Operator‘s manual gb + instructions for product delivery . . . Page 3 "translation of the original operating manual" nr. • disc mower 99 3834.Gb.80o.1 novacat s10 (type psm 3832 : + . . 00001) novacat s12 (type psm 3834 : + . . 00001).

1300_gb-seite 2 product liability, information obligation product liability obliges manufacturers and dealers to issue operating instructions with the sale of machinery and to instruct the customer at the machine pointing out the operating, safety and maintenance regulations. A confirmation is requi...

Dokument d gb-0600 dokum d anbaugeräte - 3 - alois pÖttinger maschinenfabrik gmbh a-4710 grieskirchen tel. (07248) 600 -0 telefax (07248) 600-2511 gebr. PÖttinger gmbh d-86899 landsberg/lech, spöttinger-straße 24 telefon (0 81 91) 92 99-111 / 112 telefax (0 81 91) 92 99-188 gebr. PÖttinger gmbh serv...

- 4 - table of contents 1400_gb-inhalt_3834 gb attention! Safety hints to observe in supplement! Table of contents warning signs ce sign ...................................................................... 5 meaning of warning signs.......................................... 5 specification overvie...

- 5 - 9700_gb-warnbilder_361 gb warning signs stay clear of swinging area of implements close both side protective coverings before engaging p.T.O.. Never reach into the crushing danger area as long as parts may move. Ce sign the ce sign, which is affixed by the manufacturer, indicates out ward ly t...

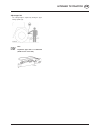

- 6 - 1401-gb-Übersicht_3834 gb specification overview designations: (1) headstock (2) swivel arm transport position (3) cutter bar (4) buffer (inner transport position) (5) lighting variations description description novacat s10 working width: 9.52 m with 3.5m front mower 9.10 m with 3.0m front mow...

- 7 - 1401-gb-schleppervoraussetzung_3834 gb tractor requirements tractor to operate this machine the following tractor requirements are necessary: - tractor power: novacat s10 - from 103kw / 140ps, novacat s12 - from 118kw / 160ps, - hitching: lower link cat. Iii / weite 3 - connections: see table ...

- 8 - 1401-gb-schleppervoraussetzung_3834 tractor requirements gb necessary hydraulic connections design consumer dual action hydraulic connection with floating position dual action hydraulic connection without floating position standard lifting cylinder, folding cylinder or hydraulic relief x hydra...

- 9 - 1401_gb-anbau_3834 gb hitching to tractor ensure that you secure the locating screw in the hole in the bolt! Otherwise the mower may loosen from the coupling, fall to the ground and cause damage to property. - connect upper link and secure. Be advised! Check cardan shaft length before initial ...

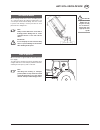

- 10 - 1401_gb-anbau_3834 hitching to tractor gb adjust upper link - the cutting height is adjusted by turning the upper linkage spindle (16). Note: a hydraulic upper link is recommended (double-action control unit).

- 11 - 1401_gb-anbau_3834 hitching to tractor gb carry out trial run set lifting height - adjust both lower links to 700mm distance to ground. 700mm set power take-off r.P.M. - set suitable power take-off r.P.M. On tractor note: an illustration located near the gearing advises which power take-off r...

- 12 - 1400 gb-transport 3834 gb transport and working position safety hints: see attachment a1, 7.), 8c. - 8h.) changing from working to transport position and vice versa is only to be carried out on even, firm ground. Never let mowing mechanism run with the mower raised. Safety hints: check the wo...

- 13 - 1401_gb-abbauen_3834 gb unhitching and parking unhitching implement from tractor be advised! • always park the implement on firm, flat ground. • use support stand - otherwise danger of tipping • danger of injury from crushing and shearing sections in the area of the support stand depending on...

- 14 - 1401_gb-abbauen_3834 unhitching and parking gb note the safety lever (1) is a safety fixture. It should not be changed in its form and functions. The lever is constructed so that it won’t spring out of the lock position when hydraulically raising the mower bar. • do not operate the hydraulic ...

- 15 - 1400-gb einsatz 3834 gb operation important notes prior to the start of work safety hints: see attachment a, 1. - 7.) after the first hours of operation • retighten all blade screw connections. Safety advice 1. Check - check the condition of knives and the knife holder. - check cutting discs ...

- 16 - 1400-gb einsatz 3834 operation gb mowing 1. Adjust the cutting height by turning the upper link spindle and with the hydraulic upper link (max. 5° inclination to mower discs) 2. To mow, slowly engage the pto outside the mowed fodder (in field transport position) and take the mower rotor to fu...

- 17 - 1301_gb-hangfahrt_358 gb working on slopes take care when turning on slopes! The tractor's travelling characteristics are influenced by the weight (g) of the mower unit. This can lead to dangerous situations, especially on slopes. Danger of tipping occurs - when the mower unit is facing downh...

- 18 - 1400_gb-schwadformer_3783 gb swath former swath disc a narrow swath is formed when using the swath plates while mowing. This avoids driving over the crop with wide tractor tyres. 530-13-13 10 mm conical disc the conical disc supplied is to be fitted if: - an improvement in conveying in the sw...

- 19 - 1400 gb_anfahrsicherung_3834 gb anti-collision device anti-collision device when mowing around trees, fences, boundary stones etc., collisions between the cutter bar and obstacles can occur despite careful and slow driving. Therefore, in order to prevent such damage, collision protection has ...

- 20 - 1400-gb-arbeitsbreite_3834 gb adjusting working width working width the working width can be altered between two positions, e.G. In order to adapt the rear mower to the front mower. Position: for a front mower of 3.50m width the mower bar is mounted outward on the swing arm. Position: for a f...

- 21 - gb 1400_gb-allg wartung_ba hydraulic unit caution injury and infection hazard! Liquids discharging at high pressure may penetrate the skin. Therefore seek immediate medical help! Make sure that the hydraulic system is suitable for the tractor before connecting the hydraulic lines. After the f...

- 22 - gb 1401-gb-wartung_3834 maintenance note • too much oil leads to the mow- er bar overheating during operation. • too little oil does not guarantee the necessary lubri- cation. 4. Oil level check the oil level is correct when the oil comes up to the level screw 1) (oil level). 1) the oil filli...

- 23 - gb 1401-gb-wartung_3834 maintenance cutter bar oil change - change oil after the first 50 operating hours or after 100 ha at the latest. Note: • change oil when at operating temperature. The oil is too viscous when cold. Too much old oil remains stuck to the gearwheels and thus any suspended ...

Gb - 24 - 1400_gb-sichtkontrolle_3776 maintenance wear control cutting blades bracket be advised! There is danger of accidents if: - the blade pin in the middle is worn off up to 15 mm - the wear area (30a) has reached the edge of the hole. - the lower blade pin (30b) is worn off - the blade pin is ...

Gb maintenance and service - 25 - 1100-gb klingen-schnellw 3776 checking the mowing blade suspension - normal check every 50 hours. - check more often when mowing on stony terrain or in other difficult operating conditions. - check immediately after driving over a hard obstacle (e.G. Stones pieces o...

- 26 - 1400_gb-hebel_3834 gb maintenance and service h 2 changing the cutter blades (from 2004 model) 1. Move lever (h) from the left or right to the stop between mower disk and blade holder (30) into position "a" 2. Swivel lever from pos. A to pos. B and thus press the moveable blade holder (30) do...

- 27 - 1401_gb-tech daten_3834 gb technical data technical data all data subject to alteration without notice equipment on request: • warning sign • high cut skids • wear skids • swath discs connections required • 1 dual-action hydraulic plug connection with floating position (minimum equipment requ...

- 28 - 1401_gb-tech daten_3834 technical data gb the defined use of the mower unit the mower „novacat s12 (type 3834)“ is only intended for customary use in agricultural work. • the mowing of grassland and short stemmed fodder. Any other use outside of this is regarded as not in accordance with the ...

Gb-anhang titelblatt _ba-allgemein gb supplement.

Gb-anhang titelblatt _ba-allgemein gb the decision must be made, ”original” or ”imitation”? The decision is often governed by price and a ”cheap buy” can sometimes be very expensive. Be sure you purchase the ”original” with the cloverleaf sym- bol! • quality and precise fitting - operating safety. •...

- 31 - 1200_gb-anhanga_sicherheit supplement - a gb recommendations for work safety recommendations for work safety all points refering to safety in this manual are in di ca ted by this sign. 1. Operating instructions a. The operating instructions are important for the correct operation of the machi...

- 32 - 1200_gb-anhanga_sicherheit supplement - a gb 20% kg 9.) transport of persons prohibited a. The transport of persons on the machine is not permitted. B. The machine may only be driven on public roads when in the position sti pu la ted for road trans port. 10.) driving ability with auxiliary eq...

- 33 - 1300_gb-anhangb_gelenkwelle_150h pto shaft gb supplement - b instructions for working the permissible pto speed may not be exceeded when using the implement. - the hitched implement may continue to run after the pto is switched off. Work may only be performed once it has reached complete stan...

- 34 - 1300_gb-anhangb_gelenkwelle_150h pto shaft gb supplement - b l l k92e,k92/4e k90,k90/4,k94/1 important for driveshafts with friction clutch torque is limited with overloading and brief torque peaks and evenly transferred during slipping. Prior to initial operation and after long periods out o...

9900-zentral_legende-schmierplan - 35 - schmierplan x h alle x betriebsstunden 40 f alle 40 fuhren 80 f alle 80 fuhren 1 j 1 x jährlich 100 ha alle 100 hektar fett fett = anzahl der schmiernippel = anzahl der schmiernippel (iv) siehe anhang "betriebsstoffe" liter liter * variante siehe anleitung des...

- 36 - 1400-schmierplan 3834 fett 50 h (100 ) h 1 j 1 j fett (iv) (iii) 5,0 liter novacat s10 novacat s12 (iii) 1,7 liter (iii) 5,0 liter (iii) 1,2 liter (iii) 1,2 liter.

- 37 - 1400_en-betriebsstoffe gb the per formance and t he lif etime of t he f arm machines ar e highly depending on a car eful maint enance and application of corr ect lubricants. Our schedule enables an easy selection of select ed pr oducts. The applicable lubricants ar e symbolized (eg. “iii”). A...

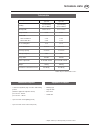

- 38 - 1400_en-betriebsstoffe compan y i (ii) Öl iii (iv) fett v v i viii not a tions a gip oso 32/46/68 arnic a 22/46 mo to r oil hd 30 sigma mul ti 1 5w -40 super tra ct or oil univers. 1 5w -30 r o tra hy 80w -90/85w -1 40 r o tra mp 80w -90/85w -1 40 gr mu 2 gr sll gr lf o - r o tra mp 80w -90 r...

- 39 - 1400_en-betriebsstoffe compan y i (ii) Öl iii (iv) fett v v i viii not a tions shell tell us s32/s 46/s68 tell us t 32/t46 a g r oma 1 5w -30 r o tell a x 30 rimul a x 1 5w -40 spirax 90 ep spirax hd 90 spirax hd 85/1 40 retin ax a alv ania ep 2 spez. Getriebefett h simmnia grease o aer oshel...

- 40 - 1501-gb-rep hinweise_397 repair instructions gb k1 repairs to the cutter bar • markings aligned (k1, k2). Up to 2005 model (marking k1 = centre point on the hub) from 2006 model (marking k1 = larger countersink when drilling) • only screw on nut (m) when there is sufficient thread length (l) ...

- 41 - 1501-gb-rep hinweise_397 repair instructions gb assembly instructions • for easier assembly of the cutting discs please proceed as follows: 1. With the disc's direction of rotation to the left = marking (k1) at the top 2. With the disc's direction of rotation to the right = marking (k1) at th...

- 42 - 1501-gb-rep hinweise_397 repair instructions gb novadisc 225 novadisc 265 / novadisc 730 novadisc 305 / novadisc 810 novadisc 350 / novadisc 900 novadisc 400 novadisc 265 direction of rotation "towards the centre" / novadisc 730

- 43 - 1501-gb-rep hinweise_397 repair instructions gb novadisc 810 novadisc 900 novadisc 730 direction of rotation "towards the centre" novadisc 730

- 44 - 0700_gb-taperscheibe gb taper bushes taper bushes installation instructions to assemble 1. Clean and degrease the bore and taper surfaces of the bush and the tapered bore of the pulley. 2. Insert the bush in the pulley hub and line up the holes (half thread holes must line up with half straig...

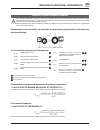

- 45 - 1401_gb-service_3834 gb service hydraulic plan explanation: 1 hydraulic block 2 relief 3 lifting 4 movement stops 5 folding guard 6 back swivel 7 tractor control unit, double-acting y3 y1 a5 a4 a6 y2 b6 b5 b4 a3 a2 b2 y4 sp 1 sp 2 b3 b1 a1 p1 1l 60 bar 1l 60 bar 1l 60 bar 1l 60 bar pb pa pb p...

- 46 - 1401_gb-service_3834 service gb electric circuit diagram (control) (0,7m 4x1,0) (2,0m 2x1,5) 10a s1 s2 schaltbild br 1,5 bl 1,5 sw(4) sw(1) 15/30 31 2 1 3 br 1,5 sw(2) sw(3) 4 s2 s1 31 15/ 30 bl (-) br (+) 1 6 sw(4) sw(1) sw(3) sw(2) 2 3 4 5 530-13-15 diagram view of plug from outside view of...

- 47 - 1401_gb-service_3834 service gb cable harness y3 y1 4, 5 7, 5 4, 5 y4 y2 4, 5 7, 5 4, 5 7, 5 10 10 nw10 -3500 nw7, 5-20 0 nw7, 5-20 0 nw4, 5-10 0 nw4, 5-10 0 nw4, 5-15 0 nw4, 5-15 0 1 2 gn d s ch a ltle it. Bl 1 2 y1. .Y4 16 2 5 4 3 bl 1, 5 gr ge gr gr br x1 y2 y4 y3 y1 gr ge 1 1 2 gn d s ch ...

0000-gb zusinfo / ba-el allg. Gb - z.48 - important! Additional information see instruction handbook of the tractor see price list and/or instruction handbook of the implement to be measured consideration of rear mounted implement and front/rear combinations 1. Calculation of minimum ballasting at t...

0000-gb zusinfo / ba-el allg. Gb - z.49 - important! Additional information 3. Calculation of the real front axle load t v tat (if with the front mounted implement (g v ) the required minimum front ballasting (g v min ) cannot be reached, the weight of the front mounted implement has to be increased...

Name and address of the manufacturer: alois pöttinger maschinenfabrik gmbh industriegelände 1 at - 4710 grieskirchen machine (interchangeable equipment): mower type serial no. The manufacturer declares that the machines adhere to all relevant provisions in the following eu directive: machinery 2006/...

A empresa pÖttinger ges.M.B.H esforçase continuamente por melhorar os seus produtos, adaptando-os à evolução técnica. Por este motivo, reservamonos o direito de modificar as figuras e as descrições constantes no presente manual, sem incorrer na obrigação de modificar máquinas já fornecidas. As carac...

Gebr. PÖttinger gmbh servicezentrum spöttinger-straße 24 postfach 1561 d-86 899 landsberg / lech telefon: ersatzteildienst: 0 81 91 / 92 99 - 166 od. 169 kundendienst: 0 81 91 / 92 99 - 130 od. 231 telefax: 0 81 91 / 59 656 alois pÖttinger maschinenfabrik gesellschaft m.B.H a-4710 grieskirchen telef...