- DL manuals

- O'Brien

- Paint Sprayer

- 223-635 C series

- Owner's Manual

O'Brien 223-635 C series Owner's Manual

OWNER’S MANUAL

308–028

Rev D

Supersedes C and PCN D

PRO 201

Electric Airless Paint Sprayer

1/4 Gallon Per Minute, 120 VAC, 60 Hz

Model 223–635, Series C

3000 psi (210 bar) Maximum Working Pressure

U.S. Patent No. 4,616,982

U.K. Patent No. 2,165,591

Other Foreign Patents Pending

THE O’BRIEN CORPORATION, 450 E. Grand Avenue, So. San Francisco, CA 94080

COPYRIGHT 1990, GRACO INC.

This manual contains important

warnings and information.

READ AND RETAIN FOR REFERENCE

Summary of 223-635 C series

Page 1

Owner’s manual 308–028 rev d supersedes c and pcn d pro 201 electric airless paint sprayer 1/4 gallon per minute, 120 vac, 60 hz model 223–635, series c 3000 psi (210 bar) maximum working pressure u.S. Patent no. 4,616,982 u.K. Patent no. 2,165,591 other foreign patents pending the o’brien corporati...

Page 2: Table Of Contents

Welcome to graco’s painter’s team before you use the pro 201 sprayer, please read this entire instruction manual. The manual contains important information that will help you operate the sprayer safely and efficiently, and will help you keep the sprayer in top operating condition. Table of contents ...

Page 3: Sprayer Description

Sprayer description key a hydraulic pump b rac iv dripless tip guard and spray tip 4 pressure control knob 5 hydraulic oil fill cap 11 on/off switch 18 motor 21 diaphragm 22 paint pump 27 strainer 59 drain tube 63 outlet valve 66 bypass valve 67 outlet 101paint hose 102spray gun 59 0266 0267 0270 27...

Page 4: Warnings

4 308-028 warnings high pressure spray can cause serious injury. For professional use only. Observe all warnings. Read and understand all instruction manuals before operating equipment. Fluid injection hazard general safety this equipment generates very high fluid pressure. Spray from the gun, leaks...

Page 5

5 308-028 equipment misuse hazard general safety misuse of the spray equipment or accessories, such as over pressurizing, modifying parts, using incompatible chemicals and fluids, or using worn or damaged parts, can cause them to rupture and result in fluid injection, splashing in the eyes or the sk...

Page 6: Avertissement

6 308-028 avertissement la pulvérisation à haute pression peut causer des blessures très graves. Réservé exclusivement à l’usage professionnel. Observer toutes les consignes de sécurité. Bien lire et bien comprendre tous les manuels d’instructions avant d’utiliser le matériel. Risques d’injection co...

Page 7

7 308-028 ne jamais altére ou modifier une pièce de cet appareil; ceci ris- querait d’entraîner son mauvais fonctionnement. Verifier régulièrement tout l’appareil de pulvérisation et ses équipements et réparer ou remplacer immédiatement les pièces usées ou abîmées. Toujours porter une protection pou...

Page 8: Advertencia

Advertencia el rociado a alta presiÓn puede causar graves lesiones. Solo para uso profesional. Respete los avisos de advertencia. Lea y entienda todo el manual de instrucciónes antes de manejar el equipo. Peligro de inyeccion de fluido seguridad general este equipo general un fluido a una presión mu...

Page 9

Peligro por mal uso del equipo seguridad general cualquier mal uso del equipo pulverizador o los accesorios, tal como sobre presurización, modificación de piezas, uso de ma- teriales y productos químicos incompatibles, o utilización de piezas dañadas o desgastadas, puede hacen que se rompan y causen...

Page 10: Setup

10 308-028 setup 1. Prepare the paint according to the manufactur- er’s recommendations. This is probably the most important step toward trouble-free spraying! Remove any skin that may have formed on the top of the paint. If necessary, thin the paint. Finally, strain the paint through a fine nylon m...

Page 11: Startup

11 308-028 startup caution the wallet sized warning card provided with the gun should be kept with the operator at all times. The card contains important information on reducing the risk of a fluid injection injury , and treatment information should an injection injury occur. Additional copies of th...

Page 12: Startup

12 308-028 startup 7. Release the trigger safety lever and trigger the gun onto a piece of paper to check the spray pattern. Ad- just the pressure setting to obtain the best atomiza- tion and spray pattern. Always use the lowest pressure necessary . Excessive pressure cause premature tip wear and pu...

Page 13: Maintenance

13 308-028 maintenance caution thorough flushing and proper maintenance are essential to keep the sprayer working properly and avoid costly damage to the sprayer or the ob- ject being sprayed. Diaphragm failure: always replace the diaphragm after every 500 hours of operation (once every 4 to 6 month...

Page 14: Maintenance

14 308-028 maintenance lubricate the inlet valve. See fig. 9. 1. Follow the pressure relief procedure on page 11. Remove the inlet screen. 2. Turn the sprayer over. Press down lightly on the stem (a) of the inlet valve (26) with a small screwdriver . Pour about a teaspoon of mineral spirits or solve...

Page 15: Application Methods

15 308-028 application methods always hold the gun perpendicular to the surface and keep the gun at an even 12 to 14 inch (300 to 356 mm) from the surface you are spraying. See fig. 12. Begin moving the gun in a horizontal direction at a steady rate. Start the spray stroke off the target surface and...

Page 16: Troubleshooting

16 308-028 troubleshooting warning to reduce the risk of serious injury, including fluid in- jection, always follow the pressure relief proce- dure warning on page 11 before checking or repair- ing any part of the spray system. Note: repairs, other than those for which instructions are given on page...

Page 17

17 308-028 problem cause solution sprayer starts but will not suck paint paint supply empty refill and prime pump inlet screen clogged clean inlet valve stuck or damaged see page 18 outlet valve stuck see page 18 air trapped in hydraulic system see page 18, diaphragm, step 9 hydraulic oil level low ...

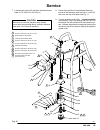

Page 18: Service

18 308-028 service repairs, other than those for which instructions are given below, should be performed by a trained and qualified re- pair agency. Warning to reduce the risk of injury , including fluid injection, splashing in the eyes or on the skin, or injury from moving parts, always follow the ...

Page 19: Service

19 308-028 service 7. Lubricate the screws (25) and then install and torque them to 170–200 in–lb (19–23 n.M). Caution whenever you remove the paint pump screws, torque them as instructed above, and then retorque them after 3 to 5 hours of operation. 8. Check the hydraulic oil level and add graco-ap...

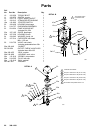

Page 20: Parts

Parts 38 34 56 37 60 1 59 54 55 86 56 8 70 13 14 71 9 65 49 50 48 53 7 89 6 5 52 4 4a 40 47 45 46 44 64 42 43 66 35 3 63 67 2 16 19 27 18 41 39 61 62 37 36 33 17 92 97 95 40 57 58 0280 98 99 75 1 3 4 2 lubricate the threads. Torque to 40–45 in–lb (54–60 n.M). Torque to 130–140 in–lb (15–16 n.M). App...

Page 21: Parts

21 308-028 parts model 223–635, series c, with a hose and a gun. Includes items 1 to 102 note: the part numbers and drawings for items 10 to 12, 15, 18a, 20 to 26 and 28 are shown on page 22. Ref. No. Part no. Description qty. 1 180–462 pipe, pump, 5 gallon size 1 2 180–467 tube, paint, 5 gallon siz...

Page 22: Parts

Parts ref. No. Part no. Description qty. 10 105–659 toggle boot 1 11 105–679 switch, toggle 1 12 105–774 plate, switch, on/off 1 15 106–013 strain relief bushing 1 18a 110–900 .Starter switch 1 20 180–406 housing, diaphragm 1 21 218–727 diaphragm assembly 1 22 224–624 pump housing kit includes 22a, ...

Page 23: Manual

Manual change summary assembly changed part status ref no. Part no. Part name 223–635 sprayer old new old new delete delete add add 27 27 28 28 28c 28e 28c 28e 108–143 218–798 218–732 236–954 107–521 101–701 112–619 112–618 strainer strainer outlet valve outlet valve spring ball spring ball the comp...

Page 24: Technical Data

24 308-028 technical data power requirements 120 vac, 60 hz, . . . . . . . . . . . . . . 1 phase, 15 amp minimum pressure operating range 0–3000 psi . . . . . . . . . . . . . . (0 – 210 bar) maximum delivery 0.28 gpm (1.1 liter/min) . . . . . . . . . . Power cord no. 16 awg, 3 wire, . . . . . . . . ...