Summary of TR 250 H Clipper

Page 1

Tr 250 h operating instructions.

Page 2

2.

Page 3: Declaration Of Conformity

3 the undersigned manufacturer: saint - gobain abrasives s.A. 190, bd j.F. Kennedy l- 4930 bascharage declares that this product: tile saw: tr 250 h code : 70184629084 70184629611 is in conformity with the following directives: • european machinery directive 2006/42/ec • “low voltage" 2006/95/ec • e...

Page 4

4.

Page 5: Tr 250 H

5 tr 250 h operating instructions 1 basic safety instructions 6 1.1 symbols 6 1.2 machine plate 7 1.3 safety instructions for particular operating phases 7 2 machine description 8 2.1 short description 8 2.2 purpose of use 8 2.3 layout 8 2.4 technical data 9 3 assembly and commissioning 10 3.1 assem...

Page 6

6 1 basic safety instructions the tr 250 is exclusively designed for the cutting of tiles and abrasive materials with norton diamond disks mainly on construction sites. Uses other than the manufacturer's instructions shall be considered as contravening the regulations. The manufacturer shall not be ...

Page 7

7 1.2 machine plate important data can be found on the following plate located on the machine: 1.3 safety instructions for particular operating phases before commencing work • before commencing work, make yourself familiar with the working environment at the place of use. The working environment inc...

Page 8

8 2 machine description any modification, which could lead to a change in the original characteristics of the machine, may be done only by saint-gobain abrasives who shall confirm that the machine is still in conformity with the safety regulations. 2.1 short description the tr 250 saw is designed fo...

Page 9

9 2.4 technical data electric motor 1,3kw voltage 230v, 50hz protection rating ip 54 max. Blade diameter 250 mm bore 25.4 mm rotation speed of the blade 2800 min -1 flange diameter 90 mm cutting depth mm 60 mm cutting length mm 1000 mm sound pressure level 73 db (a) (iso en 11201) sound energy level...

Page 10

10 3 assembly and commissioning the machine is delivered fully equipped. It is ready for operation after assembly the diamond blade and after connection to the appropriate power supply. 3.1 assembly of the legs lift up one side of the saw, slide in the legs (with no wheels) to the front side of the ...

Page 11

11 3.5 water cooling system • fill the water pan with clean water to 1cm of the edge of the water tray. • ensure that water is delivered adequately to both sides of the blade, as insufficient water supply may result in premature failure of the diamond blade. • the water pump must never run without w...

Page 12

12 4 transport and storing 4.1 securing for transport before transporting the machine, always remove the blade and empty the water pan. Secure the cutting head on the rail by using the knob. 4.2 long period of inactivity if the machine is not going to be used for a long period, please take the follo...

Page 13

13 5 operating the machine 5.1 site of work 5.1.1 siting the machine • remove from the site anything, which might hinder the working procedure! • make sure the site is sufficiently well lit! • observe manufacturer's conditions for connecting to power supplies! • place electric cables in such a way t...

Page 14

14 5.2.2 multiple step cutting multiple step cutting consists of moving the head back and forward on the material to be cut. • place the material to be cut on the table firmly against the guide-a-cut and the backstop, keeping the hands well away from the blade. • move blade forward near the material...

Page 15

15 6 maintenance and servicing to ensure a long-term quality from the cutting with the tr 250, please follow the maintenance plan below: b e g in o f th e d a y d u ri n g t h e c h a n g in g o f to o l e n d o f th e d a y o r m o re o ft e n i f re q u ir e d a ft e r a f a u lt a ft e r a d a m ...

Page 16

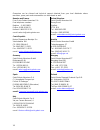

16 7 faults: causes and cures 7.1 fault-finding procedures should any fault occur during the use of the machine, turn it off, and isolate it from the electrical supply. Any works dealing with the electrical system or supply of the machine can only be carried out by a qualified electrician. 7.2 troub...

Page 17

17 7.3 circuit diagram 7.4 customer service when ordering spare parts, please mention: • the serial number (7 digits). • the code of the part. • the exact denomination. • the number of parts required. • the delivery address. • please indicate clearly the means of transportation required such as "exp...

Page 18

18 guarantee can be claimed and technical support obtained from your local distributor where machines, spare parts and consumables can be ordered as well: benelux and france: from saint-gobain abrasives s.A. Free telephone numbers: belgium : 0 800 18951 france: 0 800 90 69 03 holland: 0 8000 22 02 7...

Page 19

19.

Page 20

20 saint-gobain abrasives 190, bd. J. F. Kennedy l-4930 bascharage luxembourg tel.: ++352 50401-1 fax: ++352 501633 e-mail: sales.Nlx@saint-gobain.Com www.Construction.Norton.Eu 28.04.2008.