O.S. Engine GT55 Owner's Instruction Manual

GT55

入力電圧

消費電流

出力電圧

Inpu

t volt

age

Con

sum

ption

cur

rent

Outp

ut vo

ltage

DC

4.8V

-7.6

V

600

mA/6

000

rpm

/4.8

V

20K

V/60

00rp

m/4

.8V

It is of vital importance, before attempting to

operate your engine, to read the general

'SAFETY INSTRUCTIONS AND WARNINGS'

section on pages 2-5 of this booklet and to

strictly adhere to the advice contained therein.

Also, please study the entire contents of this

instruction manual, so as to familiarize

yourself with the controls and other features of

the engine.

Keep these instructions in a safe place so that

you may readily refer to them whenever

necessary.

It is suggested that any instructions supplied

with the aircraft, radio control equipment, etc.,

are accessible for checking at the same time.

Two stroke gasoline engine for airplanes

1

SAFETY INSTRUCTIONS AND

WARNINGS ABOUT YOUR O.S. ENGINE

ABOUT THE ENGINE

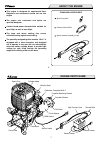

ENGINE PARTS NAME

SILENCER / INSTALLATION

FUEL TANK & LINES

CARBURETOR WLA-2 PARTS NAME

CARBURETOR LINKAGE

IGNITION MODULE

PROPELLER

MIXING OF OIL

CONTENTS

RUNNING-IN / STARTING

NEEDLE ADJUSTMENTS

FLIGHT & MAINTENANCE

ENGINE EXPLODED VIEW

ENGINE PARTS LIST

CARBURETOR EXPLODED VIEW

CARBURETOR PARTS LIST

O.S. GENUINE PARTS & ACCESSORIES

ENGINE THREE VIEW DRAWINGS

2-5

6

7

8

9

10

11-12

13-14

15-16

17

18-23

24-25

26-27

28

29

30

31

32-33

34