- DL manuals

- O.S. Engine

- Engine

- MAX-61RX-H RING WC Series

- Owner's Instruction Manual

O.S. Engine MAX-61RX-H RING WC Series Owner's Instruction Manual

It is of vital importance, before attempting to

operate your engine, to read the general

'SAFETY INSTRUCTIONS AND WARNINGS'

section on pages 2-5 of this booklet and to strictly

adhere to the advice contained therein.

•

Also, please study the entire contents of this

instruction manual, so as to familiarize yourself

with the controls and other features of the

engine.

Keep these instructions in a safe place so that

you may readily refer to them whenever

necessary.

It is suggested that any instructions supplied

with the model, radio control equipment, etc.,

are accessible for checking at the same time.

•

•

Summary of MAX-61RX-H RING WC Series

Page 1

It is of vital importance, before attempting to operate your engine, to read the general 'safety instructions and warnings' section on pages 2-5 of this booklet and to strictly adhere to the advice contained therein. • also, please study the entire contents of this instruction manual, so as to famil...

Page 2: Contents

Contents safety instructions and warnings about your o.S. Engine introduction basic engine parts, installation of the carburetor installation of the engine before starting facts about glow plugs fuel,carburetor controls starting running-in,adjustment subsequent readjustments carburettor cleanliness ...

Page 3: Warnings

Remember that your engine is not a "toy", but a highly efficient internal- combustion machine whose power is capable of harming you, or others, if it is misused. As owner, you, alone, are responsible for the safe operation of your engine, so act with discretion and care at all times. If at some futu...

Page 4: Warnings

Warnings • • • • • never touch, or allow any object to come into contact with, the rotating parts. Model engine fuel is poison- ous. Do not allow it to come into contact with the eyes or mouth. Always store it in a clearly marked container and out of the reach of children. Model engine fuel is also ...

Page 5: Notes

Notes • • • • • these engine were designed for model helicopters. Do not attempt to use it for any other purpose. Mount the engine in your model securely, fol- lowing the manufacturers' recommendations, using appropriate screws and locknuts. Install an effective silencer (muffler). Frequent close ex...

Page 6: Notes

Notes • • • take care that loose clothing (ties, shirt sleeves, scarves etc.) do not come into contact with the rotor. Do not carry loose objects (such as pen- cils, screwdrivers, etc.) in a shirt pocket from where they could fall through the rotor disc. For their safety, keep all onlookers (especia...

Page 7: Introduction

Because of initial tightness, a standard electric starter may have difficulty in rotating the engine when cold, before it has been adequately run-in. In this case, use a high-torque type starter. Do not, however, confuse tightness with the symptoms of hydraulic lock caused by an excess of fuel withi...

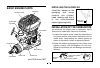

Page 8: Basic Engine Parts

Basic engine parts heatsink head carburettor typr 60b crankshaft propeller nut crankcase drive hub glowplug beam mount installing the glowplug install the washer on the glowplug and screw carefully into cylinder- head, making sure that it is not cross-threaded before tightening firmly. Glow plug was...

Page 9: Installation of The Engine

Front view correct side view top surfaces are in the same plane. Re-align the surfaces as necessary incorrect top surfaces are not in the same plane. Top surfaces are not in the same plane. Engine does not rest firmly. Make sure that only the under-surfaces of the engine’s mounting lugs are in conta...

Page 10: Before Starting

3 glowplug battery the power source for heating the glowplug may be either a large heavy-duty 1.5volt dry cell, or preferably, a 2-volt rechargeable lead-acid cell . 1.5 volt heavy-duty dry battery or 2 volt rechargeable lead-acid cell (at least 5ah) if a 2-volt cell is employed, use a resistance wi...

Page 11

Fuel can filter 12v battery starter 7 fuel container filter install a filter on the outlet tube of your refuelling container to prevent entry of foreign matter into the fuel tank 8 silicone tubing this is required for the connection between the fuel tank and engine. 9 hexagon starting shaft this sha...

Page 12: Facts About Glowplugs

Install a plug suitable for the engine. Use fuel containing a moderate percentage of nitromethane. Do not run the engine too lean and do not leave the battery connected while adjusting the needle. However, plug life can be extended and engine performance maintained by careful use, i.E.: apart from w...

Page 13: Carburetor Controls

Carburetor controls with a fixed-wing model, power failure is rarely a serious threat to the safety of the aircraft since it can usually glide down to a safe landing. In a helicopter, on the other hand, it is vitally imporant that the engine keeps running and that there is a quick and reliable respo...

Page 14: Starting

The medium speed needle valve this is an extra control that can be brought into play, if necessary, after adjusting a and b above. It provides the means of fine-tuning mixture strength over that all-important part of a helicopter's throttle range where the model is flying in, or near, the hovering m...

Page 15

4. 5. 6. Checking the rotating direction of the starter make sure that the starter rotates to the direction shown in the sketch. If the direction is reverse, reverse the leads on battery. Inserting the starter shaft insert the starting shaft into the shaft cup securely. Priming without heating the g...

Page 16: Adjustment

- - short and simple running-in procedure is required and can be carried out with the engine installed in the model. For the first few flights with a new engine i.E. While the engine is being run-in set the needle-valve for a slightly rich mixture not excessively rich as this may result in poor thro...

Page 17

As a safety measure, first check the transmitter controls, including the throttle stick and trim lever positions, and hold the main rotor securely before starting the engine. The general course of adjustments procedure is shown in the adjusting chart and is correct for a fuel containing 20% lubrican...

Page 18

Having provisionally set the idle mixture, the next step is to adjust the mixture for hovering flight. Hover the model and actuate the throttle to observe response over the medium speed range. Lf the engine smokes excessiveiy and throttle response is poor, the mixture is too rich ; in which case, la...

Page 19

Now re-check hovering performance it may be found that (with the high-speed needle valve now set for optimum full-throttle performance) hovering will reveal symptoms of slightly lean running at medium speeds. Do not touch the high-speed needle valve. Now adjust the high-speed needle valve to achieve...

Page 20: Carburetor Cleanliness

Carburetor cleanliness the correct functioning of the carburetor depends on its small fuel orifices remaining clear. The minute particles of foreign matter that are present in any fuel can easily partially obstruct these orifices and upset mixture strength so that engine performance becomes erratic ...

Page 21: Adjusting Chart

Adjusting chart high speed needle valve - 2 turns opened from fully closed position. Medium speed needle valve - 1 turns opened from fully closed position. Idle mixture control screw - 2 turns opened from fully closed position. Start the engine warm up the engine observe the mixture condition while ...

Page 22: Care and Maintenance

Care and maintenance the minute particles of foreign matter, that are present in any fuel may, by accumulating and partially obstructing fuel flow, cause engine performance to become erratic and unreliable. O.S. 'super-filters' (large and small)are available, as optional extras, to deal with this pr...

Page 23: 61Sx-H

Type of screw c … cap screw m … oval fillister-head screw f … flat head screw n … round head screw s … set screw max- 61sx-h ring "wc" exploded view y t r e w q = - 0 9 8 7 6 5 4 3 2 1 c.M3.5x15 c.M3.5x8 - -1 i u 22 ✽.

Page 24: 61Sx-H

The specifications are subject to alteration for improvement without notice. Max- 61sx-h ring "wc" engine parts list screw set cover plate gasket set crankshaft crankshaft ball bearing(rear) crankcase crankshaft ball bearing(front) thrust washer propeller nut carburetor retainer assembly carburetor ...

Page 25: 61Sx-Hg/hgl

Type of screw c … cap screw m … oval fillister-head screw f … flat head screw n … round head screw s … set screw max- 61sx-hg/hgl ring "wc" exploded view y t r e w q = - 0 9 8 7 6 5 4 3 2 1 c.M3.5x15 c.M3.5x8 i u 1 -a 24 ✽.

Page 26: 61Sx-Hg/hgl

The specifications are subject to alteration for improvement without notice. Max- 61sx-hg/hgl ring "wc" engine parts list screw set cover plate gasket set crankshaft crankshaft ball bearing(rear) crankcase crankshaft ball bearing(front) thrust washer propeller nut carburetor retainer assembly carbur...

Page 27: 61Rx-H

Type of screw c … cap screw m … oval fillister-head screw f … flat head screw n … round head screw s … set screw max- 61rx-h ring "wc" exploded view y t r e w q = - 0 9 8 7 6 5 4 3 2 1 c.M3.5x15 c.M3.5x8 - -1 i u 26 ✽.

Page 28: 61Rx-H

The specifications are subject to alteration for improvement without notice. Max- 61rx-h ring "wc" engine parts list screw set cover plate gasket set crankshaft crankshaft ball bearing(rear) crankcase crankshaft ball bearing(front) thrust washer propeller nut carburetor retainer assembly carburetor ...

Page 29: 61Rx-Hg/hgl

Type of screw c … cap screw m … oval fillister-head screw f … flat head screw n … round head screw s … set screw max- 61rx-hg/hgl ring "wc" exploded view y r e w q = - 0 9 8 7 6 5 4 3 2 1 c.M3.5x15 c.M3.5x8 i u 1 -a t ✽ 28.

Page 30: 61Rx-Hg/hgl

The specifications are subject to alteration for improvement without notice. Max- 61rx-hg/hgl ring "wc" engine parts list screw set cover plate gasket set crankshaft crankshaft ball bearing(rear) crankcase crankshaft ball bearing(front) thrust washer propeller nut carburetor retainer assembly carbur...

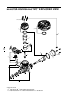

Page 31: 60B Carburetor Exploded View

60b carburetor exploded view q w = = - 0 9 8 8 7 6 5 4 3 2 1 -1 1 5 -3 5 -2 - -4 - -3 - - -2 - -1 5 -1 - -4 - -3 - -2 - -1 c.M3x8 c.M2.6x5 c.M2.6x5 c.M2.6x8 n.+m3x4 e cºcap screw fºflat head screw nºround head screw sºset screw ] type of screw 30

Page 32: 60B Carburetor Parts List

No. No. Q 2 7915 000 w 2 7915 100 = 4 1621 000 - -4 2 4981 837 - -3 2 7981 910 - -2 2 6711 305 - -1 2 7381 940 - 2 7981 900 0 2 7981 332 9 2 2681 953 8 2 7881 120 7 2 7981 600 6 2 7981 110 5 -3 2 2781 800 5 -2 2 7881 820 5 -1 2 7981 850 5 2 7981 301 4 2 7981 220 3 2 7981 920 2 2 7981 200 1 -1 2 2826...

Page 33: Three View Drawing

9.95 cc (0.607 cu.In.) 24.0mm (0.945 in.) 22.0mm (0.866 in.) 2,000 ~ 18,000 r.P.M. 2.2 bhp / 16,000 r.P.M. 600g(21.2oz.) sx-h ■ ■ ■ ■ ■ ■ 88.7 28 79 42 28 43.5 25 52 4- φ 4.2 61 9 42.6 unf5/16-24 2- φ 4.2 61sx-h ring "wc" three view drawing displacement bore stroke practical r.P.M. Power output weig...

Page 34: Three View Drawing

9.95 cc (0.607 cu.In.) 24.0mm (0.945 in.) 22.0mm (0.866 in.) 2,000 ~ 18,000 r.P.M. 2.2 bhp / 16,000 r.P.M. 597g(21.1oz.) rx-h ■ ■ ■ ■ ■ ■ 42 30 10 25 52 4- φ 4.2 88.7 28 unf5/16-24 79 42.6 61 2-m3.5 dimensions(mm) 61rx-h ring "wc" three view drawing specifications displacement bore stroke practical ...

Page 35

(71608001) (71521000) (l) no.8 (71605100) a 5 (72403050) (71705000) (55500002) (27983000) (71530300) o.S. Genuine parts & accessories ■ o.S. Glow plugs ■ in-flight control needle valve ■ long socket wrench with plug grip ■ super filter ■ lock washer(10set) m3 ■ mixture control carburetor 60d ■ crank...

Page 36

C copyright 2001 by o.S.Engines mfg. Co., ltd. All rights reserved. Printed in japan. Un eq ua lle d qu ality precision & perfo rma nc e est ablish ing the standards of ex cel len ce 070100 tel. (06) 6702-0225 fax. (06) 6704-2722 6-15 3-chome imagawa higashisumiyoshi-ku osaka 546-0003, japan url : h...