- DL manuals

- Nova Florida

- Boiler

- DELFIS Monothermal

- Installation, Use And Maintenance Manual

Nova Florida DELFIS Monothermal Installation, Use And Maintenance Manual

Summary of DELFIS Monothermal

Page 1

Delfis monothermal installation, use and maintenance en translation of the original instructions (in italian) ist 04 c 404 - 01.

Page 2

2 dear sirs, thank you for choosing and buying one of our products. Please read these instructions carefully in order to properly install, operate, and maintain the product. Warning • we inform users that: • boilers shall be installed by an authorised company under the requirements set forth by the ...

Page 3

3 general notes for installing and maintenance technicians, and users this instruction manual is an integral and essential part of the product. It shall be supplied by the installer to the user who shall keep it carefully to consult it whenever necessary. This document shall be supplied together wit...

Page 4

4 danger with gas fired boilers, take the following measures if you smell gas: • do not turn on or off electric switches and do not turn on electric appliances. • do not ignite flames and do not smoke. • close the main gas cock. • open doors and windows. • contact a service centre, a qualified insta...

Page 5

5 1. Instructions for the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 1.1 control panel ........................................................................................................................................

Page 6

6 fig. 1 control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 fig. 2 filler cock. . . . . . . . . . . . . . . . . . ....

Page 7

7 tab. 1 adjustment specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 tab. 2 general specifications . . . . . . . . . . . . . . . . . . . . ...

Page 8

8 instructions for the user 1. Instructions for the user 1.1 control panel 2 1 10 5 6 8 7 c d b a f g 9 3 4 e fig. 1 control panel a. Dhw setting (+/- dhw). B. Parameter confirmation and information request. C. Operating status selection. D. Alarm reset and back to the starting page during parameter...

Page 9

9 instructions for the user ref. Description steady on flashing 1 flue cleaning function indicator (for the installer) flue cleaning function active. Indicates that you are accessing the flue cleaning function. 2 dhw indicator boiler is in dhw mode. Displaying of the dhw temperature set- point. 3 pa...

Page 10

10 instructions for the user 1.2 interpreting boiler status from display indications 1.2.1 normal operation boiler in standby mode boiler in summer mode no active function flow temperature displayed boiler in winter mode no active function flow temperature displayed boiler in central heating only mo...

Page 11

11 instructions for the user 1.3 boiler operation 1.3.1 switching on danger it is presumed that the boiler has been installed by a qualified installer, it has been commissioned and is ready to operate correctly. • open the gas shut-off cock. • turn the master switch installed ahead of the boiler to ...

Page 12

12 instructions for the user 1.3.4 dhw function boiler electronics always gives priority to dhw over ch supply. To set the domestic hot water temperature, press dhw +/- buttons. The dhw temperature setting range is from +35 °c to +57 °c. During temperature setting, the symbol flashes on the screen a...

Page 13

13 instructions for the user 1.3.7 timed post-circulation function after each central heating, dhw or freeze protection request, the pump continues to be powered for 30 seconds. If a new central heating, dhw or freeze protection request is received during this period, the post-circulation function i...

Page 14

14 instructions for the user 1.4 boiler shut-down the boiler shuts down automatically if a malfunction occurs. To determine the possible causes of malfunction (see troubleshooting on page 44 ). Below is a list of shut-down types and the procedure to follow in each case. 1.4.1 burner shut-down fault ...

Page 15

15 instructions for the user 1.4.4 shut-down due to low water pressure fault code e04 is displayed on the lcd display in the event of shut-down triggered by the water pressure switch. Fill the system by working on filler cock (a) (see fig. 2 filler cock). Water pressure must be 1÷1.3 bars while the ...

Page 16

16 instructions for the user 1.4.6 alarm due to (optional) remote control connection malfunction the boiler recognises whether or not there is a remote control (optional, not compulsory). If the boiler does not receive information from the remote control after the remote control itself is connected,...

Page 17

17 technical features and dimensions 2. Technical features and dimensions 2.1 technical features the boiler is equipped with an integrated gas atmospheric burner. The following models are available: • ctn open chamber, natural draught boiler with electronic ignition for heating and instantaneous dhw...

Page 18

18 technical features and dimensions 2.1.3 operating features • electronic flame modulation in ch mode, with timed rising ramp. • electronic flame modulation in dhw mode. • flow freeze protection function: on 5°c; off 30°c or after 15 minutes of operation if ch temperature > 5 °c. • dhw freeze prote...

Page 19

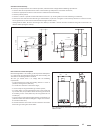

19 technical features and dimensions 2.2 dimensions 400 700 232 11 8 250 66 60 62 67 82 63 11 43 1 91 81 m c g f r fig. 3 model ctn dimensions m ch system flow - 3/4" c dhw outlet - 1/2" g gas inlet - 1/2” f cold water inlet - 1/2" r ch system return - 3/4”.

Page 20

20 technical features and dimensions 2.3 boiler layouts fig. 4 boiler layout ctn 1. Automatic by-pass 2. Dhw temperature probe 3. Motorised 3-way valve 4. Modulating gas valve 5. Burner 6. Ch temperature double probe 7. Ignition/detection electrode 8. Mono-thermal heat exchanger 9. Flue gas thermost...

Page 21

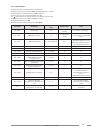

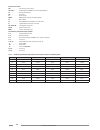

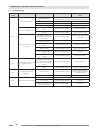

21 technical features and dimensions 2.4 operating data burner pressures reported in the following page must be verified after the boiler has been operating for 3 minutes. Gas category: ii2h3+ fuel gas mains pressure [mbar] nozzle [mm] min pressure at the burner [mbar] max pressure at the burner [mb...

Page 22

22 technical features and dimensions description um max. Output min. Output 30% load heat loss from the boiler casing % 3,04 4,24 - flue system heat loss with burner on % 6,86 8,56 - flue system mass capacity g/s 16,72 14,98 - flue temp. – air temp. °c 83 62 - co2 value (methane/butane/propane) % 5....

Page 23

23 instructions for the installer 3. Instructions for the installer 3.1 installation standards this boiler must be installed in compliance with the laws and standards in force in the country of installation, which are herein considered as entirely transcribed. To find out about the gas category and ...

Page 24

24 instructions for the installer 3.3 positioning the boiler each boiler is supplied with a paper template, found inside the packaging (see fig. 5 paper template). The template allows you to ensure that the pipes connected to the ch system, the dhw system and the gas mains, and the air intake/flue g...

Page 25

25 instructions for the installer 3.4 installing the boiler danger before connecting the boiler to ch and dhw networks, clean the pipes carefully. Before commissioning a new system, clean it to remove any metal chips due to machining and welding, and any oil and grease that might negatively affect b...

Page 26

26 instructions for the installer danger the boiler is equipped with a safety device for flue gas exhaustion check. It is strictly forbidden to tamper with and/or prevent operation of such safety device. Should an air/flue gas system malfunction occur, the device will shut-down the boiler by interru...

Page 27

27 instructions for the installer connection to the chimney the chimney is indispensable for correct boiler operation; it must therefore comply with the following requirements: • it must be made of waterproof material and be resistant to flue gas temperature and related condensate; • it must have ap...

Page 28

28 instructions for the installer 3.6 checking combustion efficiency 3.6.1 flue cleaning function • the boiler features a flue cleaning function which must be used to measure combustion efficiency during operation and to adjust the burner. • to activate the flue cleaning function, press and hold the...

Page 29

29 instructions for the installer 3.8 hydraulic connections 3.8.1 central heating prior to installing the boiler, the hydraulic system is to be cleaned in order to remove impurities; they could be present in system components and damage the pump and the heat exchanger. The ch outlet and return pipes...

Page 30

30 instructions for the installer 3.10 connection to ambient thermostat (optional) the boiler is designed to be connected to an ambient thermostat (optional, not compulsory). Ambient thermostat contacts must be properly sized in compliance with a load of 5 ma at 24 vdc. The ambient thermostat cables...

Page 31

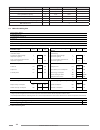

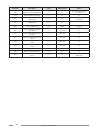

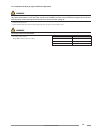

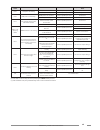

31 instructions for the installer 3.12 tsp parameters the boiler operation is controlled by several parameters. To modify parameters press buttons reset and - ch together for 3 seconds. Scroll through the parameters by pressing ch +/- buttons. As soon as you reach the one to be modified, press ok. T...

Page 32

32 instructions for the installer parameter description configurable value range default values notes p30 display of external temperature n.A. N.A. Only with external probe connected p31 display of flow temperature n.A. N.A. N.A. P32 nominal calculated flow temperature n.A. N.A. Only with external p...

Page 33

33 instructions for the installer 3.12.1 installation of the (optional) external probe and sliding temperature operation the boiler can be connected to an (optional) external temperature probe (optional, provided by the manufacturer) for sliding temperature operation. Warning only original external ...

Page 34

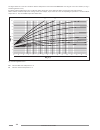

34 instructions for the installer the figure shows the curves for a fictitious ambient temperature of 20°c.Parameter p10 allows selecting the curve value shown (see fig. 9 thermoregulation curves). If fictitious ambient temperature value is edited on boiler display, the curves shift up or down, resp...

Page 35

35 instructions for the installer 3.13 filling the system once all boiler connections have been completed, ch system can be filled. The procedure is to be cautiously carried out, following each step: • open the bleeding valves on all radiators and verify the boiler automatic valve operation. • gradu...

Page 36

36 instructions for the installer 3.14 starting up the boiler 3.14.1 preliminary checks before starting the boiler, check that: • the flue gas venting duct and the relevant terminal are installed in conformity with the instructions: with the boiler operating, there must be no leakage of combustion b...

Page 37

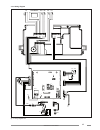

37 instructions for the installer 3.16 wiring diagram 1 2 3 4 5 6 7 8 9 10 11 1516 17 18 1 4 1 5 x2 x7 x6 x5 x4 x3 x2 3 1 2 7 1 cn_e cn_h cn_a acc1 cn_i cn_m cn_l cn_j cn_d cn_b cn_c jp1 x14 mdv n bu risc. Bk sanit. Bn x4 x3 cn_l cn_i cn_m cn_a cn_c cn_d sr1 sr2 tf e ss cn_n k4 k3 k2 k5 f1 x8 x10 x9...

Page 38

38 instructions for the installer internal connections dk : . . . . . . . . . . . . . . Low water pressure swich sr1-sr2 : . . . . . . . . . Ch ntc probe 10k ohm at 25°c b=3435 (double) tf : . . . . . . . . . . . . . . . Flue gas thermostat vg : . . . . . . . . . . . . . . Gas valve p : . . . . . . ...

Page 39

39 instructions for the installer 3.17 adaptation to other gas types and burner adjustment warning this boiler is built to run on the type of gas specified on the packaging and on the boiler rating plate. Any later transformation is to be exclusively carried out by qualified personnel, using manufac...

Page 40

40 instructions for the installer 3.17.1 gas valve setting maximum heating output adjustment • check the flow pressure value (see operating data on page 21 ); • remove the plastic cover a at the top of the modulator coil, protecting the pressure regulator adjuster screws; • connect a pressure gauge ...

Page 41

41 testing the boiler 4. Testing the boiler 4.1 preliminary checks before testing the boiler, it is recommended to check the following: • the flue gas venting duct and the relative terminal are installed in conformity with the instructions: there must be no leakage of combustion by-products from any...

Page 42

42 maintenance 5. Maintenance warning any maintenance (and repair) work must only be carried out by qualified personnel. The user is strongly advised to have the product serviced and repaired by a service centre or qualified personnel. Appropriate boiler maintenance ensures efficient operation, envi...

Page 43

43 decommissioning, disassembly and disposal warning should the boiler not operate correctly, while not posing danger to people, animals or property, notify the system supervisor both verbally and in writing. 5.2 combustion analysis the combustion parameters of the boiler, which have to be checked i...

Page 44

44 malfunctions, possible causes and solutions 7. Malfunctions, possible causes and solutions 7.1 troubleshooting boiler status malfunction probable cause user's tasks qualified personnel's tasks e01* burner does not ignite. Gas supply failure. Check gas supply. Check gas supply cock or gas network ...

Page 45

45 malfunctions, possible causes and solutions boiler status malfunction probable cause user's tasks qualified personnel's tasks e05** flow probe not working. Flow probe disconnected. Contact qualified personnel reconnect it. Flow probe faulty. Contact qualified personnel replace it. E06** dhw probe...

Page 46

46.

Page 47

Attenzione! Se vedi questa pagina significa che devi aggiungere una pagina bianca in fondo al manuale 47 this page is intentionally left blank.

Page 48

Fondital s.P.A. 25079 vobarno (brescia) italy - via cerreto, 40 tel. +39 0365/878.31 fax +39 0365/878.304 e mail: info@fondital.It www.Fondital.Com the manufacturer reserves the right to modify his/her products as deemed necessary, without altering the basic characteristics of the products themselve...