- DL manuals

- Nova Florida

- Boiler

- DRAGO DUAL 23

- Installation, Use And Maintenance Manual

Nova Florida DRAGO DUAL 23 Installation, Use And Maintenance Manual

Summary of DRAGO DUAL 23

Page 1

Ist 04 c 154 - 01 drago dual installation, use and maintenance gb.

Page 2

Thank you for choosing our boilers. Please read these installation and maintenance instructions with care. Please note that the boiler must only be installed, repaired and serviced by qualified personnel. 2.

Page 3

3 general information for installers, service engineers and users this instruction manual, which is an integral and indispen- sable part of the product, must be handed over to the user by the installer and must be kept in a safe place for future reference. The manual must accompany the boiler should...

Page 4

Table of contents to the user page 2 general information for installers, service engineers and users page 3 1 instructions for the user page 5 1.1 control panel page 5 1.2 boiler operation page 6 1.2.1 switching on page 6 1.2.2 burner shutdown page 6 1.2.3 shutdown due to overheating page 6 1.3 main...

Page 5

5 main switch with power light (green) (a) when the switch is turned to posi- tion 0, the boiler is off and the green power light is off. When the switch is in position i, the boiler is powered on and the light on the switch is on. Ch temperature control (b) with this knob you can set the temperatur...

Page 6

1.2 boiler operation (pic. 1) 1.2.1 switching on * open the fuel tap. * turn the boiler main switch a to the on position (the light comes on). * turn the heating water tempera- ture control knob b to the required setting. * set the room temperature value on the room thermostat (if there is one). * l...

Page 7

2.1 technical features this is a floor-standing gas or oil boiler with a cast iron heat exchan- ger with 3 smoke passes, working with oil or gas free-standing blown- air burners. The following models are available: 23 with 24 kw heat output 33 with 33 kw heat output 43 with 43 kw heat output 53 with...

Page 8

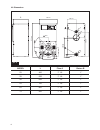

8 l 150 850 mm 450 mm 285 4 fori m8 110 150 mm 65 mm 57 486,5 mm mm mm 82,5 mm 235 mm 627 mm 225 mm 65 mm 82,5 mm model l flow a return b 23 400 1" 1/4 1" 33 525 1" 1/4 1" 43 625 1" 1/4 1" 53 700 1" 1/4 1" 63 800 1" 1/4 1" 73 900 1" 1/4 1" pic. 2 2.2 dimensions.

Page 9

9 2.3 technical characteristics note the installation of blown-air burners, according to the standards in force (ec marking as per directives: cee/73/23 – cee/89/336; en267 regulation), must be done respecting the burner manufacturer instructions and making a burner adjusting which permits to obtain...

Page 10

10 3 instructions for the installer 3.1 installation standards the boiler must be installed in compliance with current laws and standards which are considered an integral part of this han- dbook. 3.2 installation 3.2.1 packaging the boiler comes packed in a sturdy cardboard box on a wooden pallet. T...

Page 11

Rectangular chimneys, the inside cross section must be 10% greater than that of the boiler fitting. * the material used must be water- proof and resistant to the flue gas temperatures and acid conden- sate. * mandatory features are low ther- mal conductivity, adeguate mecha- nical resistance, perfec...

Page 12

Comply with the applicable stan- dards and laws on boiler instal- lation, which are considered an integral part of this handbook. A bipolar switch must be fitted upstream of the boiler so that maintenance operations can be carried out safely. The boiler mains supply must be protected by a differenti...

Page 13

13 3.5 wiring diagrams 3.5.1 boiler layout pic. 8 ch pump feeding room thermostat connection water pressure switch connection electric feeding 3.5.2 general layout a = light blue bl = blue bk = black br = brown g = grey gn = green r = red v = purple y = yellow ygn = yellow/ green ig f lon pa ta ts l...

Page 14

R2-3 r2-6 r2-7 r4-1 r2-2 bk bl g r8-2 g r7-1 g r7-2 v r5-1 v r5-2 l1 l3 l5 bk r1-3 mn fu1 1 2 r3-6 r r3-5 br r3-4 a pc 12 11 10 9 ts r3-2 gn r6-1 y r6-2 v r3-1 v r3-3 y r2-5 r2-4 r2-1 g r8-1 r4-2 r4-3 r r1-4 3 4 5 tm r 7 6 pa br bl r1-1 br r1-2 bl r6-4 br r6-3 ig l4 l1 n s3 br n pcb 1 (2)pr6 (3)pr5 ...

Page 15

To ensure that the boiler conti- nues to run efficiently, it must be serviced once a year as specified below. Maintenance or repairs must be performed by qualified person- nel. For maintenance and repairs, users are advised to contact a qualified technician or a service centre where the personnel is...

Page 16

Fondital s.P.A. Via mocenigo, 123 25078 vestone (brescia) italia tel. (+39)0365 878.31 fax (+39)0365 596.257 e mail: fondital@fondital.It www.Fondital.It the manufacturer reserves the right to implement any necessary and/or useful variation to products, without modifying fundamental characteristics....