- DL manuals

- Nova Florida

- Boiler

- BTFSE 24

- User Manual

Nova Florida BTFSE 24 User Manual

Summary of BTFSE 24

Page 1

Installation use and maintenance gb ist 04 c 149 - 01 altair b btne 25 - btne 32 - btne 42 btfse 24 - btfse 32 - btfse 36.

Page 2

Dear customer, thank you for choosing and buying one of our boilers. Please read these instructions carefully in order to install, operate, and maintain this equipment properly. 1.

Page 3

This instruction manual, which is an integral and indispen- sable part of the product, must be delivered to the user by the installer and must be kept in a safe place for future reference. The manual must accompany the boiler should it be sold or its possession transferred. The boiler must be used f...

Page 4

General information for the installer, maintenance technicians and users page 2 1. Instructions for the user page 4 1.1. Control panel page 4 1.2. Operating the boiler page 5 1.2.1. Switching on page 5 1.2.2. Operation page 5 1.2.2.1. Aqua premium system page 5 1.2.2.2. Instantaneous dhw production ...

Page 5

1. Indication light (red): when the light is on, it indicates that the flame detection electronics have shut down the boiler. Boiler reset is operated through switch no. 16. 2. Indication light (red): when the light is on, it indicates that the safety thermostat has shut down the burner. The boiler ...

Page 6

1.2 operating the boiler 1.2.1 switching on - open the gas stop cock. - turn power mains switch to on. - set boiler power switch no. 17 (pic.1) to on (the switch lights up) - choose boiler mode through knob no. 11, no. 12 and no. 13 and the programmable programmer no. 15 (please, refer to 1.2.2.3 an...

Page 7

6 “anti-frost” position boiler is in stand-by mode. All boiler functions are inactive besides ´$qwliurvwµ´$qwliurvwµixqfwlrqsurwhfwlqj&+ÁrzzkhqwkhÁrz probe detects a temperature below 5°c, the boiler turns on until wkhÁrzwhpshudwxuhuhdfkhv&ruplqv “anti-frost” function protecting dhw: when the water...

Page 8

- channel 2 as described in the “thermal unit managing one high temperature ch area and dhw supply” section. The programmer can host up to 8 on daily times and 8 off daily times. 5 programmable time areas are available for each day, for repetition of on/off programs within the same week (1: single d...

Page 9

8 d. Programmer operation modes selector 1 on the programmer sets the following boiler operation modes: i permanently on mode (the selected channel or channels are always active) auto operation through programmed setup (the two channels, 1 and 2, are activated or deactivated following the programmed...

Page 10

6kxwgrzqgxhwrlqvxiÀflhqwzdwhusuhvvxuh in the event of boiler shutdown due to water pressure switch inter- vention, no. 4 uhgoljkwvwduwveolqnlqjvljqdoolqjlqvxiÀflhqwzdwhu pressure in the ch system. In order to restore water pressure, proceed as follows (see pic. 4): - open the loading tap by rotating...

Page 11

10 2. Technical characteristics and dimensions 2.1 technical characteristics the boiler is equipped with a high output cast iron heat exchanger and atmospheric gas burners. $ooyhuvlrqvduhhtxlsshgzlwkhohfwurqlfljqlwlrqlrql]dwlrqÁdph detection device, aqua premium system for dhw supply em- sor\lqjdowu...

Page 12

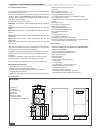

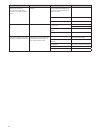

11 pic. 5b model btn ev pic. 5c model btfs e g: gas inlet c: dhw flow f: cold water inlet m: ch flow r: ch return g: gas inlet c: dhw flow f: cold water inlet m: ch flow r: ch return m1: low temperature zone flow m2: low temperature zone return d: flue gas outlet (130 mm for btn 25, 150 mm for btn 32 and...

Page 13

12 s1: ch probe ts: limit thermostat v3v: 3-way motorized valve vm: 2-way motorized valve pr: ch pump with air purging device ps: dhw pump f: priority flow meter se: external probe (optional equipment) vmi: mixing valve ts1: low temperature zone safety thermostat 2.3. Boiler layout boiler layout btn...

Page 14

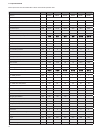

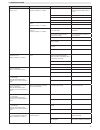

13 btn 25 btn 32 btn 42 btfs 24 btfs 32 btfs 36 category - ii2h3+ ii2h3+ ii2h3+ ii2h3+ ii2h3+ ii2h3+ type - b11bs c12 - c32 - c42 - c52 - c82 number of elements of primary heat exchanger - 4 5 6 3 4 4 number of nozzles of burner - 3 4 5 3 3 3 max heat input kw 27.87 34.80 47.00 26.6 34.4 39.2 max he...

Page 15

G20 gas btn 25 btn 32 btn 42 btfs 24 btfs 32 btfs 36 co2 content % 5.1 4.5 6 7.6 8.3 8.2 flue gas temperature °c 111 103 121 120/130 110/120 120/130 )oxhjdvpdvvÁrzudwh kg/h 101.16 133.56 162 55 67 76 max output gas consumption stm 3 /h 2.95 3.7 4.97 2.81 3.64 4.15 gas pressure mbar 20 20 20 20 20 20...

Page 16

3.2.4. Boiler room ventilation the boiler is to be installed in an adequate room according to law requirements, which are considered as fully transcribed in this ma- nual. Btn, open combustion chamber boiler model is to be connected to a chimney system: combustion air is taken from the boiler room. ...

Page 17

Type c32 7klverlohulvghvljqhgiruyhuwlfdodluÁxhjdvwhuplqdovfrqqhfwhg to the outside by means of coaxial or split pipes. 7khglvwdqfhehwzhhqwkhdlulqwdnhslshdqgwkhÁxhjdvslshlv to be at least 250 mm and both terminals are positioned within a square having 500 mm sides. • air / flue gas coaxial pipe, 60/1...

Page 18

9huli\lqjfrpexvwlrqhiÀflhqf\ ,qrughuwrghwhuplqhfrpexvwlrqhiÀflhqf\wkhiroorzlqjphdvxuh- ments are to be performed: - combustion air temperature Áxh jdv whpshudwxuh dqg &2 2 concentration, from the relevant rshqlqjrqwkhÁxhjdvslsh perform the above measurements when the boiler has reached working tempe...

Page 19

3.2.12. Installation of original kits the manufacturer provides original kits for thermoregulation con- trol unit installation. The kits are to be installed as described in their relevant instruction manuals. 3.3. Loading the system after completion of all hydraulic connections the central heating s...

Page 20

3.5. Wiring diagrams model btn e model btfs e m: terminal board for connection to power mains, external temperatu- re probe, room thermostat m6: telemetry connection m1- m24: available connectors ta: room thermostat se: 10k ohm b = 3977 external temperature probe (optional equipment) ct: phone conne...

Page 21

Sp sz bc mod. Btn e v and btfs e v sp: main pcb sz: zone pcb ig: two-poled main power switch bc: flame detection pcb vg: gas valve v: fan pv: fan pressure switch e.Riv: flame detection electrode e.Acc: ignition electrode psb: reset button ts: safety thermostat tf: flue gas thermostat dk: low water p...

Page 22

7kherlohulvwreh\hduo\vhuylfhgwrhqvxuhhiÀflhqwdqgwurxeoh free operation following to the below described plan. Maintenance (and repair) operations are to be exclusively perfor- phge\txdolÀhgshuvrqqho the manufacturer recommends customers to have an authorized service center implement any maintenance ...

Page 23

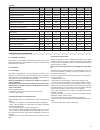

Boiler status malfunction probable cause solution the boiler has shut down, the red light no. 1 is on. Burner does not ignite. Reset by pressing no. 16 button gas supply failure check gas network pressure check gas network safety valves to be open gas valve is disconnected reconnect gas valve gas va...

Page 24

Boiler status malfunction probable cause solution 5hgoljkwqrlvÁdvklqjdqgwkh boiler has not shut down. Boiler will automatically resume operation as soon as the problem is solved boiler water temperature has excee- ded 85°c :dwhulvqrwÁrzlqjlqwkhv\vwhpsl- pes are clogged, thermostatic valves are close...

Page 25

24.

Page 26

25.

Page 27

26.

Page 28

0libisen24 uf f. Pubblicità fondital ist 04 c 149 - 01 novembre 2005 (1 1/2005) the manufacturer reserves the right to implement any necessary and/or useful variation to products, without modifying fundamental characteristics. Fondital s.P.A. Via mocenigo, 123 25078 vestone (brescia) italia tel. 036...