It is of vital importance, before attempting to operate your engine, to read the general 'safety instructions and warnings' section on pages 2-6 of this booklet and to strictly adhere to the advice contained therein. Also, please study the entire contents of this instruction manual, so as to familia...

2 remember that your engine is not a "toy", but a highly efficient internal- combustion machine whose power is capable of harming you, or others, if it is misused. As owner, you, alone, are responsible for the safe operation of your engine, so act with discretion and care at all times. If at some fu...

4 notes this engine was designed for model aircraft. Do not attempt to use it for any other purpose. Mount the engine in your model securely, following the manufacturers' recommenda- tions, using appropriate screws and lock- nuts. Be sure to use the silencer (muffler) supplied with the engine. Frequ...

6 notes adjust the throttle linkage so that the engine stops when the throttle stick and trim lever on the transmitter are fully retarded. Alternatively, the engine may be stopped by cutting off the fuel supply. Never try to stop the engine physically. Take care that loose clothing (ties, shirt slee...

8 notes when applying an electric starter do not over-prime. This could cause a hydraulic lock and damage the engine on application of the electric starter. If over-primed, remove glowplug, close needle-valve and apply starter to pump out surplus fuel. Cover the head with a rag to prevent pumped out...

10 it is suggested to use as heavy and rigid as possible engine mounting for highest performance and safe running. Conventional wooden mounting beams should be of rigid hardwood and of at least 12mm or 5/8-in square section. Use at least 3mm steel screws, such as allen type, with locknuts, for bolti...

12 the angled exhaust of the silencer can be rotated to any desired position in the following manner: 1) loosen the locknut and assembly screw. 2) set the exhaust outlet at the required position by rotating the rear part of the silencer. 3) re-tighten the assembly screw, followed by the locknut. The...

14 8mm s fuel can filter fit a filter to the outlet tube of your refuelling container to prevent entry of foreign matter into the fuel tank. (refer to of starting the engine section.) 3 battery leads these are used to conduct current from the battery to the glowplug. Basically, two leads, with clips...

16 fuel use a good quality commercial fuel or one of the blends shown in the table. Fuel "a" is suitable for running-in and ordinary use. Fuel "b" is for use when more power is required and for improved flexibility. Note that even a small quantity of nitromethane (3-5%) will improve flexibility, mak...

18 ! Starting the engine be sure to use an electric starter to start the engine. Never fail to check the tightness of screws and nuts, especially engine mounting and moving parts (e.G. Throttle lever). Preparations 1 installing the glowplug install washer on the glowplug and insert carefully into cy...

20 close open needle-valve open the needle-valve 4 turns (for 10la), 3 turns (for 15la), 1 turns (for 25la) in the direction of arrow from the closed position. 2 1 fully closed position fully opened position throttle close open 4 opening and closing of the needle-valve 5 setting the needle-valve tur...

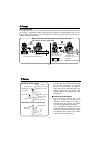

22 1 / 3 2 / 3 9 hold model securely when starting 10 setting the throttle starter assistant should hold the model so that it cannot move forward when the engine starts. Be careful not to be hit by propeller! Fully opened position fully closed position set at this position. Assistant glowplug batter...

24 beware of the rotating propeller. 13 engine starts if the engine does not start, refer to the trouble shooting chart on page 32- 33. In the interests of safety, keep your face and other parts of the body away from the vicinity of the propeller. Listen to the sound carefully. 14 needle-valve adjus...

26 17 needle-valve adjustment (summary) practical best (optimum) needle-valve setting exhaust note starts to change. Disconnect battery leads from glowplug at about this point. Clear, high-pitched two-stroke exhaust note maximum rpm setting("lean"). "rich" needle-valve setting when starting the engi...

28 note: when re-starting the engine on the same day, provided that atmospheric conditions have not changed significantly, it may be practicable to re-start the engine on its optimum (running) setting. Also, if the engine is being re-started immediately after a run (i.E.Hot), priming should not be n...

30 start the engine. Make sure that the throttle is fully open. Adjust the neede-valve. Close the throttle gradually. Find the idling position. Fix the idling position. Open the throttle fully. Does the engine regain full power? Continue running at high speed for 10 seconds. Close the throttle. Run ...

33 symptom factor cause corrective action 2 3 1 2 3 3 3 3 2 voltage too high or too low. Re-check and readjust referring to "before starting". Continue flipping propeller. If engine does not start after more than 10 flips, disconnect battery from glowplug and leave for a few minutes, then re- energi...

34 care and maintenance please pay attention to the matters described below to ensure that your engine serves you well in regard to performance, reliability and long life. As previously mentioned, it is vitally important to avoid operating the engine in conditions where dust, disturbed by the propel...

36 m.+m2.6x7 s.M3x3 m.+m2.6x10 1 2 3 4 5 6 7 8 9 12 13 10 11 11- 1 11- 2 10la engine exploded view type of screw c...Cap screw m...Oval fillister-head screw f...Flat head screw n...Round head screw s...Set screw 37 10la enginen pa r ts list the specifications are subject to alteration for improvemen...

38 1 2 3 4 5 6 7 8 9 10 11 12 12- 1 12- 2 12- 3 12- 4 12- 5 13 14 b.+m2.6x8 s.M3x3 m.+m2.6x10 15la engine exploded view type of screw c...Cap screw m...Oval fillister-head screw f...Flat head screw n...Round head screw s...Set screw 39 15la enginen pa r ts list the specifications are subject to alte...

40 n.+m3x12 n.+m3.5x5 b.+m2.6x8 s.M3x3 1 2 13 3 4 5 6 7 8 9 10 11 12 14 12-1 12-2 12-3 12-4 12-5 25la engine exploded view type of screw c...Cap screw m...Oval fillister-head screw f...Flat head screw n...Round head screw s...Set screw 41 25la enginen pa r ts list the specifications are subject to a...

42 n.+m2.6x6 n.+m3x4 1 1-1 2 4 3 5 1 1-1 2 3 4 5 21081400 24081300 21081200 21081100 21081300 27881120 10h carburetor exploded view & parts list type of screw c...Cap screw m...Oval fillister-head screw f...Flat head screw n...Round head screw s...Set screw throttle lever assembly throttle lever fix...

44 1 1-1 2 3 4 5 6 7 22081408 22081313 22381200 24081600 22581100 22581300 22615000 23081706 n.+m3x6 n.+m2.6x15 n.+m3.5x5 n.+m2.6x7 1 1-1 2 3 4 5 6 7 20h carburetor exploded view & parts list type of screw c...Cap screw m...Oval fillister-head screw f...Flat head screw n...Round head screw s...Set s...

46 (71521000) (72403050) (79870030) (55500002) (71531000) (71531010) non-bubble weight super filter (l) long socket wrench with plug grip lock washer (10sets) blind nuts (10pcs. /sets) m3 m3 non-bubble weight s the specifications are subject to alteration for improvement without notice. 23 38.6 11.7...

48 unf1/4-28 (m5) 39 (30.8) 14 (14.4) 46.5 (39.5) 36 (33) 32 (27.5) 30.5 (25.8) 60 (48.5) 74.5 (61) 22 (20) 29 (24.8) 44 (40) 67.5 (56.5) 4- 3.3 max-15la/25la three view drawing displacement bore stroke practical r.P.M. Power output weight 4.07 cc (0.249 cu.In.) 18.0mm (0.709 in.) 16.0mm (0.630 in.)...