It is of vital importance, before attempting to operate your engine, to read the general 'safety instructions and warnings' section on pages 2-5 of this booklet and to strictly adhere to the advice contained therein. Also, please study the entire contents of this instruction manual, so as to familia...

! ! 2 remember that your engine is not a "toy", but a highly efficient internal- combustion machine whose power is capable of harming you, or others, if it is misused. As owner, you, alone, are responsible for the safe operation of your engine, so act with discretion and care at all times. If at som...

! 4 notes • • • • • this engine was designed for model helicopters. Do not attempt to use it for any other purpose. Mount the engine in your model securely, fol- lowing the manufacturers' recommendations, using appropriate screws and locknuts. Install an effective silencer (muffler). Frequent close ...

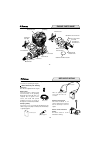

6 notes on installing cooling fan and clutch do not use a tool which locks piston when installing a cooling-fan and clutch, or top of the piston may be damaged. Also, do not insert a screw driver or the similar into the exhaust port. It is recommended to use crankshaft clamp 3246 (code no.71530400) ...

8 notes when applying an electric starter because of this initial tightness, a standard electric starter may have difficulty in rotating the engine when cold, before it has been adequately run-in. In this case, use a high-torque type starter. Do not over-prime. This could cause a hydraulic lock and ...

10 note on heating the glow plug the heatsink head on the engine is treated with an anodized finish which does not conduct current. Therefore, when heating a glow plug, connect one lead to the glow plug and the other to the cover plate retaining screw. Example 11 introduction as delivered, the engin...

12 heatsink head carburetor type 40l crankshaft propeller nut crankcase glowplug beam mount cover plate high speed needle valve fuel inlet mixture control valve throttle lever idle mixture control screw mixture control valve stopper thrust washer carburetor rubber gasket medium speed needle valve en...

14 select, by practical tests, the most suitable fuel from among the best quality fuels available in your country for helicopter use. For the best throttle response, a fuel containing 10% to 30% nitromethane is preferable. Lubricants may be either castor-oil or a suitable synthetic oil (or a blend o...

16 the under-surfaces of all o.S. Engine beam mounting lugs are precision machined flat and exactyly parallel to the engine's horizontal axis. It is essential that the engine mounts in the model are also accurately made and aligned. If they are not, they will cause stress and distortion within the e...

18 glowplug the role of the glowplug glowplug life particularly in the case of very high performance engines, glowplugs must be regarded as expendable items. However, plug life can be extended and engine performance maintained by careful use, i.E.: install a plug suitable for the engine. Use fuel co...

20 basic position of mixture control screw (mixture control valve) rich mixture control valve mixture control screw lean as delivered, the mixture control screw is positioned at approximately the center as shown in the sketch. Mixture gets lean when the mixture control screw is turned right, while m...

22 open 1. 2. Opening and closing of the needle-valve turn the needle clockwise to close the needle- valve, and turn the needle counter-clockwise to open the needle-valve as shown in the sketch. High speed needle-valve: exactly two turns open from the fully closed position.( note: if a different muf...

24 in case the engine does not stop. Hold the rotor head, and pinch the fuel line to stop the fuel supply. If it still does not stop, pull off the fuel line from the carburetor. It is necessary to readjust the throttle linkage so that the carburetor rotor is fully closed when the throttle stick and ...

26 please observe the following before beginning to make any adjustment. High-speed needle valve. Turn this approximately 30 degrees (3 to 4 clicks) at a time, when making initial adjustments; then in steps of approximately 15 degrees (1 to 2 clicks) when making final adjustments. Medium-speed needl...

28 having provisionally set the idle mixture, the next step is to adjust the mixture for hovering flight. Hover the model and actuate the throttle to observe response over the medium speed range. Lf the engine smokes excessiveiy and throttle response is poor, the mixture is too rich ; in which case,...

30 carburetor cleanliness the correct functioning of the carburetor depends on its small fuel orifices remaining clear. The minute particles of foreign matter that are present in any fuel can easily partially obstruct these orifices and upset mixture strength so that engine performance becomes errat...

32 care and maintenance please pay attention to the matters described below to ensure that your engine serves you well in regard to performance, reliability and long life. As previously mentioned, it is vitally important to avoid operating the engine in conditions where dust, disturbed by the propel...

34 trouble shooting symptom cause corrective action engine fails to fire. Fuel tank is empty. Fuel not reaching the engine. Fill the tank with fuel and repeat. Priming procedure. Glowplug element is burnt out. Glowplug battery discharged replace glowplug. Recharge or replace the battery. Clogged fue...

36 symptom cause corrective action symptom cause corrective action unstable idle unsuitable glowplug use suggested glowplug in the instructions. Unsuitable fuel do not use extremely high nitro or low oil fuel. Silencer is disconnected or is loose install silencer securely. Not reaching expected peak...

38 c.M3x15 1 2 3 4 5 6 7 8 9 10 11 12 14 15 16 c.M3x8 17 18 13 12- 1 c.M2.6x18 1- 1 engine exploded view type of screw c … cap screw * 79871055 m2.6x18 cap screw sets (10pcs ./sets ) code no . Si ze pcs . Used in an engine retainer screw (1pc.) 39 the specifications are subject to alteration for imp...

40 2 3 4-1 4-2 4-3 4 5 6 7 8 9-1 9-2 9-3 9-4 9 11-1 11-2 11-3 11-4 10 3-1 12 c.M3x8 1 1-1 c.M2.6x7 11 carburetor exploded view type of screw c...Cap screw 41 1 1-1 2 3 3-1 4 4-1 4-2 4-3 5 6 7 8 9 9-1 9-2 9-3 9-4 29085140 22826131 25881200 25881220 79871020 29085510 27881810 27881800 27881820 4558182...

42 (72144000) (71531000) (71531010) (72403050) (55500002) (71521000) (l) m3 long socket wrench with plug grip super filter lock washer (10set) o.S. Genuine parts & accessories the specifications are subject to alteration for improvement without notice. Glowplug non-bubble weight non-bubble weight s ...

44 memo c copyright 2009 by o.S.Engines mfg. Co., ltd. All rights reserved. Printed in japan. 60092230 100903 tel. (06) 6702-0225 fax. (06) 6704-2722 6-15 3-chome imagawa higashisumiyoshi-ku osaka 546-0003, japan url : http://www.Os-engines.Co.Jp.