- DL manuals

- O.S. Engine

- Engine

- FS-40S-C

- Owner's Instruction Manual

O.S. Engine FS-40S-C Owner's Instruction Manual

It is of vital importance, before attempting to

operate your engine, to read the general

'SAFETY INSTRUCTIONS AND WARNINGS'

section on pages 2-5 of this booklet and to strictly

adhere to the advice contained therein.

●

Also, please study the entire contents of this

instruction manual, so as to familiarize yourself

with the controls and other features of the

engine.

Keep these instructions in a safe place so that

you may readily refer to them whenever

necessary.

It is suggested that any instructions supplied

with the vehicle, radio control equipment, etc.,

are accessible for checking at the same time.

●

●

Summary of FS-40S-C

Page 1

It is of vital importance, before attempting to operate your engine, to read the general 'safety instructions and warnings' section on pages 2-5 of this booklet and to strictly adhere to the advice contained therein. ● also, please study the entire contents of this instruction manual, so as to famil...

Page 2: Contents

Safety instructions and warnings about your o.S. Engine introduction, basic engine parts installation of the carburetor engine installation super air cleaner type 102s notes concerning the recoil starter glowplug tools, accessories, etc. Pressurized fuel system starting, running and adjustment if th...

Page 3: Warnings

Remember that your engine is not a "toy", but a highly efficient internal- combustion machine whose power is capable of harming you, or others, if it is misused. As owner, you, alone, are responsible for the safe operation of your engine, so act with discretion and care at all times. If at some futu...

Page 4: Warnings

Warnings model engine fuel is poisonous. Do not allow it to come into contact with the eyes or mouth. Always store it in a clearly marked container and out of the reach of children. Model engine fuel is also highly flammable. Keep it away from open flame, excessive heat, sources of sparks, or anythi...

Page 5: Notes

This engine is intended for model cars. Do not attempt to use it for any other purpose. Mount the engine in your model securely, following the manufacturers' recommendations, using appropriate screws and locknuts. Fit an effective silencer (muffler). Frequent close exposure to a noisy exhaust (espec...

Page 6: Notes

Notes to stop the engine, fully retard the throttle stick and trim lever on the trans-mitter, or, in an emergency, cut off the fuel supply by pinching the fuel delivery tube from the tank. • warning! Immediately after a glowplug- ignition engine has been run and is still warm, conditions sometimes e...

Page 7: Introduction

These are overhead-valve four-stroke- cycle engines designed for 1/8 scale radio-controlled model cars. The engine is distinguished by a black- anodized crankcase and rocker-cover and is supplied complete with an o.S. Super air cleaner as standard. The fs-40s-cx is equipped with a built in recoil st...

Page 8: Engine Installation

Engine installation make sure that the vehicle's engine mounting surfaces are level and in the same plane. Poor installation may cause distortion of the crankcase, bearings, etc., resulting in erratic running and loss of performance. The recommended screws for securing the engine are 3.5mm or 4-40 s...

Page 9: Air Cleaner Type 102S

Air cleaner type 102s installation of air cleaner carefully clean the carburettor, removing any old adhesive or sealant that may have been previously used on the outside of the air intake. • press the air cleaner body firmly over the carburettor air intake. Make sure that the outer rim of the air in...

Page 10: •

◆ notes concerning the recoil starter ( fs-40s-cx only) reminder! ◆ ◆ do not attempt to disassemble the recoil starter. If you do so, the very strong spring inside will be suddenly ejected. This can be very dangerous. Do not extend the starter cord more than 40cm(16"). Do not abruptly release the op...

Page 11: Glowplug

Glowplug the role of the glowplug glowplug life particularly in the case of very high performance engines, glowplugs must be regarded as expendable items. With a glowplug engine, ignition is initiated by the application of a 1.5-volt power source. When the battery is disconnected, the heat retained ...

Page 12: Tools, Accessories, Etc.

Tools, accessories, etc. The following items are necessary for operating the engine. Fuel use only top quality methanol-based model engine fuel.For consistent performance and long engine life, it is advisable to use fuel containing at least 18% lubricant. This engine is designed to run on both low a...

Page 13

Long socket wrench recommended for easy removal and replacement of the angled and recessed glowplug, the o.S.Long socket wrench incorporates a special grip. Silicone fuel line heatproof silicone tubing of approx. 5mm o.D. And 2mm i.D. Is required for the connection between the fuel tank and engine. ...

Page 14: Pressurized Fuel System

In the interests of a long working life and high performance, every internal-combustion engine needs to be "run-in" (or "broken-in" as the procedure is also known). This means giving the engine extra care and attention during the first hour or so of its operational life. New parts need to become "be...

Page 15

2mm turn the needle-valve gently clockwise until it stops. Do not use force to turn the needle beyond this point. Now reopen it 1 3/4 turns. Set the throttle-stop screw so that the minimum throttle opening (idle setting) is approximately 2mm. Switch on the transmitter, followed by the receiver. Clos...

Page 16

It is vitally important to set the throttle at the correct position before attempting to start the engine. If the engine is allowed to run with the throttle too far open under "no load" conditions, it will rapidly overheat and may be seriously damaged. Remember! Now, refuel and re-start the engine, ...

Page 17

30 ° 10 ° ~ 20 ° 30 ° 30 ° needle slot the position of the needle-valve when starting the engine. Close the needle-valve approx. 30 ° after running the vehicle for one full tank of fuel. Repeat this procedure several times. Optimum needle-valve position (10 ° to 20 ° opened from the position where h...

Page 18: Valve Adjusting

Note: valve clearances of all o.S. Four-stroke- cycle engines must be checked and reset only when the engine is cold. Procedure is as follows. • feeler gauge 0.04mm all o.S. Four-stroke engines have their valve(tappet) clearances correctly set before they leave the factory. However, if, after many h...

Page 19

Note: if the gap is found to be less than 0.04mm, it is not necessary to readjust the clearance if the engine has good compression and starts easily. Equally, if the gap exceeds 0.10mm but is not more than 0.14mm (i.E. The thickness of both feeler gauges inserted together), it is not essential to re...

Page 20

Re-tighten locknut while holding adjusting screw stationary. (fig.5.) 4. Hold at the screw head. Fig.5 tighten locknut. Remove 0.04mm feeler, rotate the crankshaft through two revolutions and recheck gap. 5. If clearance is correct, slacken locknut on the other rocker-arm and repeat steps 1 to 5 abo...

Page 21: Parts Replacement

When cleaning the exterior of the engine, use methanol or kerosene. Do not use gasoline or any solvent that might damage the silicone fuel tubing. ● parts replacement over a long period, depending on how well your engine has been protected from the ingress of dust and grit and other causes of wear a...

Page 22: Racing Engine Parts

(72103310) (71521000) racing engine parts (72200060) (45226200) (72403120) (71615009) (72403202) for fs-40s-c/cx (73300305) (73301012) (72403212) genuine parts & accessories ■ ■ ■ super joint tube 15 long socket wrench with plug grip valve adjusting tool kit o.S.Glow plug type f ■ ■ super air cleane...

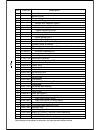

Page 23: Fs-40S-C Exploded View

I u y t r e w q = - 0 9 8 4 3 2 1 o p [ ] \ a s d 5 -3 5 -2 5 -1 4 -2 4 -1 3 -2 3 -1 5 7 f 5 -4 6 (c.M3x12) c.M3x18 c.M2.6x12 c.M2.6x8 c.M3x8 c.M2.6x7 8 -1 [ s -1 s -2 s -2 g m3.5 c … cap screw b … binding head screw m … oval fillister-head screw f … flat head screw n … round head screw s … set scre...

Page 24

Specifications are subject to alteration for improvement without notice. Description code no. Screw set rocker cover rocker support assembly rocker support rocker arm retainer (2pcs.) rocker arm assembly (1pair) rocker arm (1pc.) tappet adjusting screw valve assembly (1pair) valve (1pc.) valve sprin...

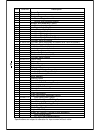

Page 25: Fs-40S-Cx Exploded View

I u y t r e w q = - 0 9 8 4 3 2 1 o p [ ] \ a s d 5 -3 5 -2 5 -1 4 -2 4 -1 3 -2 3 -1 5 7 f 5 -4 6 (c.M3x12) c.M3x18 c.M2.6x12 c.M2.6x8 m.M2.6x7 c.M2.6x7 8 -1 f -2 g m3.5 c.M3x8 u -1 u -2 \ f -1 f -2 h j c … cap screw b … binding head screw m … oval fillister-head screw f … flat head screw n … round ...

Page 26

Specifications are subject to alteration for improvement without notice. I description code no. Screw set rocker cover rocker support assembly rocker support rocker arm retainer (2pcs.) rocker arm assembly (1pair) rocker arm (1pc.) tappet adjusting screw valve assembly (1pair) valve (1pc.) valve spr...

Page 27

C … cap screw m … oval fillister-head screw f … flat head screw n … round head screw s … set screw carburettor exploded view & parts list specifications are subject to alteration for improvement without notice. 5 4 3 2 1 7 6 6 -1 6 -2 description code no. Throttle lever assembly carburetor dust cove...

Page 28: Fs-40S-C Three View Drawing

Fs-40s-c three view drawing 6.49cc (0.396cu.In.) 21.2mm (0.835in.) 18.4mm (0.724in.) 3,000 ~ 21,000r.P.M. 0.9bhp/17,500r.P.M. 323.5g (11.41oz.) dimension(mm) specification displacement bore stroke practical r.P.M. Power output weight 80.5 16.5 unf1/4-28 50 17.5 42 20.5 49 27.

Page 29: Fs-40S-Cx Three View Drawing

Fs-40s-cx three view drawing dimension(mm) displacement bore stroke practical r.P.M. Power output weight specification 17.5 38.9 42 49 50 unf1/4-28 20 20 80.5 6.49cc (0.396cu.In.) 21.2mm (0.835in.) 18.4mm (0.724in.) 3,000 ~ 21,000r.P.M. 0.9bhp/17,500r.P.M. 407g (14.35oz.) 28.

Page 30

C copyright 2000 by o.S.Engines mfg. Co., ltd. All rights reserved. Printed in japan. 040101 tel. (06) 6702-0225 fax. (06) 6704-2722 6-15 3-chome imagawa higashisumiyoshi-ku osaka 546-0003, japan u n eq ua ll ed qua lity precision & per for m an ce es ta blis hing the standards of e xce ll en ce.