solvents. A fire or explosion could result. To cl...

Page 21

21 3. Remember, too much tension shortens belt and bearing life! 4. Check the belt tension frequently during the first day of operation. Check the belt tension periodically thereafter and make any necessary adjustments. 5. The two most common causes of misalignment are shown in the figure 1 and figu...

Page 22

22 the collar used to support the turn handle's screw should be checked after each use to make sure it is lubricated and turning freely. If more lubricant must be added, nlgi #2, aluminum complex type grease is recommended. E. Dust removal system adjustment the gc55 and gc2e are equipped with a full...

Page 23: IV. Parts List Section

23 iv. Parts list section a. Ordering information 1. List model number and serial number of machine. 2. List part number and serial number of part not the item number. 3. Wherever alternate parts are shown due to product improvement, inspect the part you have and provide additional description as ne...

Page 24

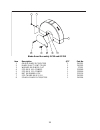

24 5 8 6 3 1 2 7 4 blade guard assembly gc55 and gc25e item description qty part no. 1 guard blade gc55/gc25e 1 241001 2 blade shaft vent cover 1 241002 3 washer m6 din125 flat 4 27539 4 scr m6 x 16 1.0 din933 1 235048 5 scr m6 x 12 1.0 din933 1 300566 6 nut m6 din985 lock 1 235136 7 scr thumb m6 x ...

Page 25

25 5 20 16 13 10 14 2 3 11 6 4 17 9 18 19 1 21 7 12 15 8 cutting head assembly gc55 and gc25e item description qty part no 1 bearing cutting head sub assy – see pg 23 for parts 1 241005 2 pulley idler tension adjuster 1 241006 3 spacer indler gc55/gc25e 1 241007 4 pulley idler assembly gc55/gc25e 1 ...

Page 26

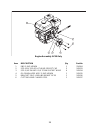

26 5 1 4 2 3 blade shaft assembly gc55 and gc25e item description qty part no 1 cutting head assembly gc55/gc25e 1 241015 2 blade shaft gc55/gc25e 1 241016 3 bearing cover blade shaft gc55/gc25e 1 241017 4 bearing radial 6204-rs 2 212142 5 retaining ring e-style 19mm x 1.8mm din6799 1 241018.

Page 27

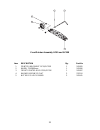

27 10 9 4 5 7 11 16 15 14 6 12 13 8 3 1 2 18 17 depth control assembly gc55 and gc25e item description qty part no 1 depth tube gc55/gc25e 1 241090 2 fit grease zerk m6 x 1.0 1 241019 3 scr depth control gc55/gc25e 1 241020 4 depth control mount gc55/gc25e 1 241021 5 spacer hand wheel gc55/gc25e 1 2...

Page 28

28 3 4 2 1 6 5 engine assembly gc55 only item description qty part no 1 eng 5.5hp honda 1 216264 2 scr m5 x 12 0.8 flat head socket cap 2 241033 3 scr 5/16"-24 unf x 3/4" c'sink socket head 4 241034 4 oil drain hose assy 5.5hp honda 1 241035 5 bracket self leveling mount gc55 1 241036 6 cutting head...

Page 29

29 motor assembly gc25e item description qty part no 1 mot 2.5hp 115-230v/60/1 gc25e complete motor (items 2 to 21) 1 241112 2 cover fan gc25e 1 241113 3 gasket run capacitor cover gc25e 1 241114 4 cover run capacitor gc25e 1 241115 5 gasket start capacitor cover gc25e 1 241116 6 cover start capacit...

Page 30

30 3 2 4 1 9 18 14 11 16 13 17 7 12 8 15 10 6 11 12 5 frame assembly gc55 only item description qty part no 1 frame gc55 1 241038 2 rear pointer gc55/gc25e 1 241039 3 scr m8 x 65 1.25 din931 hex head cap 1 241040 4 washer m8 din125 flat 6 232110 5 washer m4 din125 flat 16 235104 6 nut m8 1.25 lock d...

Page 31

31 frame assembly gc25e only item description qty part no 1 frame gc25e 1 241101 2 scr m8 x 65 1.25 din931 hex head cap 1 241040 3 rear pointer gc55 1 241039 4 washer m8 din125 flat 7 232110 5 washer m4 din125 flat 17 235104 6 nut m8 1.25 lock din985 4 241041 7 nut m4 0.7 lock din985 8 241042 8 grom...

Page 32

32 5 3 1 2 4 front pointer assembly gc55 and gc25e item description qty part no 1 pointer weldment gc55/gc25e 1 241085 2 wheel 75x28x8mm 1 241086 3 front pointer rod gc55/gc25e 1 241087 4 washer m8 din125 flat 2 232110 5 nut m8 1.25 lock din985 2 241041.

Page 33

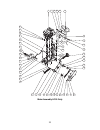

33 53 24 17 20 12 11 18 16 56 6 2 8 13 10 15 35 52 51 37 36 4 33 22 42 26 40 34 39 38 9 32 7 25 41 29 28 1 27 47 46 43 44 48 49 50 45 30 31 21 5 3 29 54 55 19 57 main assembly gc55 only.

Page 34

34 main assembly gc55 only item description qty part no 1 see frame assy gc55 page 30 1 -na- 2 handle bar gc55 1 241052 3 engine assembly gc55 see page 28 1 -na- 4 washer m6 din125 flat 8 27539 5 washer m8 din125 flat 6 232110 6 scr m6 x 55 1.0 din933 hex head cap 1 241011 7 scr m8 x 60 1.25 din933 ...

Page 35

35 main assembly gc55 only item description qty part no 38 scr m5 x 10 0.8 din916 cup point set 4 241027 39 pulley 56.5mm d x 3/4b 6g j section 1 241071 40 belt 350j6 - j section 6 groove 1 241072 41 see front point assembly gc55/gc2e page 32 1 -na- 42 belt guard gc55 1 241074 43 see blade guard ass...

Page 36

36 main assembly gc25e only item description qty part no 1 see frame assembly gc25e page 31 1 -na- 2 handle bar gc55 1 241052 3 see motor assembly gc25e page 29 1 -na- 4 washer m6 din125 flat 8 27539 5 washer m8 din125 flat 12 232110 6 scr m10 x 60 1.5 din931 1 27030b 7 scr m8 x 60 1.25 din933 hhc f...

Page 37

37 item description qty part no 9 nut m8 1.25 lock din985 2 241041 10 scr 5/16-18 unc x 2-1/2" carriage bolt 1 241054 11 washer 3/8 wave 1 241055 12 knob m8 x 1.25 adjustable 1 241091 13 pin quickrelease 5/16" x 2" grip length 1 241092 14 chain for quickrelease pin 9" long gc55 1 241056 15 scr no18-...

Page 38

38 item description qty part no 46 spacer m14 1 241079 47 cam stay level gc55 1 241080 48 loose collar gc55 1 241081 49 tight collar gc55 1 241082 50 nut 5/8-11 unc hex left hand thread 1 241083 51 depth control assembly gc55 1 241084 52 washer m6 din 125 flat 1 27539 53 wrench universal 1 233041 54...

Page 39

39 notes.

Page 40

Saint-gobain abrasives 2770 west washington stephenville, tx 76401 phone: 800-554-8003 fax: 800-443-1092.