- DL manuals

- O.S. Engine

- Engine

- MAX-46FX-Hring Series

- Owner's Instruction Manual

O.S. Engine MAX-46FX-Hring Series Owner's Instruction Manual

It is of vital importance, before attempting to

operate your engine, to read the general

'SAFETY INSTRUCTIONS AND WARNINGS'

section on pages 2-5 of this booklet and to strictly

adhere to the advice contained therein.

●

Also, please study the entire contents of this

instruction manual, so as to familiarize yourself

with the controls and other features of the

engine.

Keep these instructions in a safe place so that

you may readily refer to them whenever

necessary.

It is suggested that any instructions supplied

with the model, radio control equipment, etc.,

are accessible for checking at the same time.

●

●

Summary of MAX-46FX-Hring Series

Page 1

It is of vital importance, before attempting to operate your engine, to read the general 'safety instructions and warnings' section on pages 2-5 of this booklet and to strictly adhere to the advice contained therein. ● also, please study the entire contents of this instruction manual, so as to famil...

Page 2: Contents

Contents safety instructions and warnings about your o.S. Engine introduction, basic engine parts installation installation of cooling fan, before starting facts about glow plugs, fuel carburetor controls starting running-in adjustment subsequent readjustments carburettor cleanliness adjusting chart...

Page 3: Warnings

Remember that your engine is not a "toy", but a highly efficient internal- combustion machine whose power is capable of harming you, or others, if it is misused. As owner, you, alone, are responsible for the safe operation of your engine, so act with discretion and care at all times. If at some futu...

Page 4: Warnings

Warnings • • • • • never touch, or allow any object to come into contact with, the rotating parts. Model engine fuel is poison- ous. Do not allow it to come into contact with the eyes or mouth. Always store it in a clearly marked container and out of the reach of children. Model engine fuel is also ...

Page 5: Notes

Notes • • • • • these engine were designed for model helicopters. Do not attempt to use it for any other purpose. Mount the engine in your model securely, fol- lowing the manufacturers' recommendations, using appropriate screws and locknuts. Install an effective silencer (muffler). Frequent close ex...

Page 6: Notes

Notes • • • take care that loose clothing (ties, shirt sleeves, scarves etc.) do not come into contact with the rotor. Do not carry loose objects (such as pen- cils, screwdrivers, etc.) in a shirt pocket from where they could fall through the rotor disc. For their safety, keep all onlookers (especia...

Page 7: Introduction

Because of initial tightness, a standard electric starter may have difficulty in rotating the engine when cold, before it has been adequately run-in. In this case, use a high-torque type starter. Do not, however, confuse tightness with the symptoms of hydraulic lock caused by an excess of fuel withi...

Page 8: Installation of The Engine

Installing the glowplug install the washer on the glowplug and screw carefully into cylinder- head, making sure that it is not cross-threaded before tightening firmly. Glow plug washer installation of the engine the under-surfaces of all o.S. Engine beam mounting lugs are precision machined flat and...

Page 9: Before Starting

Before starting tools, accessories, etc. The following items are necessary for operating the engine. 1 fuel model glowplug engine fuel of good quality, preferably containing a small percentage of nitromethane. Installation of cooling fan as supplied the max-46fx-h is equipped with a conventional dri...

Page 10

Resistance coil (nichrome wire) adjust applied voltage by changing the position of clip on resistance coil until glowplug element is glowing bright red. Battery leads raise voltage to increase brightness. Lower voltage to reduce brightness. Warning (very hot) never touch the nichrome wire while the ...

Page 11: Facts About Glowplugs

Facts about glowplugs the role of the glowplug glowplug life particularly in the case of very high performance engines, glowplugs must be regarded as expendable with a glowplug engine, ignition is initiated by the application of a 1.5-volt power source. When the battery is disconnected, the heat ret...

Page 12: Fuel

Install a plug suitable for the engine. Use fuel containing a moderate percentage of nitromethane. Do not run the engine too lean and do not leave the battery connected while adjusting the needle. However, plug life can be extended and engine performance maintained by careful use, i.E.: apart from w...

Page 13: Carburetor Controls

Carburetor controls with a fixed-wing model, power failure is rarely a serious threat to the safety of the aircraft since it can usually glide down to a safe landing. In a helicopter, on the other hand, it is vitally imporant that the engine keeps running and that there is a quick and reliable respo...

Page 14: Starting

Starting close open be sure to use a muffler pressurized fuel feed. Use the same fuel as you intend to employ for actual operation of your model. 1. 2. 3. Opening and closing of the needle-valve turn the needle clockwise to close the needle-valve, and turn the needle counter-clockwise to open the ne...

Page 15: Running-In ("breaking-In")

In case the engine does not stop. Hold the rotor head, and pinch the silicone tube to stop the fuel supply. If it still does not stop, pull off the fuel tubing from the carburetor. It is necessary to readjust the throttle linkage so that the carburetor rotor is fully closed when the throttle stick a...

Page 16: Adjustment

A adjustment the following adjustments are approximately correct when using a fuel containing 25% lubricant and 10- 30% nitromethane. Bear in mind that fuels containing relatively large percentages of power-boosting nitromethane operate at richer mixture settings than are needed for mild fuels and w...

Page 17

Lf, at this time, the engine is slow to pick up and produces an excess of exhaust smoke, the mixture is too rich. Correct this condition by turning the mixture control screw clockwise. Lf the mixture is extremely rich, engine rpm will become unstable : opening the throttle will produce a great deal ...

Page 18

Exhaust unduly smoky and the model fails to reach expected straight line speed, the mixture is too rich and the needle valve setting will need to be reduced. Lf, however, after smoothly acceierating to satisfactory high-speed straight and level flight, power is lost when the model is puiled up into ...

Page 19: Subsequent Readjustments

Subsequent readjustments once the engine has been run-in and the carburetor controls properly set up, it should be unnecessary to alter the mixture settings, except to make minor adjustments to the needle valve occasionally, to take account of variations in climatic condisitions. The use of a differ...

Page 20: Adjusting Chart

Adjusting chart open the needle valve 2 turns from the fully closed position. Make sure that the mixture control valve is at the factory setting. A start the engine warm up the engine b c observe the mixture condition while "floating" the model turn the mixture control screw counter-clockwise idling...

Page 21

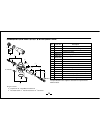

Installation of throttle servo after fitting the engine in the helicopter, please observe the following recommendations when linking the throttle servo to the carburetor. Locate the servo so that its output arm and the throttle pushrod are, as closely as possible, directry in line with carburettor's...

Page 22: Care and Maintenance

Care and maintenance the minute particles of foreign matter, that are present in any fuel may, by accumulating and partially obstructing fuel flow, cause engine performance to become erratic and unreliable. O.S. 'super-filters' (large and small)are available, as optional extras, to deal with this pr...

Page 23: Max

Type of screw c … cap screw m … oval fillister-head screw f … flat head screw n … round head screw s … set screw ✽ max -46fx-h ring exploded view y t r e w q = - 0 9 8 7 6 5 4 3 2 1 c.M3x12 c.M3x8 n.+m3.5x6 22.

Page 24: Engine Parts List

The specifications are subject to alteration for improvement without notice. Engine parts list screw set cover plate gasket set crankshaft crankshaft ball bearing(rear) crankcase crankshaft ball bearing(front) thrust washer propeller nut carburetor complete 40c connecting rod piston pin cylinder lin...

Page 25: Max

Type of screw c … cap screw m … oval fillister-head screw f … flat head screw n … round head screw s … set screw ✽ max -46fx-h ring (g) / hg (l/s) ring exploded view y t r e w q = - 0 -a 9 8 7 6 5 4 3 2 1 c.M3x12 c.M3x8 n.+m3.5x6 e -a 0 24.

Page 26: Engine Parts List

The specifications are subject to alteration for improvement without notice. Engine parts list screw set cover plate gasket set crankshaft(h ring (g)) crankshaft ball bearing(rear) crankcase crankshaft ball bearing(front) thrust washer propeller nut carburetor complete 40c connecting rod piston pin ...

Page 27

No. 22781410 22781420 25683200 25683100 24881824 26781506 45581820 22681953 27881900 24981959 24981837 26381501 27381940 26711305 46215000 25081700 2 1 -1 1 s.M3x3 n.+m3.5x6 9 8 7 6 5 4 3 3 -1 7 -1 7 -2 7 -3 7 -4 7 -5 carburetoer parts list & exploded view type of screw c … cap screw m … oval fillis...

Page 28: 46Fx-H

7.45 cc (0.455 cu.In.) 22.0mm (0.866 in.) 19.6mm (0.772 in.) 2,000 ~ 17,000 r.P.M. 1.62 bhp / 16,000 r.P.M. 385g(13.6oz.) ■ ■ ■ ■ ■ ■ made in japan 35 51 60.5 unf1/4-28 19.5 70 88 7.5 36.3 18.5 18.5 27 37 2- φ 3.2 44 17.5 4- φ 3.7 max- 46fx-h ring three view drawing dimensions(mm) displacement bore ...

Page 29

(71608001) (71521000) (l) no.8 (71605100) a 5 (72403050) (25608100) m3 (55500002) (71530400) (71531000) (25425000) (25425500) (25425600) o.S. Genuine parts & accessories ■ o.S. Glow plugs ■ super filter ■ lock washer (10set) ■ long socket wrench with plug grip ■ taper collet ■ 873 silencer ■ silence...

Page 30

C copyright 2001 by o.S.Engines mfg. Co., ltd. All rights reserved. Printed in japan. Un eq ua lle d qu ality precision & perfo rma nc e est ablish ing the standards of ex cel len ce 080101 tel. (06) 6702-0225 fax. (06) 6704-2722 6-15 3-chome imagawa higashisumiyoshi-ku osaka 546-0003, japan url : h...