- DL manuals

- O.S. Engine

- Engine

- FL-70

- Owner's Instruction Manual

O.S. Engine FL-70 Owner's Instruction Manual

FL-70

FOUR CYCLE ENGINE

OWNER'S INSTRUCTION MANUAL

It is of vital importance, before attempting to

operate your engine, to read the general

•SAFETY INSTRUCTIONS AND WARNINGS'

section on pages 2-6 of this booklet and to strictly

adhere to the advice contained therein.

• Also, please study the entire contents of this

instruction manual, so as to familiarize yourself

with the controls and other features of the

engine.

• Keep these instructions in a safe place so that

you may readily refer to them whenever

necessary.

• It is suggested that any instructions supplied

with the aircraft, radio control equipment, etc.,

are accessible for checking at the same time.

Summary of FL-70

Page 1

Fl-70 four cycle engine owner's instruction manual it is of vital importance, before attempting to operate your engine, to read the general •safety instructions and warnings' section on pages 2-6 of this booklet and to strictly adhere to the advice contained therein. • also, please study the entire ...

Page 2

Contents safety instructions and warnings about your o.S. Engine - - - - - - - - - - - - - - - - 2-6 engine construction - - - - - - - - - - - - - - - - - - - - - - - - 7 notes when applying an electtric starter ---- 8 introduction - - - - - - - - - - - - - - - - - - - - - - - - - - 9 before startin...

Page 3: Warnings

Safety instructions and warnings aboutyour o.S. Engine remember that your engine is not a "toy", but a highly efficient internal- combustion machine whose power is capable of harming you, or others, if it is misused. As owner, you, alone, are responsible for the safe operation of your engine, so act...

Page 4

Warnings model engine fuel is also highly flammable. Keep it away from open flame, excessive heat, sources of sparks, or anything else which might ignite it. Do not smoke or allow anyone else to smoke, near to it. A weakened or loose propeller may disintegrate or be thrown off and, since propeller t...

Page 5: Notes

Notes this engine was designed for model aircraft. Do not attempt to use it for any other purpose. Mount the engine in your model securely, following the manufacturers' recommenda- tions, using appropriate screws and lock- nuts. Be sure to use the silencer (muffler) supplied with the engine. Frequen...

Page 6: Notes

Notes always check the tightness of the propeller nut and retighten it, if necessary, before restarting the engine, particularly in the case of four-stroke-cycle engines. If a safety locknut assembly is provided with your engine, always use it. This will prevent the propeller from flying off in the ...

Page 7: Notes

Notes adjust the throttle linkage so that the engine stops when the throttle stick and trim lever on the transmitter are fully retarded. Alternatively, the engine may be stopped by cutting off the fuel supply.Never try to stop the engine physically. Take care that loose clothing (ties, shirt sleeves...

Page 8

Engine construction with this engine, the piston will feel tight at the top of its stroke (tdc) when the engine is cold. This is normal. The cylinder bore is a little tapered. The piston and cylinder are designed to achieve a perfect running clearance when they reach their running temperatures. When...

Page 9

Notes when applying an electric starter do not over-prime. This could cause hydraulic lock and damage the engine on application of the electric starter. If over-primed, remove glowplug, close needle-valve and apply starter to pump out surplus fuel. Cover the head with waste to prevent pumped out fue...

Page 10

Introduction the fl-70 is an air-cooled, overhead- valve four stroke engine for model aircraft use. This engine is suitable for trainer, sport and scale models. This engine reduces maintenance by incorporating the first o.S. Ringless piston/liner assembly. Also, a sealed front bearing prevents oil l...

Page 11

Items necessary for starting glow plug o.S. Type f glowplug is installed in the engine. Glowplug igniter commercialy available handy glowplug heater in which the glowplug battery and battery leads are integrated. Fuel pump alternatively, one of the purpose-made manual or electric fuel pumps may be u...

Page 12

Reminder! Model engine fuel is poisonous.Do not allow it to come into contact with the eyes or mouth. Always store it in a clearly marked container and out of the reach of children. Model engine fuel is also highly flammable. Keep it away from open flame, excessive heat, sources of sparks, or anythi...

Page 13

Spinner since the fl-70is intended to be started with an electric starter, the addition of a spinner assembly for centering the starter sleeve is desirable. Use a heavy-duty, well balanced spinner either of metal or plastic. Silicone fuel line heatproof silicone tubing of approx. 5mm o.D. And 2.5mm ...

Page 14

• tools hex wrench necessary for engine installation. 1.5mm, 2mm, 2.5mm, 3mm opposite side long socket wrench with plug grip recommended for easy removal and replacement of the angled and recessed glowplug, the o.S.Long socket wrench incorporates a special grip. Plus threaded drivers no.1,no.2,etc. ...

Page 15: Engine Parts Name

Engine parts name rocker cover 14 f-4030 silencer assembly exhaust header pipe nipple no.1 (larger hole) nipple no.5 (smaller hole) lock nut propeller washer cover plate rotor guide screw throttle lever airbleed screw glow plug lock nut set drive hub beam mount crankcase carburetor type 60w silencer...

Page 16

Installation because the fl-70 is a powerful, large-displacement, single-cylinder four-stroke-cycle engine, it is essential to use very substantial engine mounting. Conventional wooden mounting beams should be of rigid hardwood and of at least 15mm or 5/8-in square section. Make sure that the mounti...

Page 17

How to fasten the mounting screws. 15mm min radial motor mount (cast aluminum) hardwood suchas cherry or maple. Steel washer 3mm steel screw 3mm steel allen screw spring washer • make sure that these mounting beams are accurately aligned and firmly integrated with the airframe, reinforcing the adjac...

Page 18

Silencer & exhaust header pipe installation screw the header pipe into the cylinder head until it "bottoms" , then unscrew sufficiently to achieve the desired exhaust angle and tighten the lock nut securely with a 14mm wrench. Screw the silencer onto the outer end of the header pipe and tighten the ...

Page 19: Fuel Tank & Lines

Fuel tank & lines make sure that the tank is well rinsed out with methanol or glow fuel before installation and that the pickup weight is well clear ofthe bottom of the tank when held vertically. Connect between pressure nipple on the silencer (larger hole one) and the tank to apply muffler pressuri...

Page 20

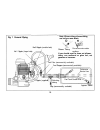

Fig. 1 general piping note: when cutting silicone tubing, use knife or razor blade. Plug (commercially available) no.5 nipple (smaller hole) silicone tubing do not use wire cutter or pliers. If you should need to clean out silicone tubes, use methanol or glow fuel, not gasoline or kerosene. No.1 nip...

Page 21

Fig. 2 piping suitable for acrobatic flights no.5 nipple (smaller hole) no.1 nipple (larger hole) install the fuel tank so that carburetor center line and fuel tank center line may come to as much close as possible. T nipple (supplied) fuel filter (commercially available) fuel stopper (commercially ...

Page 22

Throttle linkage before connecting the throttle to its servo, make sure that the throttle arm and linkage safely clear any adjacent part of the airframe structure, etc., as the throttle is opened and closed. Connect the linkage so that the throttle is fully closed when the transmitter throttle stick...

Page 23

Propeller & spinner attachment there is a risk, particularly with powerful four- stroke engines, of the propeller flying off if the prop nut loosens due to detonation ("knocking") in the combustion chamber when the engine is operated toolean, or under an excessively heavy load. Obviously, this can b...

Page 24

Note: some spinners which are fixed at the top of the cone cannot be used with the prop locknut supplied with the engine. In this case, optional locknut sets are available from o.S. - propeller locknut set for spinner (code no.45810200) and propeller locknut set for tru turn spinner (code no.1458103...

Page 25

Glowplug the fl-70 supplied with an o.S. Type f glowplug, specially designed for o.S. Four-stroke engines. The role of the glowplug with a glowplug engine, ignition is initiated by the application of a 1.5-volt power source. When the battery is disconnected, the heat retained within the combustion c...

Page 26: Type 60W Carburettor

Type 60w carburettor two adjustable controls are provided on this carburettor. They are as follows: the needle valve this is used to establish the fuel/air mixture strength required for full power when the throttle is fully open. The airbleed screw this is used to establish the mixture strength requ...

Page 27

Warning when checking the plug with energizing it, hold the plug with tools, such as pliers, etc. Do not bring your face close to the plug or the boiled fuel remaining in the filament will burn you. 3. Check that the current to the glowplug is switched off. 4. To close the needle-valve, turn it cloc...

Page 28: Note:

8. Make sure that the rotating direction of the electric starter is correct. Energize the glowplug and apply the starter. 9. When the engine starts, slowly open the throttle to the mid speed position. Then, disconnect current to the glowplug. If at this pint the engine stalls, it is probable that th...

Page 29

On the contrary, prolonged low speed running may cause the oil in the fuel gelled, which may result in seizure of the piston and cylinder liner. The recommended procedure is as follows: 1. Use the same fuel and prop as you intend for flying your model. 2. Open the needle-valve2.5 turns from the full...

Page 30

8. With each successive flight, close the needle-valve very slightly until, at the end of about 10 flights, the needle is set for full power. Do not "over-lean" the mixture in an attempt to extract more power. If overheating should be suspected at any time during flight (i.E.If the engine begins to ...

Page 31

20-30' open from maximum rp.M setting. The position where the lowest possible r p m .With steady running, is obtained. Set the throttle opening by means of the throttle trim on the transmitter so that the lowest practical speed, without risk of the engne stoppingis obtained. Start the engine make su...

Page 32: Pre-Flight Check

Carburetor air-bleed adjustment pre-flight check start engine and adjust needle- valve as previouslv described. Close the throttle gradually. Find the idling position. Hold the model. Approx 15 degrees hold model level, then slowly raise the nose. If rpm increases. If engine runs unevenly or stops. ...

Page 33

Trouble shooting when the engine fails to start four key points for quick, reliable starting, the following four conditions are required. (1.) good compression. (2.) adequate "glow"at glowplug. (3.) correct mixture. (4) sufficient electric starter rotating speed. If the engine fails to start, or doe...

Page 34

Symptom factor cause corrective action incorrect heating of . . . . . Voltage too high or too low. Re-check and readjust referring to "before glowplug. Starting". Over priming. . . • • • • • • continue applying an electric starter. Ii the engine does not start after more than 4 tries, disconnect the...

Page 35: Valve Adjusting

Valve adjusting valve clearances are correctly set before any o.S. Engine leaves the factory and, in normal use, will seldom require adjustment. However, if, after a very considerable amount of running time has been consumed, a loss of power is detected, or if he engine has been disassembled for rep...

Page 36

How to set the camshaft timing when replacing the camshaft, set the timing as follows. 1. Secure propeller. Note: if propeller is not secured, crankshaft may move backward and correct timing cannot be set. 2. Turn the crankshaft so that t mark on the drive hub may match crankcase center line. (this ...

Page 37

Care and maintenance please pay attention to the matters described below to ensure that your engine serves you well in regard to performance, reliability and long life. •as previously mentioned, it is vitally important to avoid operating the engine in conditions where dust, disturbed by the propelle...

Page 38

The use of nitromethane in the fuel can also contribute to the problem. As a primary defense, users are advised to avoid running the engine on too lean a mixture - i.E. Do not close the needle-valve and the airbleed screw too much. • do not leave unused fuel in the engine at the conclusion of a day'...

Page 39: Engine Exploded View

Engine exploded view *type of screw c cap screw b..Binding head screw m.. Oval fillister-head screw f...Flat head screw n. .Round head screw s...Set screw.

Page 40

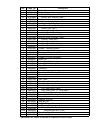

No. 1 2 2-1 2-2 3 3-1 3-2 4 4-1 4-2 4-3 4-4 5 5-1 5-2 5-3 5-4 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 23-1 23-2 24 25 26 27 28 29 29-1 29-2 29-3 code no 44404200 45961400 45961410 45761600 44753000 44753100 45761200 44460000 44460100 45960210 45060309 46160400 44461000 44461100 45960210 45...

Page 41

Carburetor exploded view * type of screw c cap screw b binding head screw m oval fillister-head screw f...Flat head screw n . Round head screw s .Set screw 40

Page 42

Carburettor parts list no. 1 1-1 2 3 4 5 5-1 5-2 6 6-1 6-2 6-3 7 code no. 22081408 22081313 44481200 44481100 45915000 22681980 24981837 26381501 44481960 26711305 45281920 22681953 44481310 description throttle lever assembly throttle lever retaining screw carburetor rotor carburetor body carbureto...

Page 43

O.S. Genuine parts & accessories o.S.Glow plug booster cable set (72200110) booster terminal kit (72200130) 0 needle valve extension cable set _ (72200080) propeller locknut set (45810100) (45810200 for spinner) propeller locknut set for tru-turn spinner 1/4"-m5 (45810300) flexible exhaust pipes exh...

Page 44

Non-bubble weight super filter (l) (72403050) long socket wrench with plug grip (71521000) valve adjusting tool lit (72200060) lock washer (10sets) m3 (55500002) blind nut (10pcs./sets) m3 (79870030) cap screw sets (10pcs./sets) m2.6x8 (79871025) m2.6x10(79871030) m3.5x12(79871080) m3.5x20(79871100)...

Page 45

44 11.45cc(0.698cu.In.) 27.7mm (1.090 in.) 19.0mm (0.748 in.) 2.300-12.000 r.P.M. 1.1ps/ 11.000 r.P.M. 467g (16.480z.) 51.5g(1.8oz.) displacement bore stroke practical r.P.M. Power output weight (silencerincluding exhaust header pipe) three view drawing dimension(mm) specification.

Page 46

6-15 3-chome imagawa higashisumiyoshi-ku osaka 546-0003. Japan tel. (06) 6702-0225 fax. (06) 6704-2722 url: http://www.Os-engines.Co.Jp (c) copyright 2004 by o.S.Engines mfg. Co.. Ltd. All rights reserved. Printed in japan. 60091500 050400