Summary of TT 200 EM

Page 1

Tt 200 em operating instructions.

Page 2

2.

Page 3

3 le constructeur soussigné: saint - gobain abrasives s.A. 190, bd. J. F. Kennedy l-4930 bascharage déclare que le matériel neuf désigné ci-après : scie de carrelage: tt 200 code : 70184625701 est conforme aux dispositions des directives : • "machines" 2006/42/ce • "basse tension" 73/23/cee • "compa...

Page 4

4.

Page 5: Tt200Em

5 tt200em operating instructions 1 basic safety instructions 6 1.1 symbols 6 1.2 machine plate 6 1.3 safety instructions for particular operating phases 7 2 machine description 7 2.1 short description 8 2.2 purpose of use 8 layout 8 2.3 technical data 9 3 assembly and commissioning 10 3.1 tool assem...

Page 6

6 1 basic safety instructions the tt200em is exclusively designed for the cutting of tiles mainly on construction sites. Uses other than the manufacturer's instructions shall be considered as contravening the regulations. The manufacturer shall not be held responsible for any resulting damage. Any r...

Page 7

7 1.3 safety instructions for particular operating phases before commencing work • before commencing work, make yourself familiar with the working environment at the place of use. The working environment includes: obstacles in the area of work and manoeuvre, the firmness of the floor, necessary prot...

Page 8

8 2.1 short description the tt200em tile saw is designed for durability and high performance for onsite wet and dry cutting operations of a wide range of tiles. As with all other clipper products, the operator will immediately appreciate the attention given to detail and quality of materials used in...

Page 9

9 frame (1) the frame is made of a strong plastic to ensure perfect rigidity. It supports the motor, the cutting table and the switch. Cutting table (2) zink coated steel top for an excellent resistance to corrosion with engraved measurements for precise guide-a-cut alignment. Electrical motor and s...

Page 10

10 3 assembly and commissioning the machine is delivered fully equipped. It is ready for operation after assembly the diamond blade, the blade guard and the guide-a-cut, and after connection to the appropriate power supply. 3.1 tool assembly only clipper continuous rim blades with a maximum diameter...

Page 11

11 3.5 water cooling system • fill the water pan with clean water up to 5mm from the upper edge of the water tray. • ensure that water is delivered adequately to both sides of the blade, as insufficient water supply may result in premature failure of the diamond blade. • always make sure that there ...

Page 12

12 4 transport and storing 4.1 securing for transport before transporting the machine, always remove the blade and empty the water pan. 4.2 long period of inactivity if the machine is not going to be used for a long period, please take the following measures: • completely clean the machine • empty t...

Page 13

13 5 operating the machine 5.1 site of work 5.1.1 siting the machine • remove from the site anything, which might hinder the working procedure! • make sure the site is sufficiently well lit! • observe manufacturer's conditions for connecting to power supplies! • place electric cables in such a way t...

Page 14

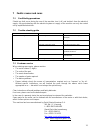

14 6 maintenance and servicing to ensure a long-term quality from the cutting with the tt200em, please follow the maintenance plan below: b e g in o f th e d a y d u ri n g t h e c h a n g in g o f to o l e n d o f th e d a y o r m o re o ft e n i f re q u ir e d e v e ry w e e k a ft e r a f a u lt...

Page 15

15 7 faults: causes and cures 7.1 fault-finding procedures should any fault occur during the use of the machine, turn it off, and isolate it from the electrical supply. Any works dealing with the electrical system or supply of the machine can only be carried out by a qualified electrician. 7.2 troub...

Page 16

16 guarantee can be claimed and technical support obtained from your local distributor where machines, spare parts and consumables can be ordered as well: benelux and france: from saint-gobain abrasives s.A. Free telephone numbers: belgium : 0 800 18951 france: 0 800 90 69 03 holland: 0 8000 22 02 7...

Page 17

17.

Page 18

18.

Page 19

19.

Page 20

20 saint-gobain abrasives 190, bd. J. F. Kennedy l-4930 bascharage luxembourg tel.: ++352 50401-1 fax: ++352 501633 e-mail: sales.Nlx@saint-gobain.Com www.Construction.Norton.Eu 08.12.2008.