Summary of Z01T

Page 1

Tm ® assembly instructions.

Page 2

2 i o’donnell history 2 2 ii warranty • o’donnell ® guarantees this kit to be free from defects in both material and workmanship at the date of purchase. O’donnell will warranty this kit for 90 days after the purchase date. O’donnell will repair or replace, at no charge, the incorrectly made part. •...

Page 3: III

3 iii safety precautions 3 3 iv general building tips use care and good sense at all times when operating this radio controlled truggy. Failure to use this vehicle in a safe, sensible manner can result in injury or damage to property. You and you alone must insure that the instructions are carefully...

Page 4

4 4 4 v required accessories servo high torque steering servo 5-cell receiver hump pack tire inserts header & pipe tires engine receiver transmitter glow plug (and spares).

Page 5

5 5 5 vi required tools & track equipment threadlock ca tire glue diff, shock & air filter oils 3.0mm hex wrench 2.5mm hex wrench 2.0mm hex wrench 1.5mm hex wrench hobby knife glow plug ignitor snap ring pliers flywheel wrench body scissors fuel 4-way wrench clutch tool fuel bottle.

Page 6

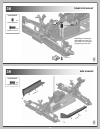

6 1 diff housing 6 6 2 diff planetary gears hardware hardware make sure the fl at spots on the planetary gear shafts interlock when installing. Make sure the bearing is fully seated on the diff housing. Apply grease in the groove and a light fi lm of grease on the shaft of all outdrives. Front/rear ...

Page 7

7 3 spur/diff gears hardware 7 7 4 diff oil hardware fill the diff until the planetary gear shafts are completely covered with diff oil. When using heavy oils, you need to allow the oil to settle and add oil if necessary. Do not overfi ll! (note: see set-up sheet for recommended diff oils.) finish t...

Page 8

8 5 center diff mounts hardware 8 8 6 mount the center diff hardware 3x8mm fh screw 4x14mm fh screw brake pad bolt large small 3x8mm fh 4x14mm fh 4x14mm fh (x2) (x4) (x4) front line up brake disc notch. 16.75mm 2 2 important! Important! The grooves for the diff bearings face inward. Make sure the br...

Page 9

9 9 7 brake actuator & fuel filter mount the angled side of the brake actuator faces the brake plate. Important! Important! Mount the fuel fi lter mount to the center upper brace before installing the center upper brace to the center diff mounts. Important! Important! Make sure the brake actuators m...

Page 10

10 8 rear diff joint hardware 10 10 9 rear diff housing hardware important! Important! Use the included shims to space gears properly in the diff case. Adjust the gear mesh for smooth rotation without excessive play. The number of shims needed, and the side on which they must be placed, may vary. Re...

Page 11

11 10 rear shock tower hardware 11 11 11 rear outdrives hardware make sure the bearings are fully seated in the hub. Secure the axle pin in the drive hub using the 5mm set screw. Place the o-ring in the groove after installing the wheel hub pin. Th re ad lo ck 4x14mm fh screw 3x14mm fh screw 3x14mm ...

Page 12

12 12 rear upper link hardware 12 12 13 wing mount hardware th re ad lo ck th re ad lo ck 3x10mm bh screw 3x25mm fh screw 3mm countersunk washer 4x20mm fh screw 4x20mm fh 4x20mm fh 3x25mm bh screw (x2) 3x6mm bh screw (x2) standard rod end ball (x4) 3mm washer (x2) 3x18mm sh screw (x2) 3mm lock nut (...

Page 13

13 14 rear swaybar hardware 13 13 15 rear swaybar links hardware make sure the swaybar links are set at equal distances from the end of the swaybar. Install the correct swaybar bushings onto the swaybar. The swaybar goes over the axles. 2.5x8mm sh screw 3x20mm bh 3x25mm sh 3x25mm sh 4x30mm bh (x4) 4...

Page 14

14 16 rear suspension hardware 14 14 17 rear chassis brace hardware th re ad loc k make sure the rear bumper is installed before installing these screws. Position the gasket between the gearbox and chassis. Make sure the tabs on the bottom of the gearbox key into the chassis. Install a 2mm dogbone s...

Page 15

15 18 front diff housing hardware 15 15 19 front suspension arms make sure the bearings are fully seated in the diff housing. Th re ad lo ck 4x14mm fh 5x5mm ss pinion shaft shim (x2) 8x16mm bearing (x2) 4x14mm fh screw (x2) 5x5mm set screw (x1) 5 hardware 5 4x16mm bh screw (x2) 4x40mm fh screw (x2) ...

Page 16

16 16 16 21 left & right front steering blocks hardware make sure the bearings are fully seated in the steering knuckles. Secure the axle pin in the drive hub using the 5mm set screw. Th re ad loc k 20 front shock tower hardware 4x14mm fh screw 3x14mm bh screw 3x14mm fh screw 3x25mm shcs 4x14mm fh 4...

Page 17

17 22 front suspension hardware 17 17 23 front upper links hardware 3x6mm bh 3x6mm bh screw (x2) outer lower front hinge pin (x2) 3x25mm bh screw (x2) 3x10mm fh screw (x6) standard rod end ball (x2) 3mm lock nut (x6) 5 make sure to use the correct part. Note the direction. 3x25mm bh 3x10mm fh 5 3x10...

Page 18

18 18 24 steering assembly thre adlo ck hardware standard rod end ball 3x16mm fh screw 6x10mm bearing shock end ball 3x14mm fh screw 3mm lock nut 4x8mm fh screw 3x16mm bh screw note the direction of the arms. Trim this edge if there is interference at full steering. 3x16mm fh 3x16mm bh 3x14mm fh 4x8...

Page 19

19 25 front chassis brace hardware 19 19 26 front end threadlock threadlock threadlock make sure the tabs on the bottom of the gearbox key into the chassis. 3x16mm bh 3x16mm bh 4x12mm fh 3x8mm fh 3x8mm fh screw (x2) standard rod end ball (x2) 3x16mm bh screw (x2) make sure the dogbone is placed unde...

Page 20

20 27 front swaybar install the correct swaybar bushings onto the swaybar. The swaybar goes over the axles. 5 hardware 2.5x8mm sh screw (x4) important! Important! There are three sizes of swaybars and swaybar bushings. Be sure to use the correct bushing with its corresponding swaybar. Front swaybar ...

Page 21

21 21 21 30 steering servo hardware 90° 3x6mm fh screw 3mm countersunk washer 3x16mm fh screw (x2) (x4) (x4) note orientation of the servo. (servo included with radio system.) included with radio system. Servo type spline adapter spacer airtronics ® /sanwa ...........23t ............. 2mm* futaba ® ...

Page 22

22 31 throttle servo hardware 22 22 32 on/off switch hardware 3mm countersunk washer 3x16mm fh screw 2x8mm sh screw (x4) (x4) (x4) 3x16mm fh servo type spline adapter spacer airtronics/sanwa ............23t ............. 3mm* futaba/duratrax .............25t ............. 3mm* hitec/hobbico ...........

Page 23

23 33 servo tray posts hardware 23 23 34 servo tray hardware 3x8mm fh screw 3x10mm fh screw 3x8mm fh screw 3x10mm fh screw 3x8mm fh 3x8mm fh 3x8mm fh 3x10mm fh 3x10mm fh 3x10mm fh (x2) (x4) (x2) (x2) thre adlo ck thre adlo ck thre adlo ck th re ad loc k 8 8.

Page 24

24 24 24 24 24 35 servo linkages hardware 3x14mm bh 3x14mm bh screw (x1) ball end (x1) 3mm lock nut (x1) 3x10mm bh screw (x1) 3x3mm set screw (x6) 3x16mm bh screw (x1) 8 37.5mm 2mm throttle linkage threadlock pivot a pivot b brake linkages thre adlo ck pivot a pivot b do not overtighten these screws...

Page 25

25 25 25 37 fuel tank hardware make sure the posts key into the chassis. Note the direction of the fuel tank. 3x18mm fh screw 3x14mm fh screw 3mm countersunk washer 3x14mm fh 3x18mm fh 3x18mm fh (x2) (x2) (x2) 36 receiver hardware 3x6mm bh screw (x1) secure the antenna tube to the radio box using a ...

Page 26

26 26 26 39 side guards hardware 3x10mm fh screw (x8) 9 38 tuned pipe mount hardware 4x4mm set screw 4x12mm fh screw (x1) (x1) depending on which pipe and header are used, you may need to cut the end of the pipe mount wire to fi t. 9 threadlock threadlock 4x12mm fh 3x10mm fh 3x10mm fh.

Page 27

27 40 engine mount hardware 4x12mm fh screw 4x10mm sh washer screw 4mm lock nut 4x12mm fh 4x10mm sh w asher 4x10mm sh w asher 4x12mm fh 4x12mm fh (x4) (x4) (x4) 27 27 41 flywheel thre adlo ck threadlock 9 10 make sure the collet is all the way on the engine’s crankshaft before installing the fl ywhe...

Page 28

28 28 28 43 header & pipe 42 clutch hardware 5x10mm bearing (x2) clutch shim (x4) 3mm sh screw with washer (x1) shim the clutch bell to allow minimal end play. The number of shims may vary. 10 header and pipe assembly header and pipe assembly sold separately! Sold separately!.

Page 29

29 44 engine installation hardware 3x14mm sh screw (x4) 29 29 45 throttle linkage snap the throttle linkage ball end onto the carb arm. Place a strip of paper between the spur and clutch bell to help properly set the gear mesh. Once the gear mesh is set, remove the paper. Threadlock 10 3x14mm sh.

Page 30

30 30 30 47 shock body assembly 46 shock shaft hardware note: the notch in the 3mm silver washer does not affect shock performance and can be positioned in any direction. Note: make sure the spacer fi ts freely with no resistance in the shock cartridge. If necessary, sand or trim spacer to fi t. Rea...

Page 31

31 48 shock oil hardware shock end ball (x4) 31 31 49 shock cap slide the shock shaft up until the piston is to the top of the shock oil. Do not push the shock piston all the way out of the shock oil. Slowly thread the shock cap onto the shock body, allowing the excess oil to come out of the bleed h...

Page 32

32 32 32 51 front shock installation hardware 3x20mm bh screw (x2) 3mm lock nut (x2) 3mm washer (x2) 50 shock boot and spring be careful not to tear the shock boots during installation. Install the shock boot over the shock end and secure it in place on the shock body. Gently work the shock end out ...

Page 33

33 33 33 53 fuel tubing install fuel tubing as shown, making sure it is not close to any moving parts or kinked. (fuel tubing not included.) 52 rear shock installation hardware 3x20mm bh screw (x2) 3mm lock nut (x2) 3mm lock nut (x2) 11 3x20mm bh.

Page 34

34 34 34 55 wing installation 54 air filter hardware secure the air fi lter to the carb with one of the included tie straps. 3x8mm bh screw (x1) 12 13 important! Important! Place the inner element into a small plastic bag and soak with air fi lter oil (not included). Work the oil into the element un...

Page 35

35 56 tire and wheel installation hardware wheel nut (x4) tires and inserts sold separately. 35 35 57 body 14 trim body as shown..

Page 36

Copyright © 2009 odoz1010 for odoc0125.