- DL manuals

- Nortrac

- Tractor

- XT20

- Owner's Manual

Nortrac XT20 Owner's Manual

Summary of XT20

Page 1

Nortrac xt20 and xt25 tractors owner’s manual sold by northern tool & equipment, inc. P.O. Box 1299 burnsville, mn 55337 tel.: 1-800-222-5381 www.Northerntool.Com yfxt20-25man.

Page 2

Nortrac 20xt and 25xt tractors product identification data sheet product part number product model machine serial number chassis serial number engine model engine serial number date of purchase where purchased/contact information owner name complete this form carefully at purchase. All sns in this f...

Page 3

User notices thank you thank you for purchasing a nortrac tractor from northern tool + equipment company. We value you as a customer and wish you many years of safe and satisfied use of your tractor. Using your owner’s manual this owner’s manual is an important part of your tractor and should remain...

Page 4

Overview this manual describes safety precautions as well as running-in, proper usage, technical maintenance, adjustment, faults and troubleshooting methods for various parts of the nortrac xt tractors. The manual gives an in-depth look and should be used as a reference tool for owners and maintenan...

Page 5

Table of contents table of contents 1.Safety precautions .....................................................................................................................................1 1.1 safety rules and notices of use ...........................................................................

Page 6

Table of contents 4.8 battery maintenance...............................................................................................................................55 4.9 dry air cleaner instructions ...................................................................................................

Page 7

Safety precautions 1 1. Safety precautions 1.1 safety rules and notices of use reading prior to use 1 the instructions for use, maintenance, and the safety warning identifiers should be fully read and understood. 2. The correct usage and operating method should be observed. 3. Local traffic rules an...

Page 8

Safety precautions 2 waste oil placement 1. used machine oil is a waste fuel substance. Do not discard at random. 2. the used acid from the battery is harmful to the environment. Do not discard at random. Fig.1-5 waste oil placement pipeline leaks do not use your hand to check for leaks in the high-...

Page 9

Safety precautions 3 emergency procedures 1. In case of a brake failure, hold the steering wheel firmly, wait until the tractor has come to a complete stop and then shut down the engine. 2. If the steering malfunctions, brake immediately and shut down the engine. 3. If fire should occur, immediately...

Page 10

Safety precautions 4 caution: your vehicle when riding on the road shoulder. 16. Never overload the tractor. Running the tractor over the specified limits can cause damage to the tractor and can result in injury. 17. When driving at night, make sure that you have proper lighting to avoid any collisi...

Page 11

Safety precautions 5 important: 1. Always operate the tractor according to the specified running-in requirements. This will prolong the life of your tractor. 2. Prior to starting the tractor, the oil system, cooling system and electric circuits must be examined. After startup, strict attention shoul...

Page 12

Safety precautions 6 9. When detaching the tractor from any implements, the upper lever of the suspension unit should be adjusted to the shortest travel and the limit lever adjusted to prevent the implements from swinging out of control. The locking nuts on the upper and limit levers must be tighten...

Page 13

Safety precautions 7 never sit on the fender when the tractor is operating as this could result in falling from the vehicle and possible injury. Post position: front side of the mudguard. Fig. 1-12 safety warning identifier vi to avoid injury, stay a safe distance from the lifting lever when the lif...

Page 14

Safety precautions 8 always start the engine from a secure position in the pilot seat. Post position: in front of the instrument panel. Post position: in front of the instrument panel. Read and understand all instruction for use, including the meaning of all non-lettered safety symbols. Post positio...

Page 15

Safety precautions 9 in order to prevent from the personal injury, please install the safety shield on the pto shaft when it is not in use. For battery service, carefully read the instruction for use to understand the correct maintenance procedures. Post position: on the surface of the battery. Fig....

Page 16: Shear and Cutting Points

Safety precautions 10 preventing farm machine hazards the following article describes important general safety precautions for machinery such as the nt-204c/nt-254 tractor. It is reprinted here with permission from professor thomas l. Bean, safety leader and professor, department of food, agricultur...

Page 17: Pinch Points

Safety precautions 11 both shear and cutting points are created on machinery designed to cut, such as harvesters, and on those that are not designed to cut, such as augers. They are hazardous because of their cutting force and they often move so rapidly that they may not be visible, so it is easy to...

Page 18: Crush Points

Safety precautions 12 increase with shafts that are not round. Clothing is more likely to catch if there is dried mud or manure on the shaft, or if the shaft is nicked. Ends of shafts that protrude beyond bearings are also dangerous. Universal joints, keys and fastening devices can also snag clothin...

Page 19: Springs

Safety precautions 13 springs compressed springs (fig. 4 below) will expand with great force when released, and springs that are stretched will contract rapidly when released. Know what direction a spring will move and how it might affect another machine part when released, and stay out of its path....

Page 20

Operation description 14 2. Operator instruction note: operating the tractor properly can bring efficiency of the tractor into full play to reduce tractor wear and prevent an accident and ensure operator to complete farm and road operations fast, efficiently, in low consumption and safety mode table...

Page 21

Operation description 15 2.1 description of products the following information will help you use, maintain, and troubleshoot the nortrac xt series tractors, including: xt20 and xt25 the nortrac xt series of tractors is a medium-sized tractor that can be used in a variety of land types. The tractor h...

Page 22

Operation description 16 instrumentation and switches figure 2-2 instrumentation and switches important notes: observe all warning lights and pay attention to the instrument panel during operations. Fuel gauge the fuel gauge indicates the amount of fuel in the tank when the indicator is in the far r...

Page 23

Operation description 17 engine tachometer the engine tachometer shows the operating rotary speed of the engine once the tractor is started. Tractor running hours are displayed in the lower box. Figure 2-5 engine tachometer amp meter the amp meter is used to indicate the status of the battery. The i...

Page 24

Operation description 18 left rocker switch assembly figure 2-9 left rocker switch combination signal switch position 1: left signal lamps are on. Position 0: power supply off. Position 2: right signal lamps are on. Figure 2-10 signal switch work lamp switch position 2: both position lamp and rear l...

Page 25

Operation description 19 hazard warning switch the hazard warning switch should be used in case of a tractor malfunction where the tractor is stopped in a potentially dangerous area. Figure 2-14 hazard warning switch horn switch horn switches are located on both arms of the steering wheel. Figure 2-...

Page 26

Operation description 20 2.3 starting the engine warning: before operating, the tractor should be checked over thoroughly to eliminate potential accidents or breakdowns. 2.3.1 engine starting preparations before starting the tractor, inspect for damaged or loose parts and leakage. Check the engine o...

Page 27

Operation description 21 2.3.2.1 battery start • starting at ambient temperature (above 23 °f): turn the key to the on position to start the auxiliary and the control circuit. Then turn the key to the st position to start the engine. Release the key immediately after starting (the key will return to...

Page 28

Operation description 22 2.4 starting the tractor • with the engine running at low speed, step on the clutch pedal. Then, put the gear box shift level in the right position. • release the brake pedal lock device. • check for obstructions and honk your horn. • release the clutch pedal immediately aft...

Page 29

Operation description 23 figure 2-19 differential operation (20xt) 2.6 shifting the tractor shift 28+2, shift shuttle 8+8, shift creeping 16+4 • the main and auxiliary gear shift is controlled by one control handle to achieve 8+2 shifts. The main gear shift lever (a) has four gears (3 and one revers...

Page 30

Operation description 24 2.8 front drive axle use the nortrac xt series of 4-wheel drive tractors can be used for normal operations in the field and on wet and soft soil. If only rear wheel drive is used, the traction performance of the tractor may not be enough. When this is the case, the front dri...

Page 31

Operation description 25 2.10 stopping the tractor and engine flameout procedures 1. Throttle down to decrease the tractor’s running speed. 2. Step on the clutch pedal, the brake pedal and lock the braking handle. When the tractor stops, put the gearshift in neutral. 3. Release the clutch/brake peda...

Page 32

Operation description 26 note: remove the counterweights from the wheel before removing the rear wheel from the tractor to avoid injury or damage. 2.13 driver’s seat adjustment the driver seat for series xt tractors can be adjusted in both a front and rear direction. During the course of adjusting, ...

Page 33

Operation description 27 2.14.3 lowering speed adjustment select a suitable lower speed for the farm implement to keep from being damaged by heavy impact when it contacts the ground. Before delivery, the descending speed regulating valve was adjusted. The owner/operator can readjust the valve accord...

Page 34

Operation description 28 2.14.5 use of multiway valve (optional) • switch off the engine. • put the lifter in lowering position. • move the hydraulic output valve operation handle forward and backward, in order to eliminate the pressure in the hydraulic adapter seat. • take out the sealing cover of ...

Page 35

Operation description 29 suspension mechanism application during tilling operations, the plow is adjusted vertically and horizontally to ensure that the tilling depth is the same. • adjusting the horizontal in a longitudinal direction: adjust the upper pull bar’s (a) length to keep the plow frame ho...

Page 36

Operation description 30 2.14.7.2 power take-off (pto) shaft use (with a dual-function clutch) power for the pto shaft is switched on and off by a 2-stage clutch, the pto disengagement control handle and the power output gear shift knob on the left rear of the gearbox. When the power output disengag...

Page 37

Operation description 31 2.14.8.2 alternator • the alternator should be used together with the regulator. • the alternator has a negative ground. Positive and negative poles of the alternator, regulator and battery need to be connected properly. If not, the alternator and the regulator will be damag...

Page 38

Operation des crip tion 32.

Page 39

Operation description 33 2.15 tractor break-in before using, the tractor should run for a certain period with proper lubrication, at a certain rpm and without a full load. After the warm up period, the tractor should be checked and adjusted. This period of time is called running-in. 2.15.1 preparati...

Page 40

Operation description 34 2.15.5 tractor break-in without a load and with a load after completing the pto shaft and hydraulic system has been broke-in, proceed with tractor break-in procedures according to table 2-2-3 on the condition that everything on the tractor checks out. Break-in time is 10 hou...

Page 41

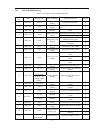

Operation description 35 table 2-2 running-in time for each stage (8f+2r shift bottom unit: h) forward shift reverse shift tractor stopper low gear 1 low gear 2 low gear 3 low gear 4 h-1 h-2 h-3 h-4 r-1 r-2 idle 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 when loading 1 ton on a trailer, road transporta...

Page 42

Operation description 36 fault fault reasons troubleshooting 3. Tractor shakes when starting. (1) disengaging lever heads are not on the same plane. (2) oil stain on the friction lining and clutch plate. (3) the clutch plate is severely warped. (4) the bolt for the flywheel and the clutch is loose. ...

Page 43

Operation description 37 fault fault reasons troubleshooting 2. Small conical gear and differential bearing is hot. ( 1)the pre-tightening force is too much. ( 2)lubrication is poor. ( 3)the backlash at gear pair side of conical gear is too small. ( 1)readjust the bearing pre-tightening force. ( 2)c...

Page 44

Operation description 38 4 drive shaft and sleeve become hot (4-wheel drive tractor). (1) the drive shaft is severely bent or deformed creating friction. (1) replace the drive shaft 5 auxiliary box noise (4-wheel drive tractor). (2) speed gear is too high. (3) bearing or gear is severely worn. (2) p...

Page 45

Operation description 39 2.16.1.6 hydraulic suspension system faults and troubleshooting table 2-9 hydraulic suspension system faults and troubleshooting sequence no. Fault fault reasons troubleshooting 1 cannot lift the load. (1) oil level inside the lifter is low. (2) the strainer of the oil filte...

Page 46

Operation description 40 sequence no. Fault fault reasons troubleshooting lift position the distributor emits a loud noise. The lifter case to open the safety valve. The force/position adjusting rod to make the lift height lower that the original position. 6 hydraulic lifter has no hydraulic output ...

Page 47

Operation description 41 2.16.2.2 alternator faults and troubleshooting table 2-12 motor faults and troubleshooting sequence no. Fault fault reasons troubleshooting 1 the alternator doesn’t work. (1) wiring is wrong, broken or not making good contact. (2) rotor circuit broken. (3) rectified diode da...

Page 48

Operation description 42 2.16.2.4 instrument faults and troubleshooting table 2-14 instrument faults and troubleshooting sequence no. Fault fault reasons troubleshooting 1 the water temperature gauge always indicates a low temperature. (1) circuit opened and contact at plug-in is poor. (2) water tem...

Page 49

Operation description 43 3. Accessories, spare parts and consumables 3.1 accessories 3.1.1 safety frame (optional) the xt series tractor can be equipped with an osha safety frame to prevent the driver from being hurt by an accidental turnover. 3.1.2 swing traction rod (optional) the swing traction r...

Page 50

Maintenance instruction 44 4. Maintenance instruction 4.1 technical maintenance regulation carrying out the technical maintenance specifications of the tractor is the effective way to prolong the service life of the tractor and reduce accidents. The technical maintenance schedule for xt series tract...

Page 51

Maintenance instruction 45 4.1.2 maintenance for every 50 hours (1) perform all of the technical maintenance after every working shift. (2) check the tightness of the fan belt (press down the belt with your hand and measure the sag (15–20mm), and make adjustments if necessary. (3) spread the grease ...

Page 52

Maintenance instruction 46 (7) rinse the fuel tank and the filter in the fuel tank with solvent. (8) maintain the diesel engine according to the requirement of level 4 technical maintenance described in the engine manual, 4.1.6 maintenance for every 1600 hours (1) perform all technical maintenance a...

Page 53

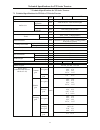

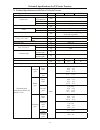

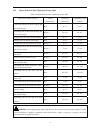

Maintenance instruction 47 table 4-1 maintenance table of xt series tractors no. Maintenance part operation content number of points maintenance period 1 engine oil pan check the oil level 1 per shift 2 oil filter check the oil filter 1 per shift 3 hydraulic pump check the oil level 1 per shift 4 ba...

Page 54

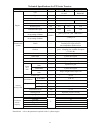

Maintenance instruction 48 figure 4-2 schematic drawing of the operating system of the clutch no. Maintenance part operation content number of points maintenance period 31 front drive axle central drive replace the lubricating oil 1 per 1600 hours 32 front drive axle final drive replace the lubricat...

Page 55

Maintenance instruction 49 4.2.2 adjustment of the clutch (double action) in order to ensure the normal operation of the clutch, the clearance between the master clutch disengaging lever 4 's working surface and the release bearing 5's end face must be kept within 2 to 2.5mm; that between the end fa...

Page 56

Maintenance instruction 50 4.3 brake adjustment 4.3.1 if one the following should occur, the brake should be adjusted: • the free stroke of the brake pedal is too large, which can cause a braking failure. • the free stroke of the brake pedal is too small, which can cause too little clearance between...

Page 57

Maintenance instruction 51 4.4 differential lock adjustment adjustment of differential lock is performed through adjustment of the bolts (1 and 2). During the adjustment, the clearance between the right coupling (3) and left coupling (4) is about 2mm. Loosen the nut (2) and rotate the bolt (1) in, a...

Page 58

Maintenance instructions 52 4.5 steering system adjustment 4.5.1 full hydraulic steering system cautions the xt series four-wheel drive tractor uses a full hydraulic steering system, as shown in the figure. Before leaving the factory, the steering system of the tractor is adjusted. Pay attention to ...

Page 59

Maintenance instruction 53 4.6 front drive axle adjustment 4.6.2 track front of the four-wheel drive model the track of front drive axle can be: 1073mm, 1193mm and 1257mm. 4.6.1 front drive axle side drive adjustment adjustment of the mesh mark and meshing-teeth side clearance of the initiative gear...

Page 60

Maintenance instruction 54 4.7 hydraulic lifting mechanism adjustment position the farm implement lifting handle in the neutral position, as shown in the figure, and then adjust the distance between the block on the push rod and the bumper pin fixed on the lifting shaft. The lifting position of the ...

Page 61

Maintenance instruction 55 4.8 battery maintenance 4.8.1 maintenance of maintenance-free battery • state inspection of the battery. Normally the maintenance-free battery does not require any special maintenance. You can observe the power levels from the view hole of the liquid densimeter: green=full...

Page 62

Maintenance instruction 56 4.9 dry air cleaner maintenance 4.9.1 dry air cleaner instructions • the main filter needs to be maintained every 50 to 100 hours in normal environments. • in dusty environments, keep up the maintenance on the filter elements per 8 hours or per each work sequence. • when t...

Page 63

Maintenance instruction 57 4.11 engine oil sump level check and oil replacement ( 1)remove the oil dipstick (a) on the left front of the oil pan and check if the oil level is between the upper scale mark and lower scale mark. If the oil level doesn’t reach the lower scale mark, add oil to the recomm...

Page 64

Maintenance instruction 58 4.13 engine oil filter maintenance the engine oil filter (a) is located in the middle lower part on the left side of the engine. The oil filter should be replaced according to the recommended maintenance schedule. Figure 4-25 engine oil filter maintenance 4.14 lifter hydra...

Page 65

Instruction on maintenance 59 4.16 transmission mechanism maintenance pull out the oil dipstick on the right of the main gear lever (as show in in the figure), wipe it clean and then insert the oil dipstick. If the oil level is lower than the lower scale mark, refill the transmission oil to a level ...

Page 66

Maintenance instruction 60 4.18 fuel tank maintenance • stop the tractor on level ground, switch off the engine and then remove the drain plug below the fuel tank. Discharge the sedimented dirt at the bottom of the fuel tank. Figure 4-31 fuel tank maintenance • the sediment bowl of the fuel tank gat...

Page 67

Maintenance instruction 61 4.20 engine cooling system maintenance the engine cooling system uses antifreeze only. In general, antifreeze is good for a period of 2 years or 1600 hours and then should be replaced, the cooling system should be flushed before new antifreeze is added. (note : antifreeze ...

Page 68

Storage 62 5. Storage when the tractor needs to be stored for a period of time (more than one month) it should be kept in proper storage building. The storage facility should provide protection from the elements so as to prevent dirt rust and corrosion. Before storing the tractor, it must undergo a ...

Page 69

Storage 63 • the tractor should be parked in a dry, well-ventilated area. Never store your tractor around flammables or corrosive materials. If you don’t have access to such an area, make sure that you cover the tractor with a waterproof covering. • any parts taken from the tractor should be cleaned...

Page 70

Storage 64 6. Transportation if the tractor is displaced by self-drive, local traffic regulations should be strictly observed with at least 180 feet of distance maintained between vehicles. If the tractor is being transported, the following points should be satisfied: 1. A smooth, level spot should ...

Page 71

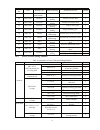

Technical specifications for xt series tractors 65 7. Technical specifications for xt series tractors 7.1 technical specifications for 2w drive xt series tractors type unit 20xt 22xt 25xt type —— wheeled 4x4 length (incl. Rear suspension mm 2890/3030(excl. Front counterweight) width mm 1470 outline ...

Page 72

Technical specifications for xt series tractors 66 type unit 20xt 22xt 25xt clamping reverse gear 0.58,2.69 type —— km385t km385t type —— vertical, water cool, 4 strokes diesel number of cylinders —— 2/3 cylinder diameter x stroke mm 95×105/80×90 100×105/85×90 combustion chamber mode straight-inject...

Page 73

Technical specifications for xt series tractors 67 type unit 20xt 22xt 25xt diameter of pothook mm φ20 clutch —— single-plate, dry type, spiral spring pressed, constant joint, single action or non-independent double actions. Gearbox —— combined (4+1) x 2; 8 drive gears; 2 reverse gears,clamping gear...

Page 74

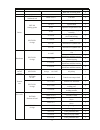

Technical specifications for xt series tractors 68 7.2 technical specifications for 4w drive xt series tractors type unit ft204a ft224a ft254a type —— wheeled 4x4 length (incl. Rear suspension mm 3030(excl. Front counterweight) width mm 1470 outline size wheelbase mm 1673/1743 front wheel mm 1150 tr...

Page 75

Technical specifications for xt series tractors 69 type unit ft204a ft224a ft254a type —— ty295it/y380t,or ll380t y385t or km385bt type —— vertical, water cool, 4 strokes diesel number of cylinders —— 2/3 cylinder diameter x stroke mm 95×105/80×90 100×105/85×90 combustion chamber mode —— straight-in...

Page 76

70 8. Disassembly and disposal after the machine reaches the end of its service life, for your personal safety and the protection of the environment, please deliver it to the licensed company specialized in the disassembly and recycle of such products. When done, the tractor should be disassembled i...

Page 77: Limited Warranty

9. Limited warranty 71 limited warranty 4wd diesel tractor & compact crawler / bulldozer nortrac ™ equipment is sold by nortrac; a division of northern tool & equipment company, inc. Nortrac will repair or replace, at its option, any part(s) thereof of the nortrac ™ 4wd diesel tractor or compact cra...

Page 78

9. Limited warranty 72 disclaimer of consequential damage: any implied warranty of merchantability or fitness for a particular purpose, to the extent that either may apply to any nortrac ™ tractor or compact crawler / bulldozer, shall be limited in duration to the periods of the express warranties s...

Page 79

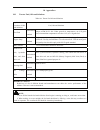

73 10. Appendixes 10.1 tractor fuel, oils and solutions table 10-1 tractor fuel oils and solutions application locations of oils and solutions fuel, oils and solutions fuel tank international standard adopt astm d-975 fuel. Under general air temperatures, use 2-d grade fuel; when ambient temperature...

Page 80

74 10.2 major bolts and nuts tightening torque table table 10-2 major bolts and nuts tightening torque table name and assembly position thread specification tightening torque[n·m] tightening torque [lb ft] connecting bolt and nut for the engine and the clutch housing m10 41~51 30~37 connecting bolt ...

Page 81

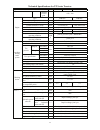

75 10.3 tractor rolling bearing table 10-3 schedule of tractor rolling bearings sequence no. Code bearing code name of bearing installation position quantity 1 gb/t 276 6203-z deep groove ball bearing front end of clutch axle 1 2 gb/t 276 6006 deep groove ball bearing front end of power take-off dri...

Page 82

76 sequence no. Code bearing code name of bearing installation position quantity 688711(for double -action clutch) 20 gb/t 5846 k202417 rolling needle bearing transfer-case idle shaft 2 21 gb/t 5846 k253120 rolling needle bearing transfer-case output shaft 2 22 gb/t 5846 k283327 rolling needle beari...

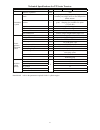

Page 83

77 part specification installation position quantity both ends of rocking shaft 2 jb/t2600 reinforced seal pd42×62×10 lift shaft 2 10×13.5 bleeder plug 1 10×13.5 cylinder head 2 18×22 hydraulic output hollow bolt 1 jb/t 982 sealing gasket 36×42 oiling ventilation plug assembly 1 71×2.65g sealing par...

Page 84

78 part specification installation position quantity bearing cap 2 75×2.65g external end of half shaft sleeve 2 80×3.55g rear bearing 2 85×3.55g driving bevel gear bearing saddle 2 170×3.55g drive shaft cap 2 175×3.55g internal end of half shaft sleeve 2 notice: before using a supporting farm implem...

Page 85: On Line Spare Parts System

On line spare parts system fill in http://222.132.52.85:8080/ choose product model and code: choose “guest” choose english choose “parts catalogue”.

Page 86

Then you can find the parts catalog and diagram of the tractor: te204-l161q5k te25 serials then search here te204-l161q5k te25 serials.

Page 87

Te25 serials te204-l161q5k.

Page 88: On Line Spare Parts System

On line spare parts system fill in http://222.132.52.85:8080/ choose product model and code: choose “guest” choose english choose “parts catalogue”.

Page 89

Then you can find the parts catalog and diagram of the tractor: te254-l161q68k te25 serials then search here te254-l161q68k te25 serials.

Page 90

Te25 serials te254-l161q68k.